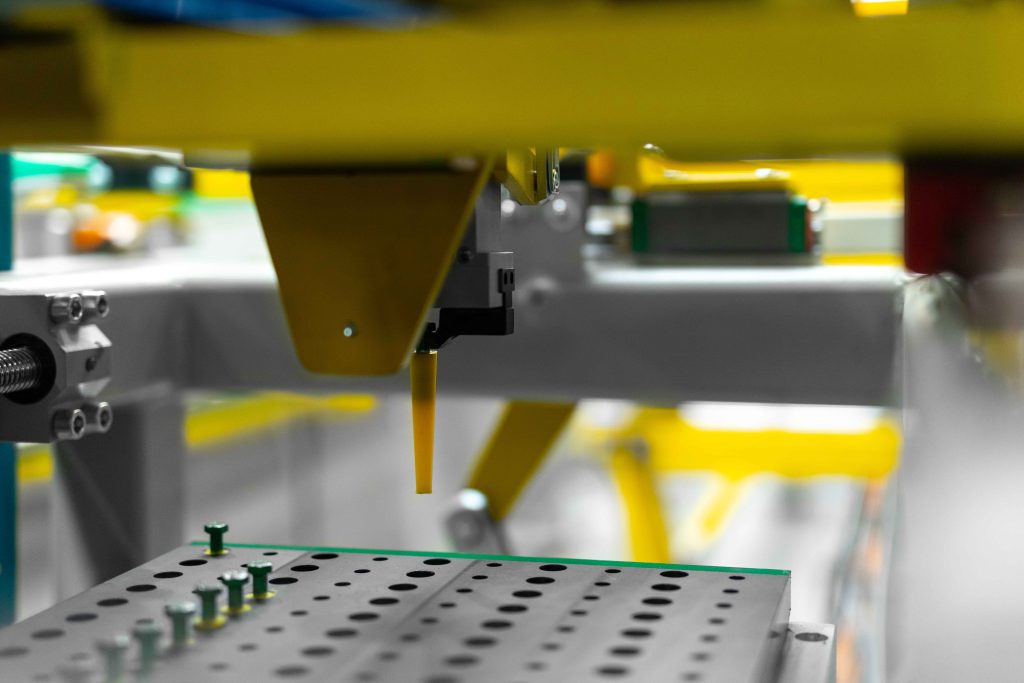

Automated plugging and unplugging – reliable and repeatable tube end sealing

To ensure accuracy and reliability in non-destructive pipe testing (NDT), in particular ultrasonic tests, it is essential to ensure hermetic sealing of pipe ends. This is exactly what our specialised plugging/unplugging equipment - a stand-alone unit that can be integrated into your production or inspection line.

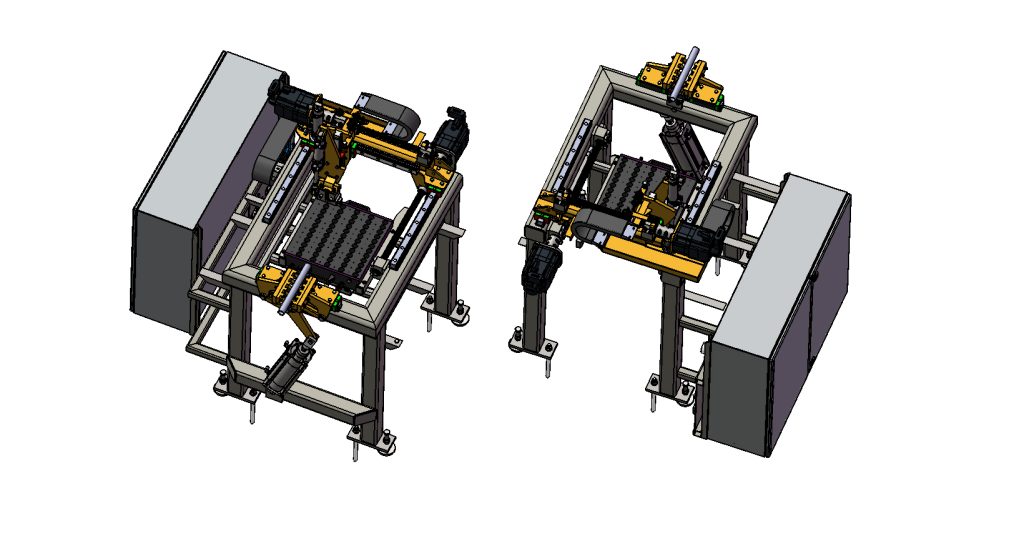

Smart, standalone machine for sealing and unsealing

The stopper/unstopper station is self-contained on a steel frame and is used to inserting or removing plugs from the ends of pipes of different diameters. In each cycle, the pipe is gripped in a vicewhose polyurethane jaws prevent damage to the surface. Clamping pressure can be finely adjusted by regulating the air into the pneumatic cylinder.

Plug storage and control system

The plugs are stored in 60-piece tray, which has milled guide grooves and is equipped with sensors to check the type of plug inserted. This ensures precision and monitoring of production according to defined dimensions.

Automatic plugging sequence

- The tube is clamped in position

- A portal arm moves above the plug and grips it

- The gripper lifts and aligns with the pipe axis

- The plug is pushed precisely into the tube

- The gripper releases and returns to standby

- The clamp opens and a new tube is loaded

Automatic unplugging sequence

- The tube is clamped in the vise

- The gripper enters the pipe and pulls the plug out

- The system moves over the empty magazine slot

- The plug is placed back into the magazine

- The arm returns to standby

- The tube is released and replaced

Key benefits of the system:

Automatic sealing of pipe ends before ultrasonic test

High repeatability thanks to gantry system with servo drives

Gentle clamping without surface damage - polyurethane jaws

Intelligent tray with detection of the correct stopper type

Easy integration into NDT lines or preparation sections

Independent control and safety covering

Practical application of pipe end sealing equipment: ultrasonic and pressure testing of pipes, inspection lines in steel and tube mills, automatic finishing processes, lines for leak checking or defectoscopy.

Contact us 🎯

Looking for sealing of pipe ends or modernization of your equipment?

Contact Prestar today or watch our product video on YouTube.