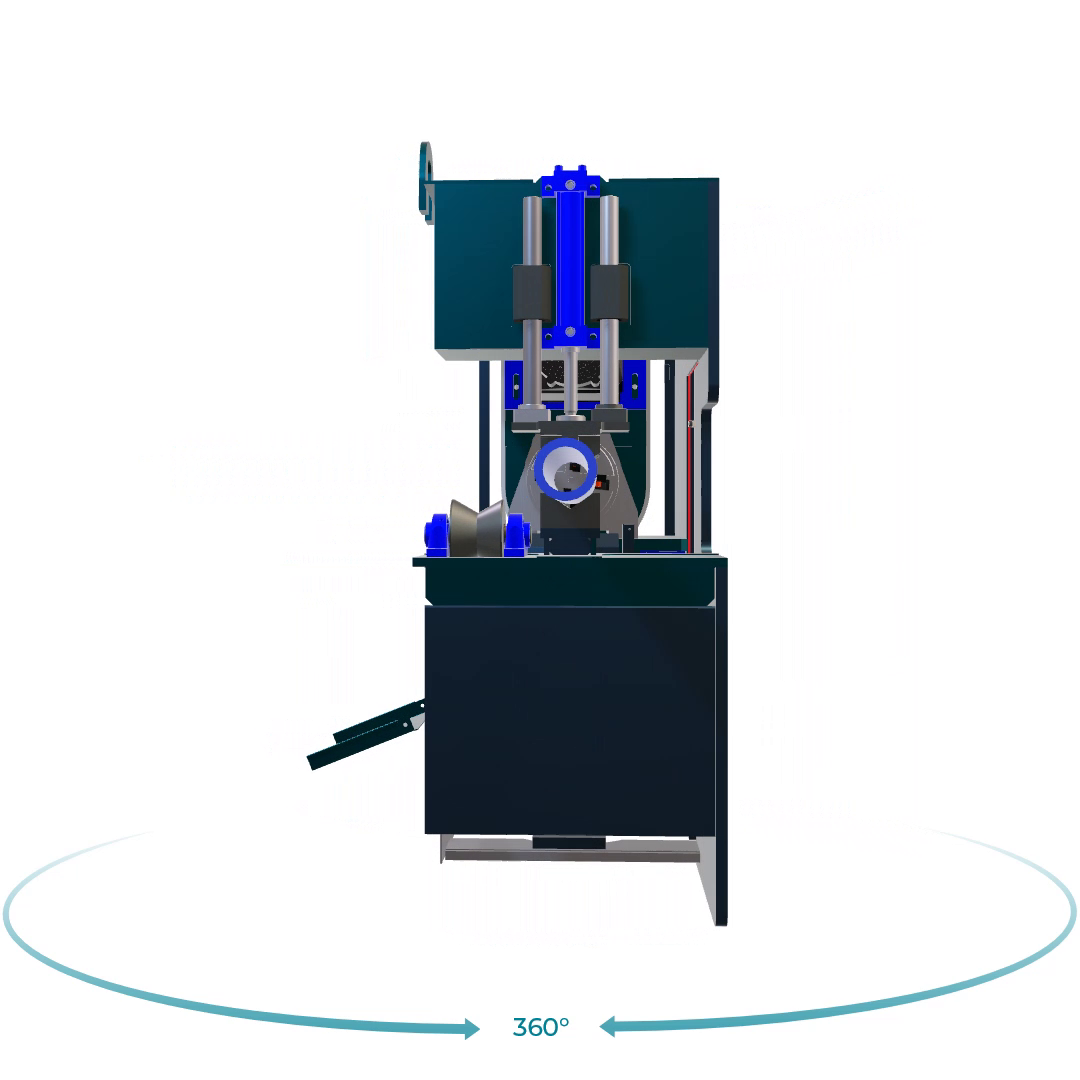

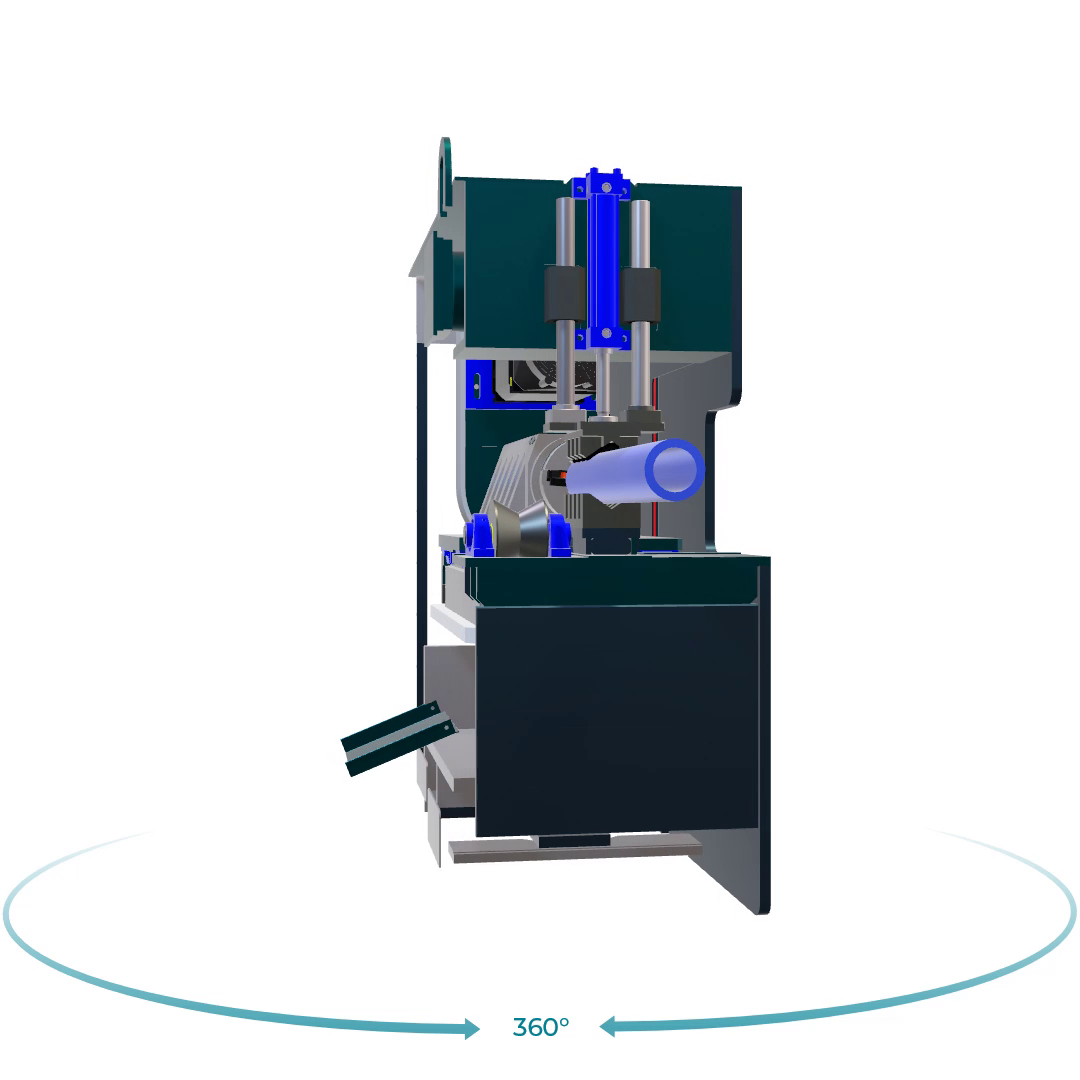

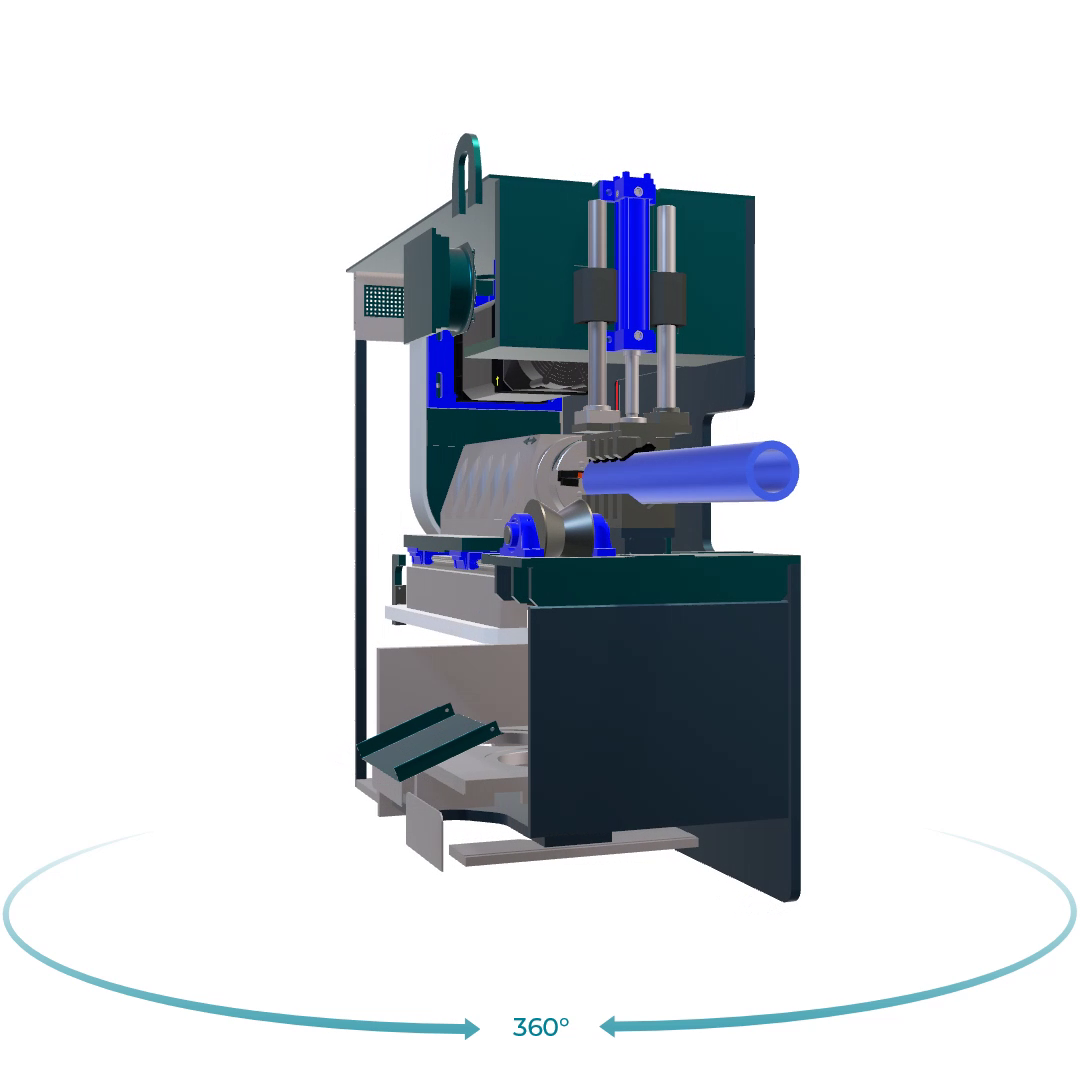

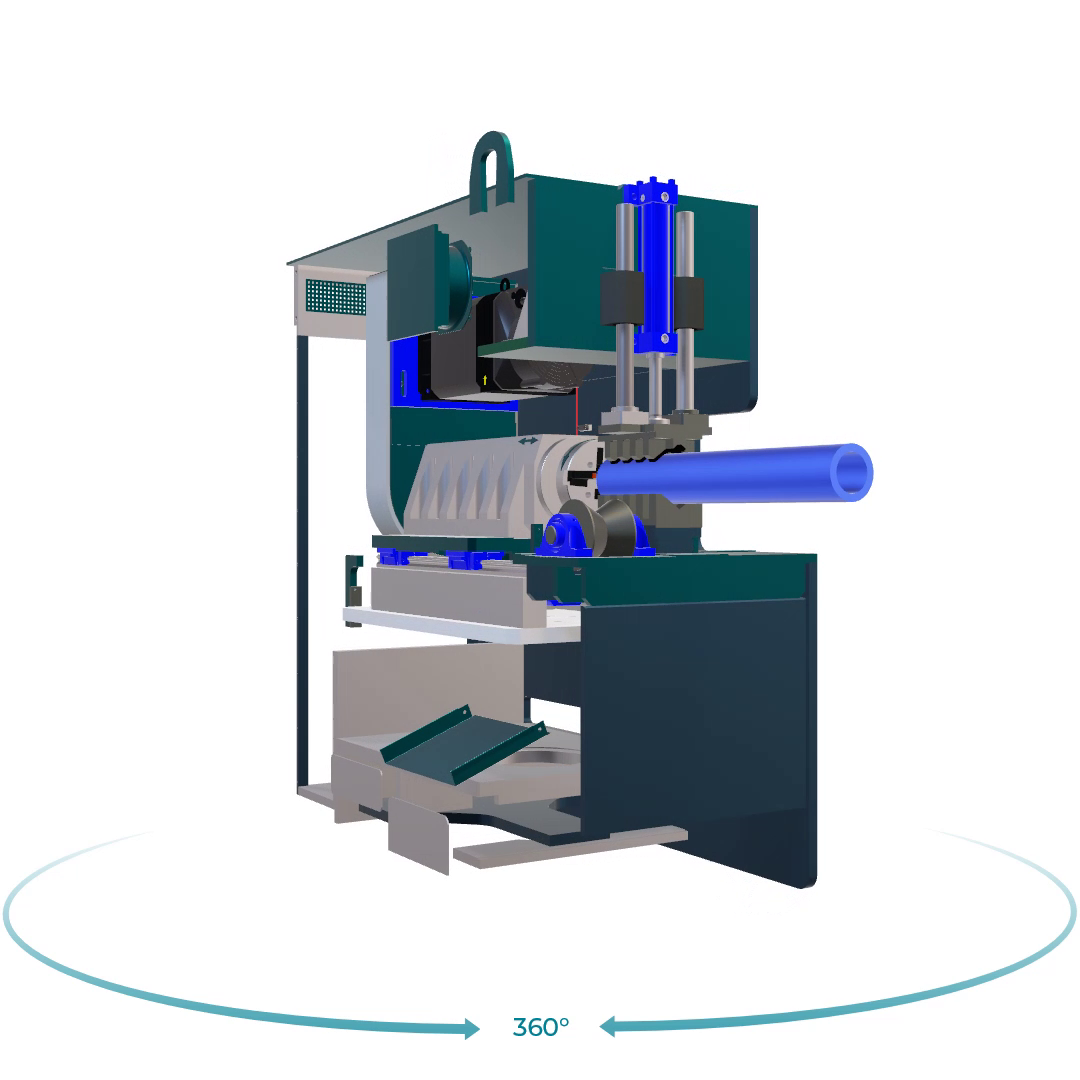

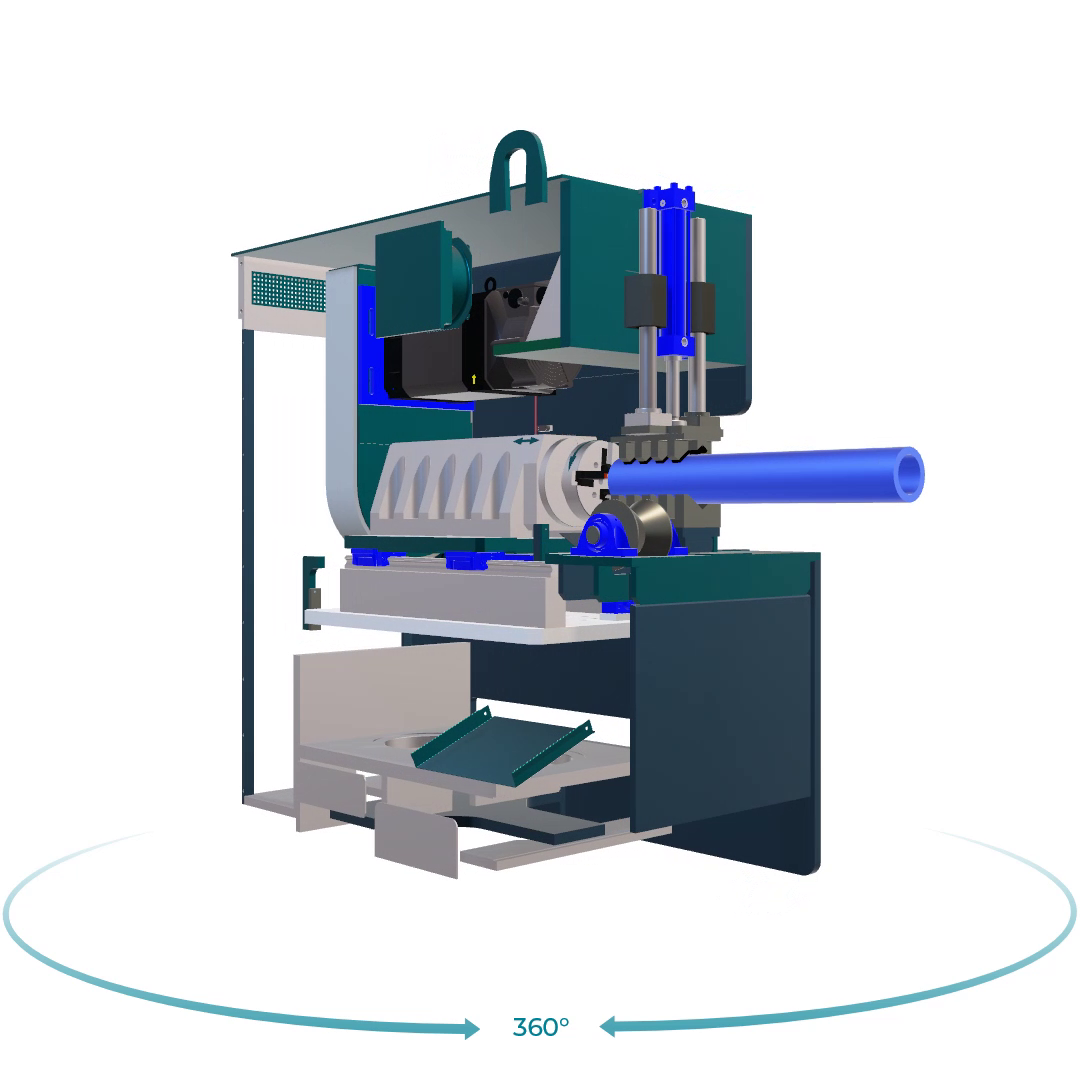

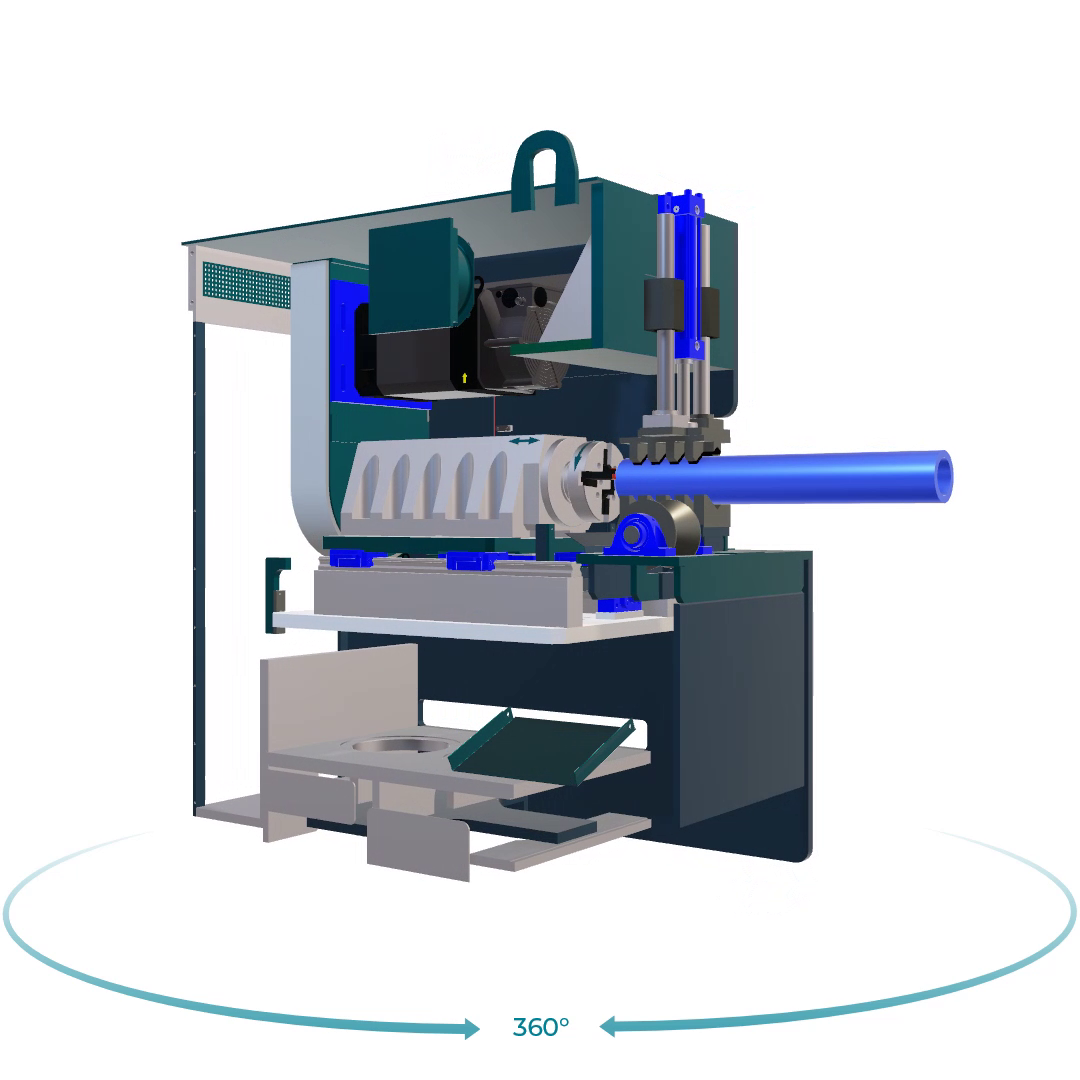

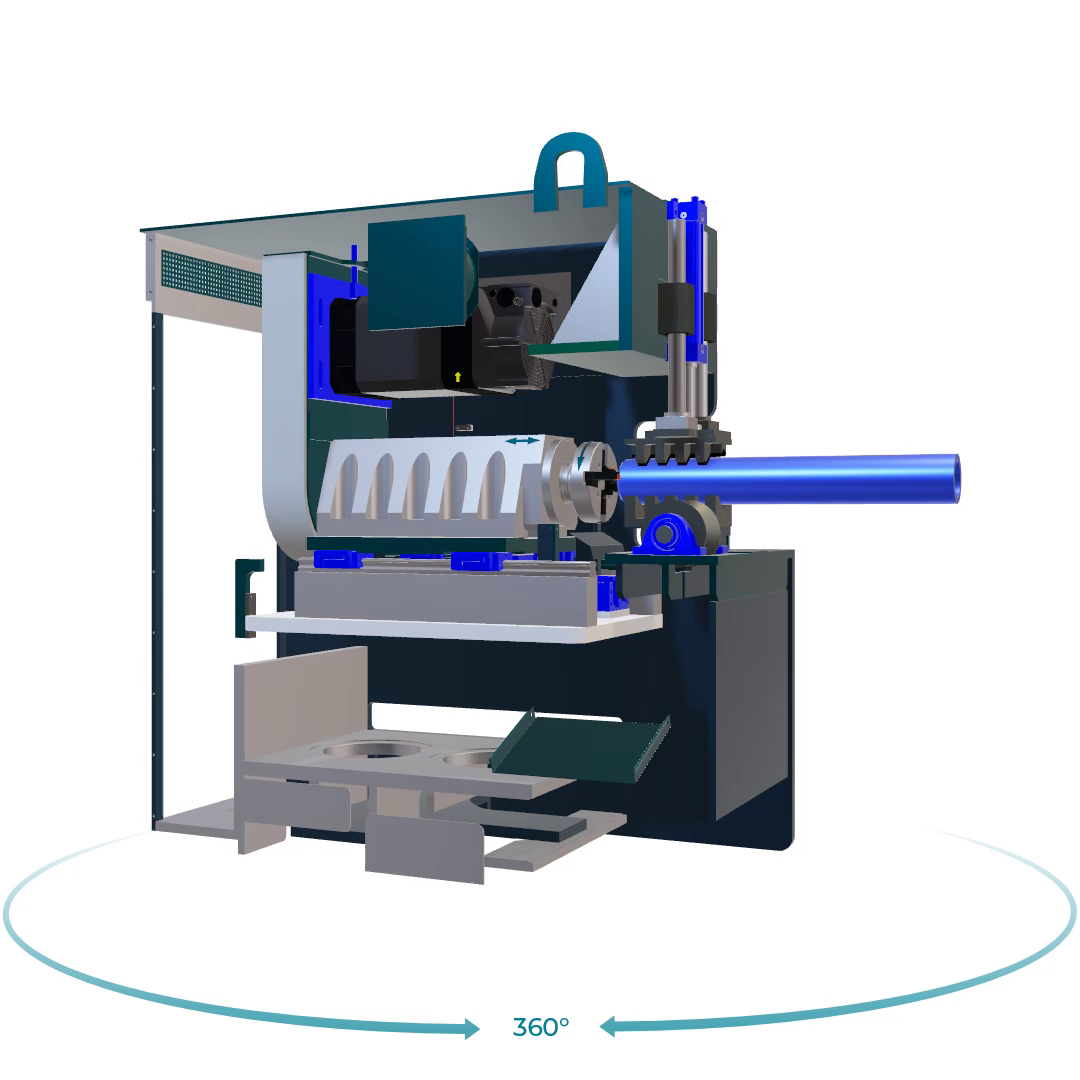

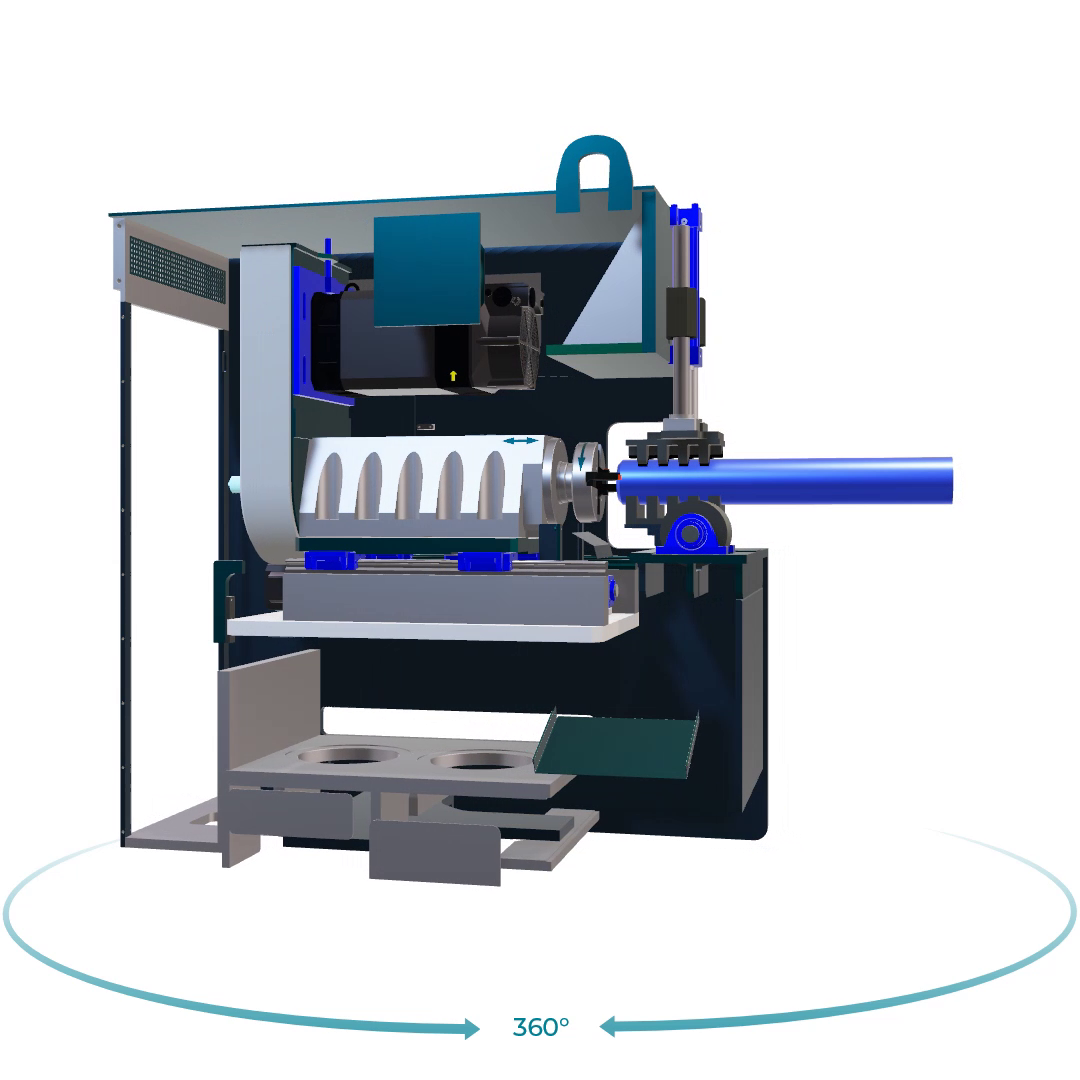

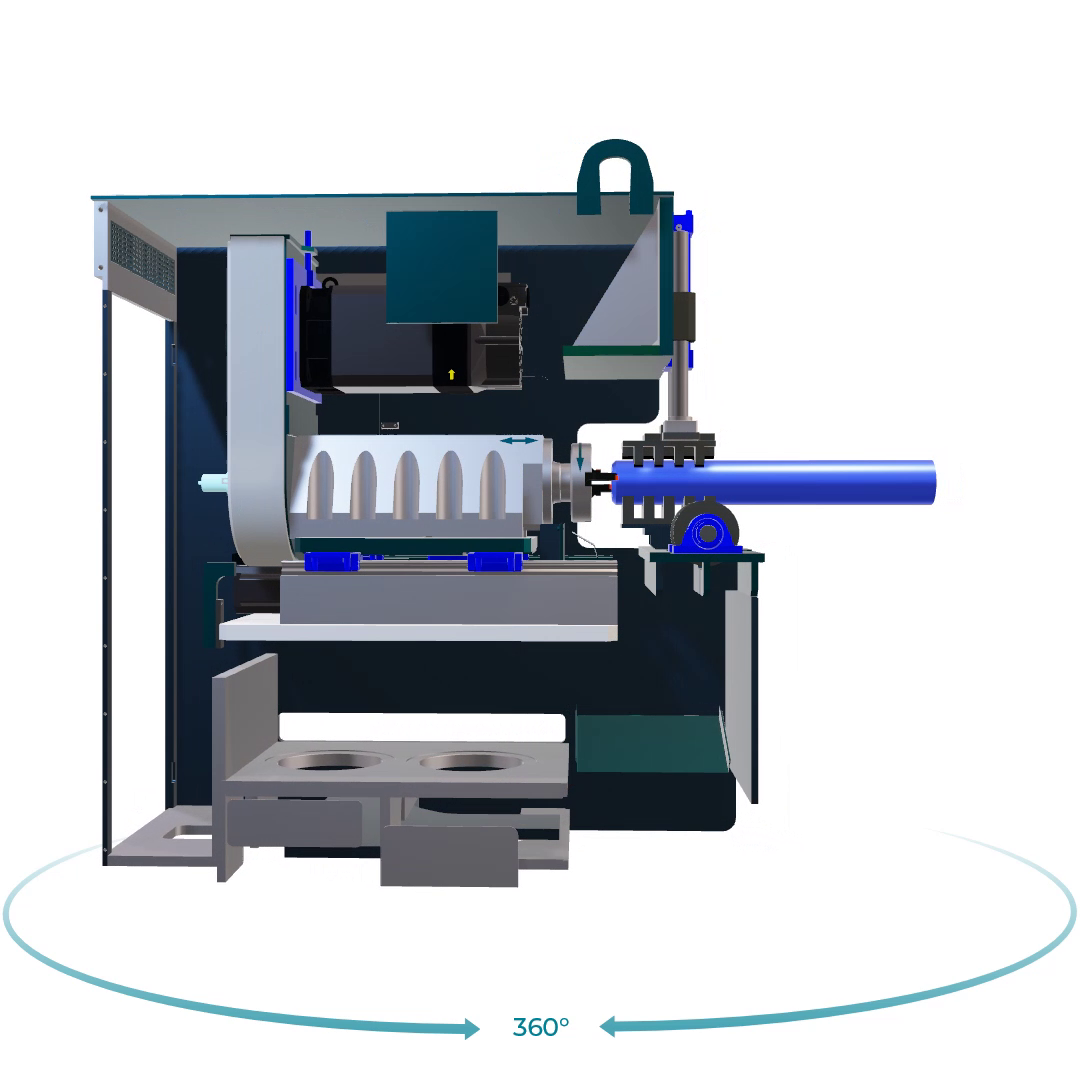

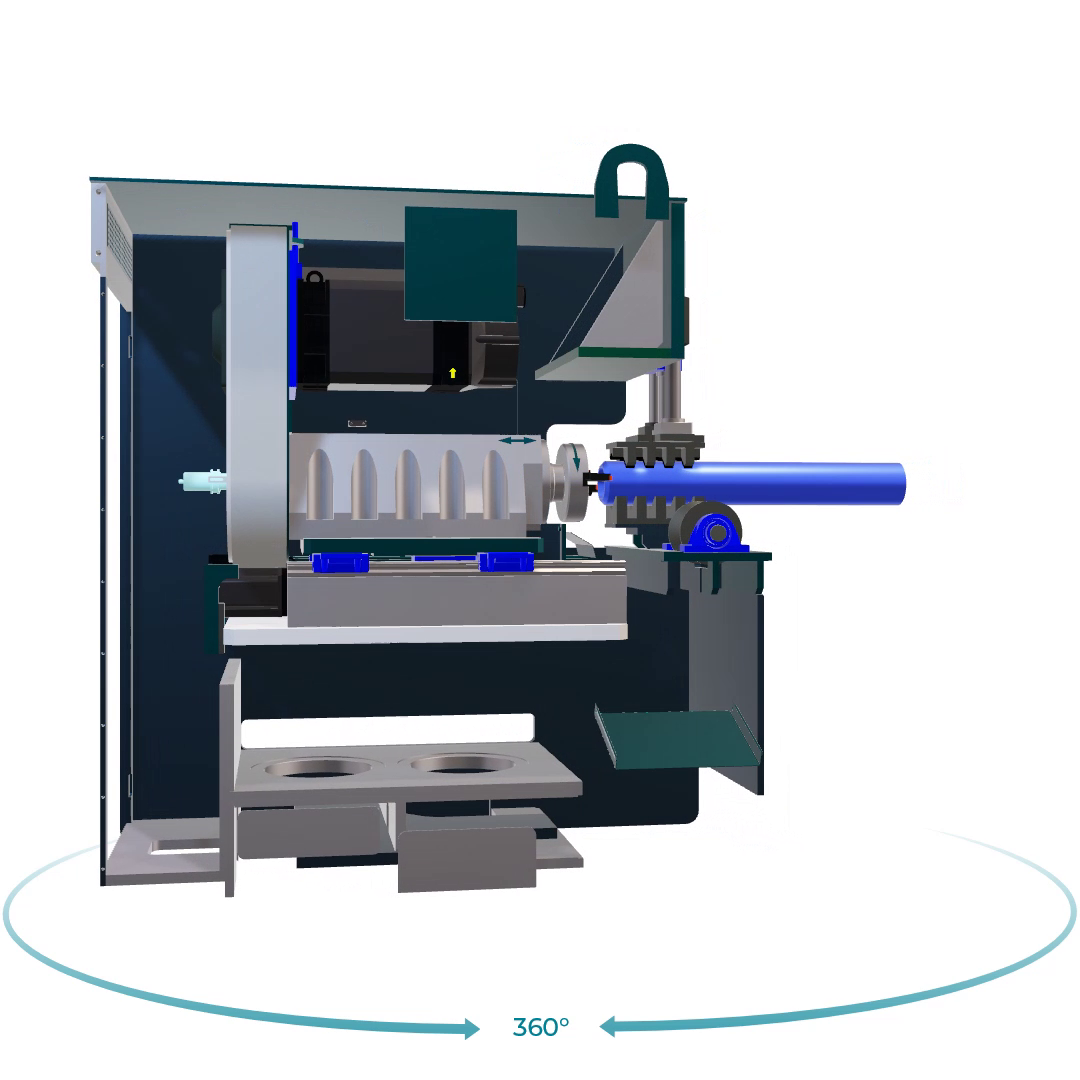

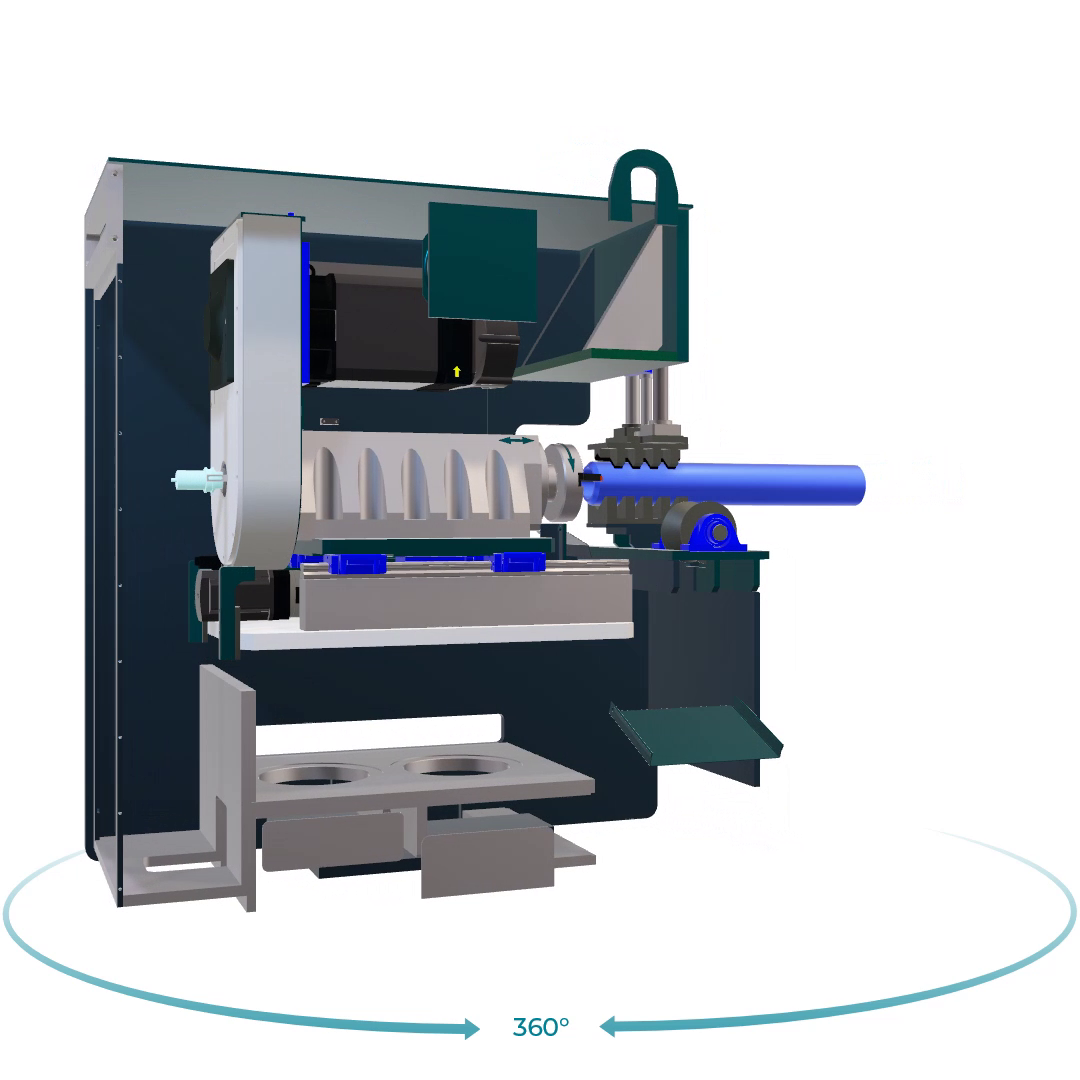

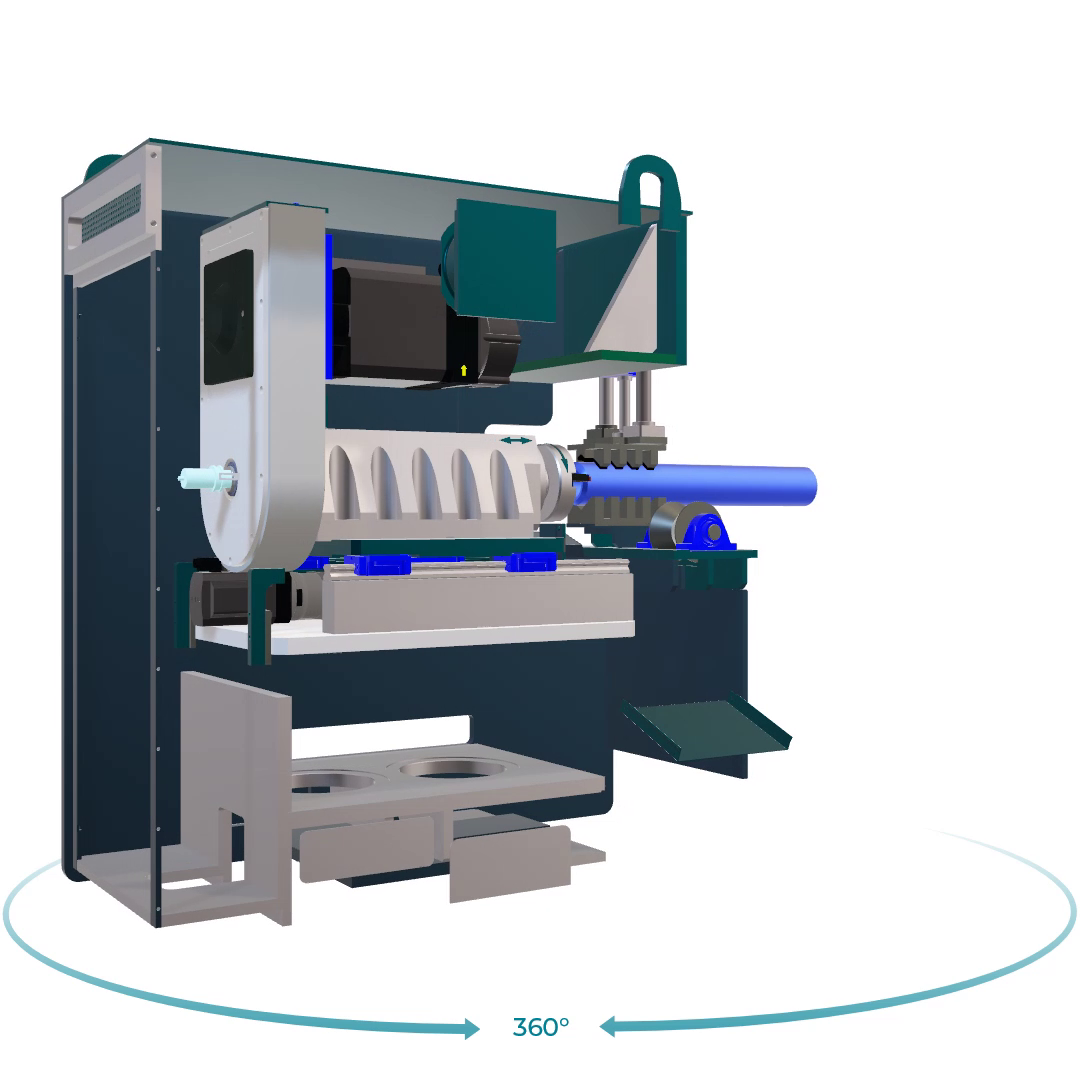

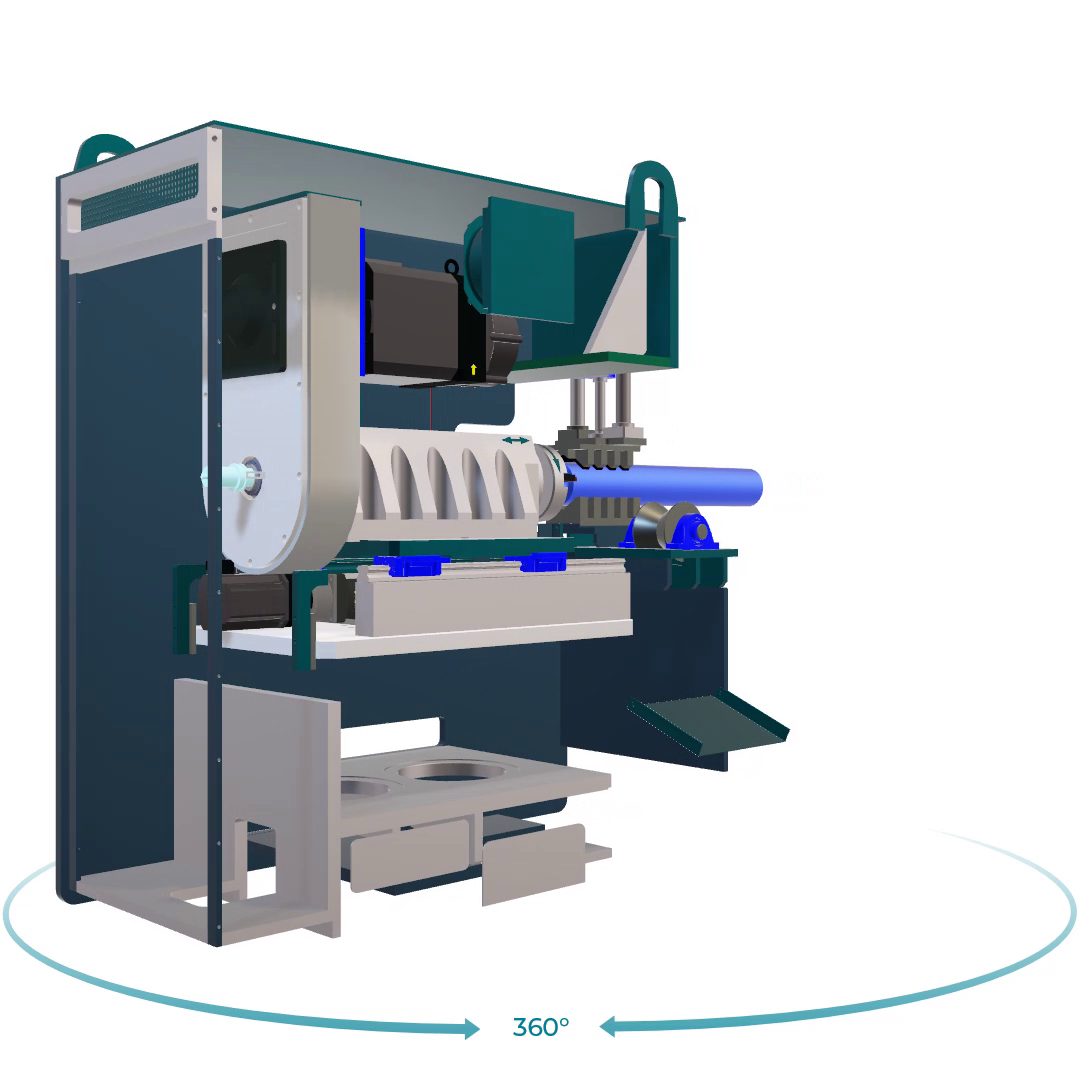

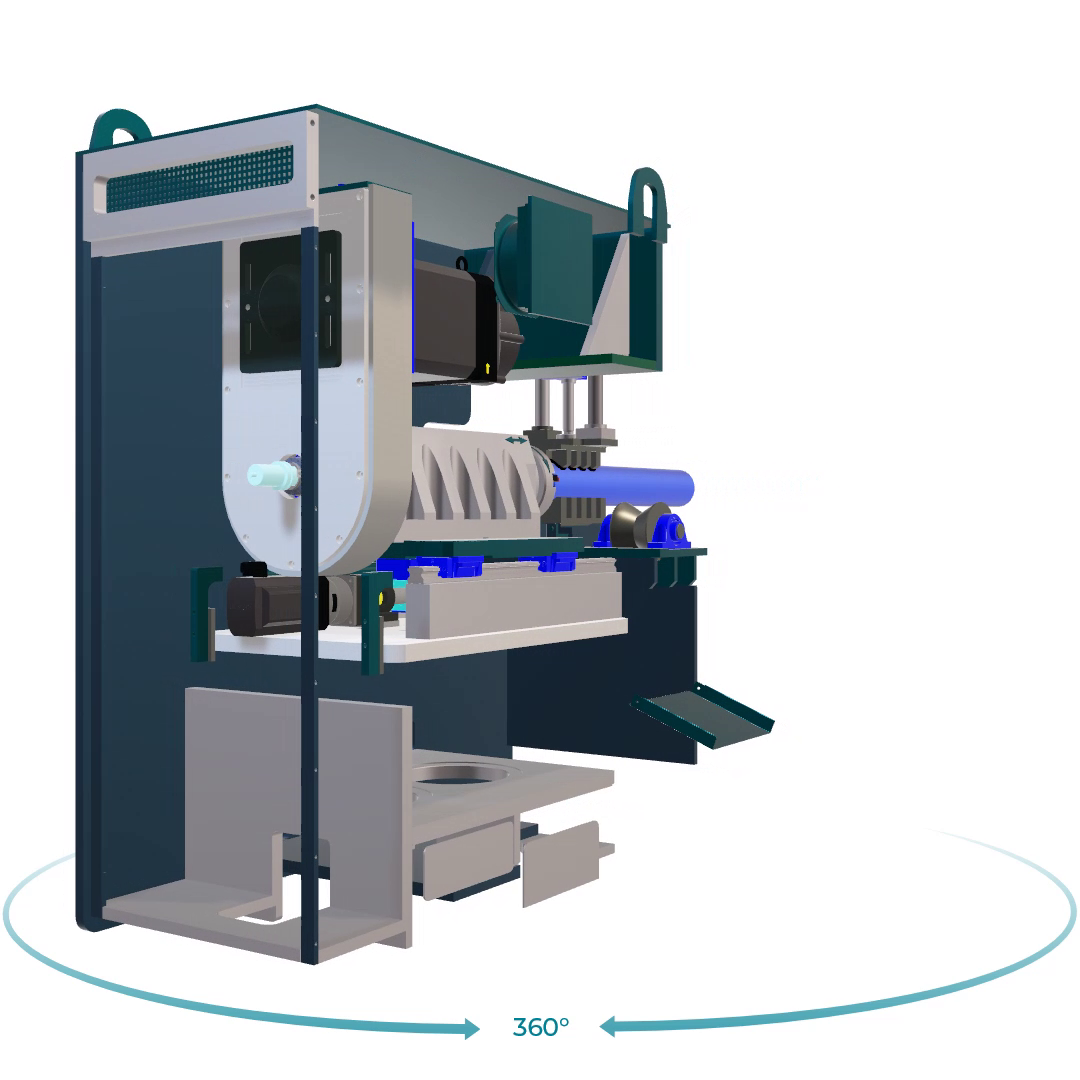

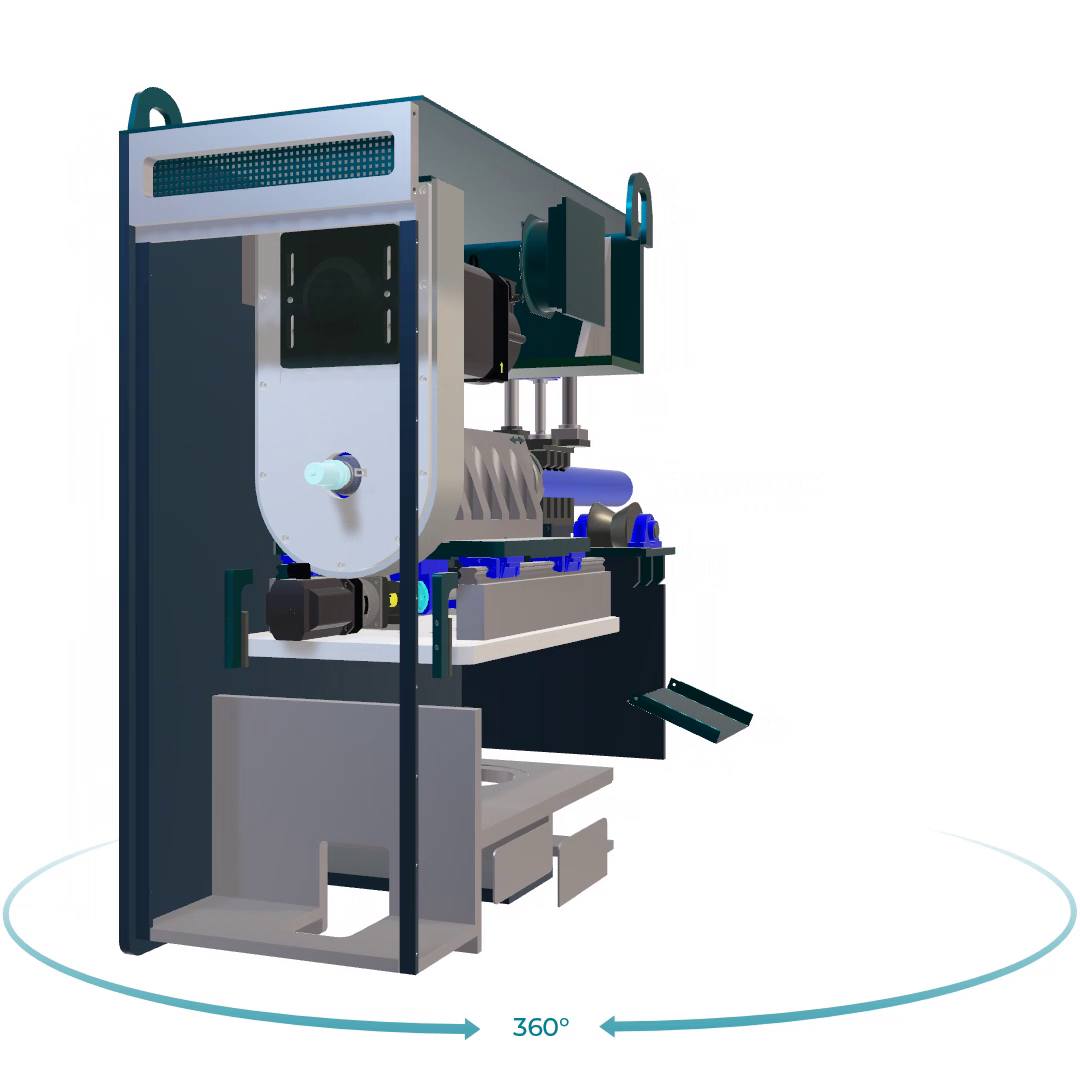

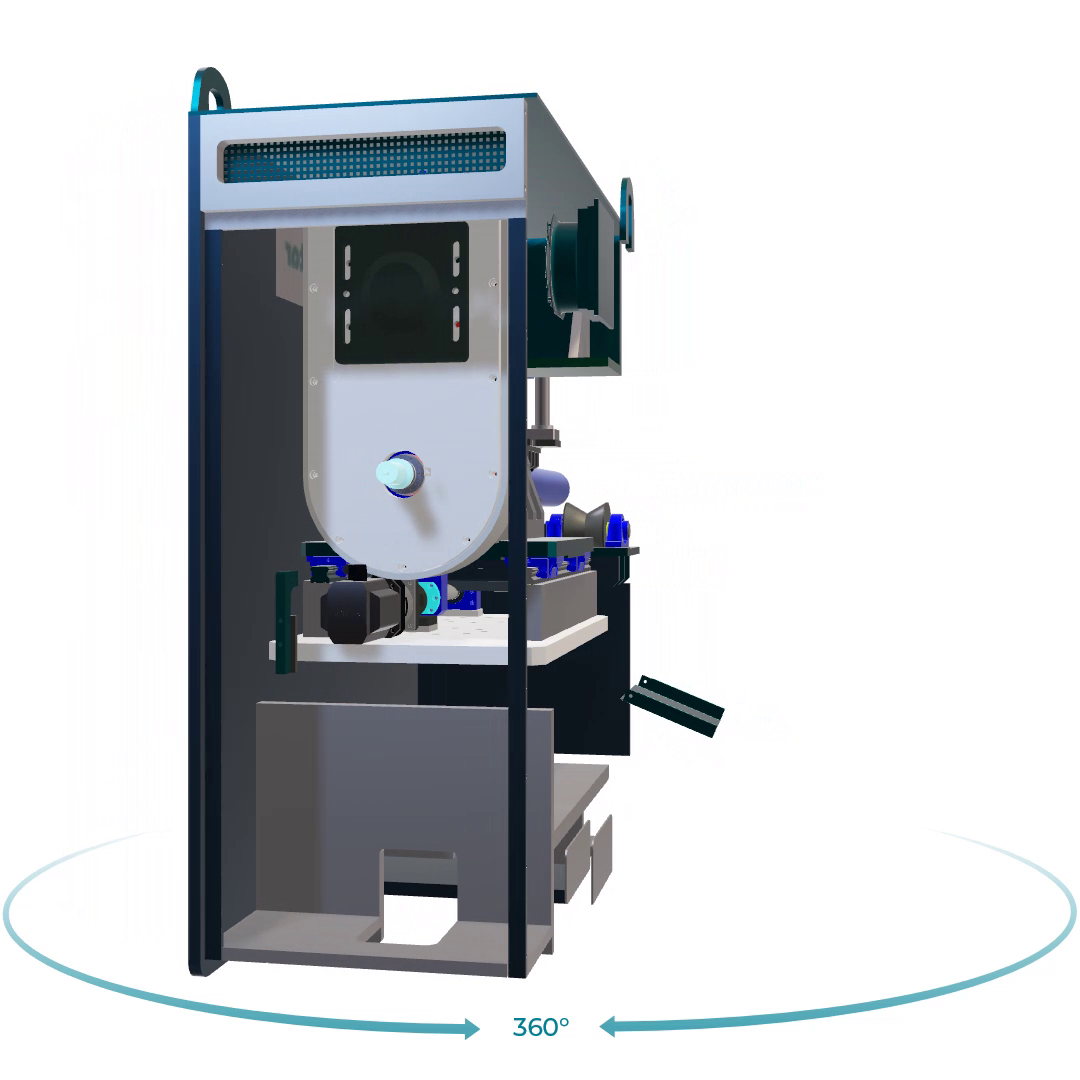

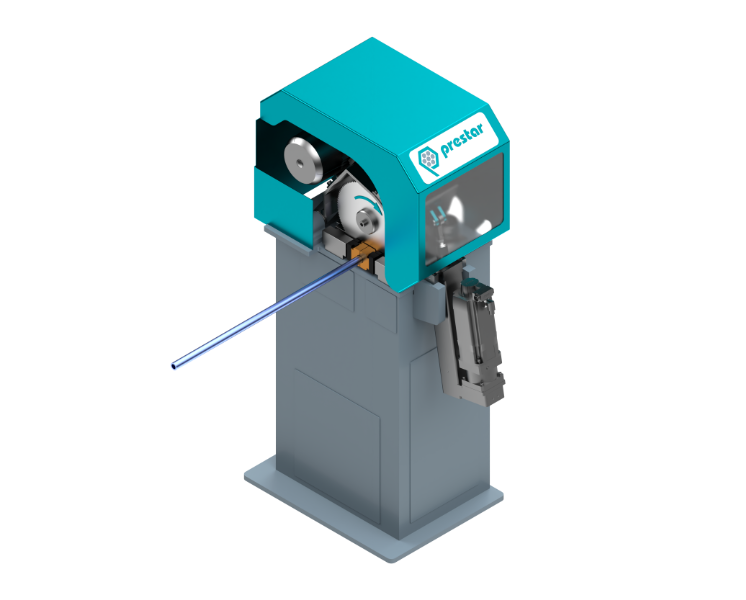

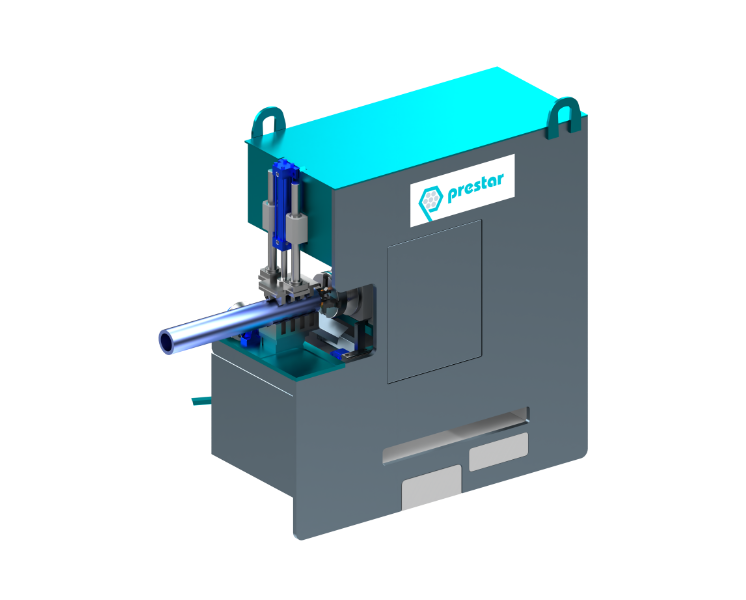

Chamfering of pipes

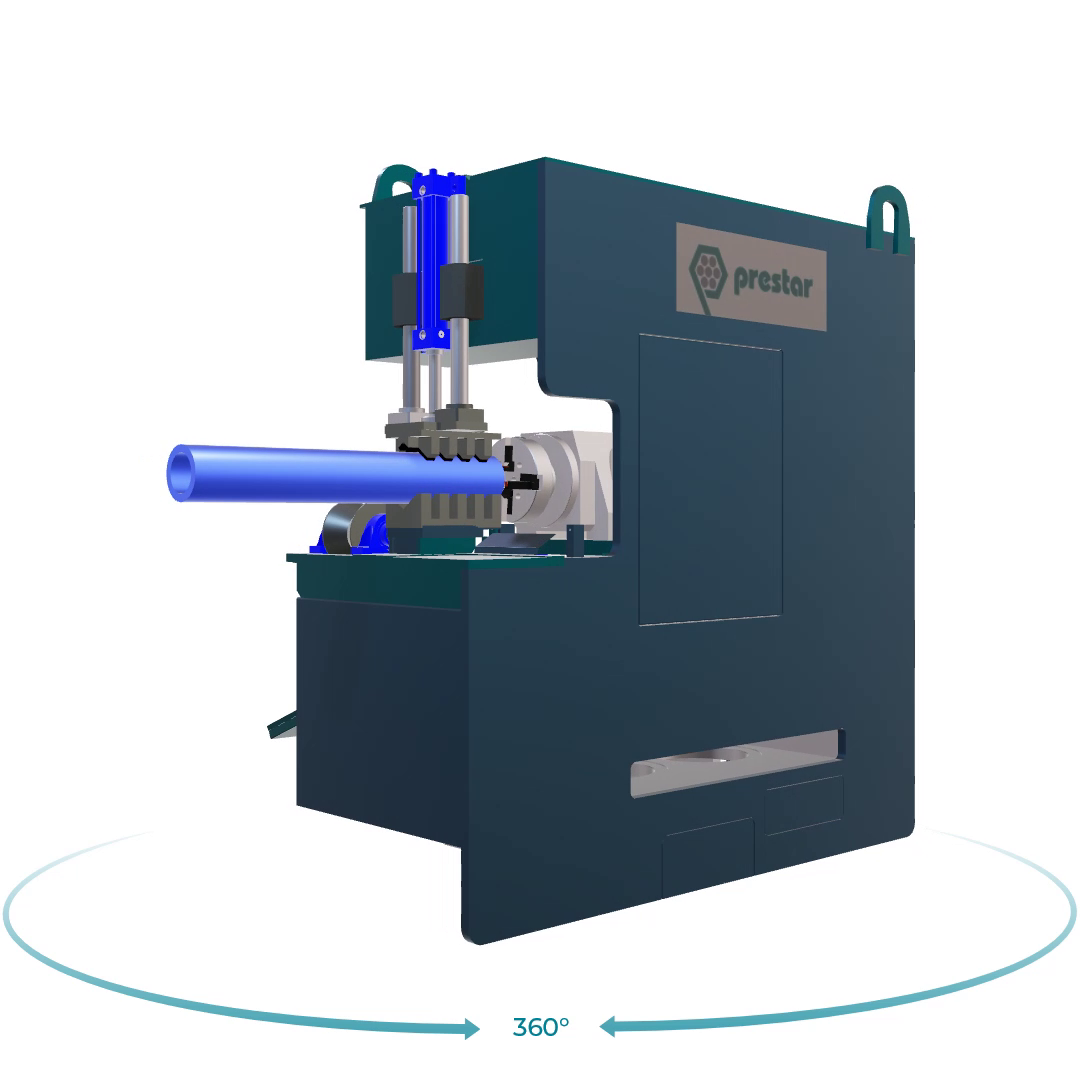

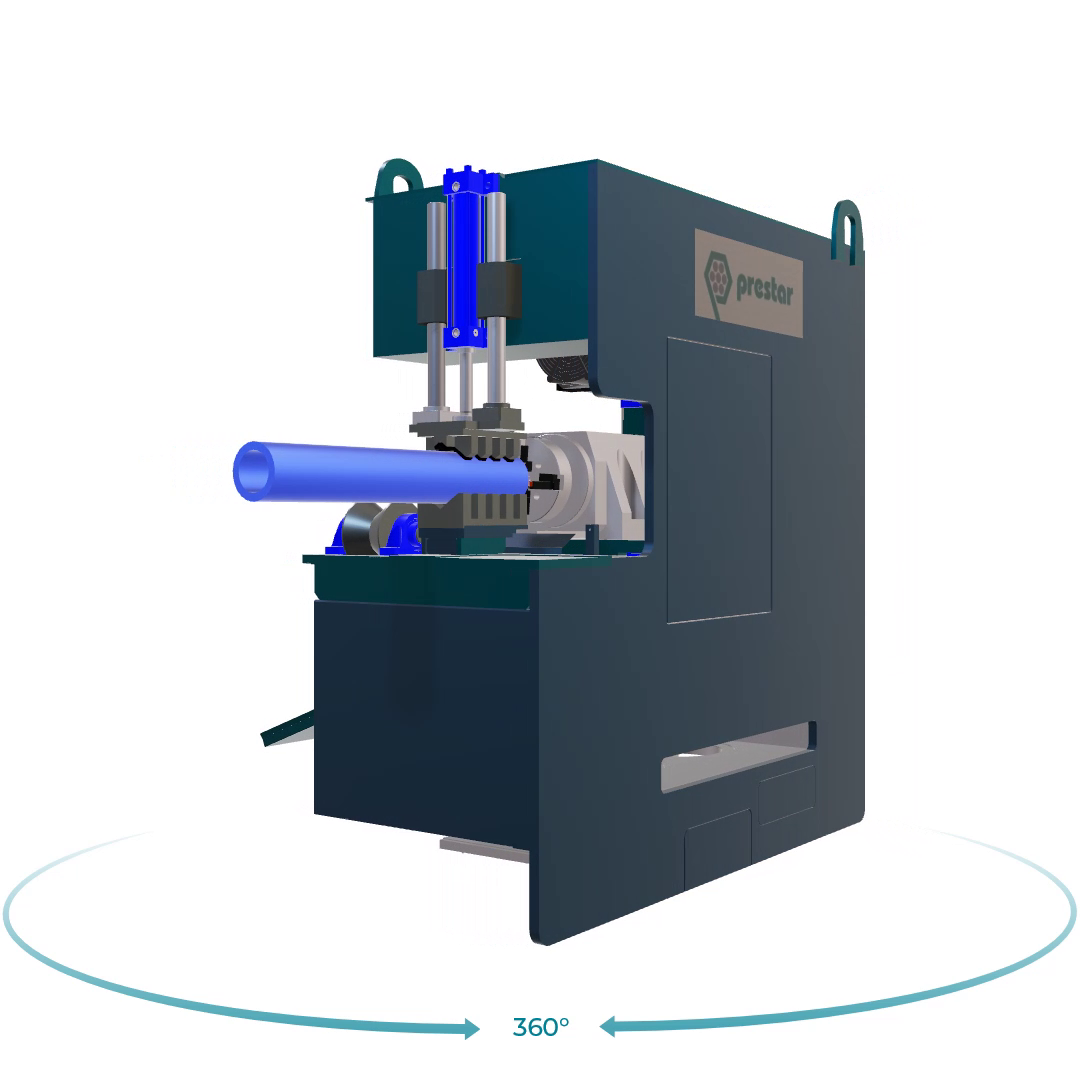

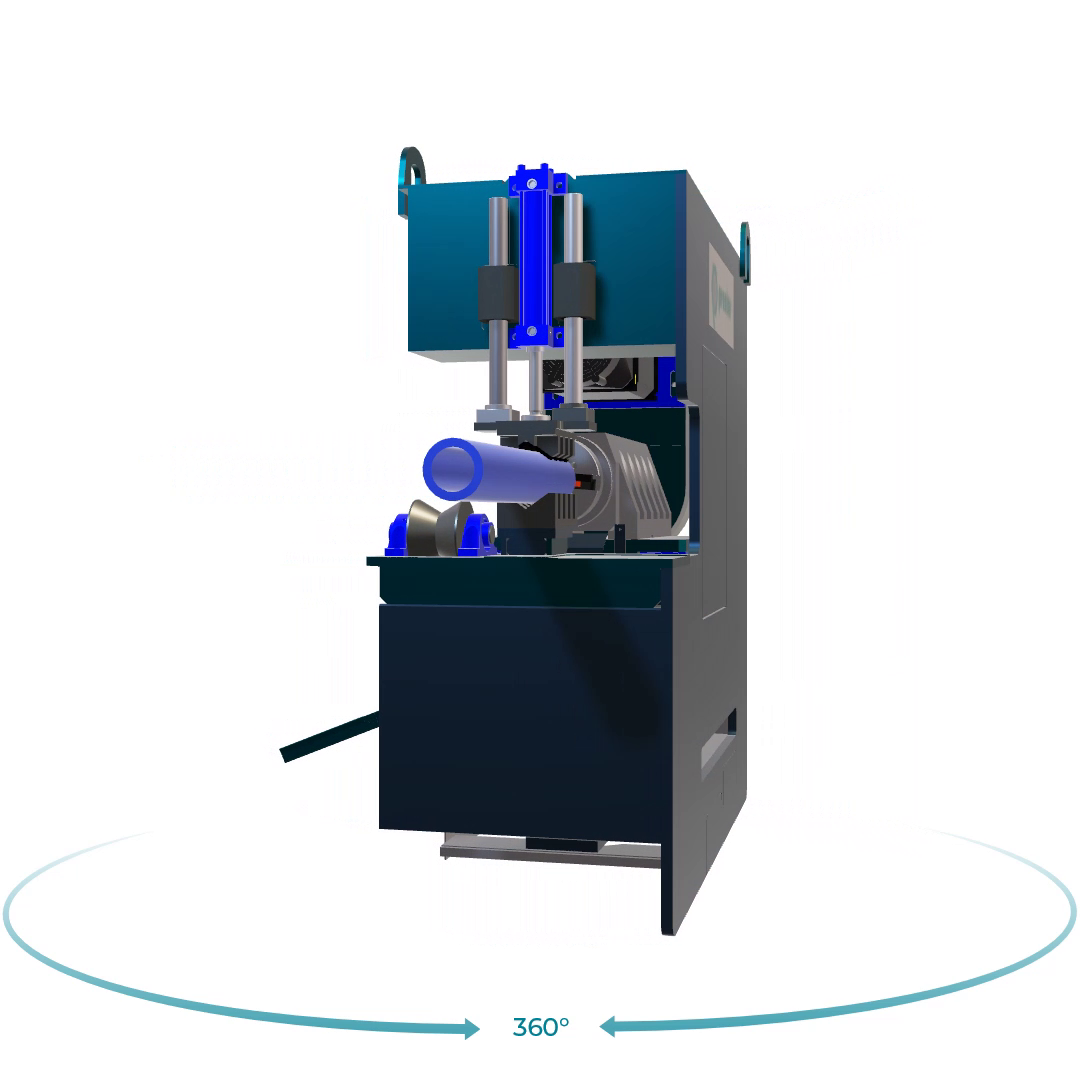

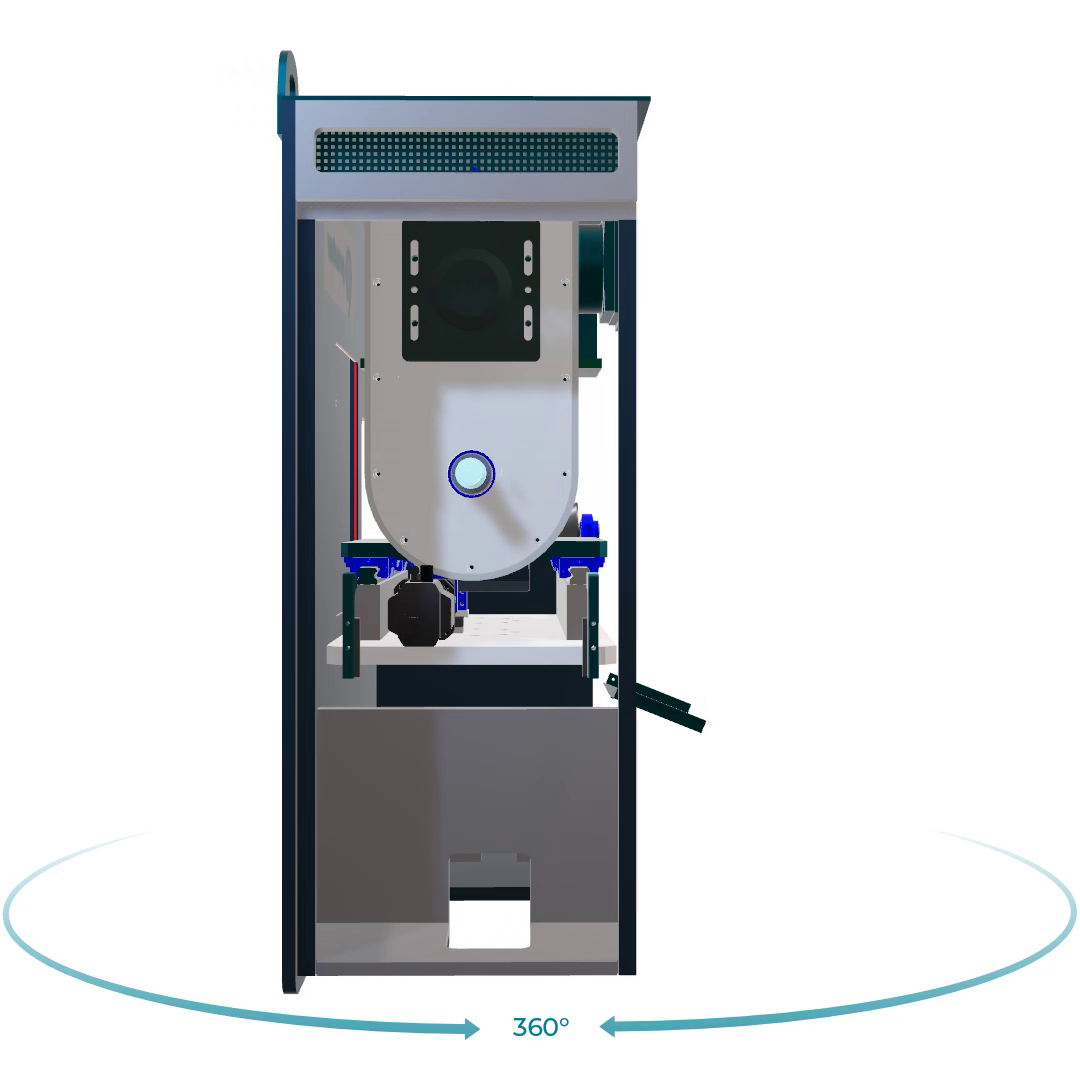

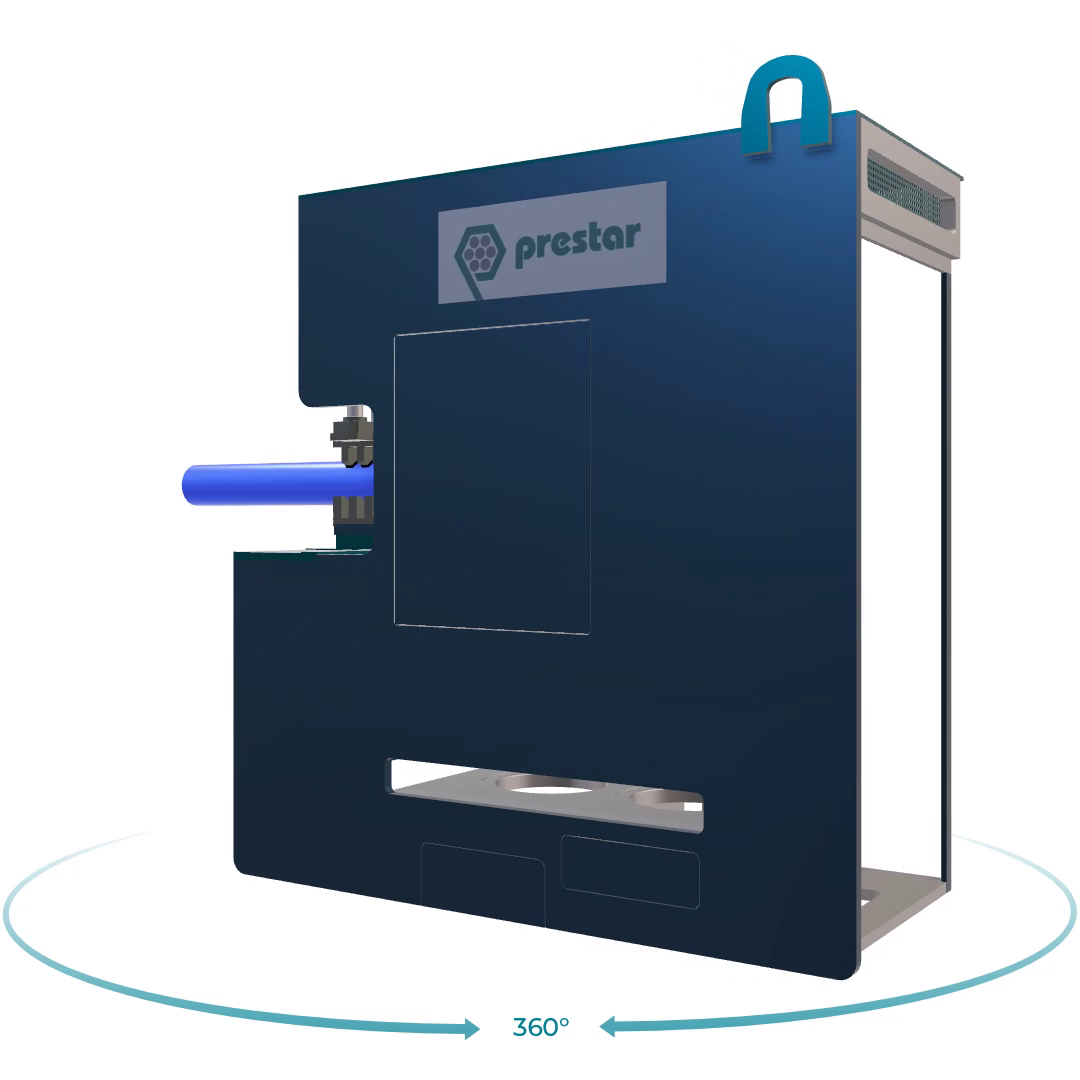

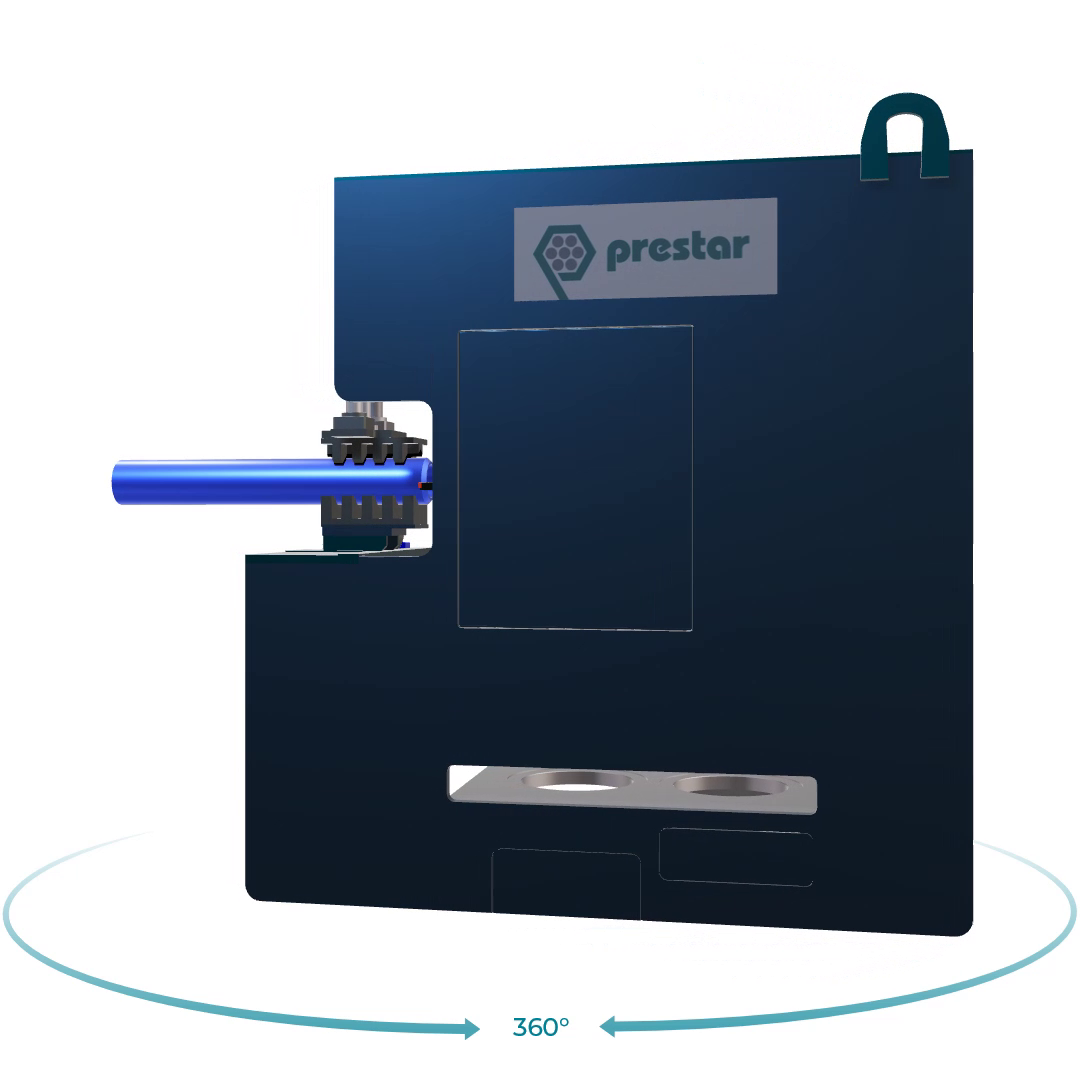

Description of the device

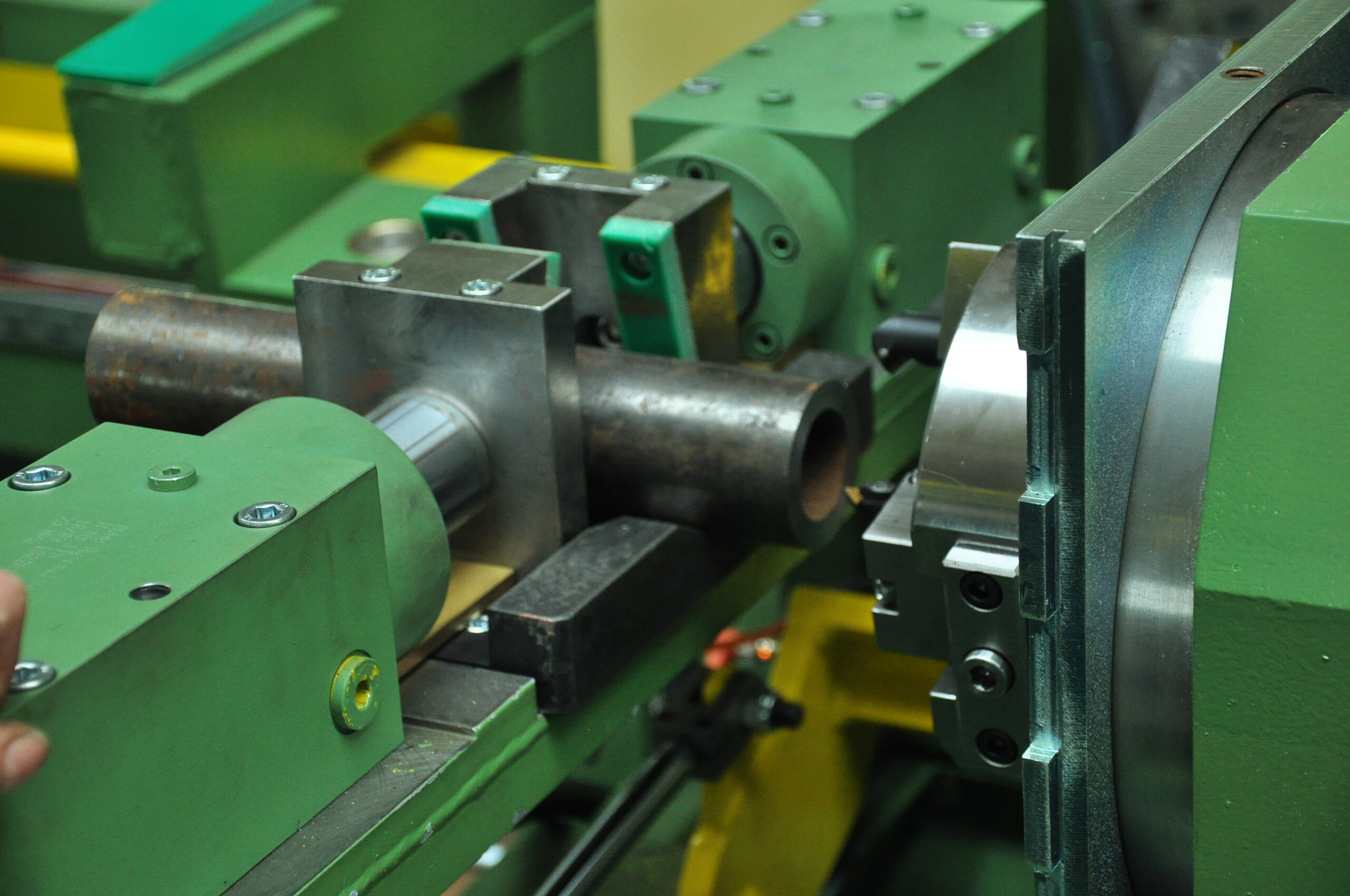

Bevelling and chamfering at the tube ends is used to remove burrs after cutting of the tubes or to make the bevels for welding of the tube ends.

Technical parameters of the machine

- Bevels for welding: 2 – 10 mm x 30, 45 or 60 deg.

- Edge and burr shrinkage: 0.5 to 1.0x 45deg.

- For large bevels, the rod or pipe is clamped in hydraulic jaws.

- The tube is centred in the jaw in the axis of the chuck

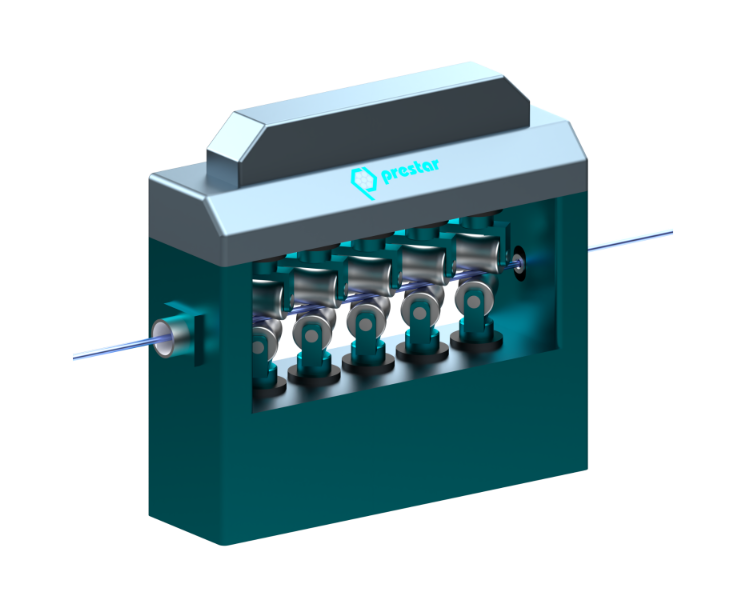

- The edge chuck is equipped with two to three clamped knives with replaceable inserts.

- When the chuck is moved, the outer edge, the inner edge is knocked off and the face of the tube is aligned.

- Cutting speed and feed rate selection is set automatically depending on the material to be machined

- Automatic spindle feed with chuck into the cut

Other equipment of the machine

- Covering the machining area

- Brushing of sponges and collection of sponges in the collection container

- Tact feeding device and prismatic conveyor for automatic feeding into the clamping jaws

- Hexagonal bars made of non-ferrous metals can also be chamfered

- Enhanced service with the ability to display manuals, service guides and other necessary documentation on the machine’s HMI to minimize service times

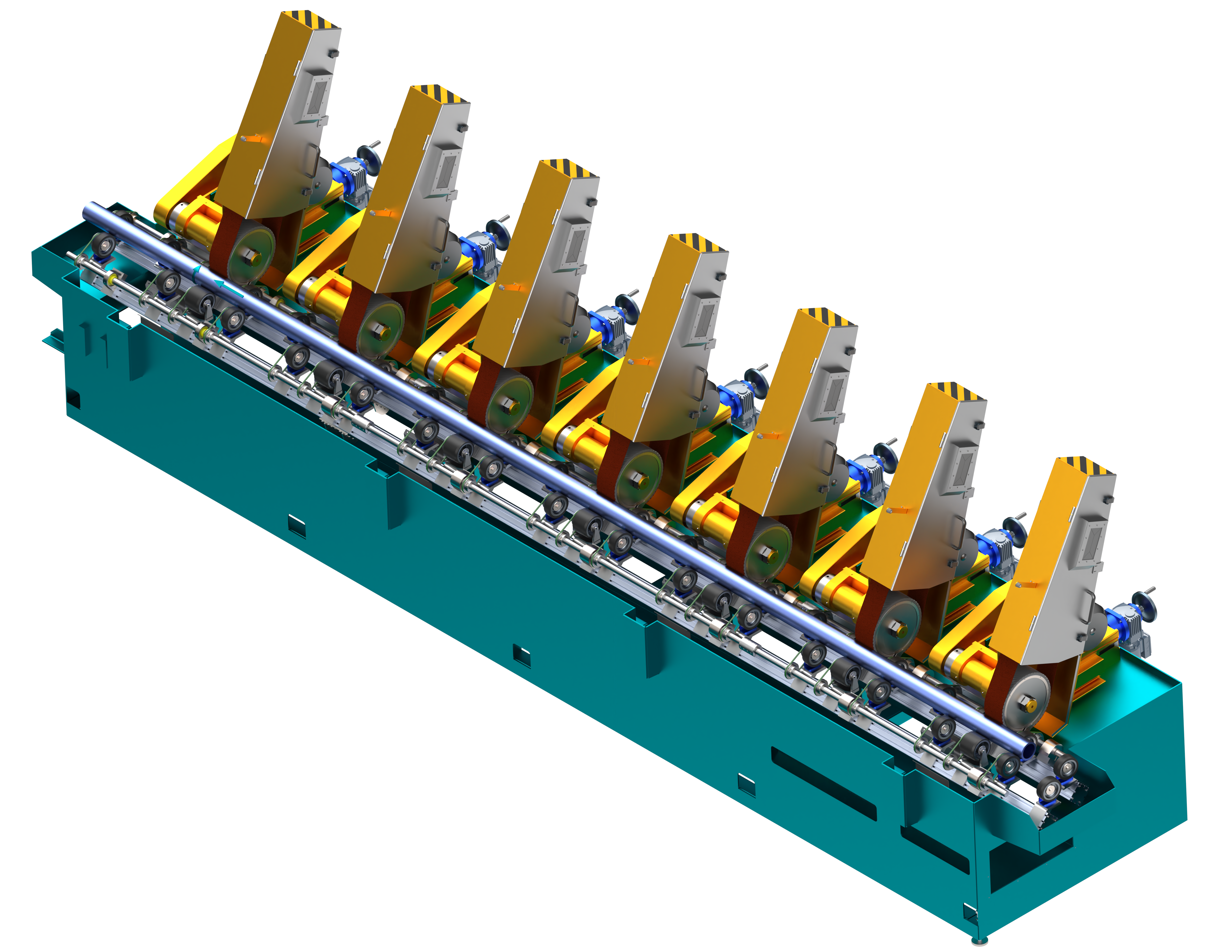

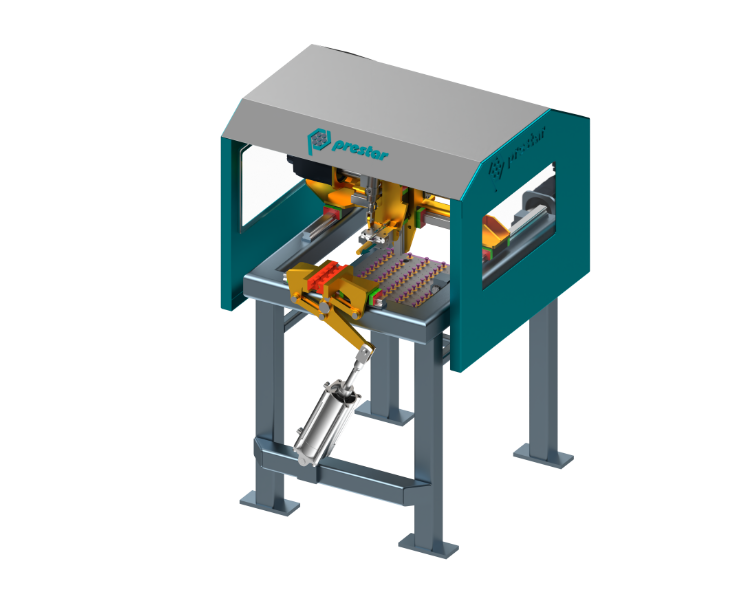

Straightening machines

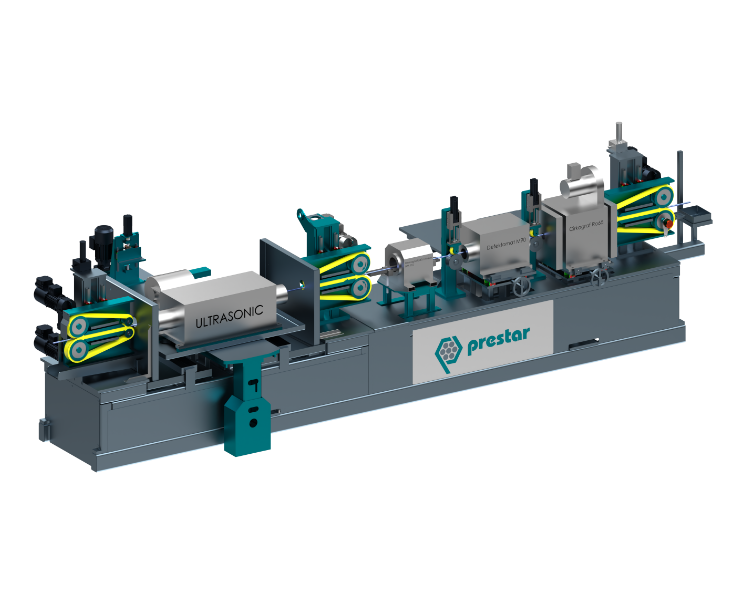

Internal pipe grinder

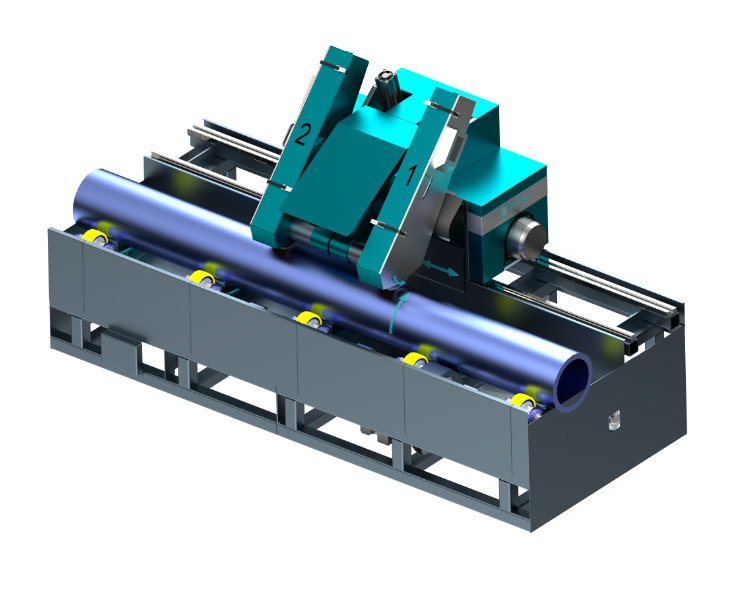

Centerless pipe grinder

External stationary pipe grinder

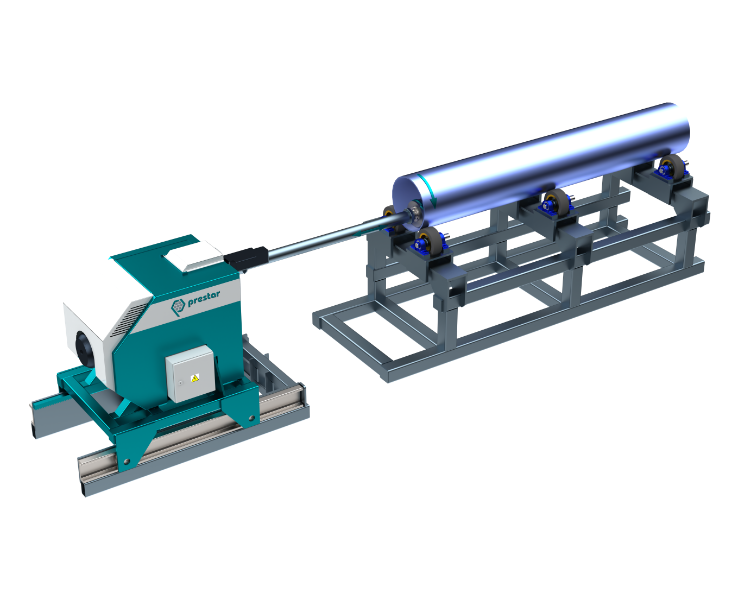

Flying saw

Circular saw

Chamfering of pipes

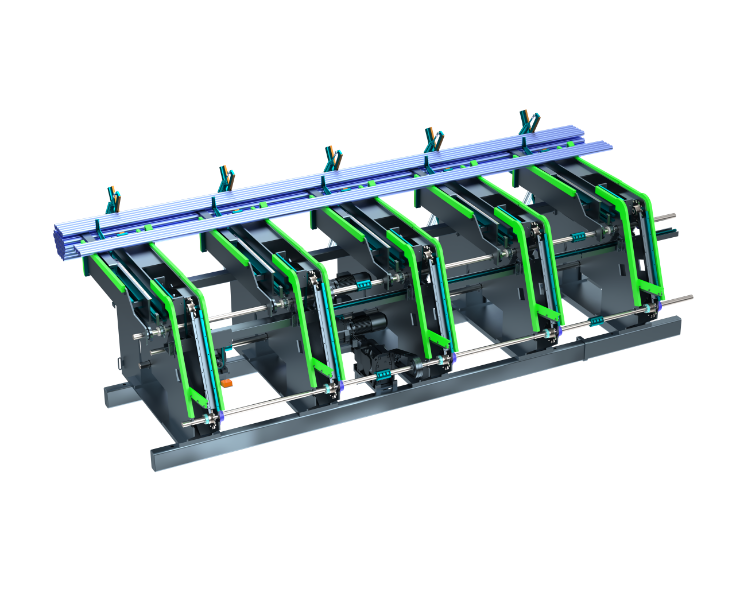

Sorting and plugging

Control tables

Packaging machines

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT