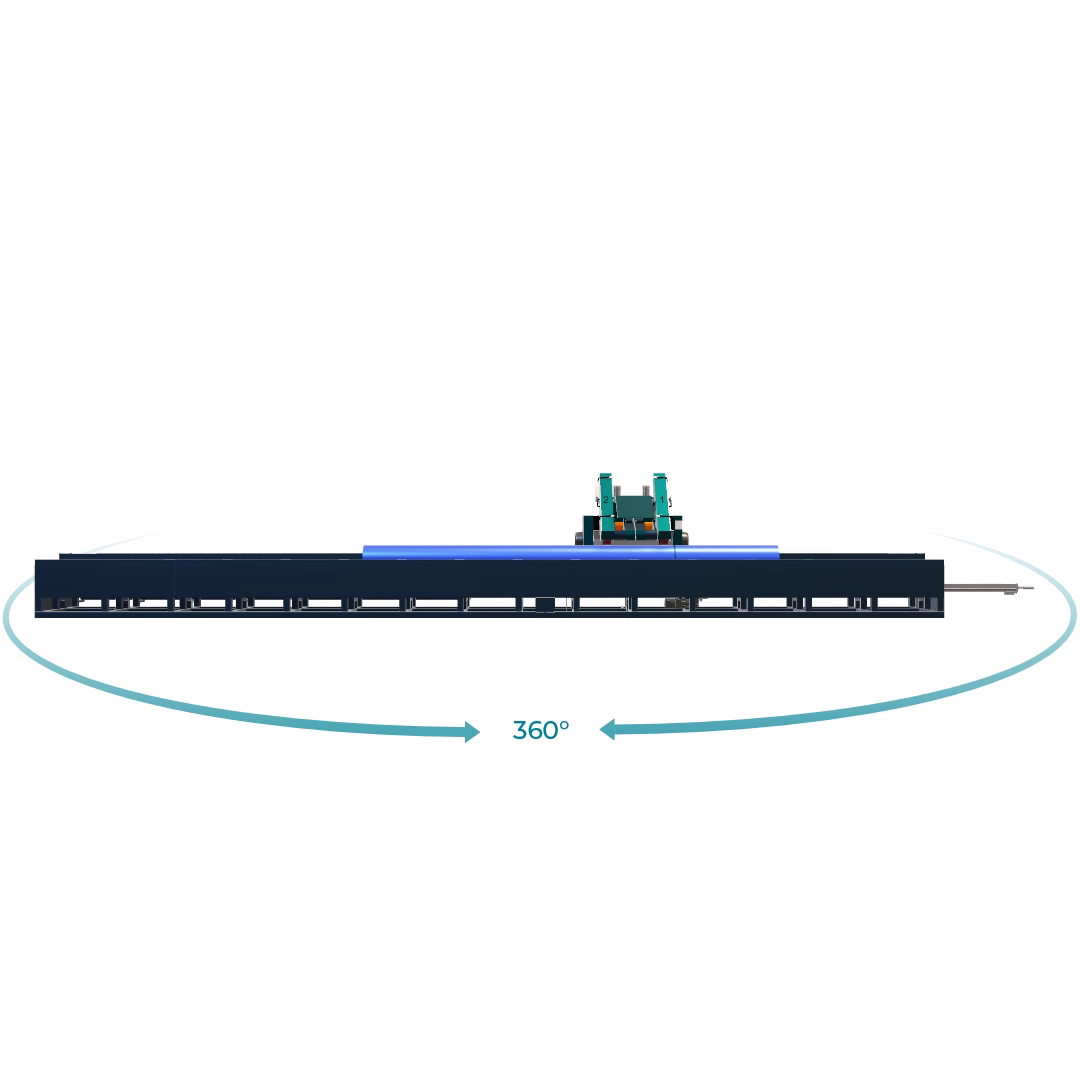

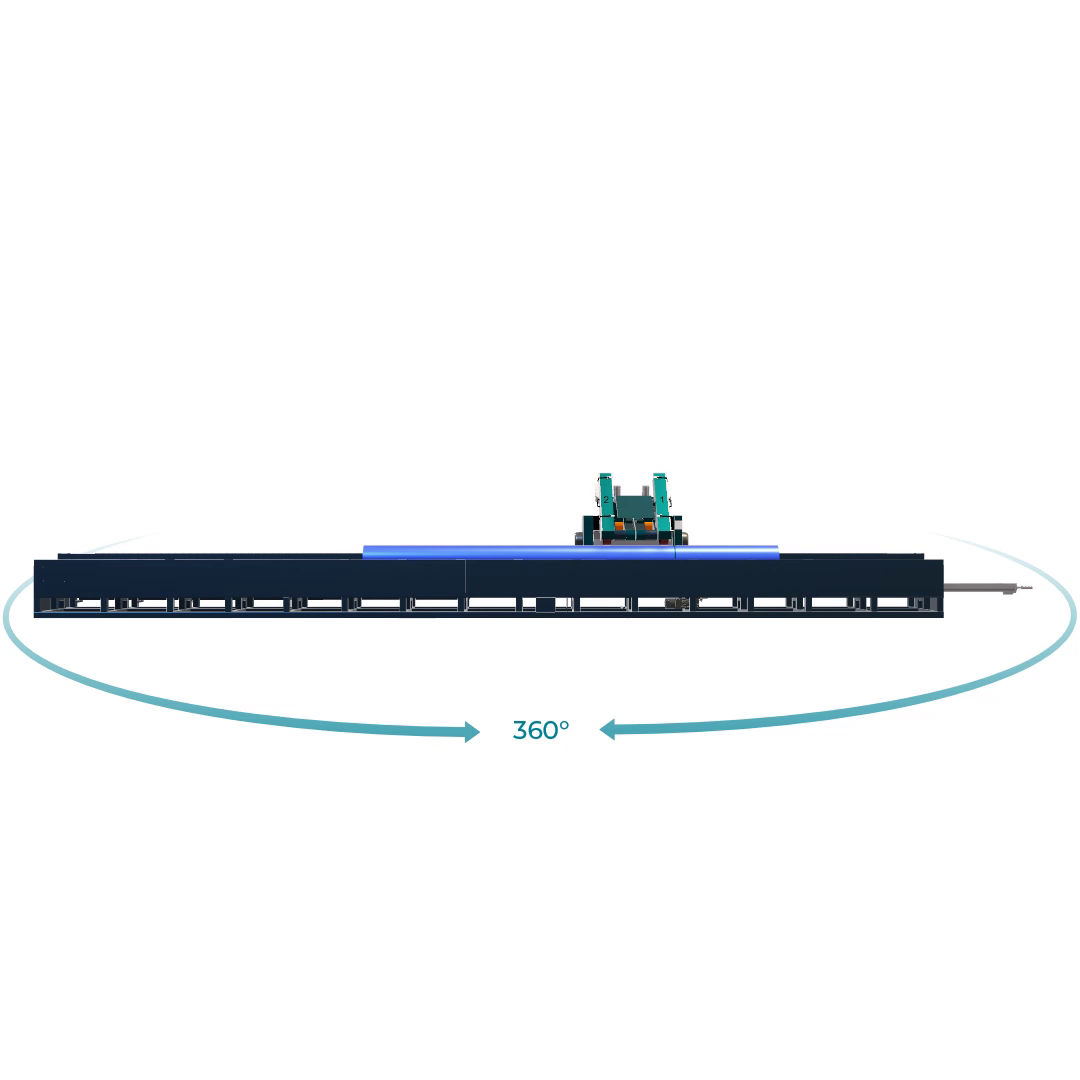

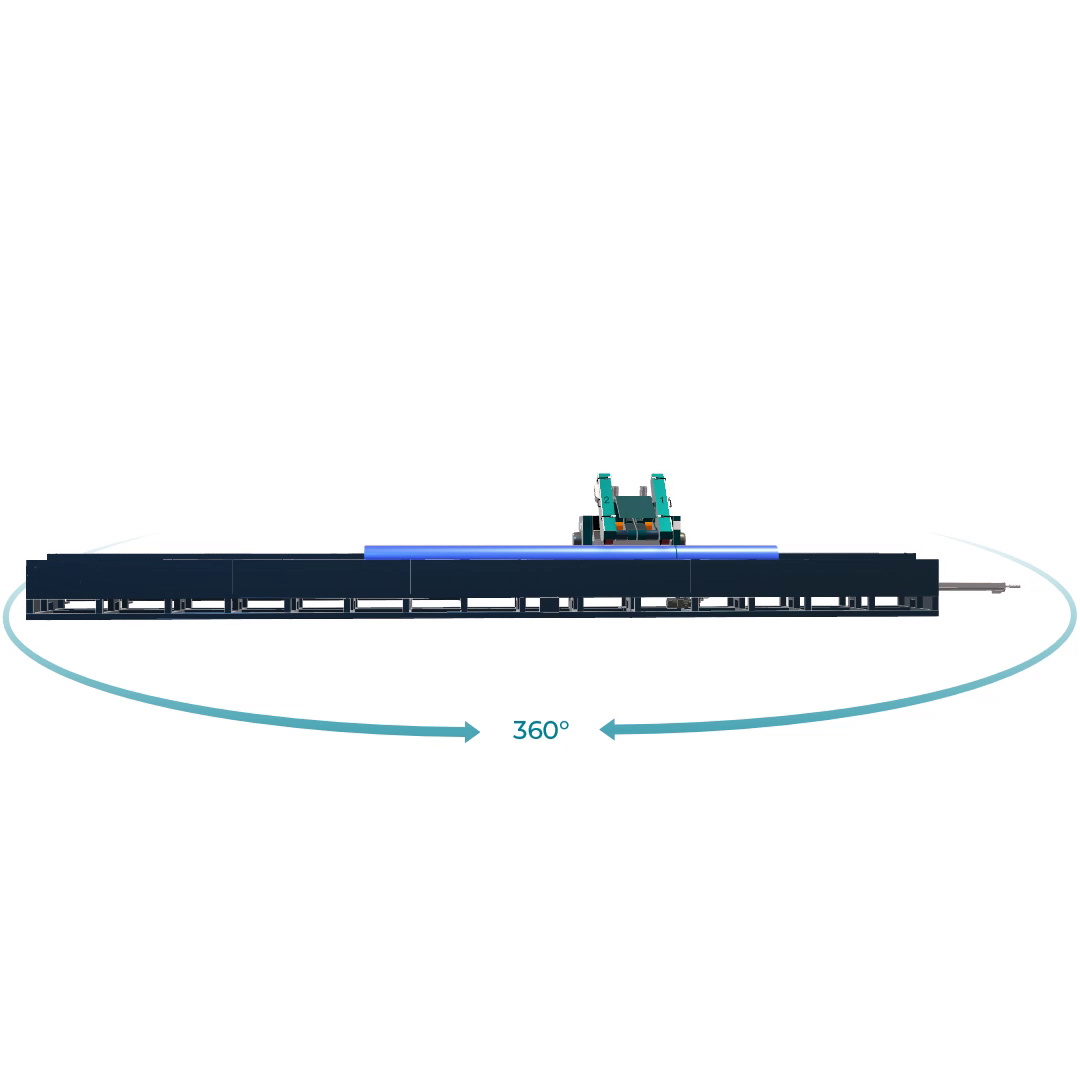

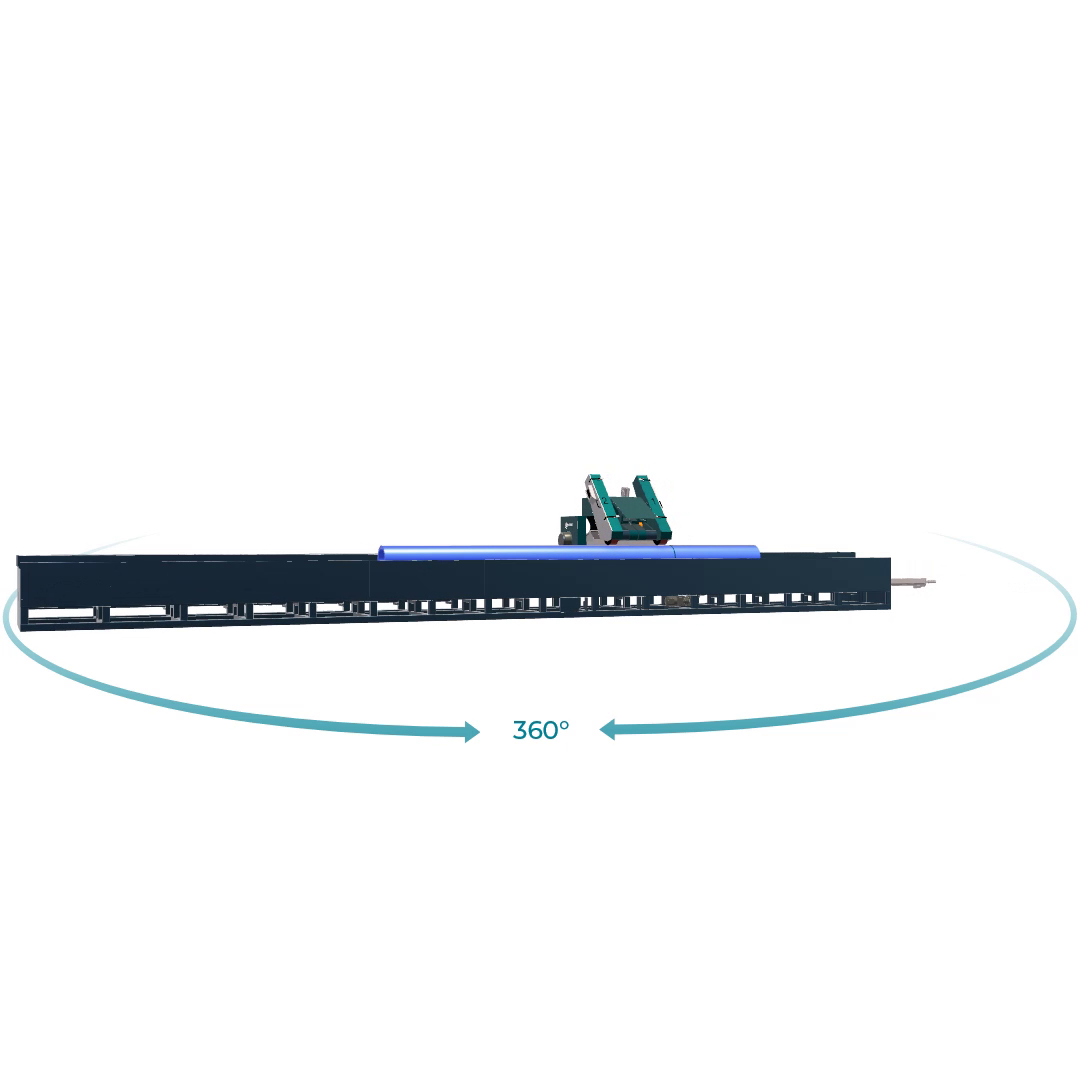

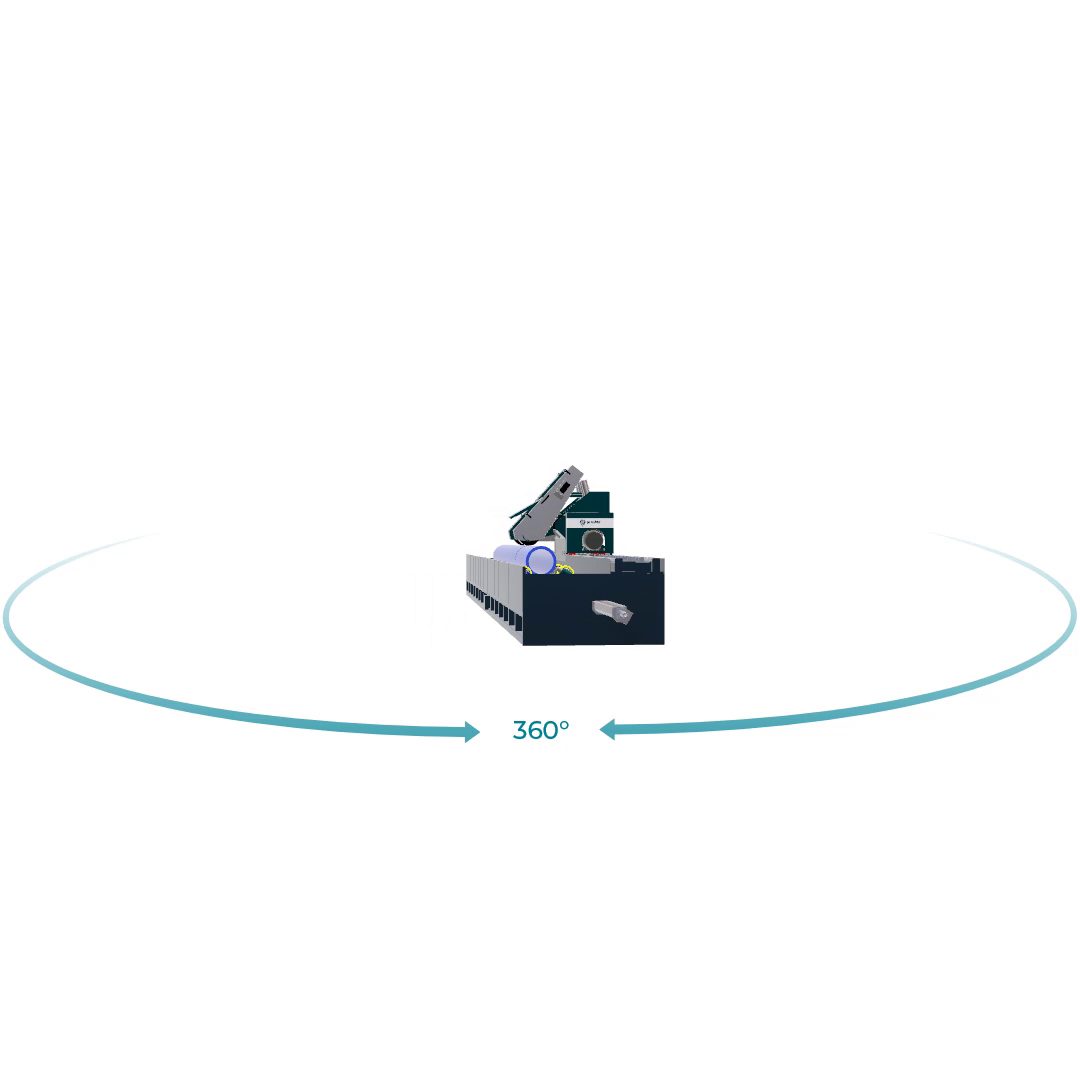

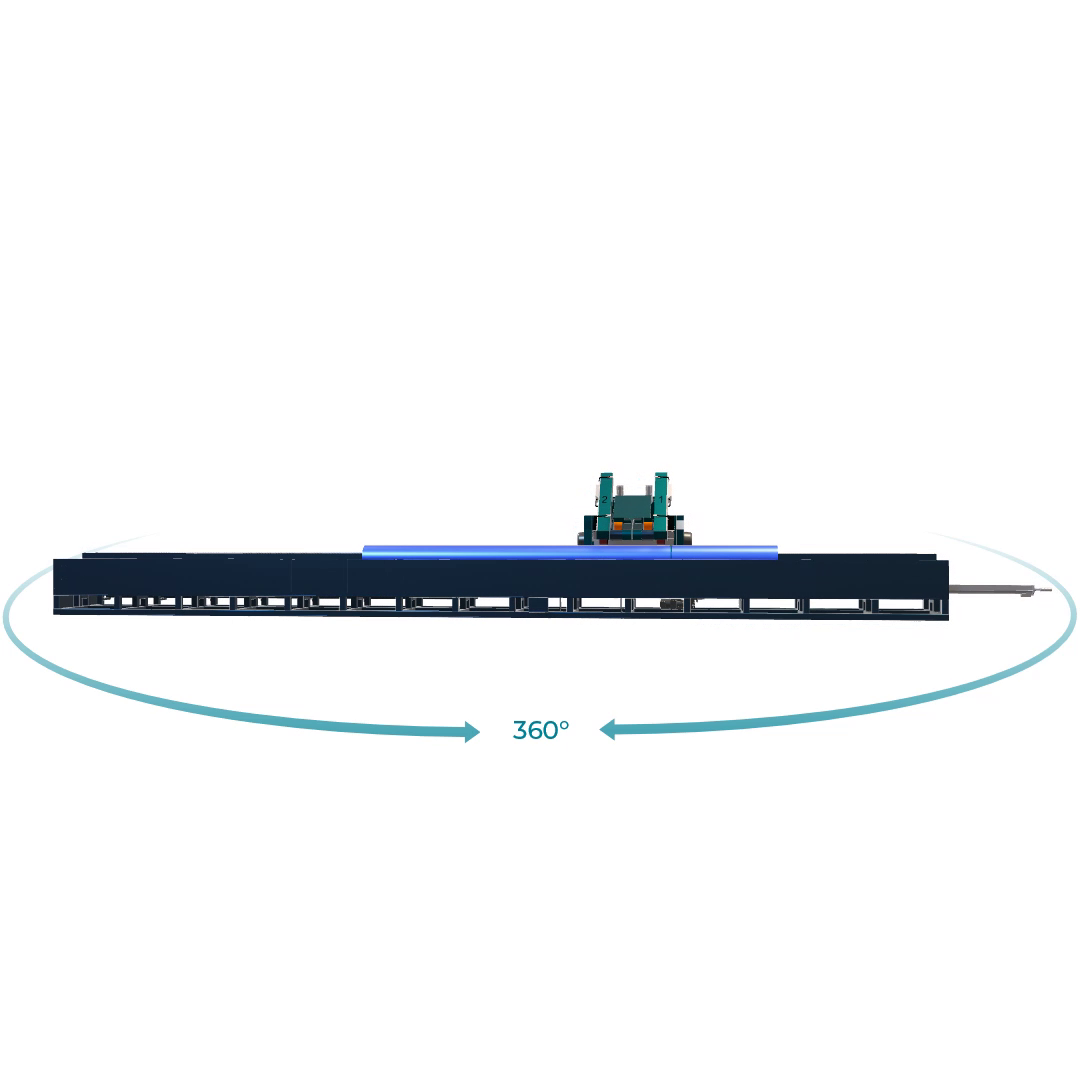

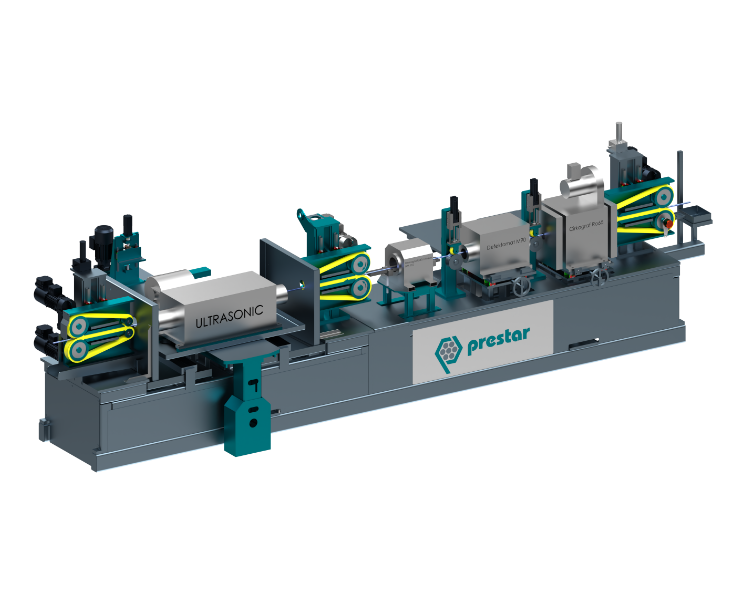

External stationary pipe grinder

For neasier removal of surface defects

Description of the device

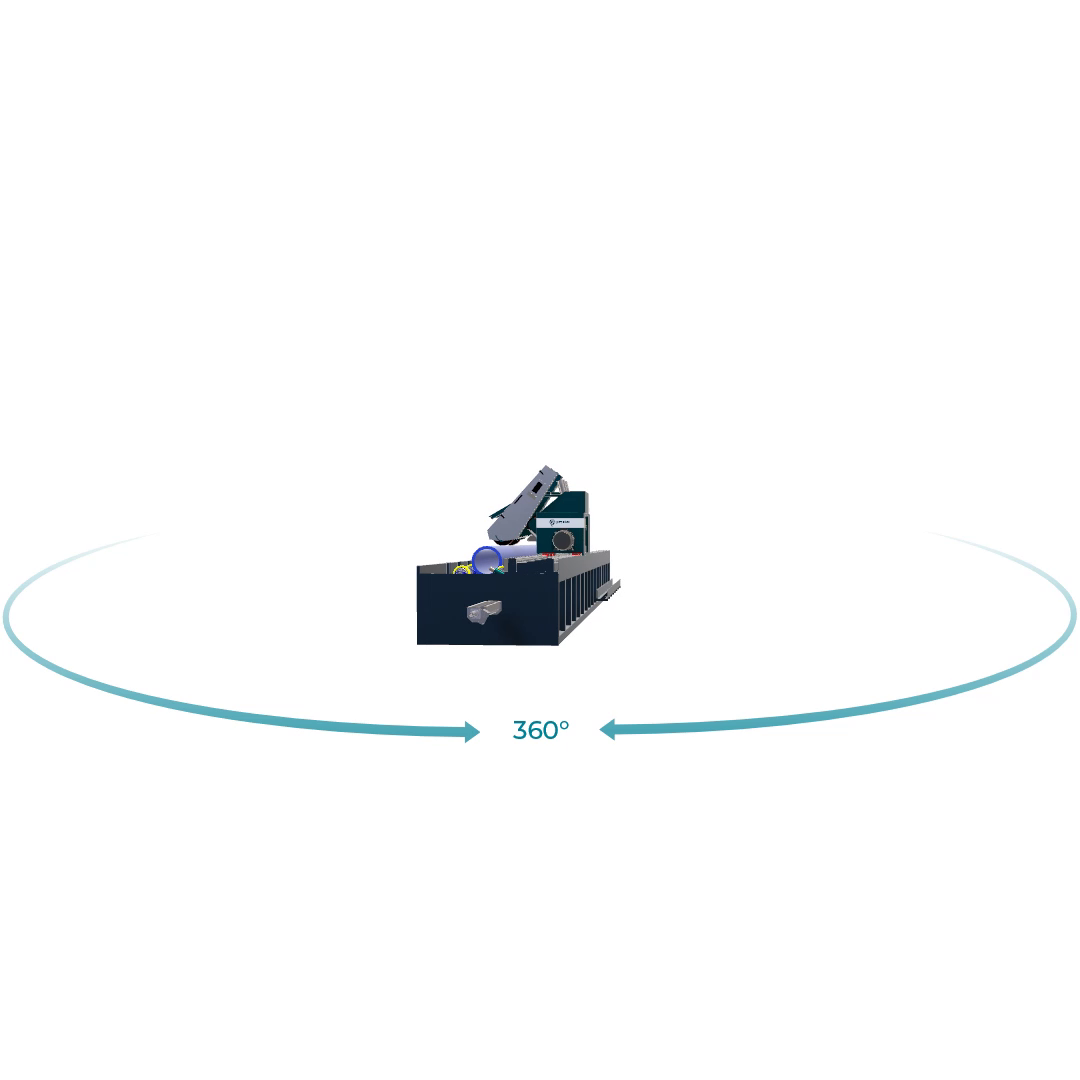

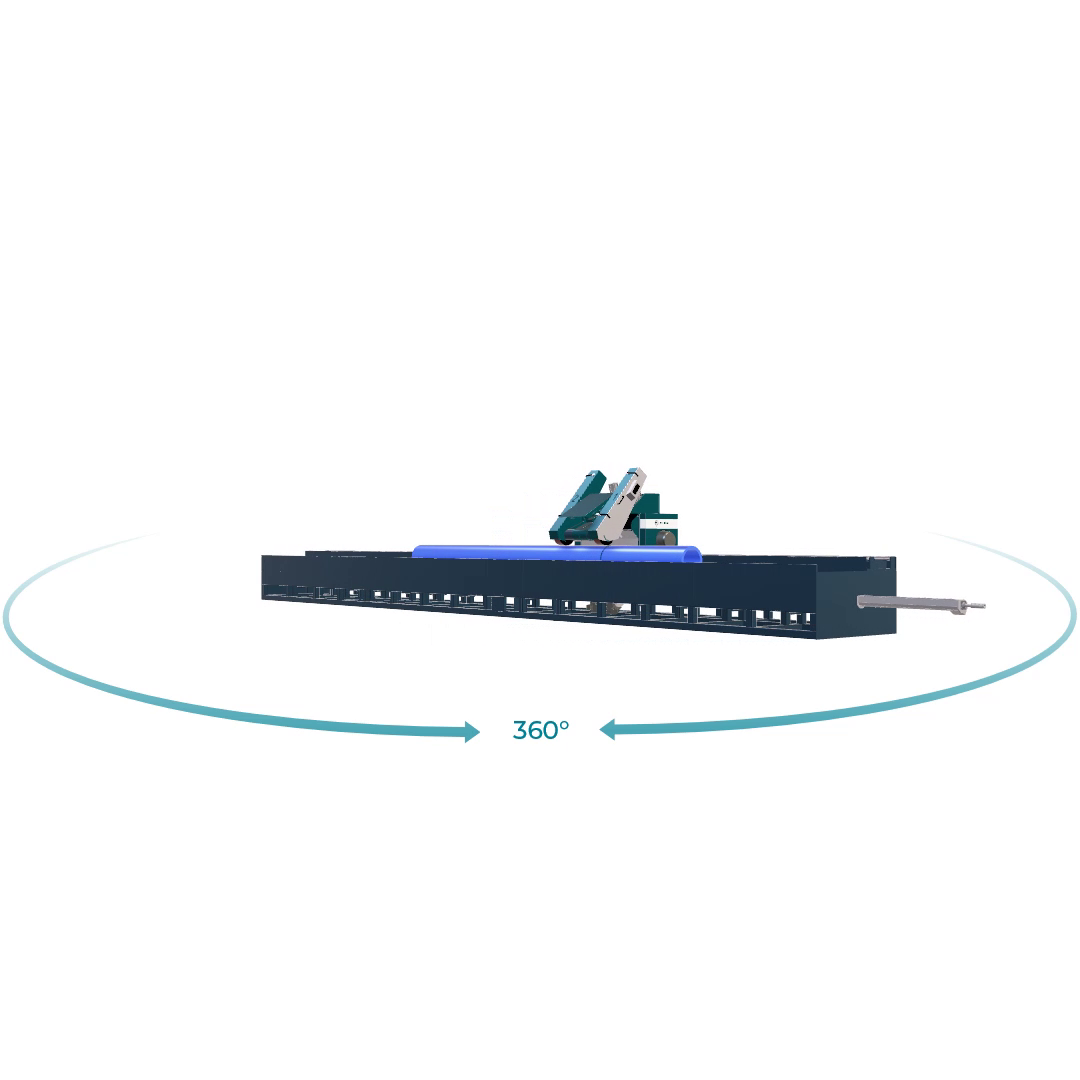

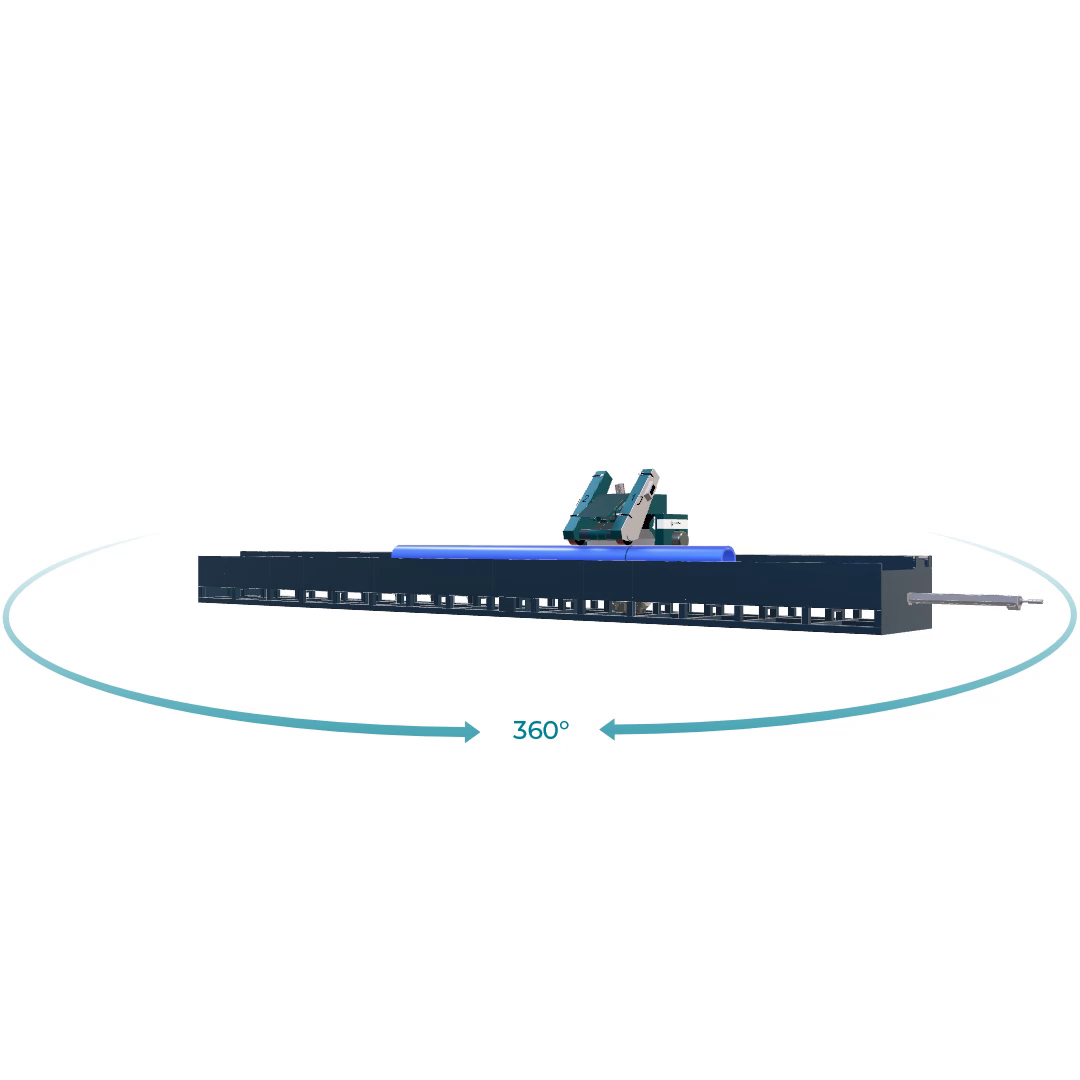

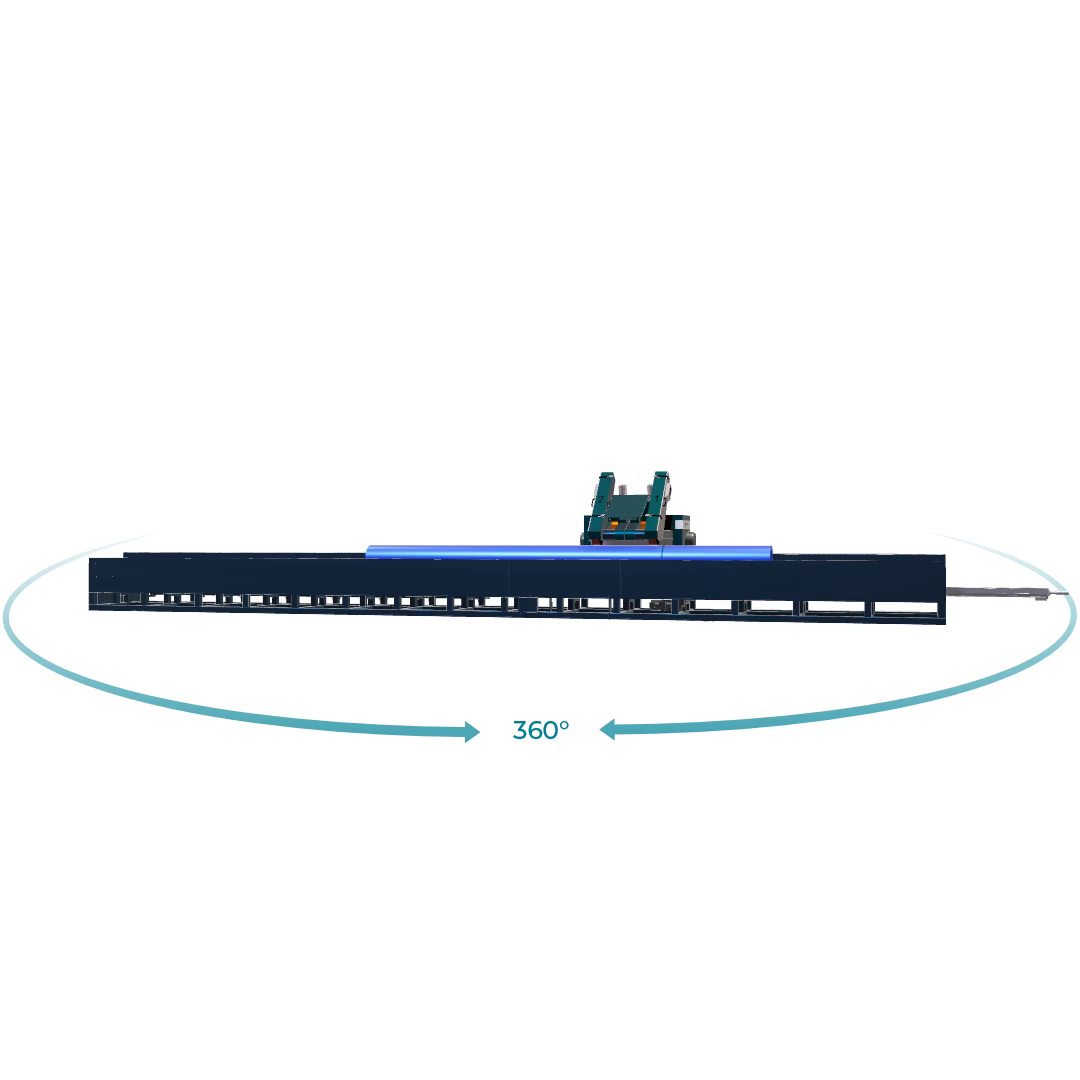

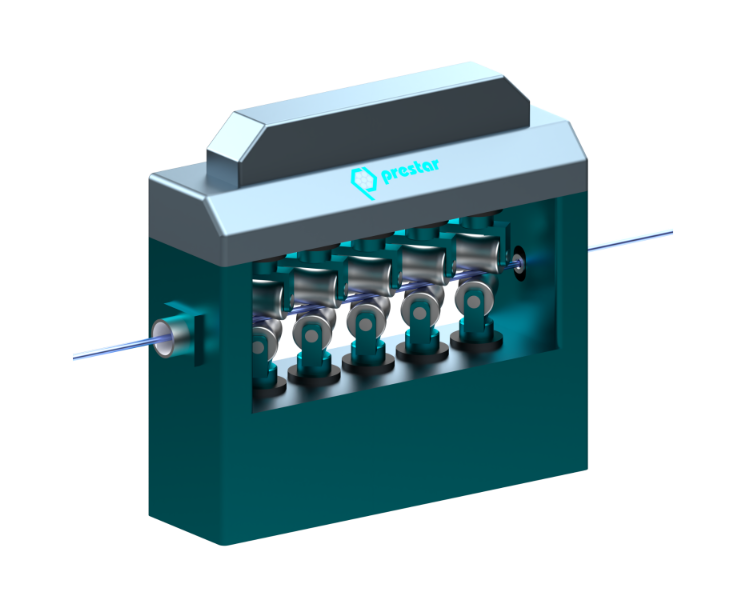

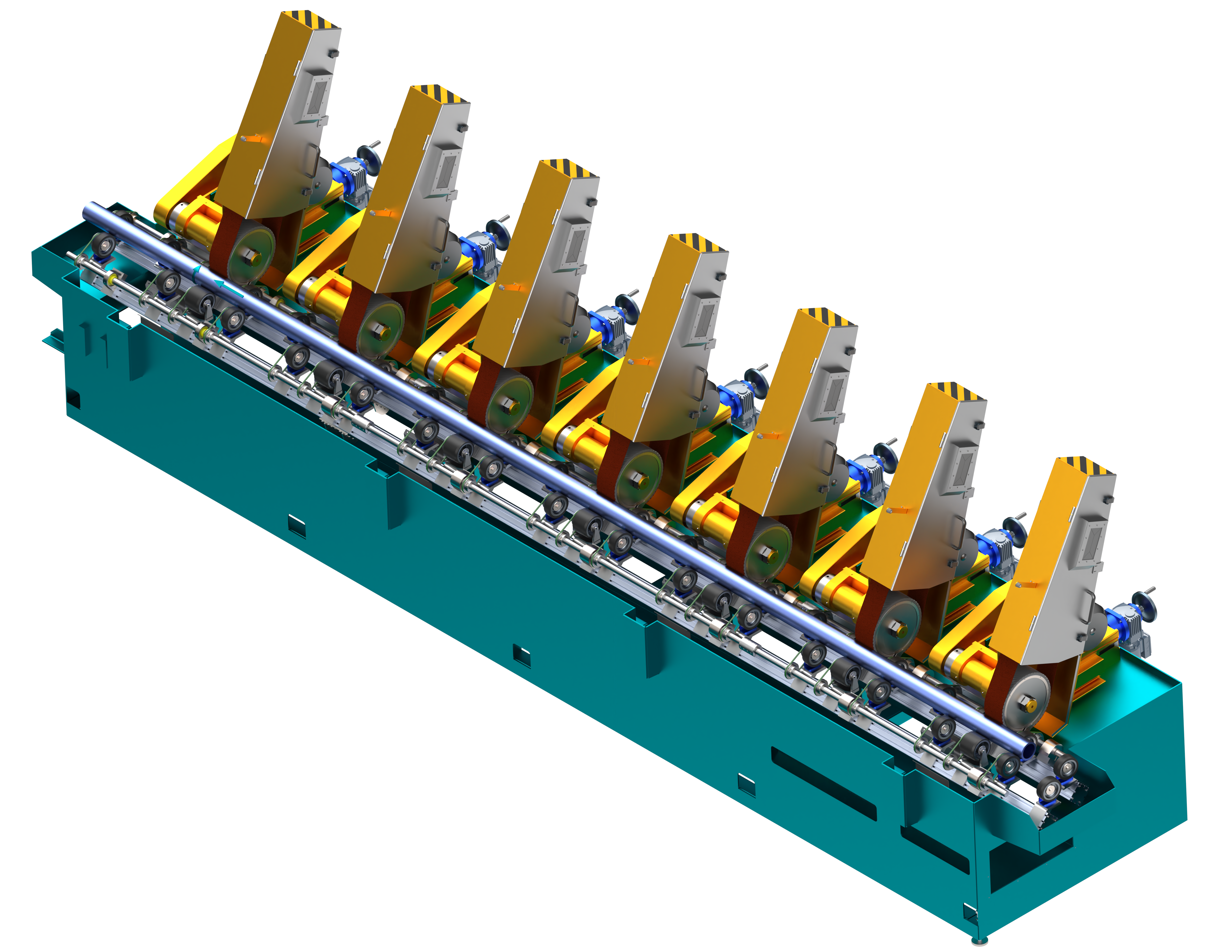

Larger diameter tubes require the outer surface to be sanded to remove scale, remove surface defects and to improve the appearance of the tubes. The pipe is loaded into the machine on driven radial rollers that are placed in a catch basin. A mobile grinding unit equipped with grinding belts is ready in the parking position next to the pipe. After start-up, the grinding unit cycles along the rotating tube and grinds the material with a constant supply of coolant. The machined material is rinsed into the tub and conveyed out of the tub by a worm shaft. Water with abraded material is filtered in three stages. Magnetic filter, fabric filter and mechanical separator. The solid residues are stored in an attached pallet and the filtered water is reused for grinding. After grinding, the pipe is removed by an overhead crane.

Technical parameters of the machine

|

Pipe diameter: |

200 – 600 mm |

|

Pipe length: |

3 000 – 16 000 mm |

|

Material removal: |

up to 0,5 mm in one cycle |

|

Sanding belts: |

150 x 3 000 mm |

|

Pressure of sanding belts: |

pneumatic |

|

Sanding belt tensioning: |

pneumatic |

|

Grinding speed: |

30 m/s |

|

Sanding belt replacement: |

in the parking position of the grinding unit there is a platform for easy access to the sanding belts |

|

Control panel with display: |

placed on the mobile grinding unit |

Other equipment of the machine

- Continuous regulation of the abrasive speed of the belts.

- Handling girder for inserting and removing pipes into and out of the machine.

- Manual ultrasound tube wall thickness measurement.

- Extended visualization with an emphasis on intuitive and detailed display of operating states and the place of failure of the grinder.

- Extended service with the possibility of displaying manuals, service manuals and other necessary documentation on machines to minimize service times.

- Collection of agreed production parameters with automatic saving, display and data export.

Straightening machines

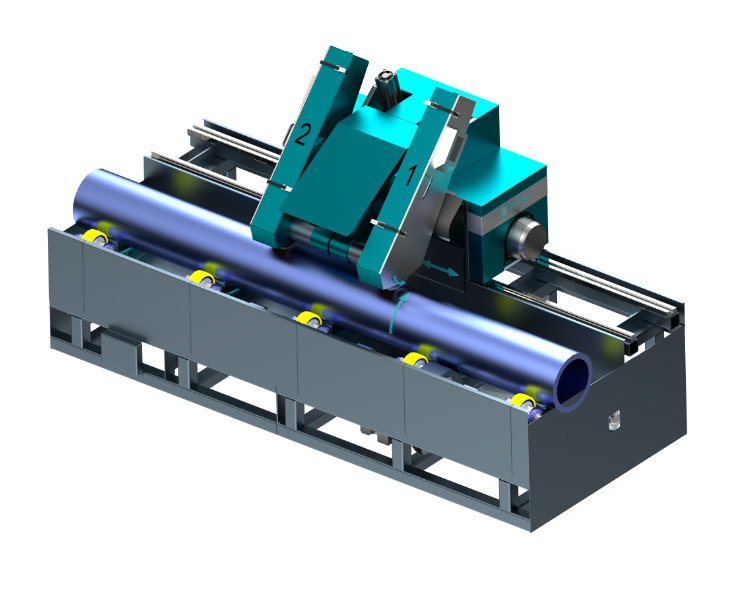

Internal pipe grinder

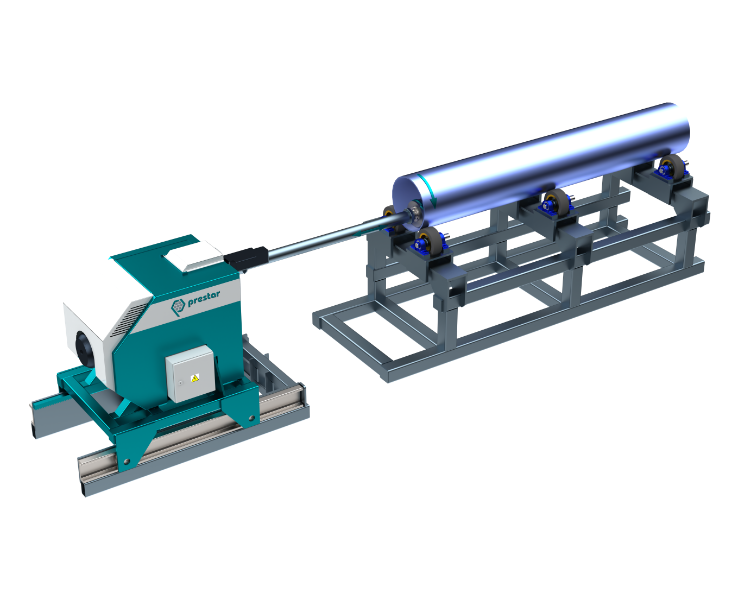

Centerless pipe grinder

External stationary pipe grinder

Flying saw

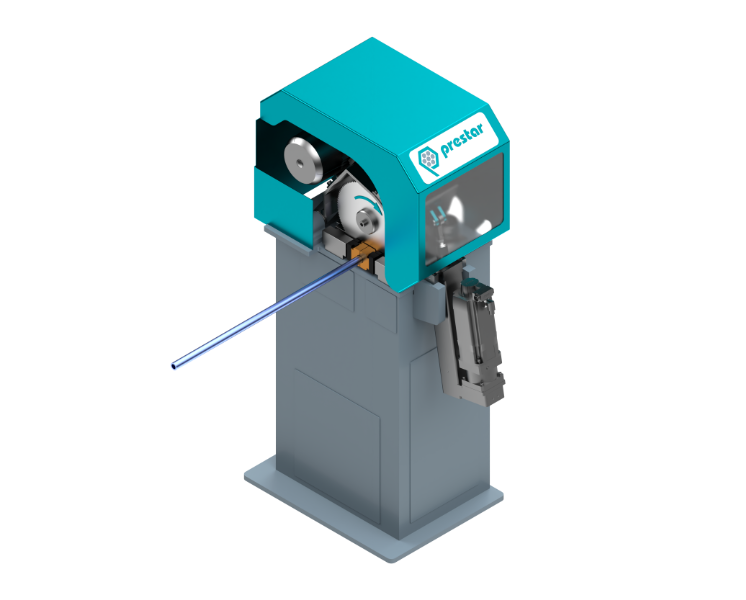

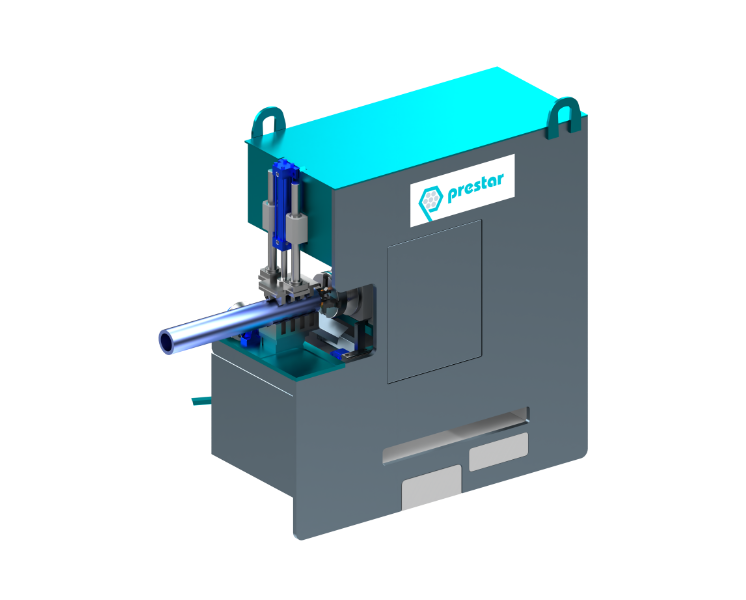

Circular saw

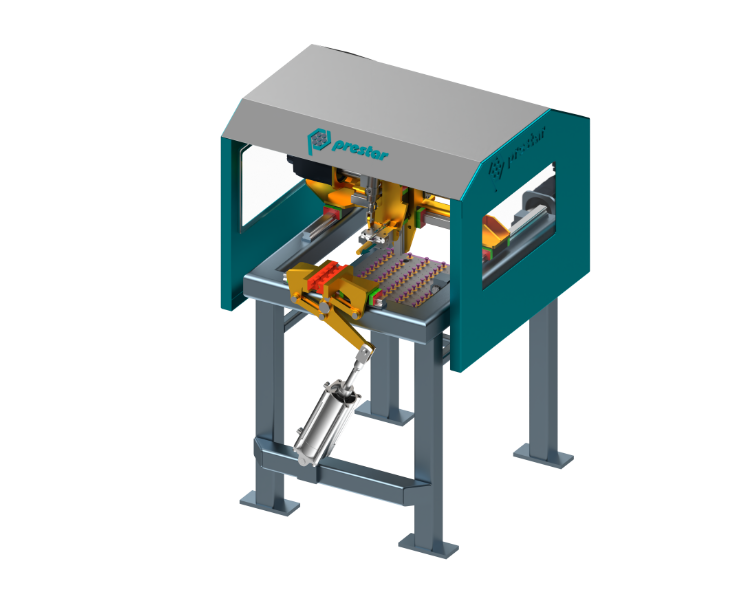

Chamfering of pipes

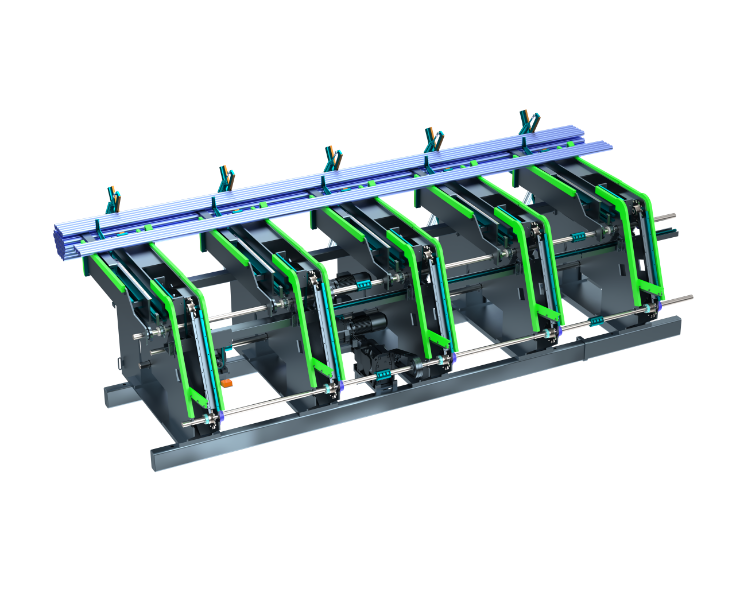

Sorting and plugging

Control tables

Packaging machines

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT