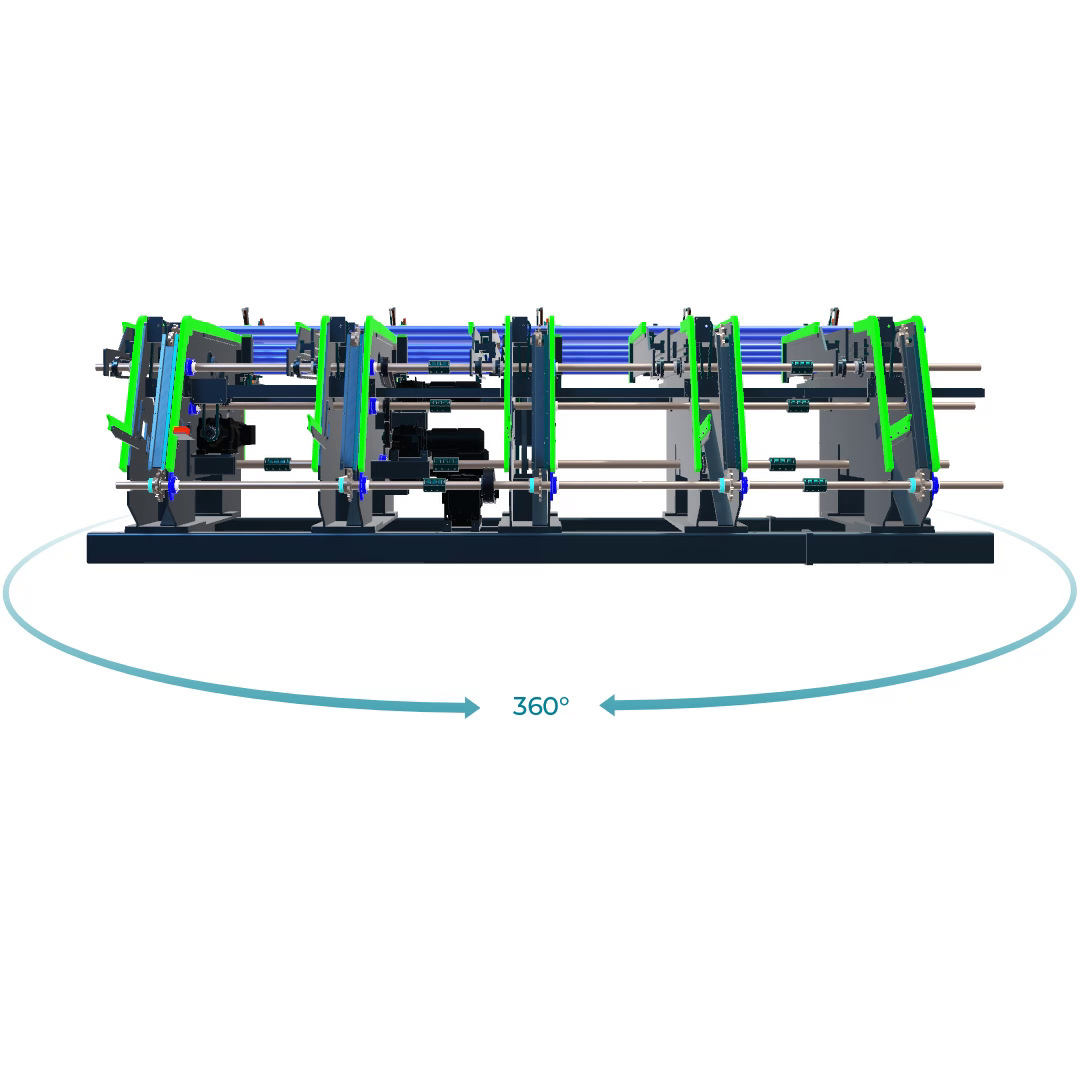

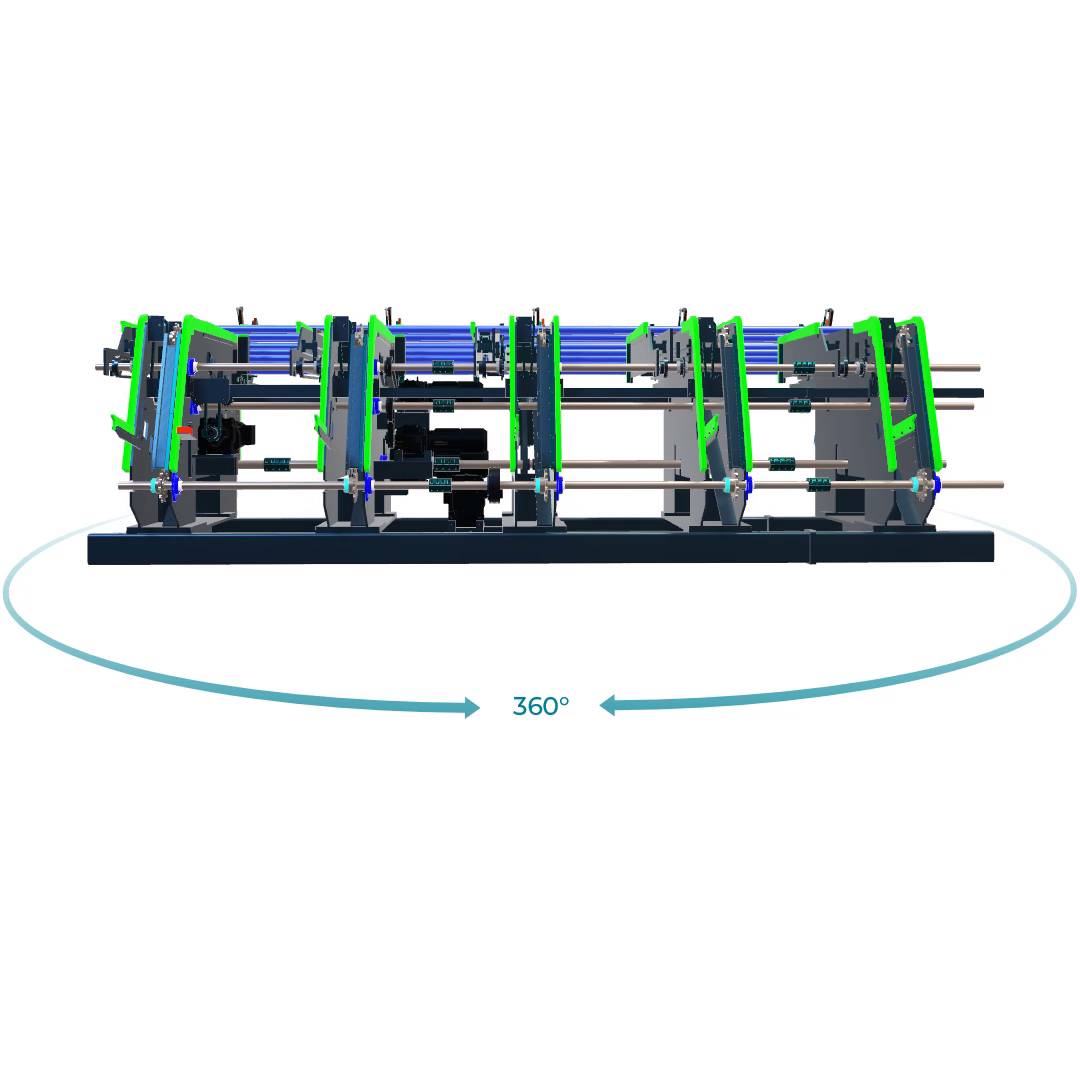

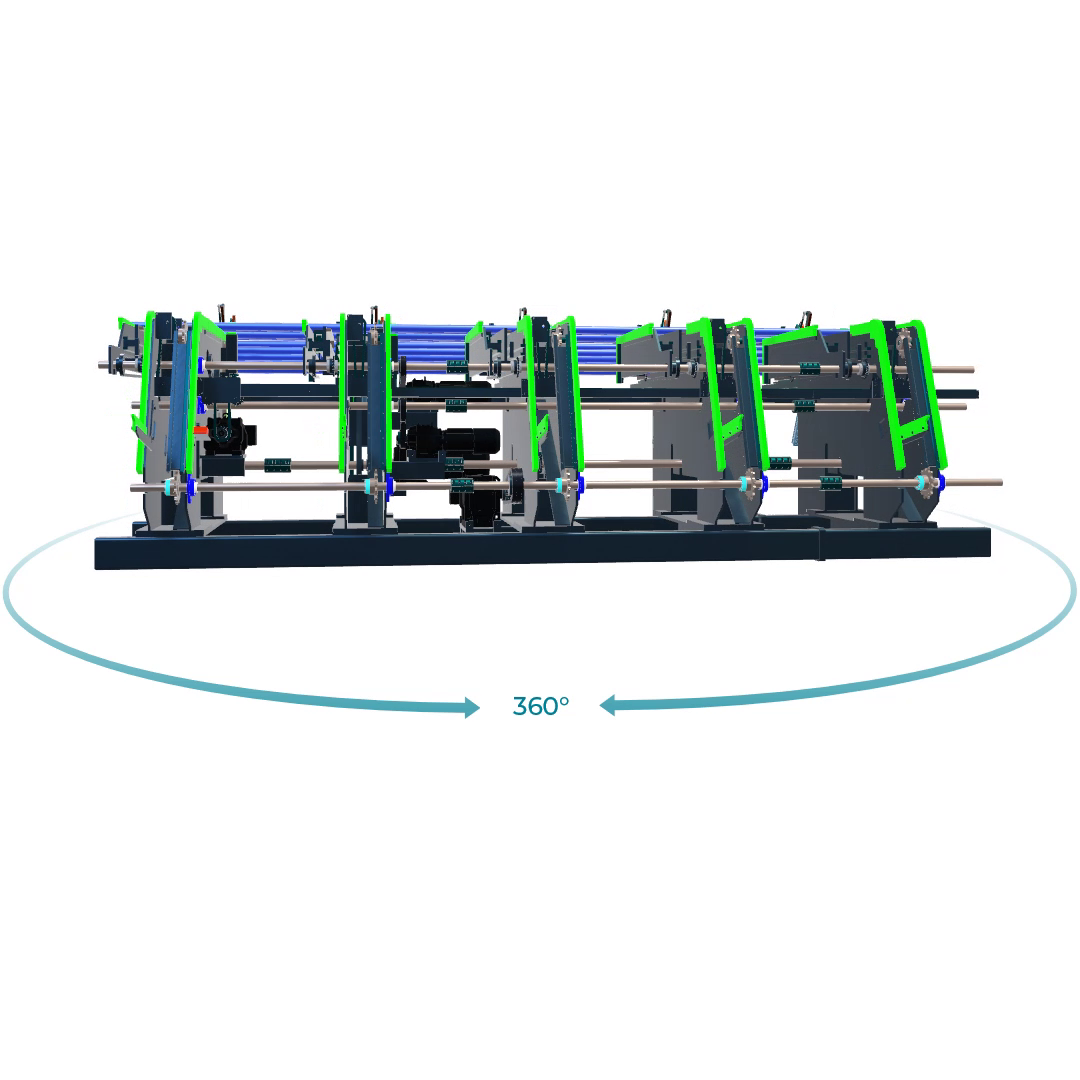

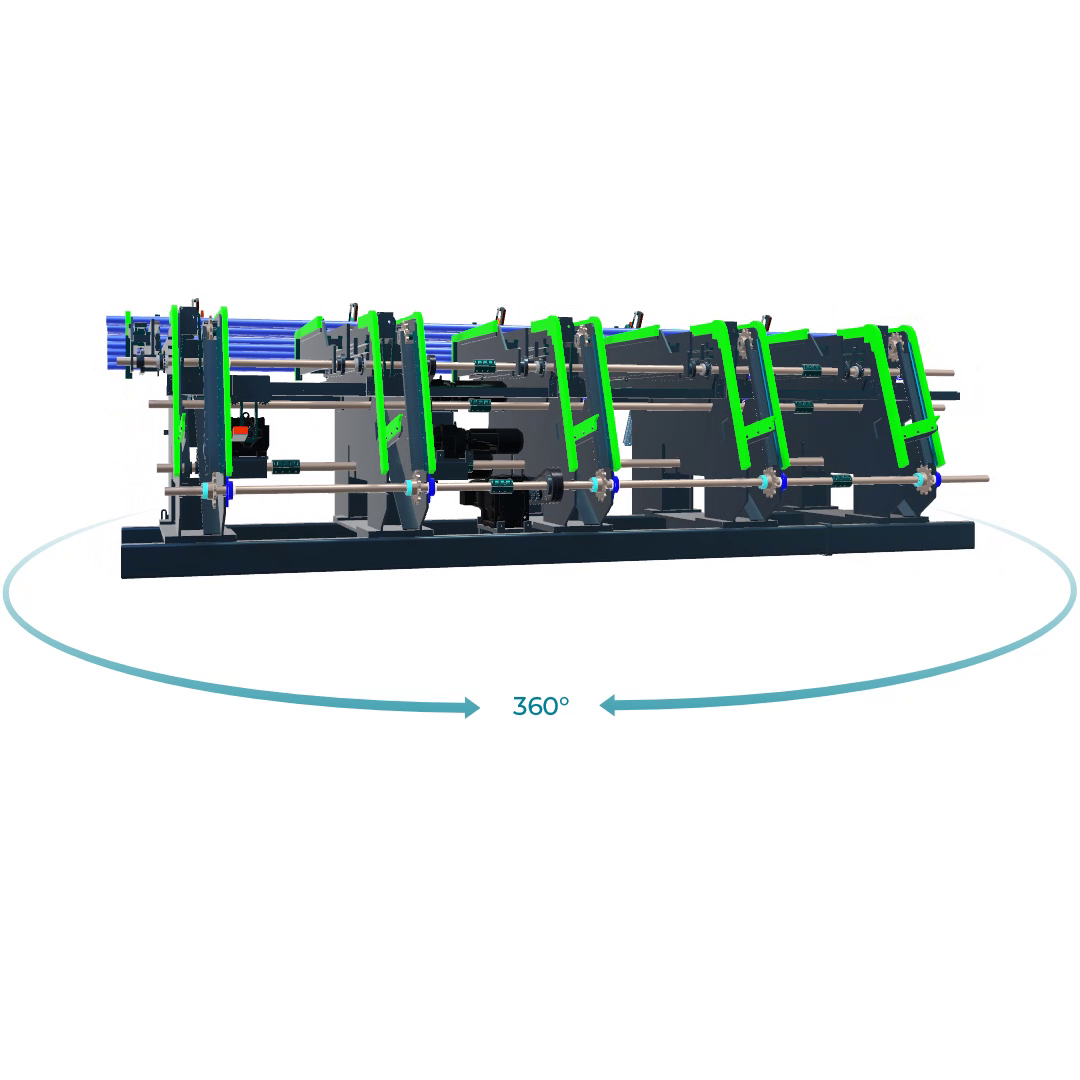

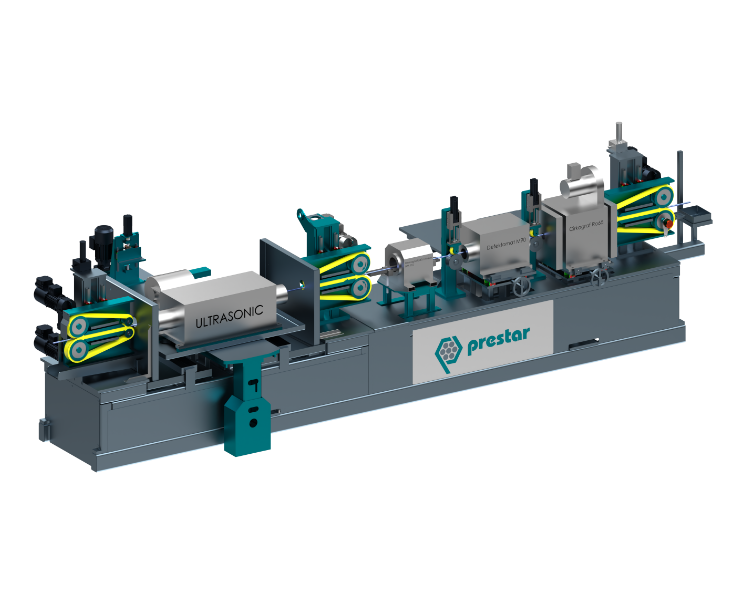

Packaging machines

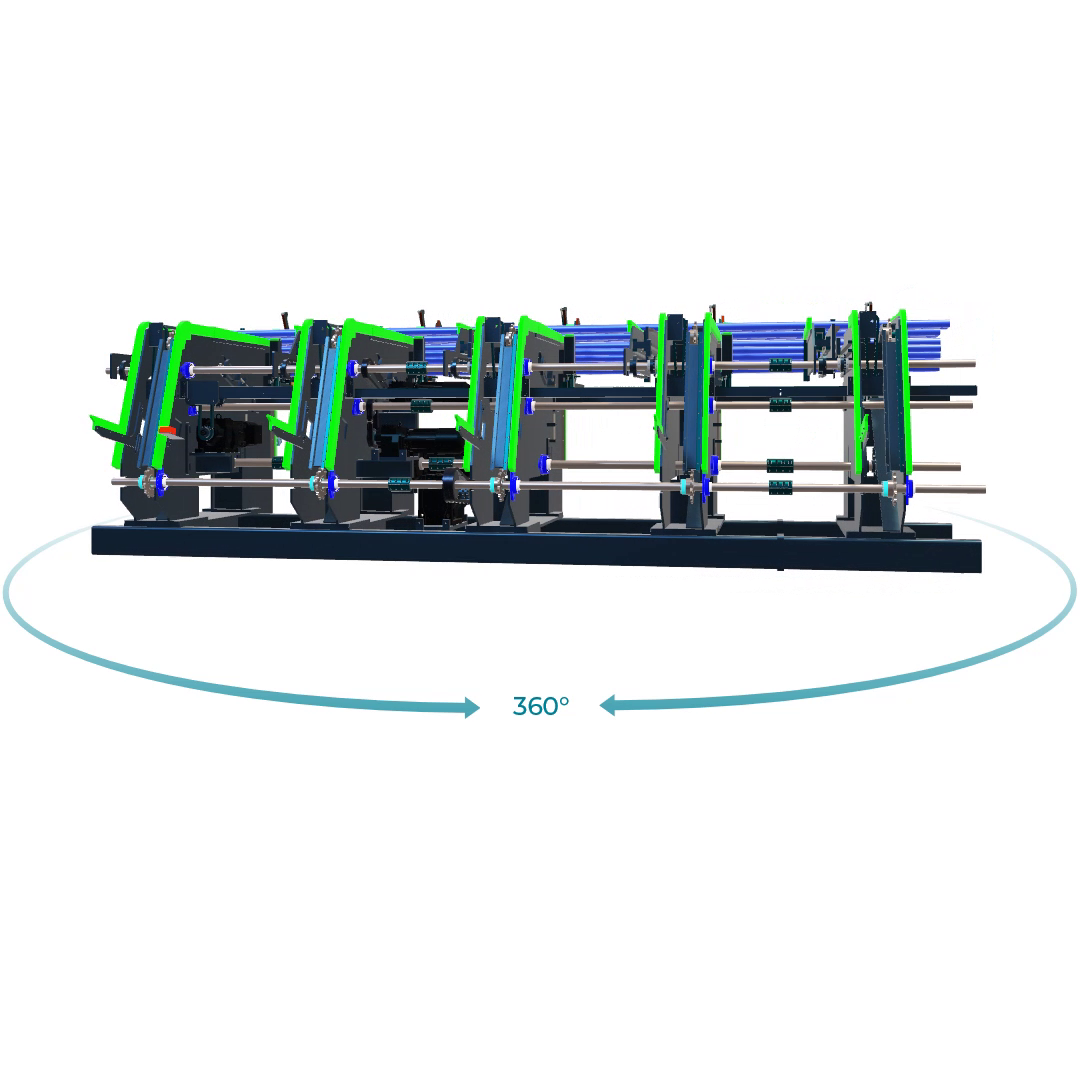

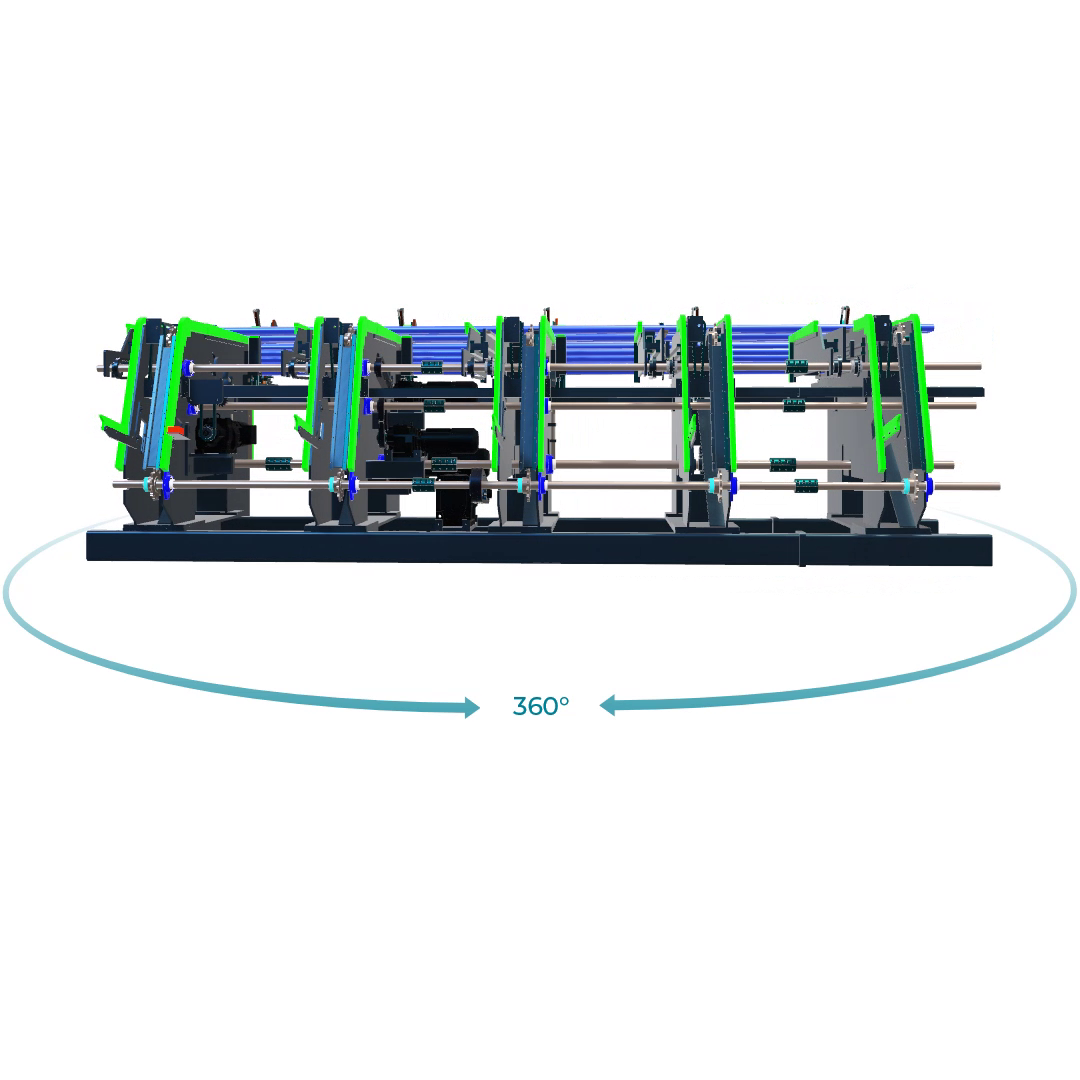

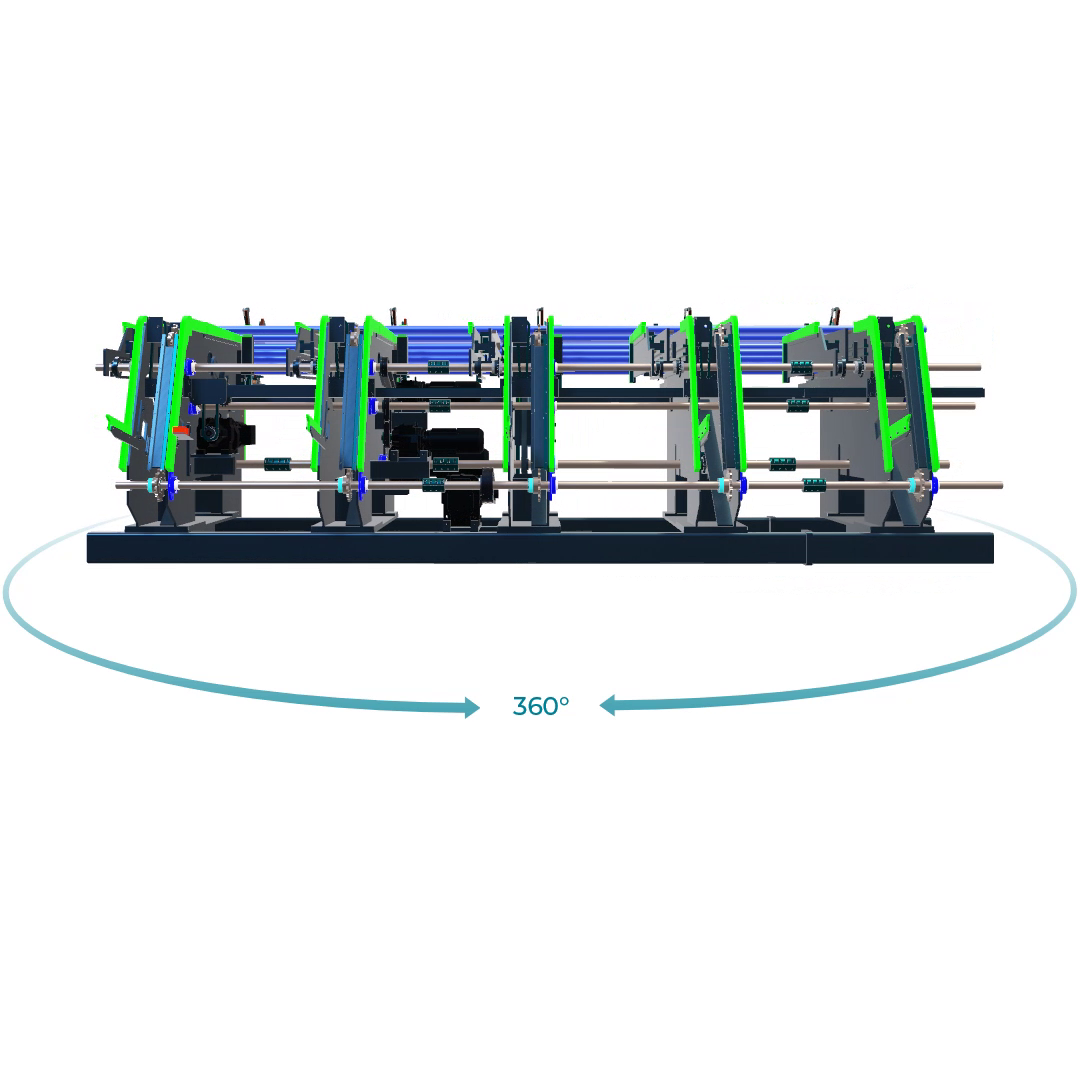

Description of the device

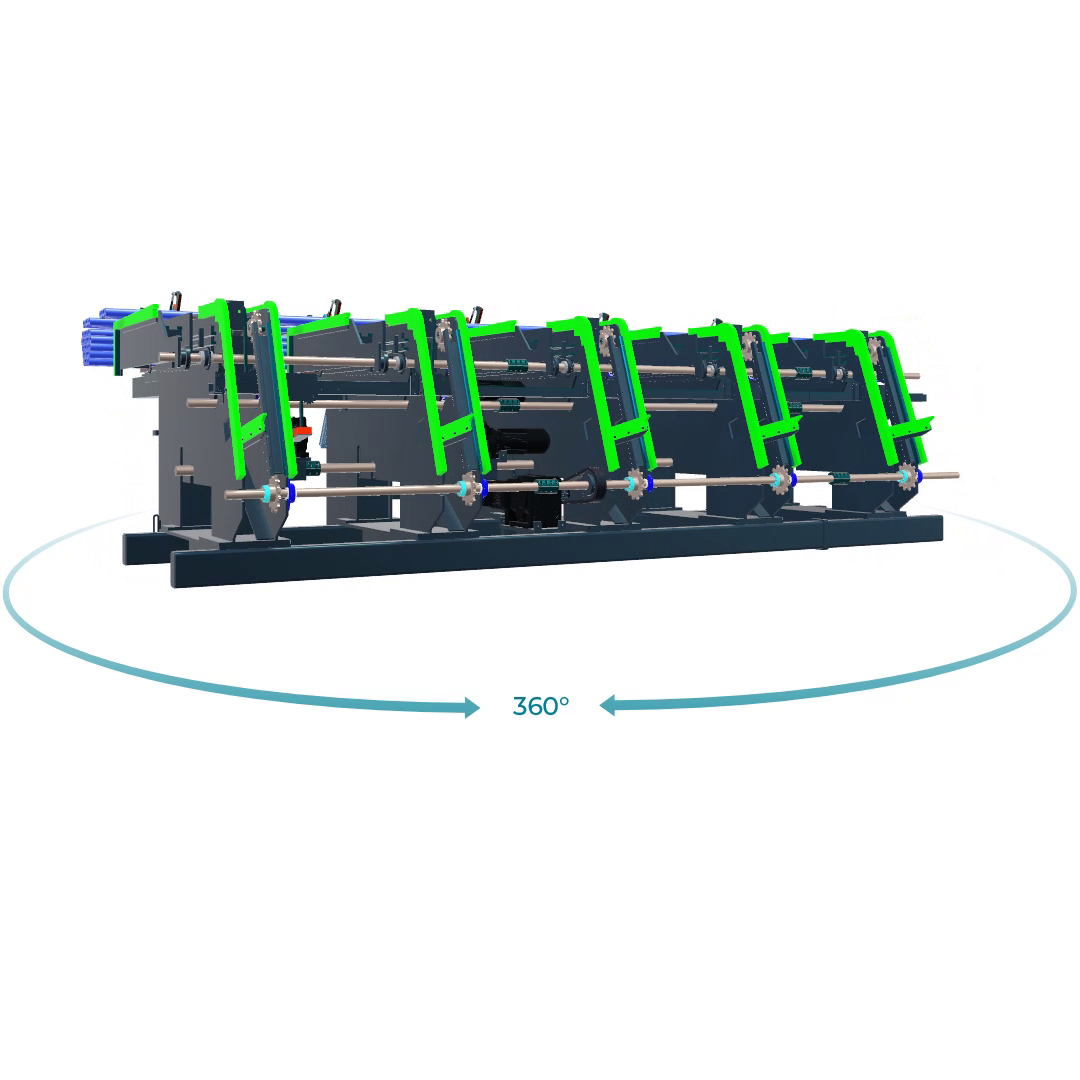

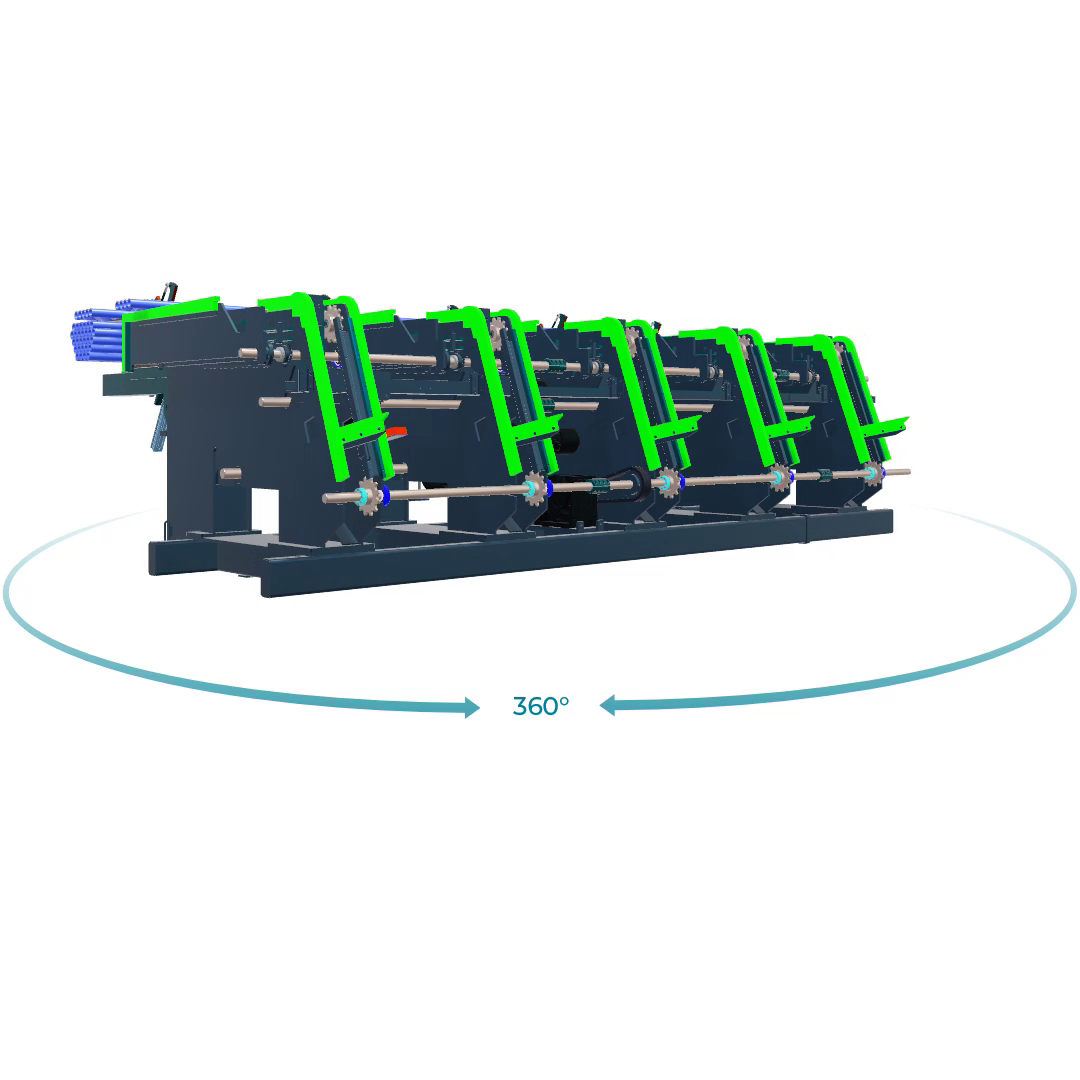

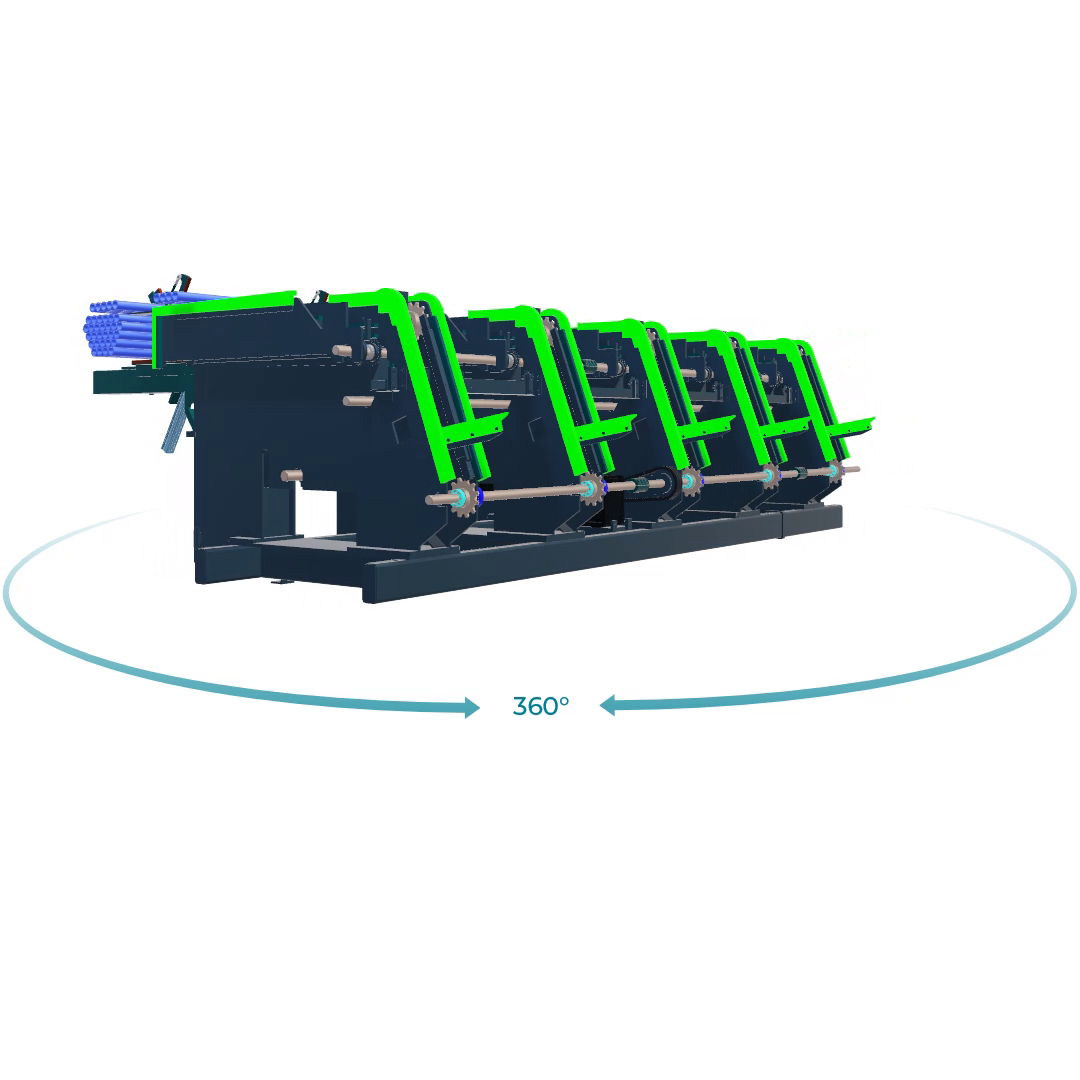

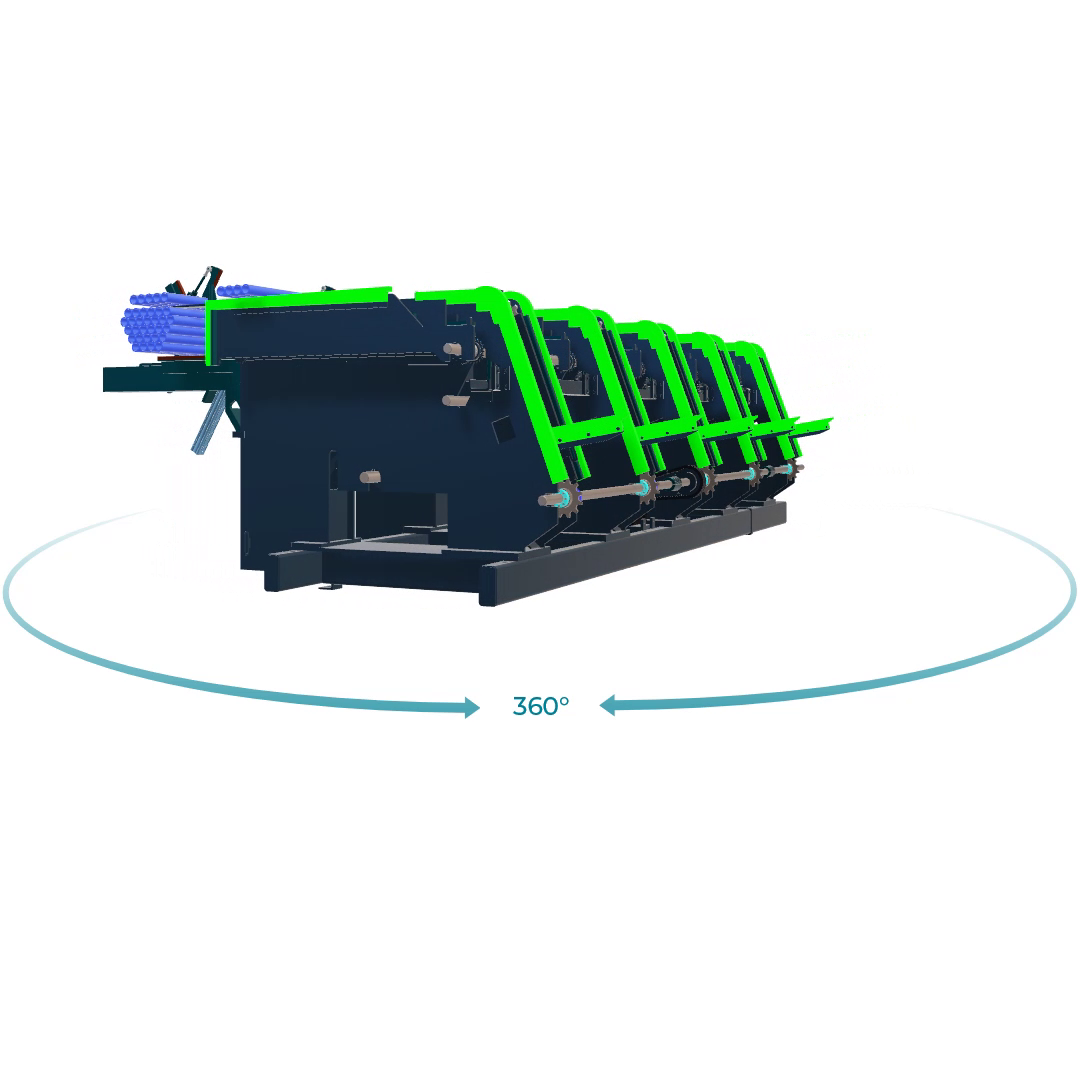

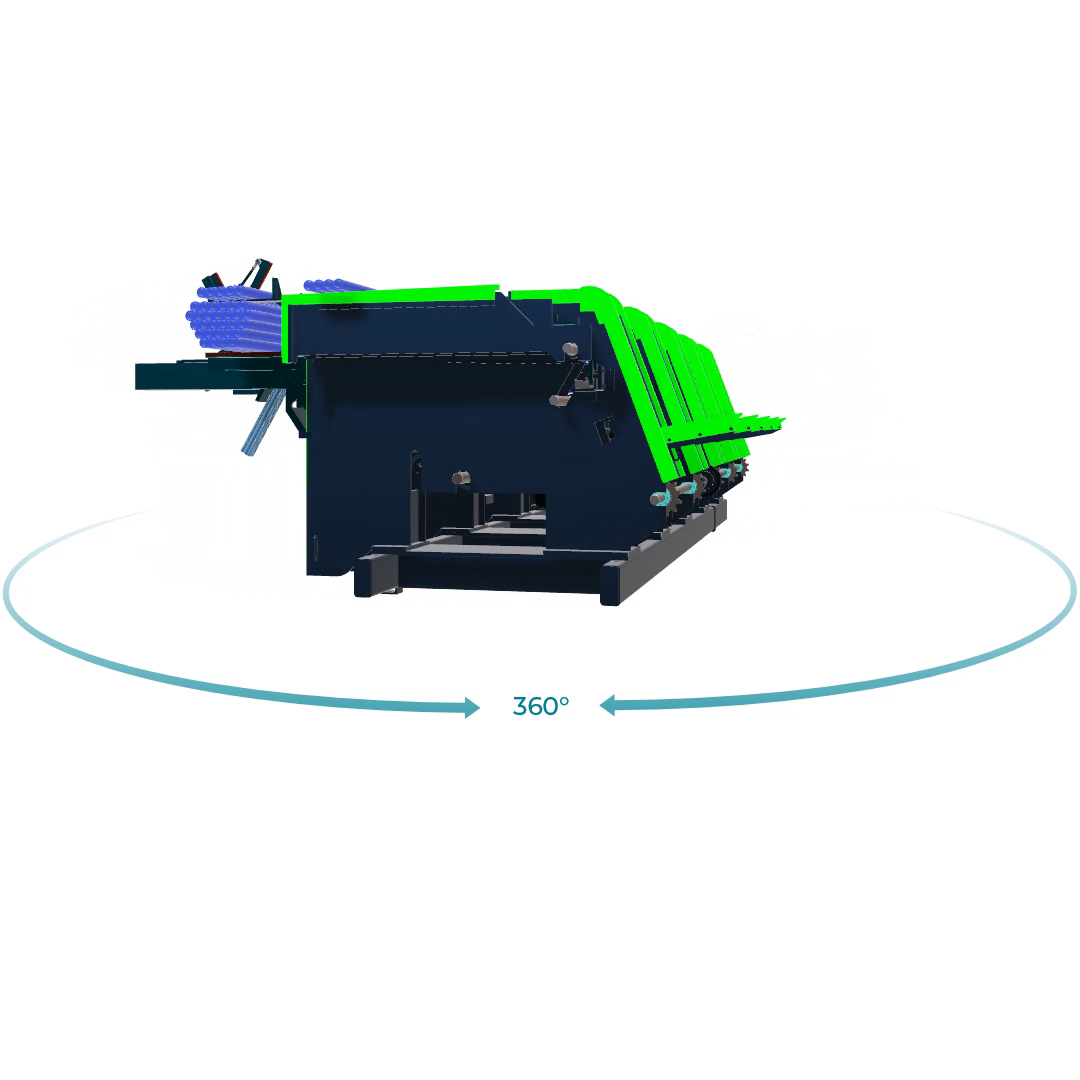

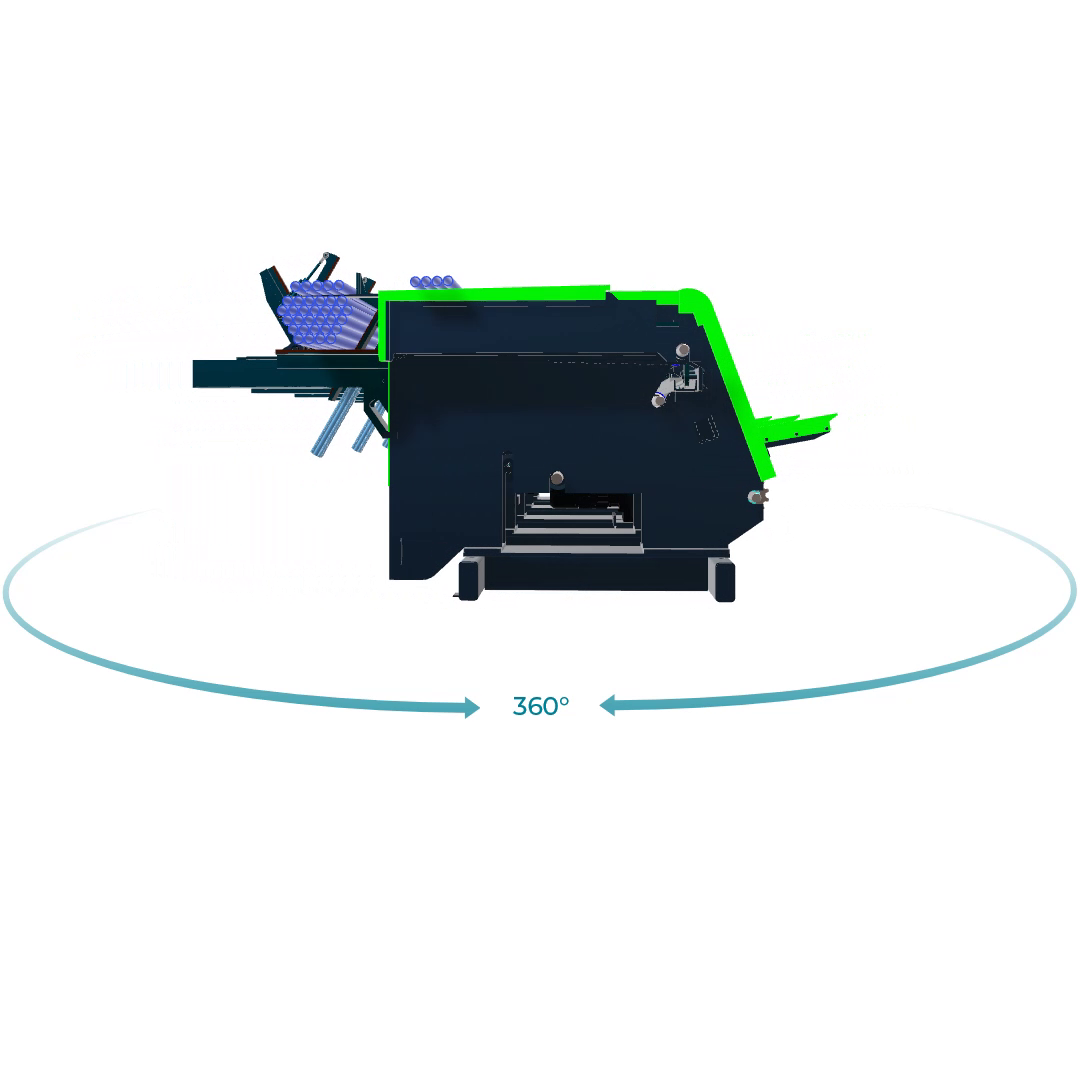

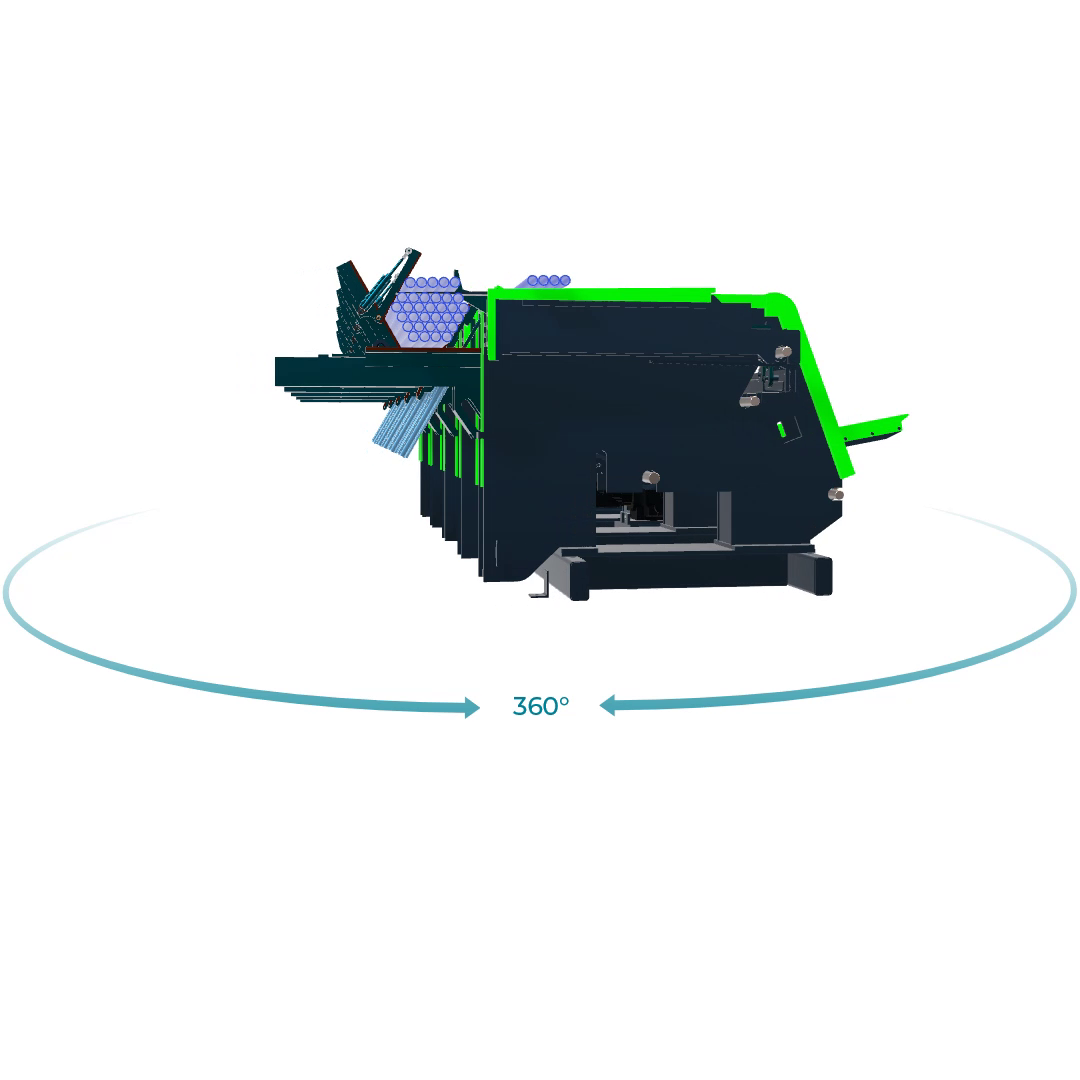

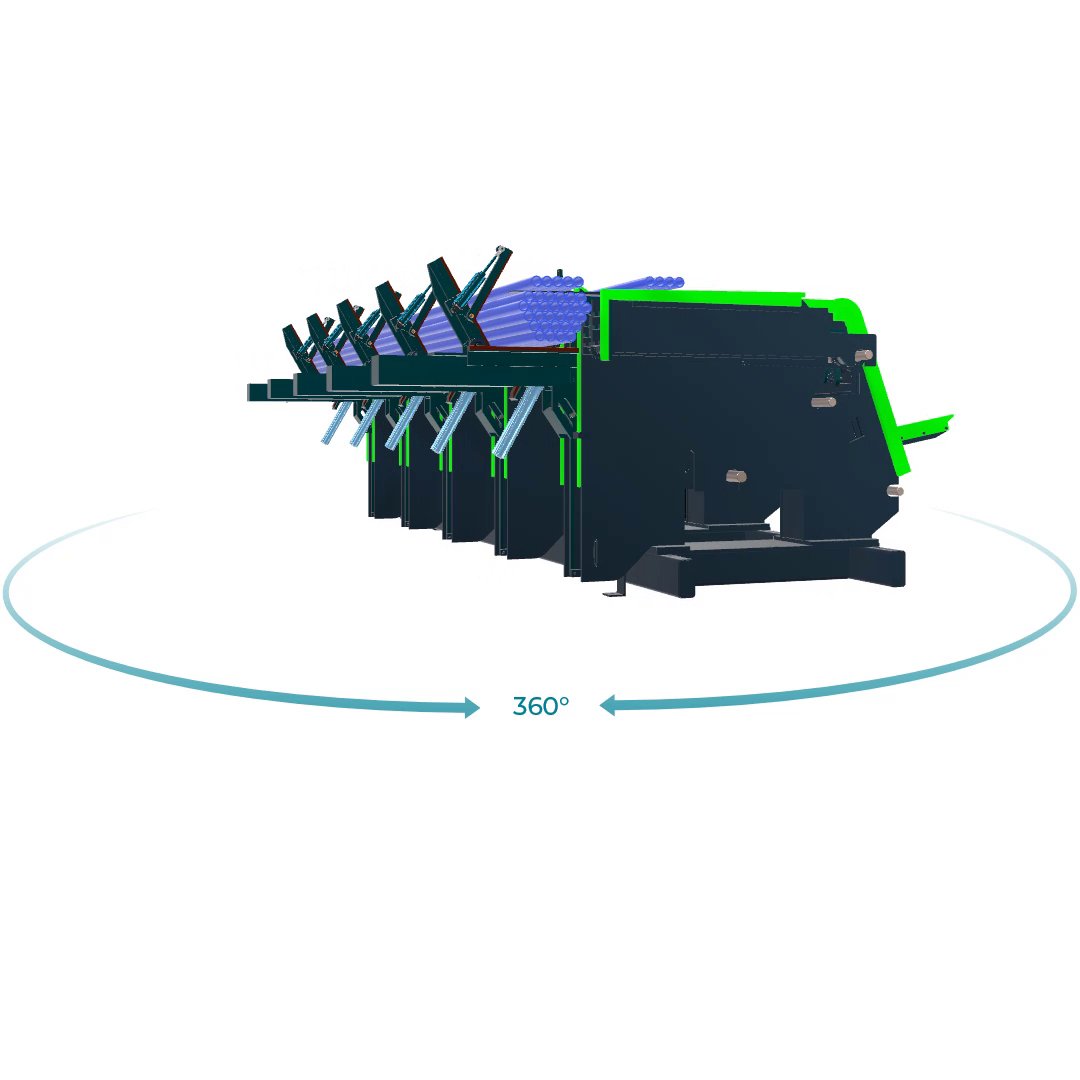

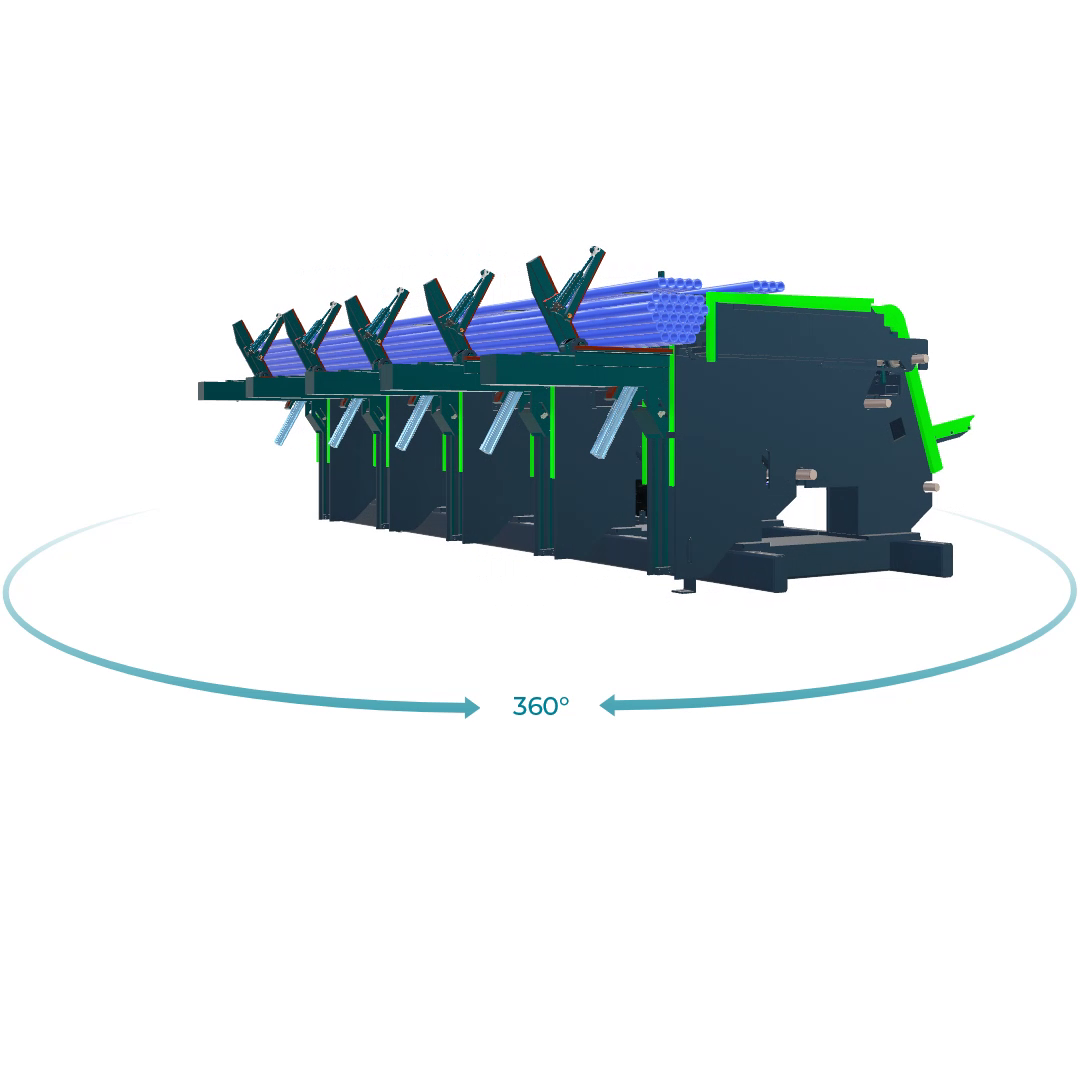

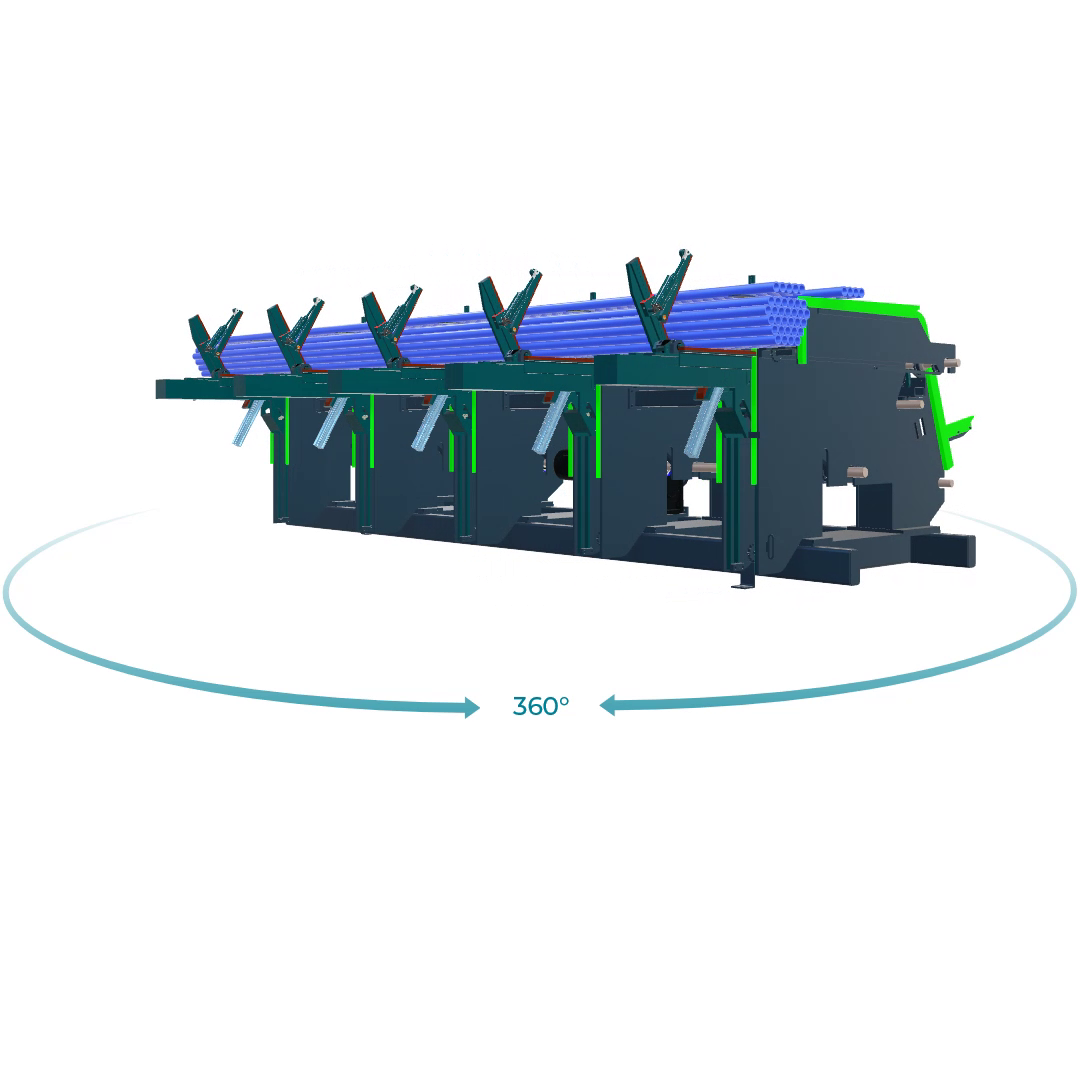

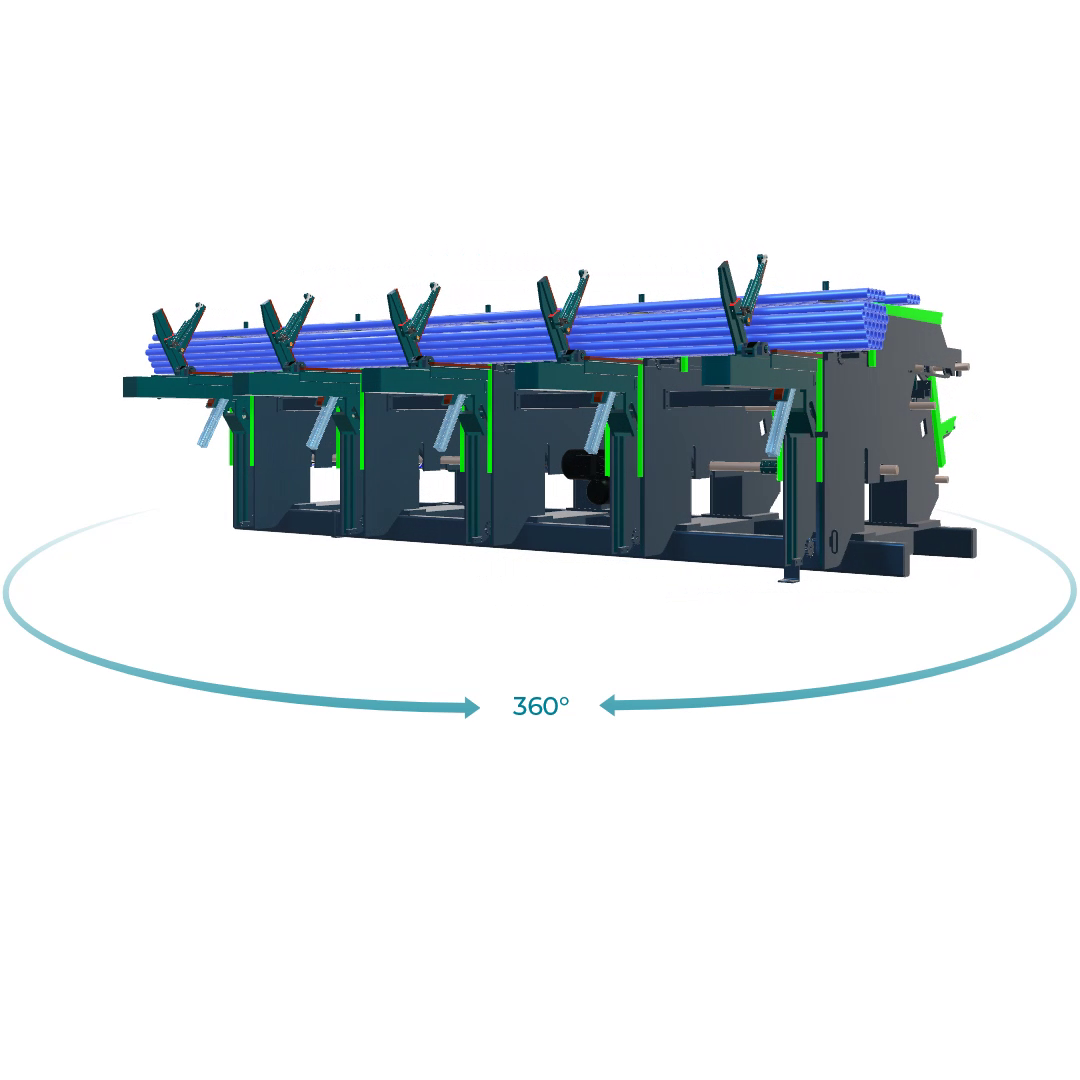

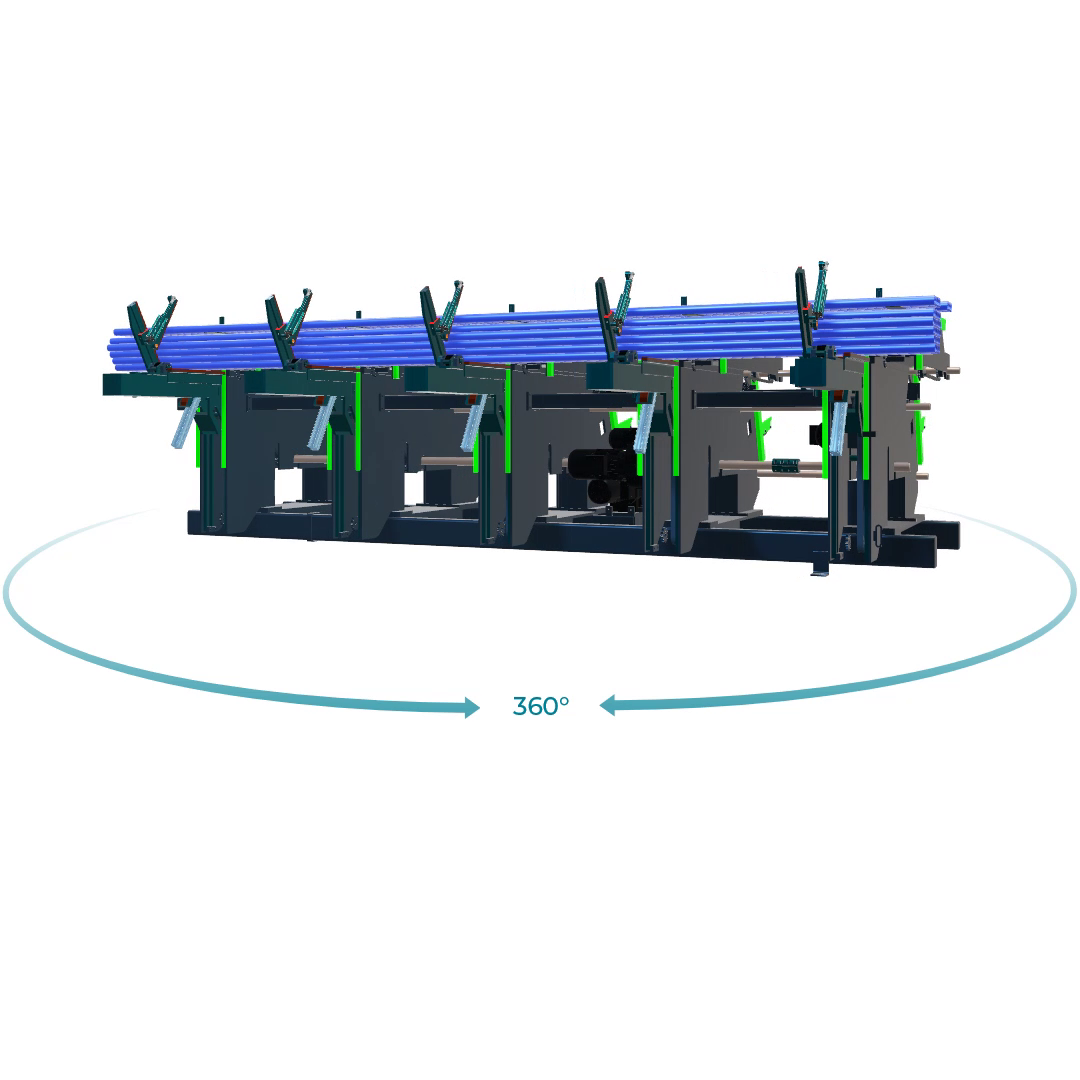

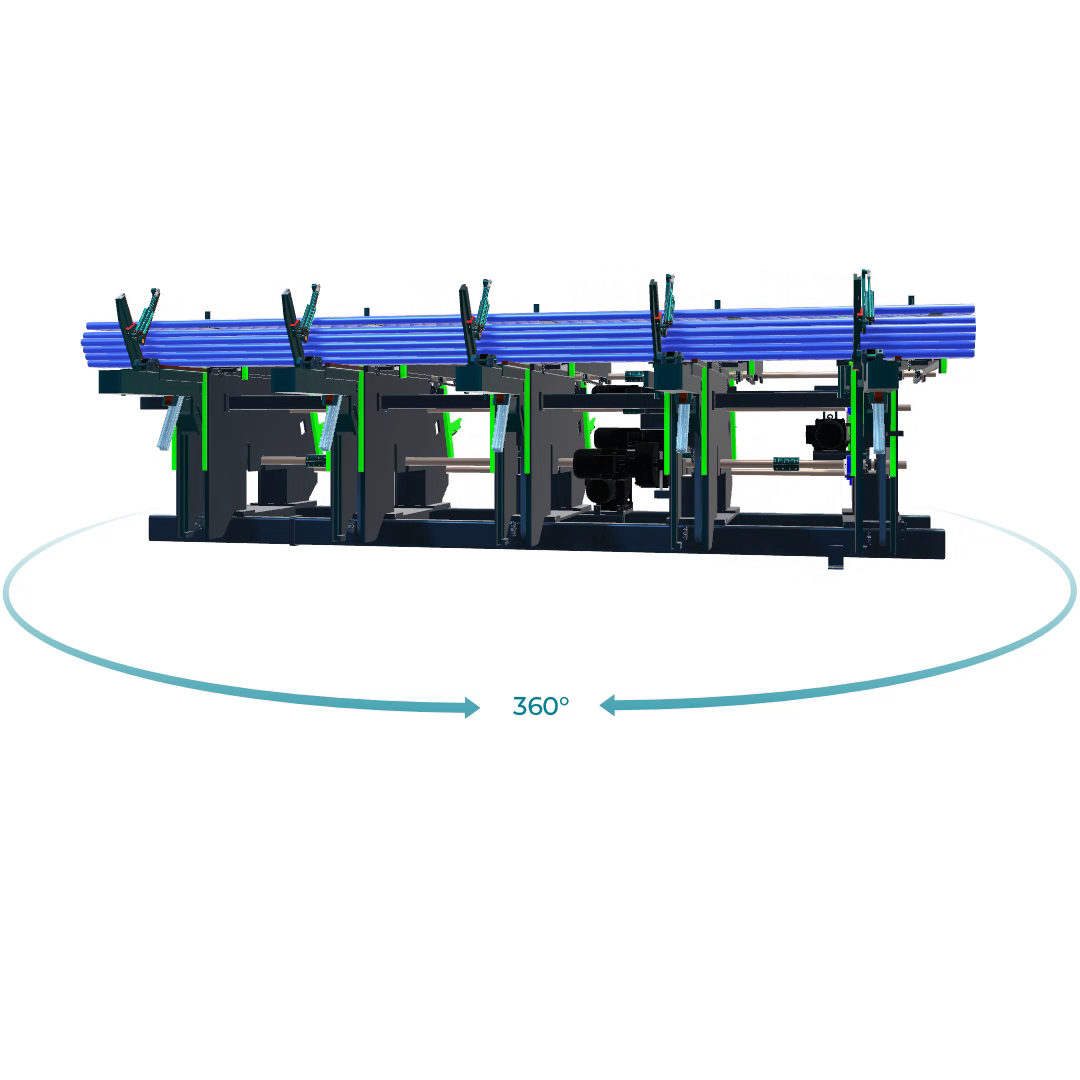

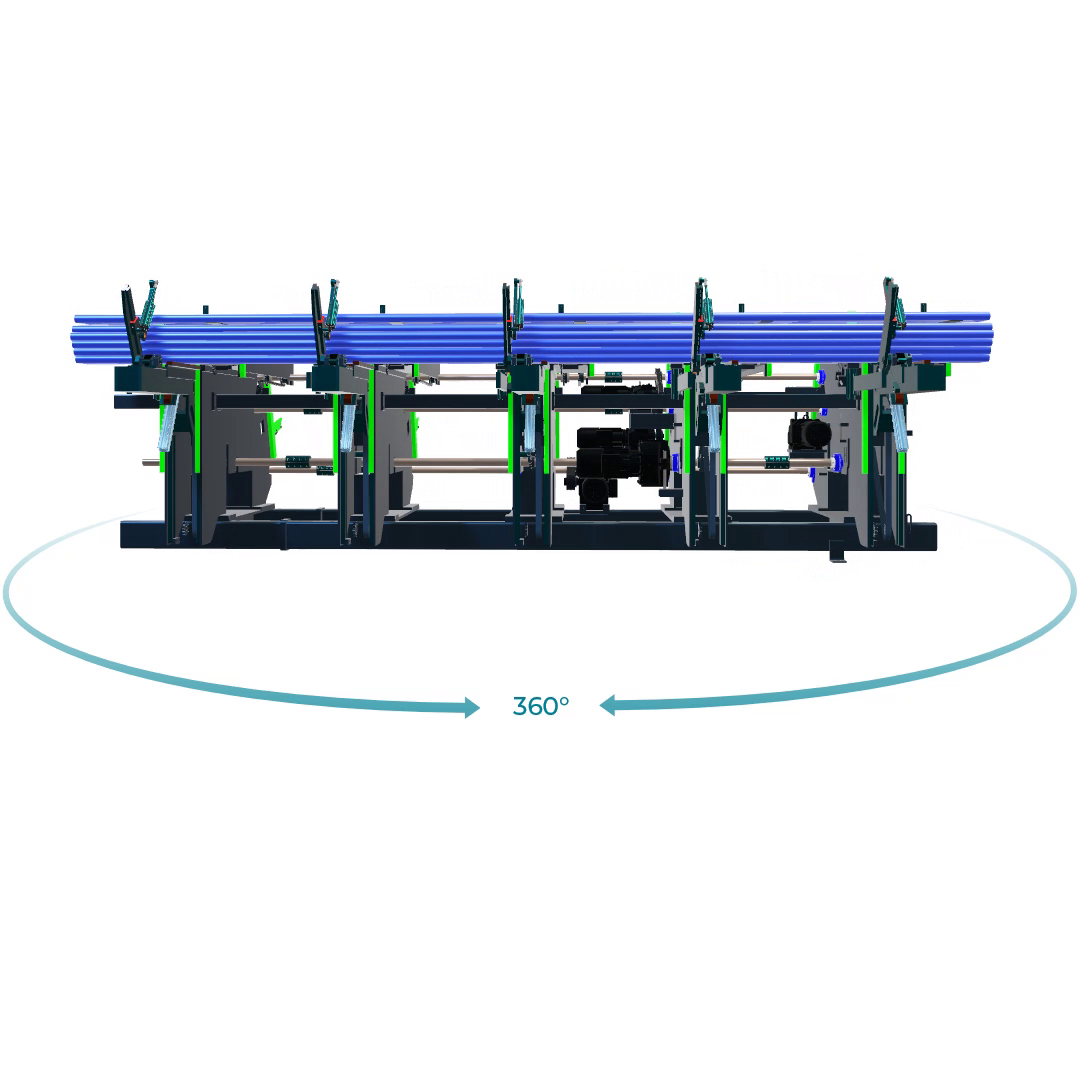

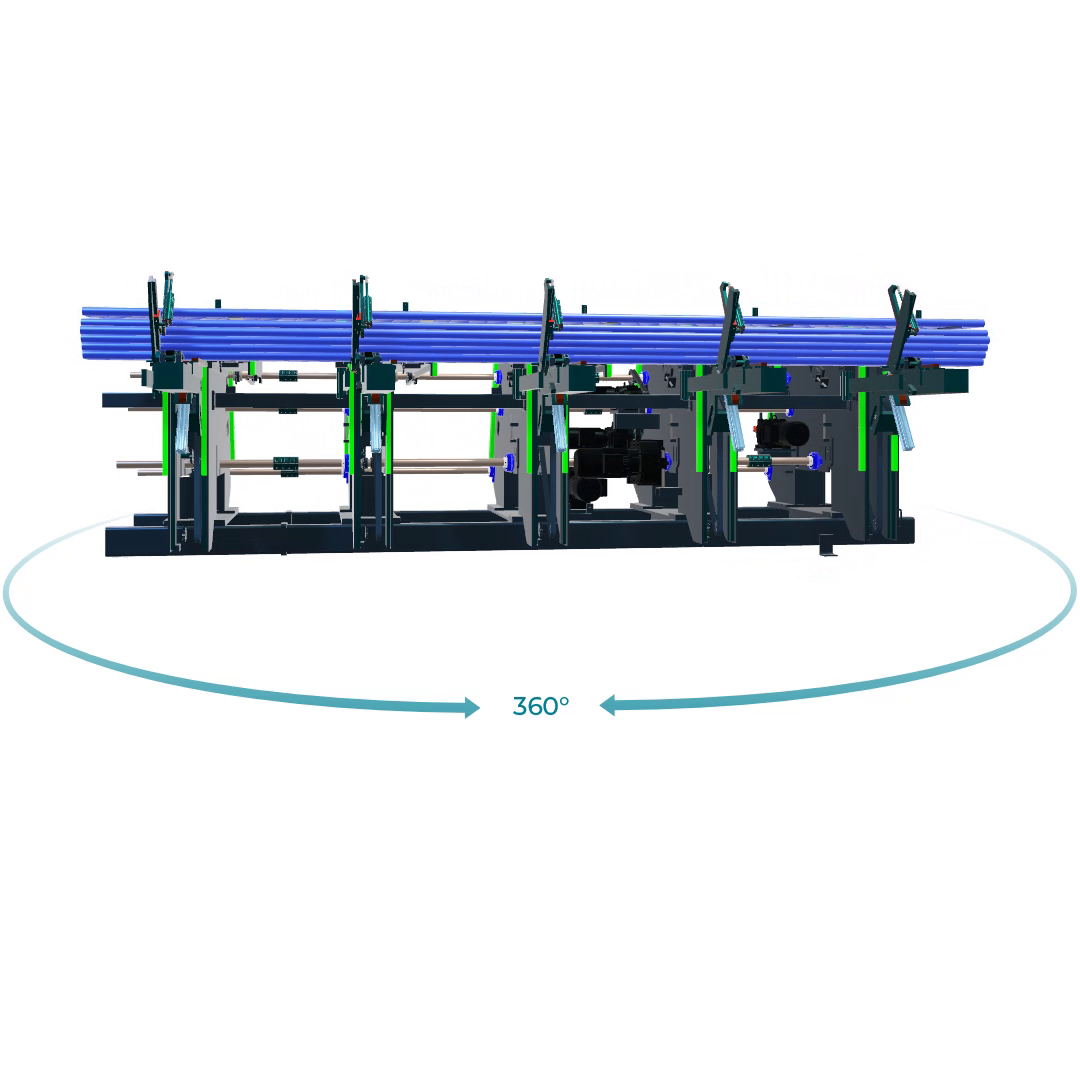

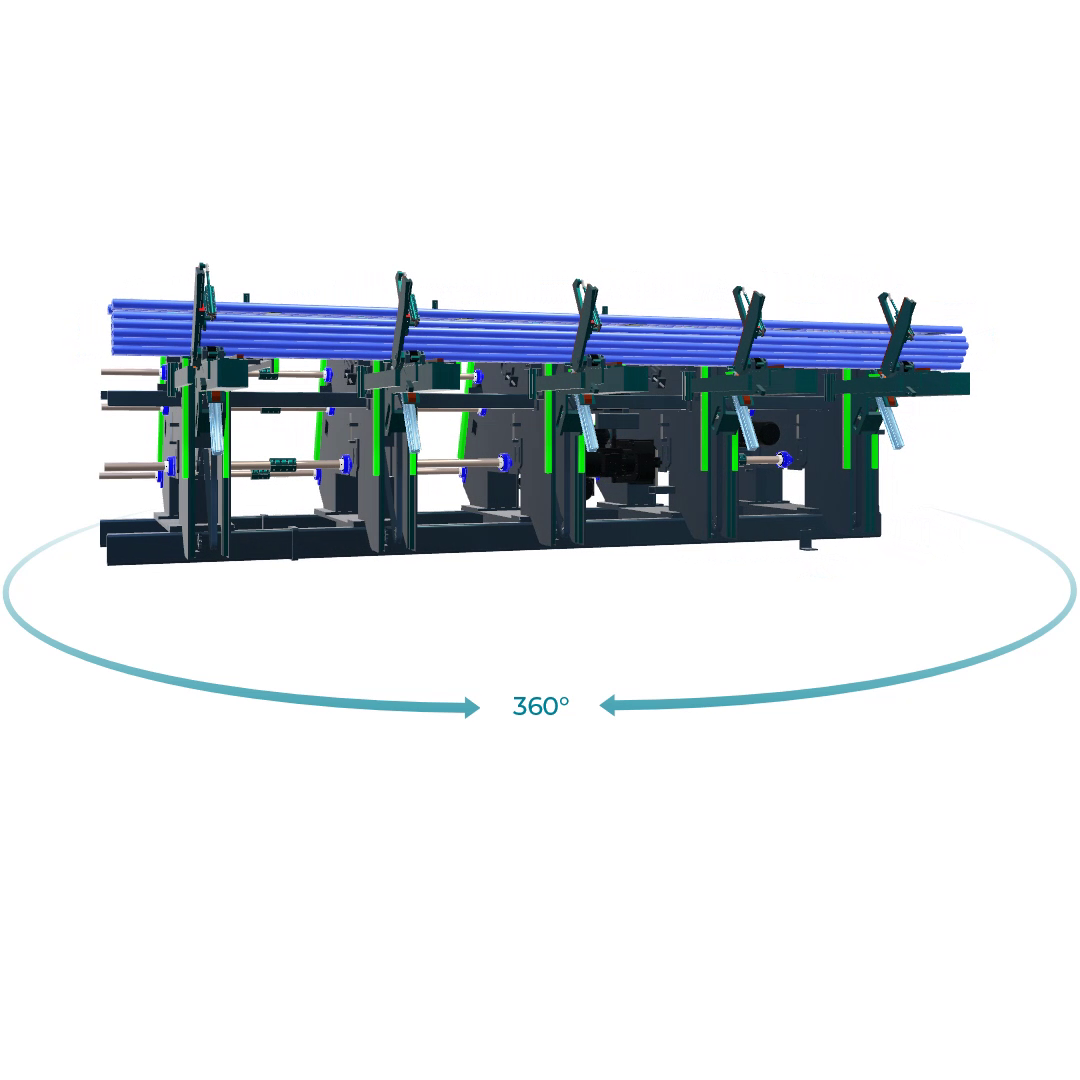

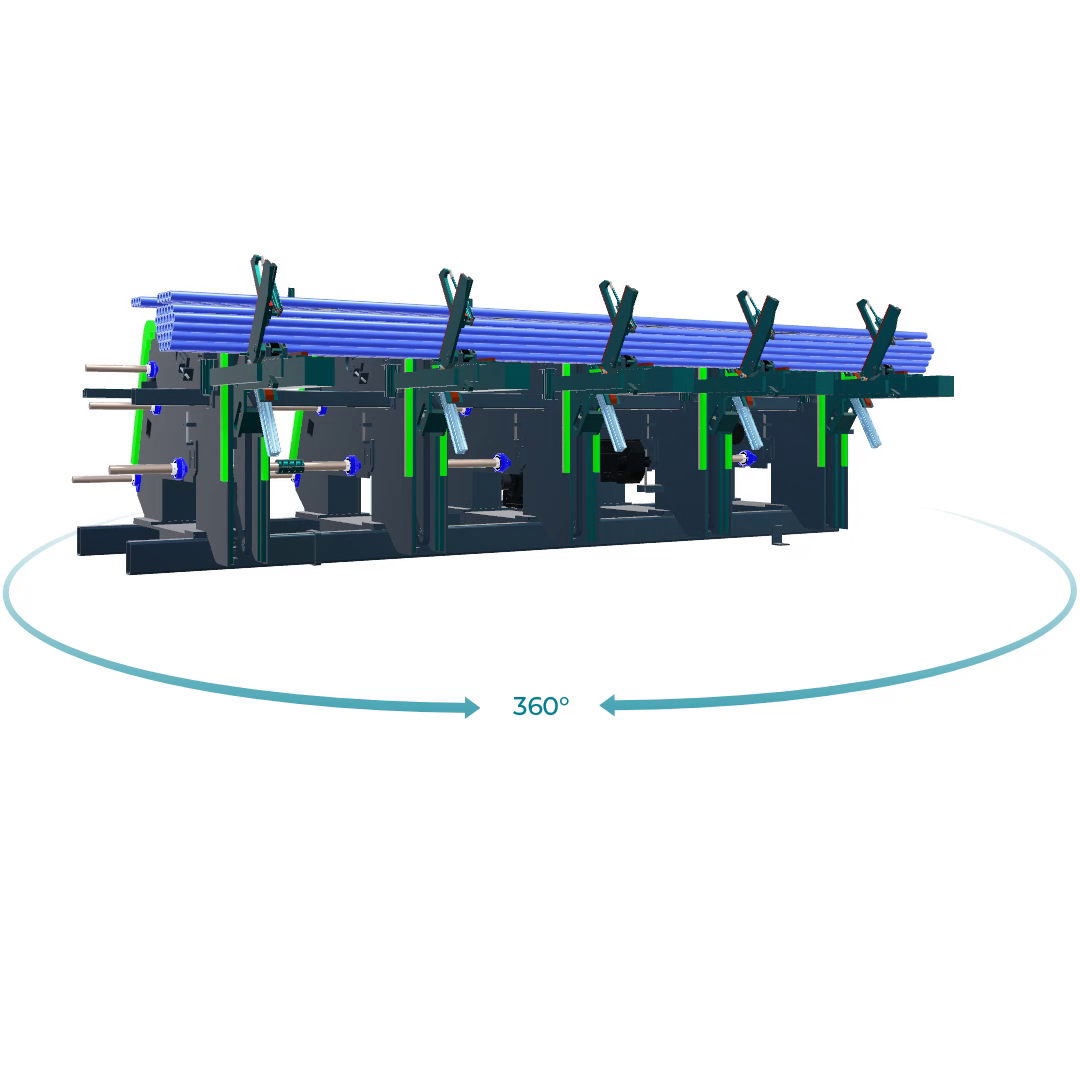

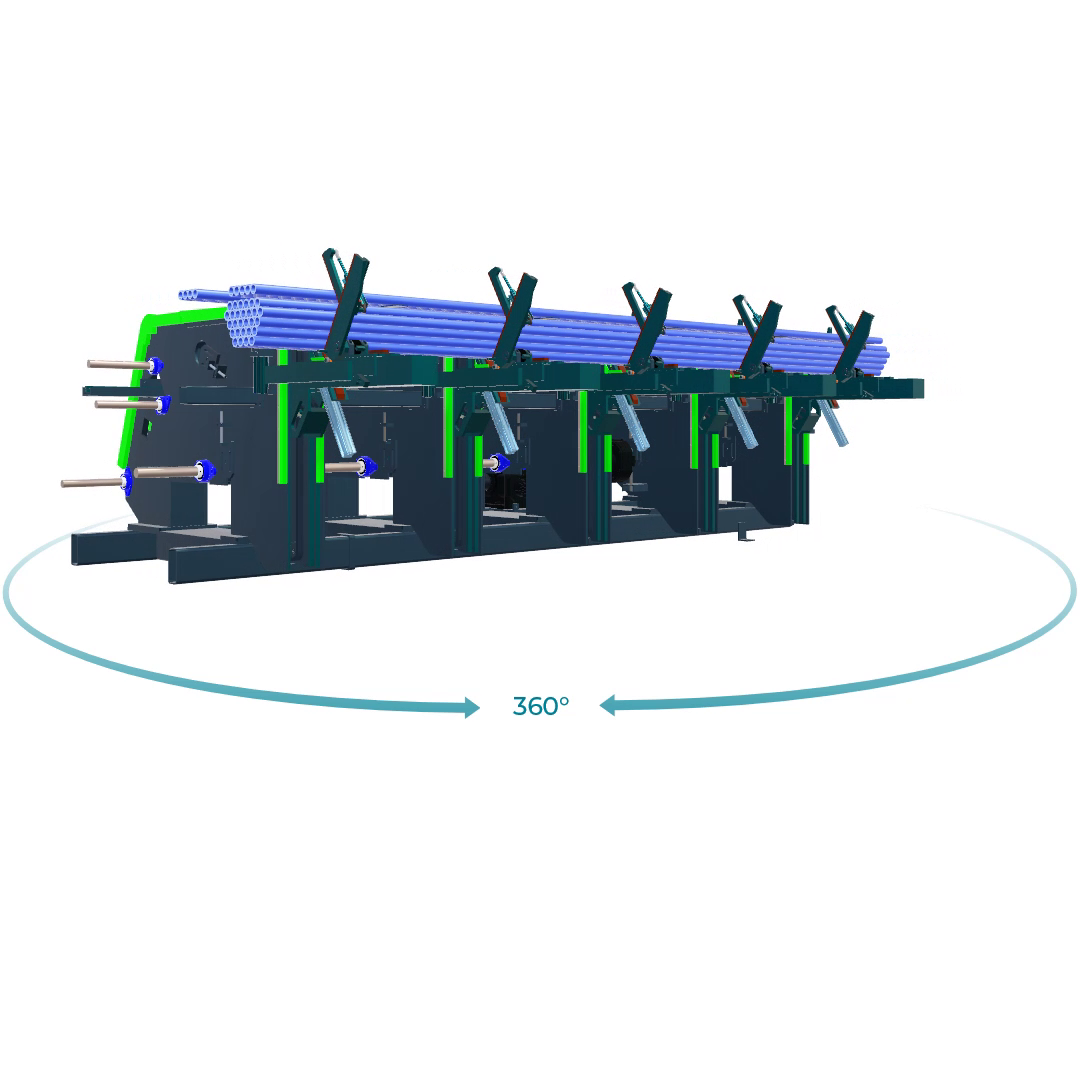

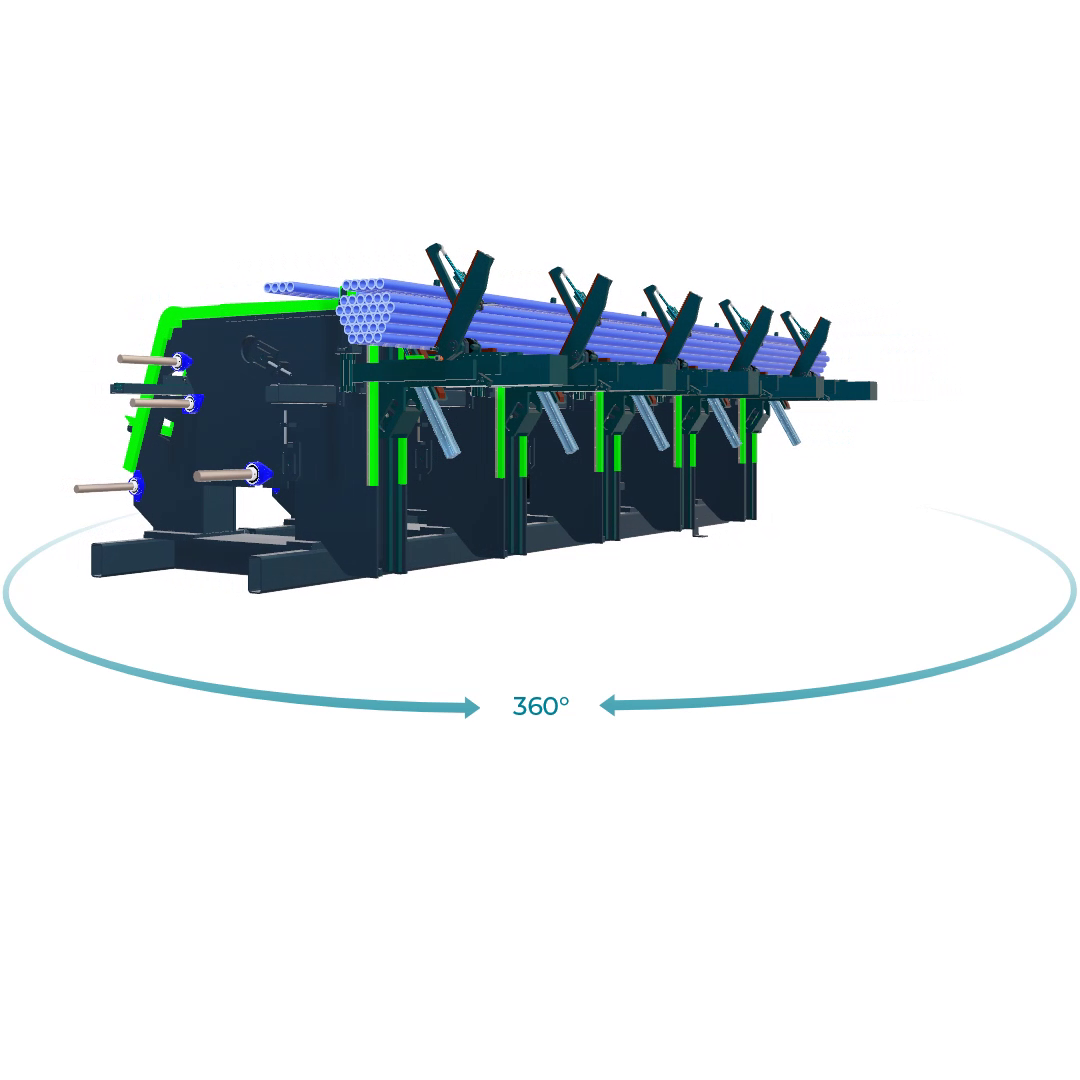

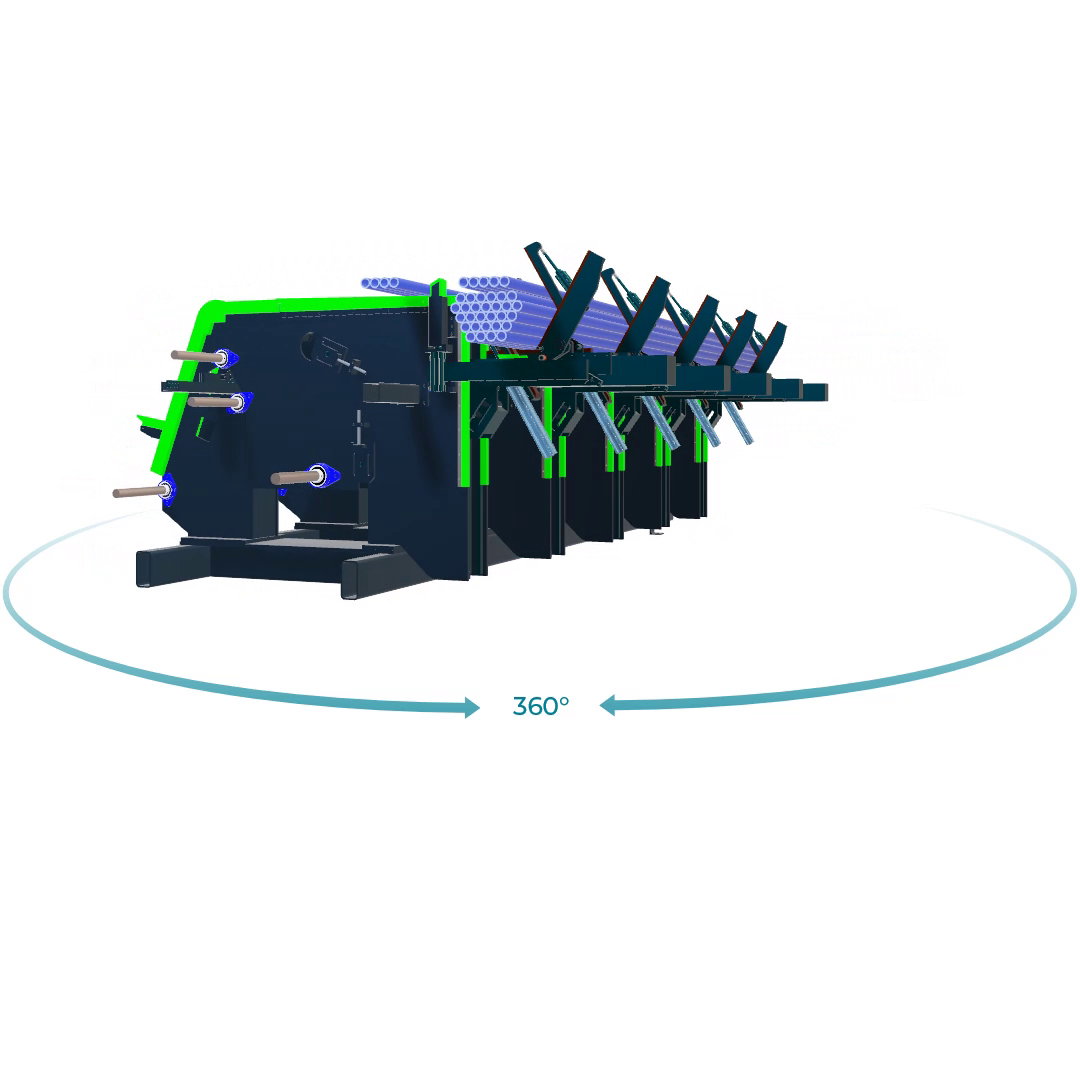

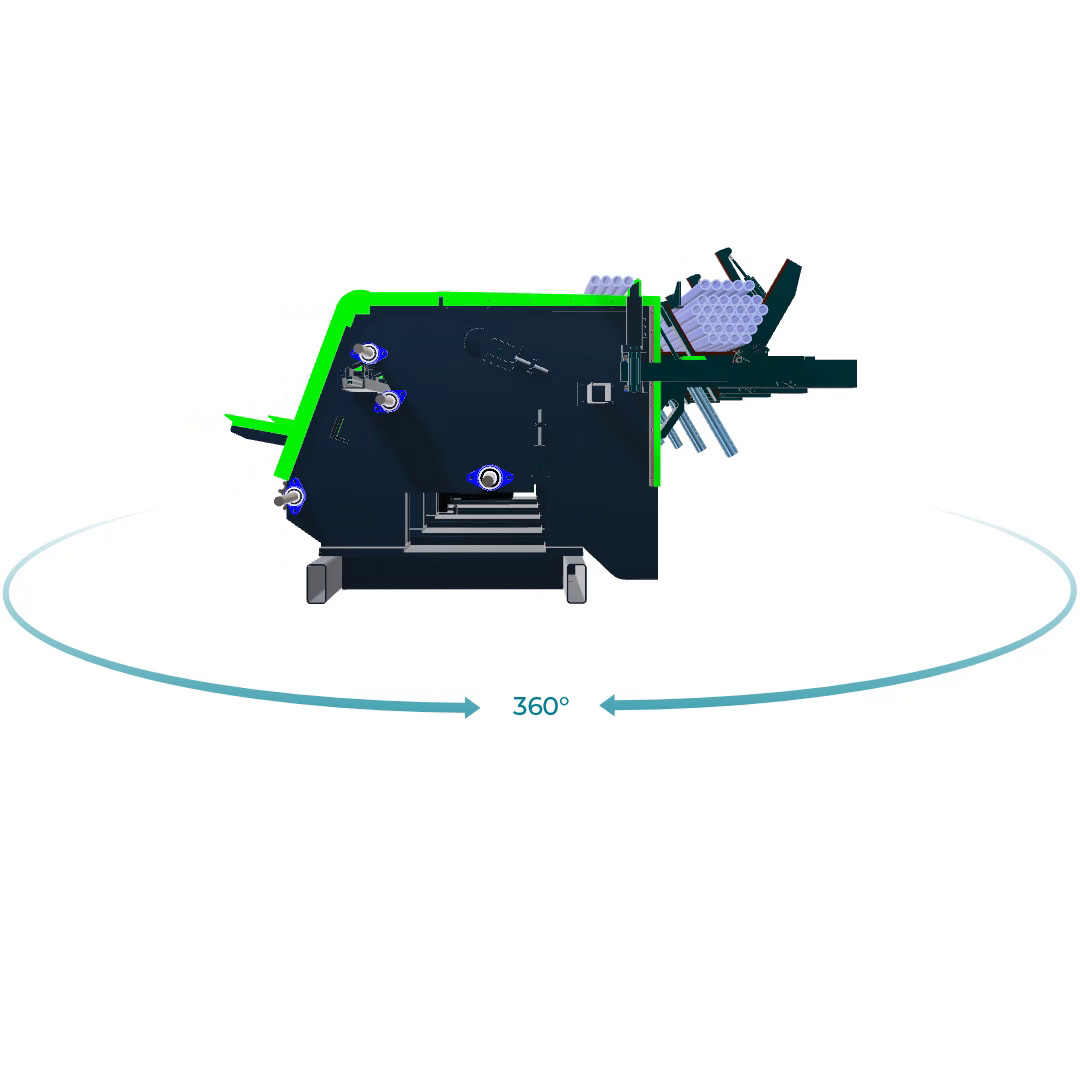

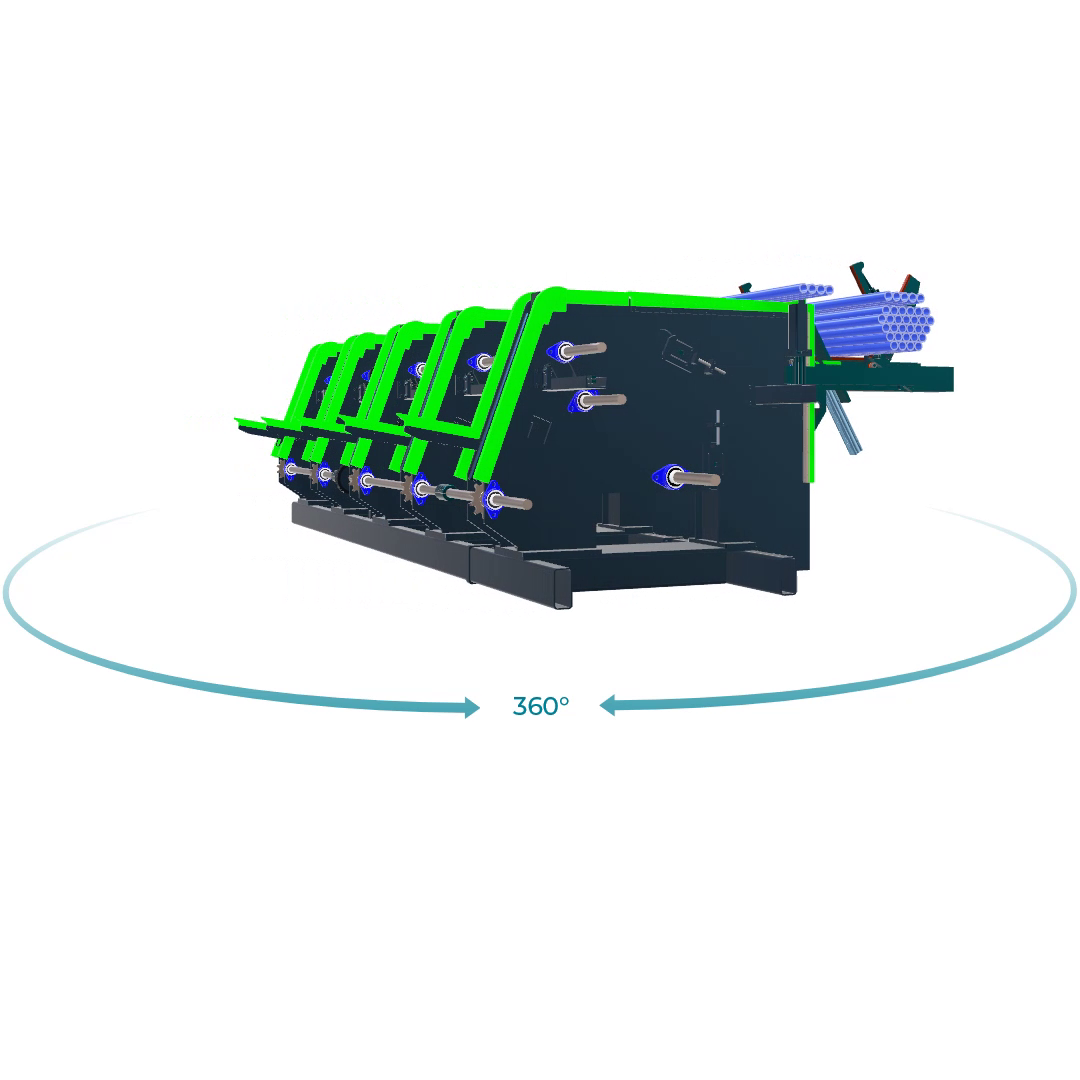

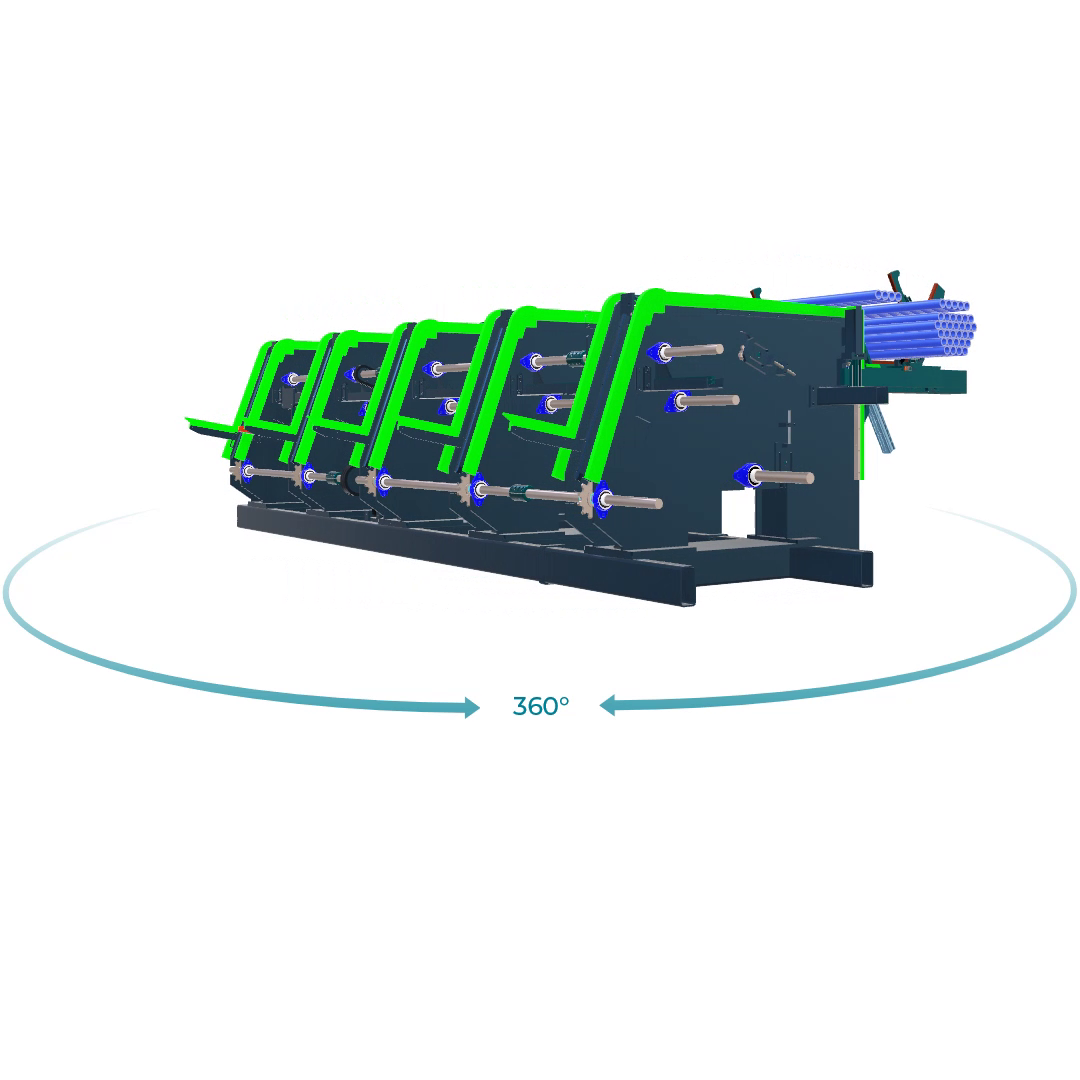

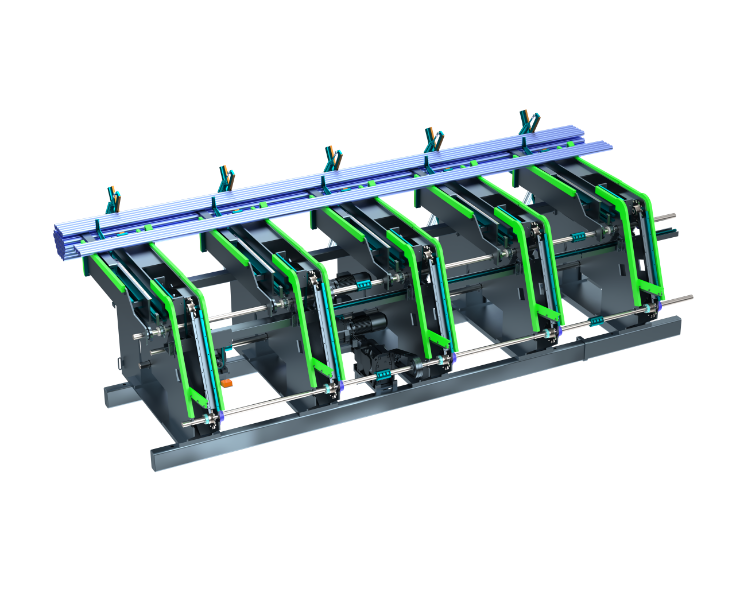

The tubes and rods are automatically packed to the square or hexagonal shape. A bundle is automatically created based on the diameter of the tubes and required bundle size.

The formed bundle is automatically or manually strapped and moved into position for removal by crane.

The entire packaging and strapping process can be controlled automatically by a single operator from the control panel

Technical parameters of the machine

|

Profiles to bundle: |

Tubes, bars, hexagonal, square and profile steel |

|

Pipe diameters: |

6 – 120 mm |

|

Lengths of tubes, rods: |

3 – 18 m |

|

Bundle size hexagon, square: |

up to 600 mm |

|

Bundle weight: |

to 6 000 kg |

|

Control system: |

Simatic S7 |

|

Inlet pipe cycle: |

from 5 sec/ pc |

|

Output cycle: |

Depending on the number of pieces in a bundle |

|

Strapping cycle: |

Approx. 60 sec per tape |

|

Desk equipment: |

Process display, production statistics, error messages, data transfer to company management |

|

Automatic, semi automatic and manual mode |

|

Other equipment of the machine

- Separating the free bundle and feeding the tubes into the packaging machine of 1 pc each

- Equipping the machine with zip ties to create a circular bundle during manual strapping

- Weighing a bundle on certified scales and printing a weighing ticket

- Automatic stoppering of pipes and closed profiles with transport plugs

- Marking of individual pipes and whole bundles based on customer requirements

- Backing of steel tape with paper tapes

- Wrapping the entire bundle or ends of the bundle into stretch foil

- Blowing through pipes to remove liquid, chips and dirt from the inner diameter

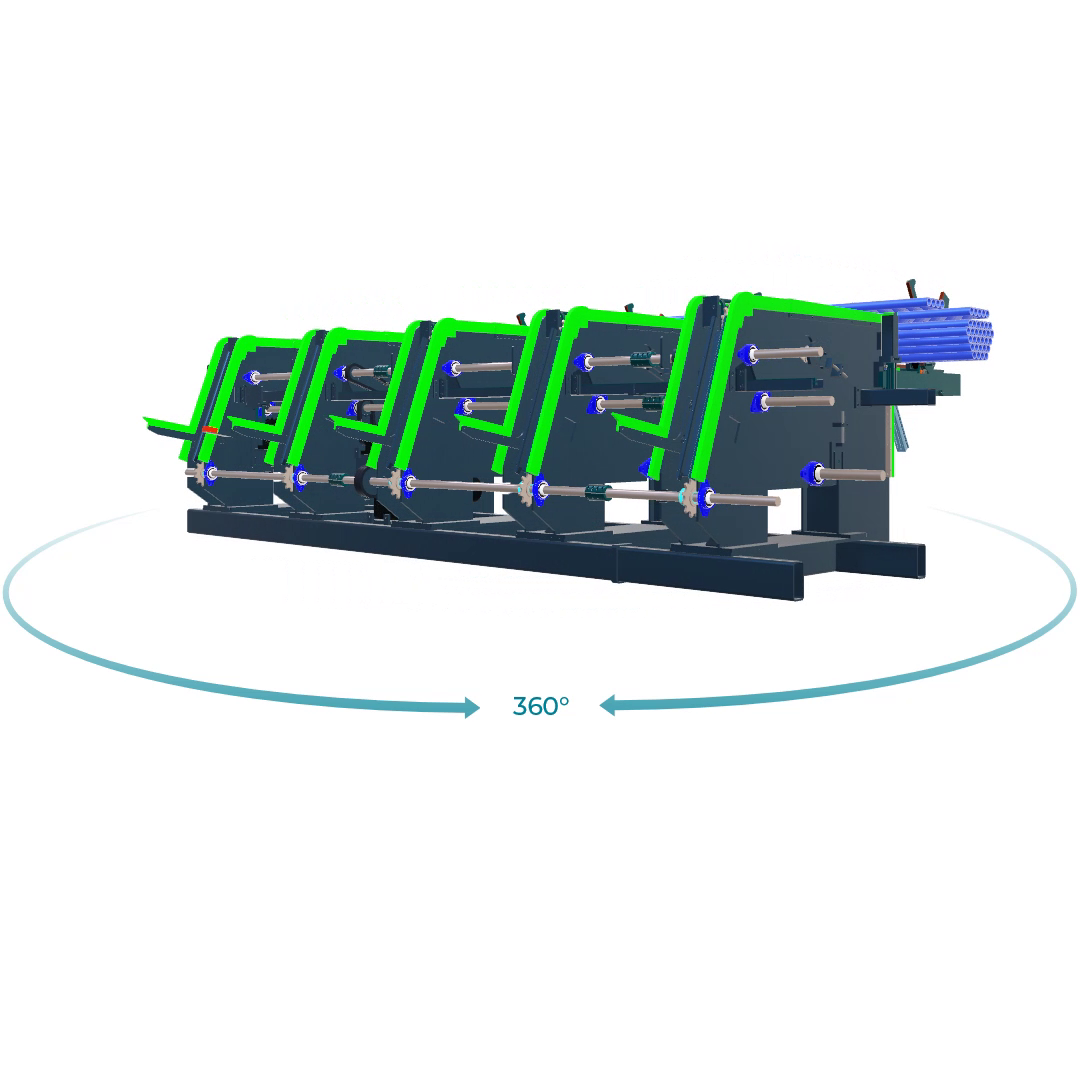

- Extended visualization of machines with an emphasis on intuitive and detailed display of the operating states of the packaging machine

- Extended diagnostics of the machine with an emphasis on displaying the place of occurrence of the fault on the layout scheme of the machine

- Extended service with the possibility of displaying manuals, service manuals and other necessary documentation on machines in order to minimize service times

- Collection of agreed production parameters with automatic saving, display and data export.

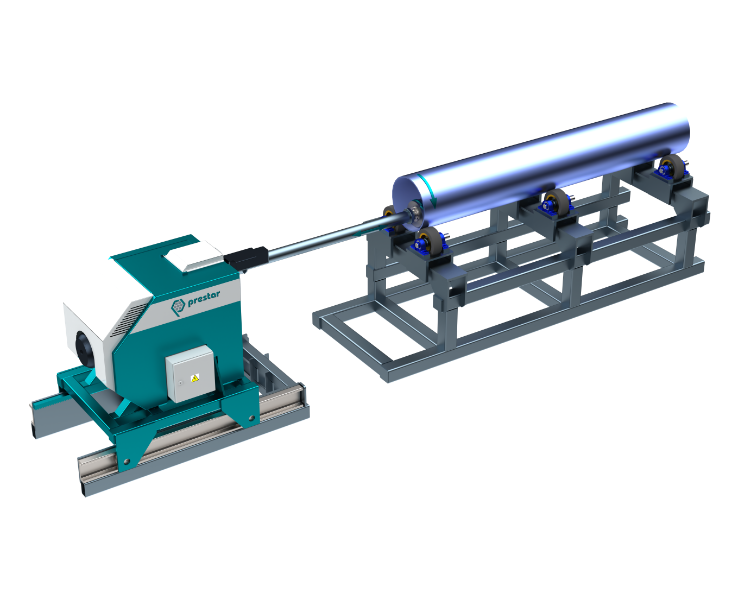

Straightening machines

Internal pipe grinder

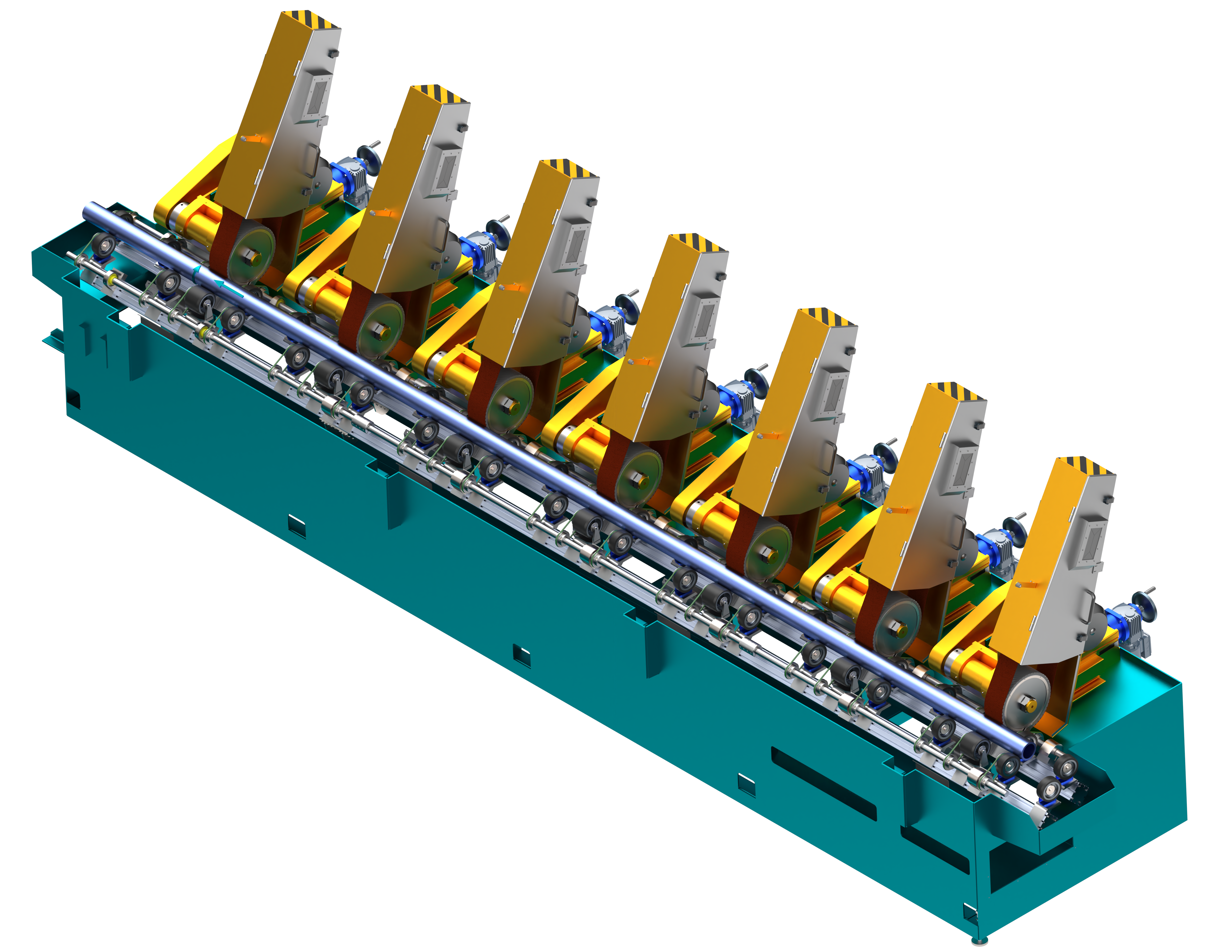

Centerless pipe grinder

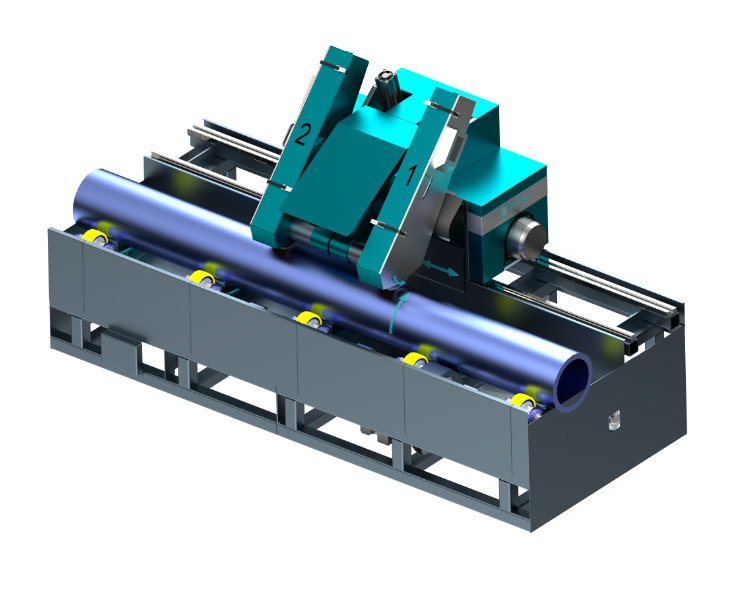

External stationary pipe grinder

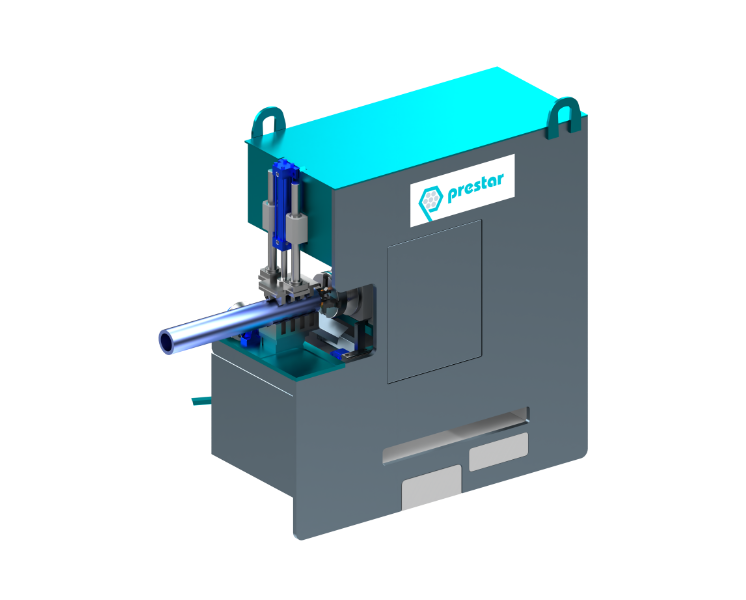

Flying saw

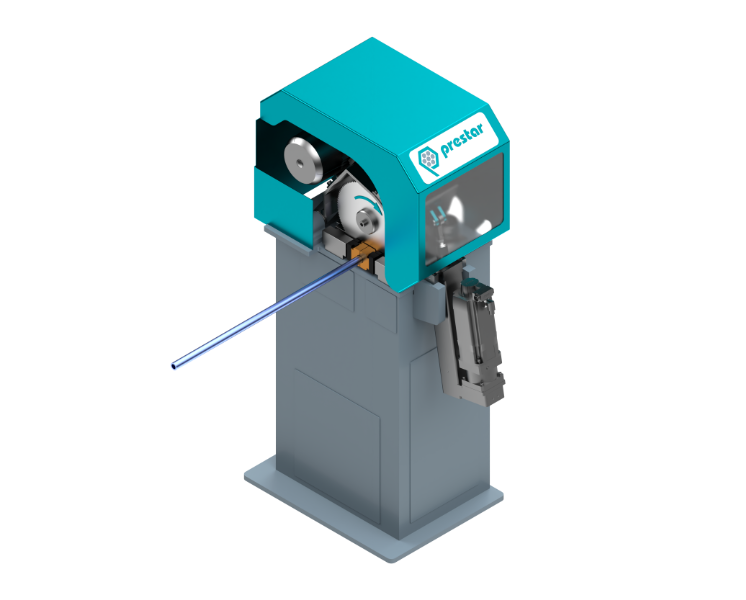

Circular saw

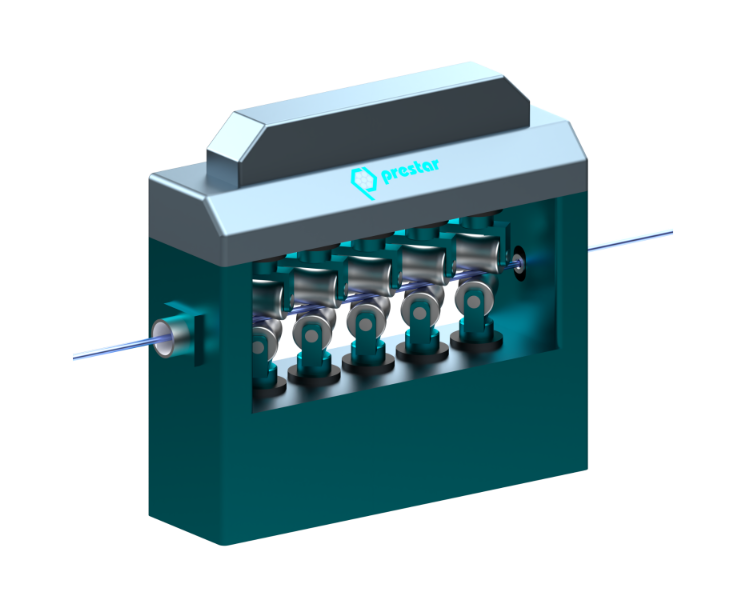

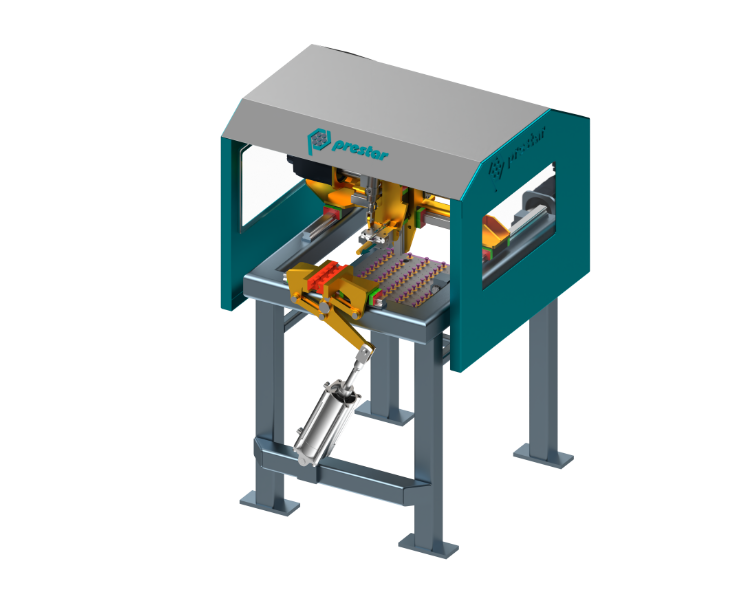

Chamfering of pipes

Sorting and plugging

Control tables

Packaging machines

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT

90% of customers perceive Prestar's technology as highly advanced

Our solutions in industry:

External pipe grinding machine – precision surface finishing for steel tubes

Why use an external pipe grinding machine? Grinding the outer surface of large-diameter steel pipes is essential for quality, safety, and finishing. Our external pipe grinding machine is specifically engineered for...

Automation and modernization of tube and rod processing lines | Prestar s.r.o.

We are Prestar s.r.o., a company specializing in custom manufacturing, in-house production of handling equipment, and industrial automation. In addition, we have extensive experience...

Presentation of the new equipment: Straightening machine RS50

This week at Prestar, we had the unique opportunity to introduce our RS50 straightening machine to a major player in the market - Alleima, a company specialising in the production of advanced, high value-added...