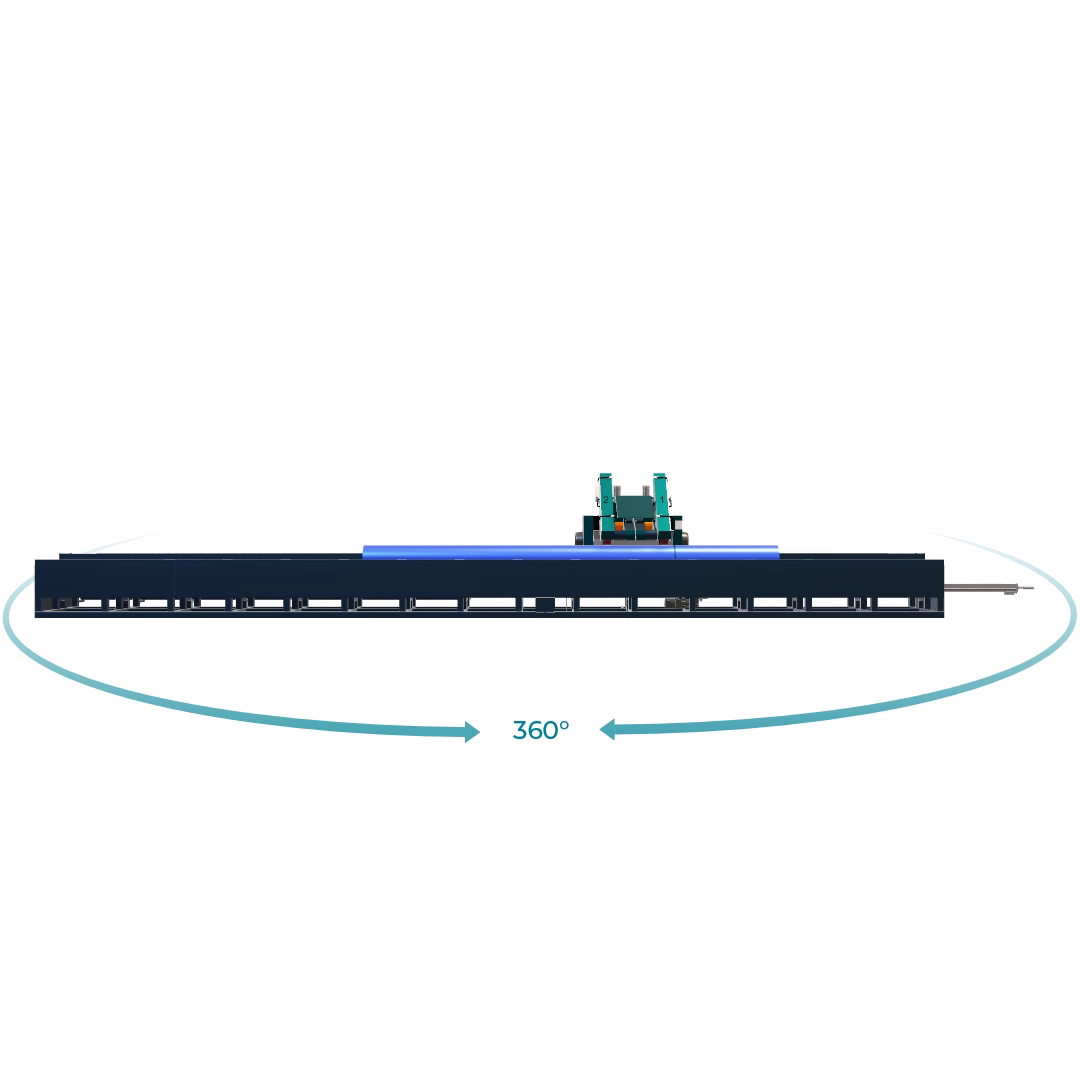

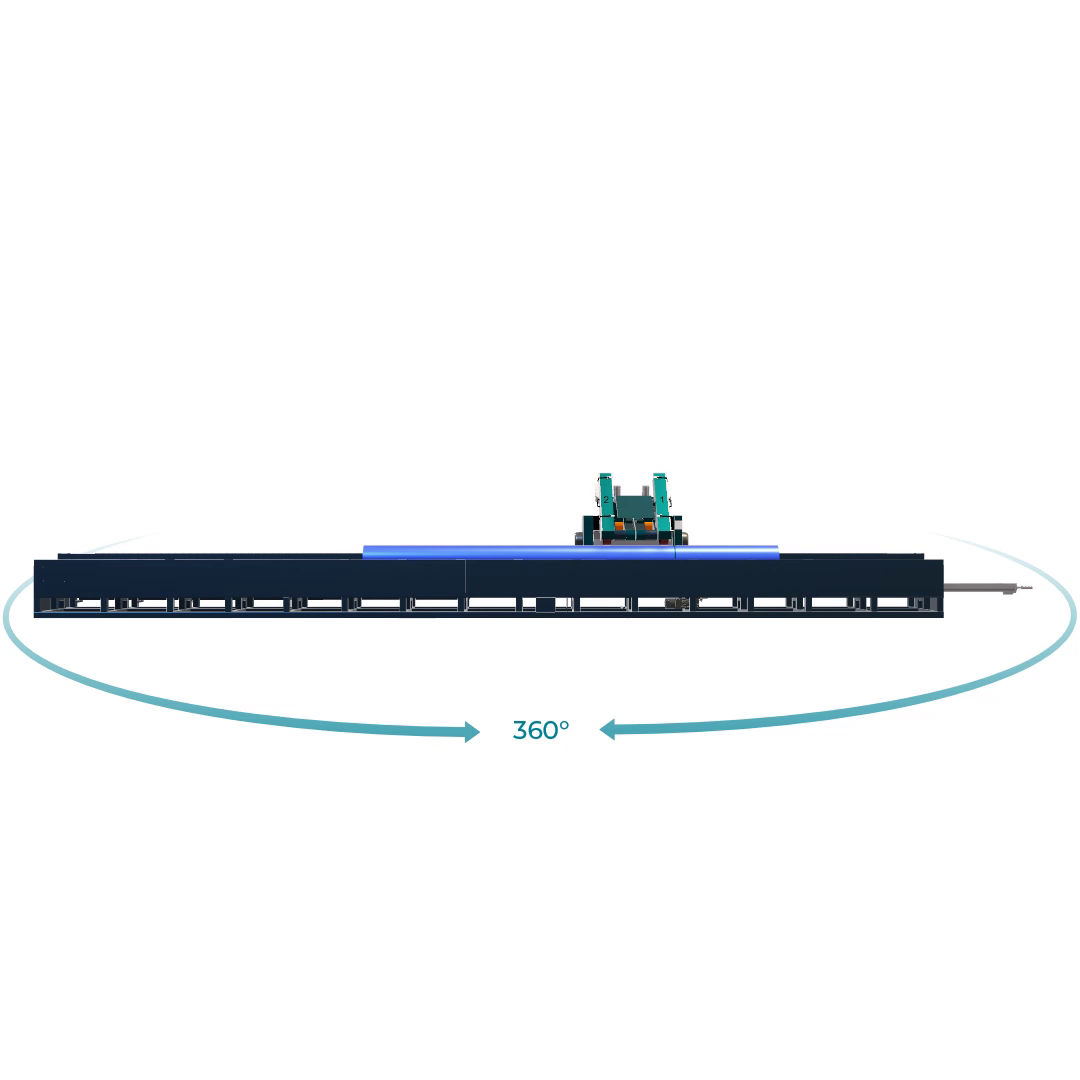

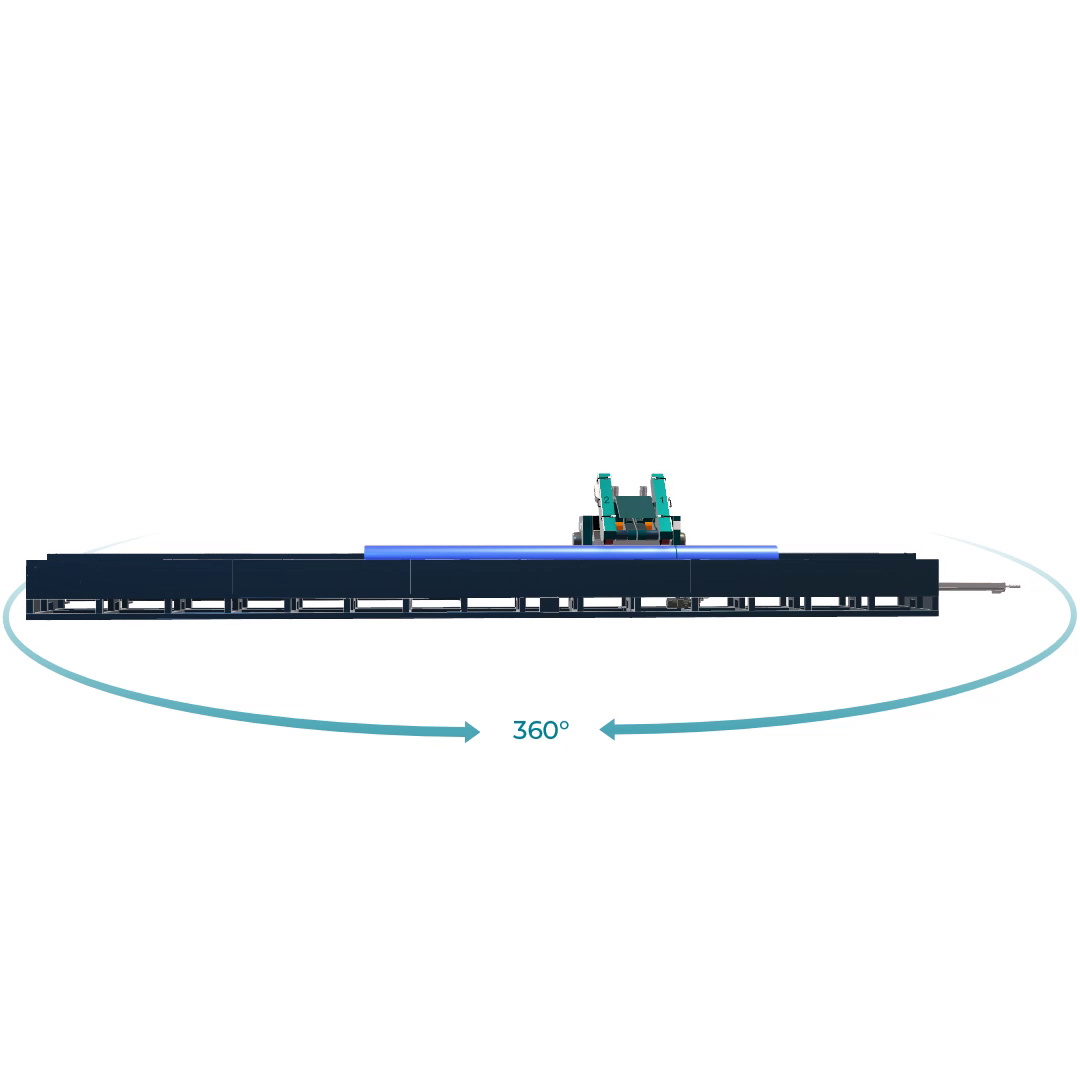

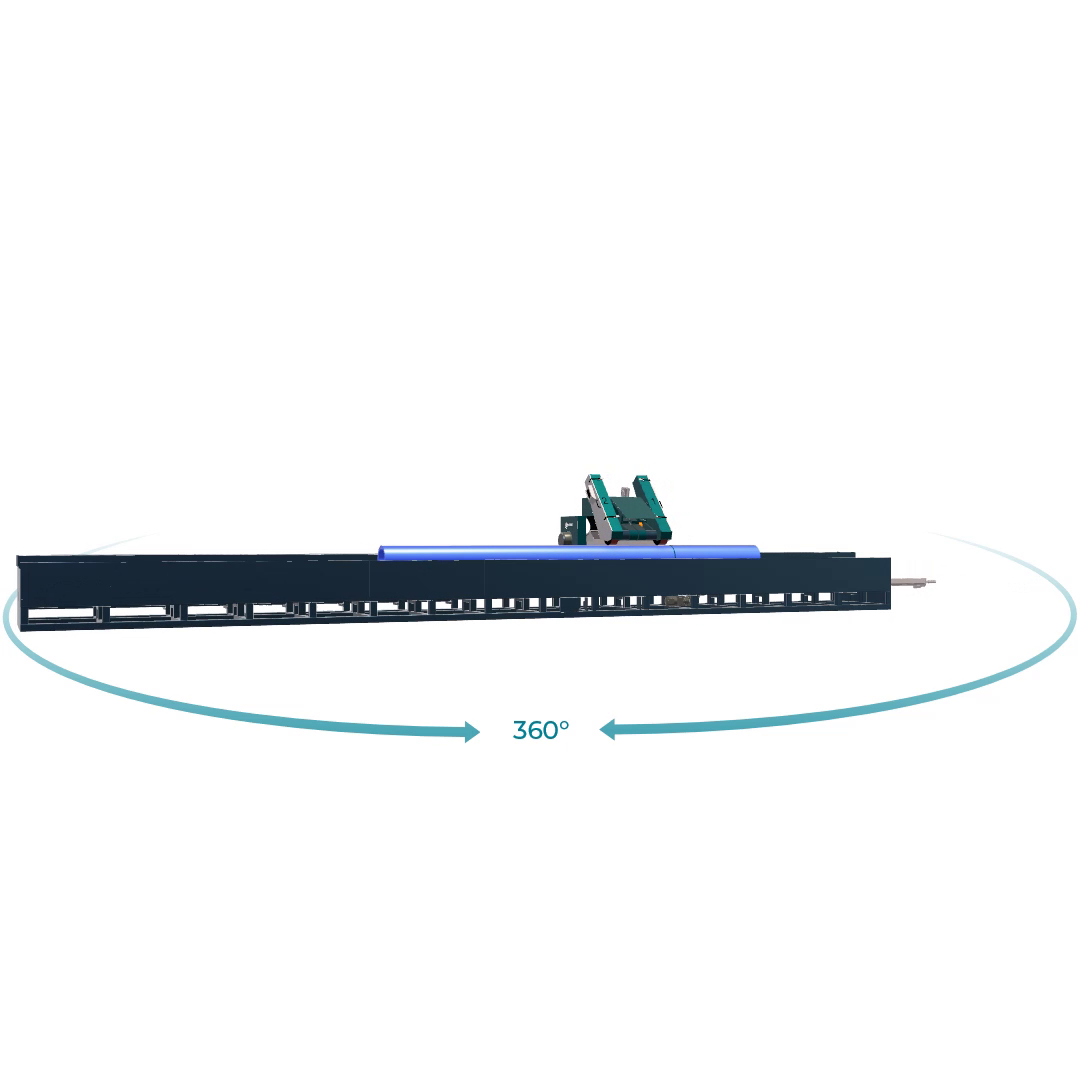

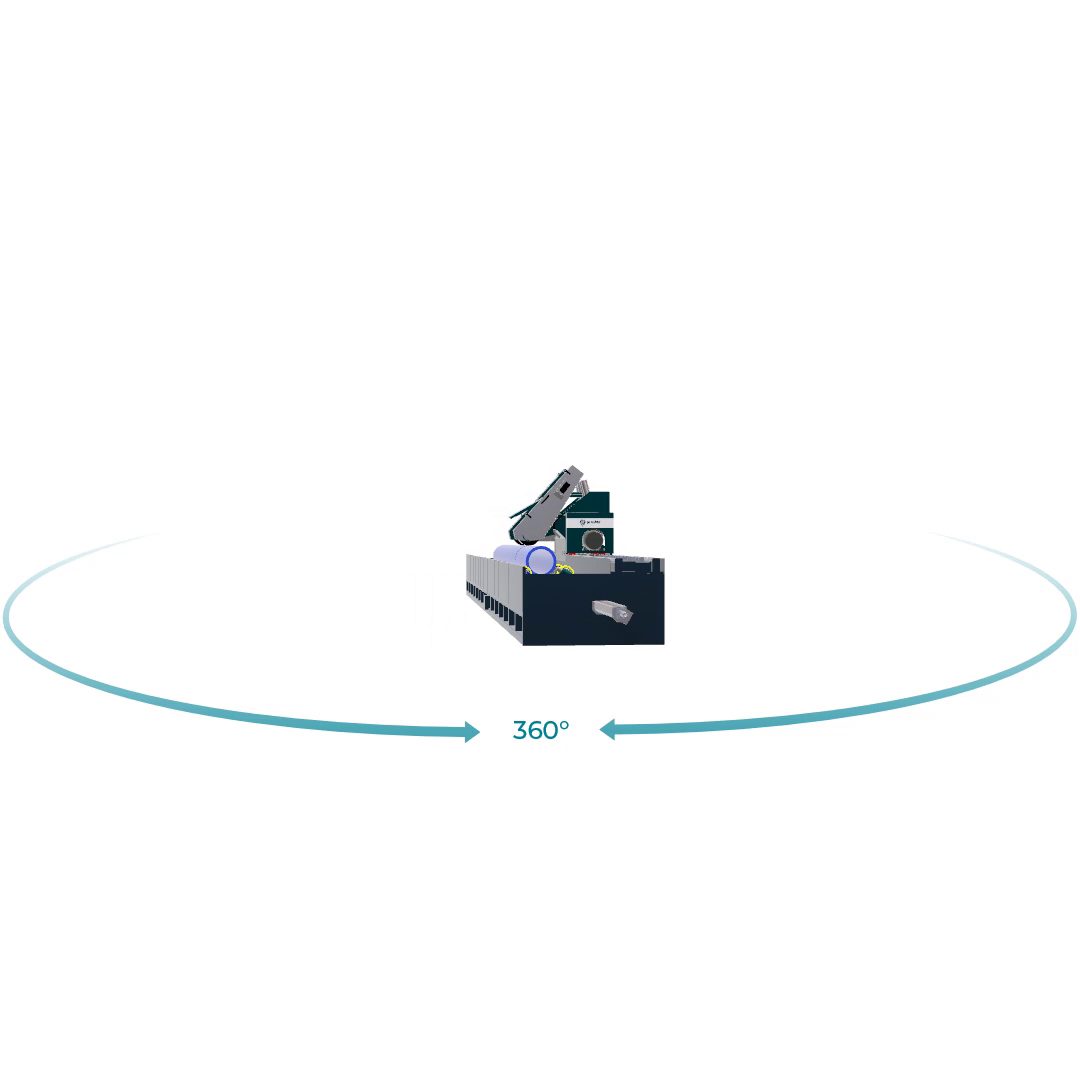

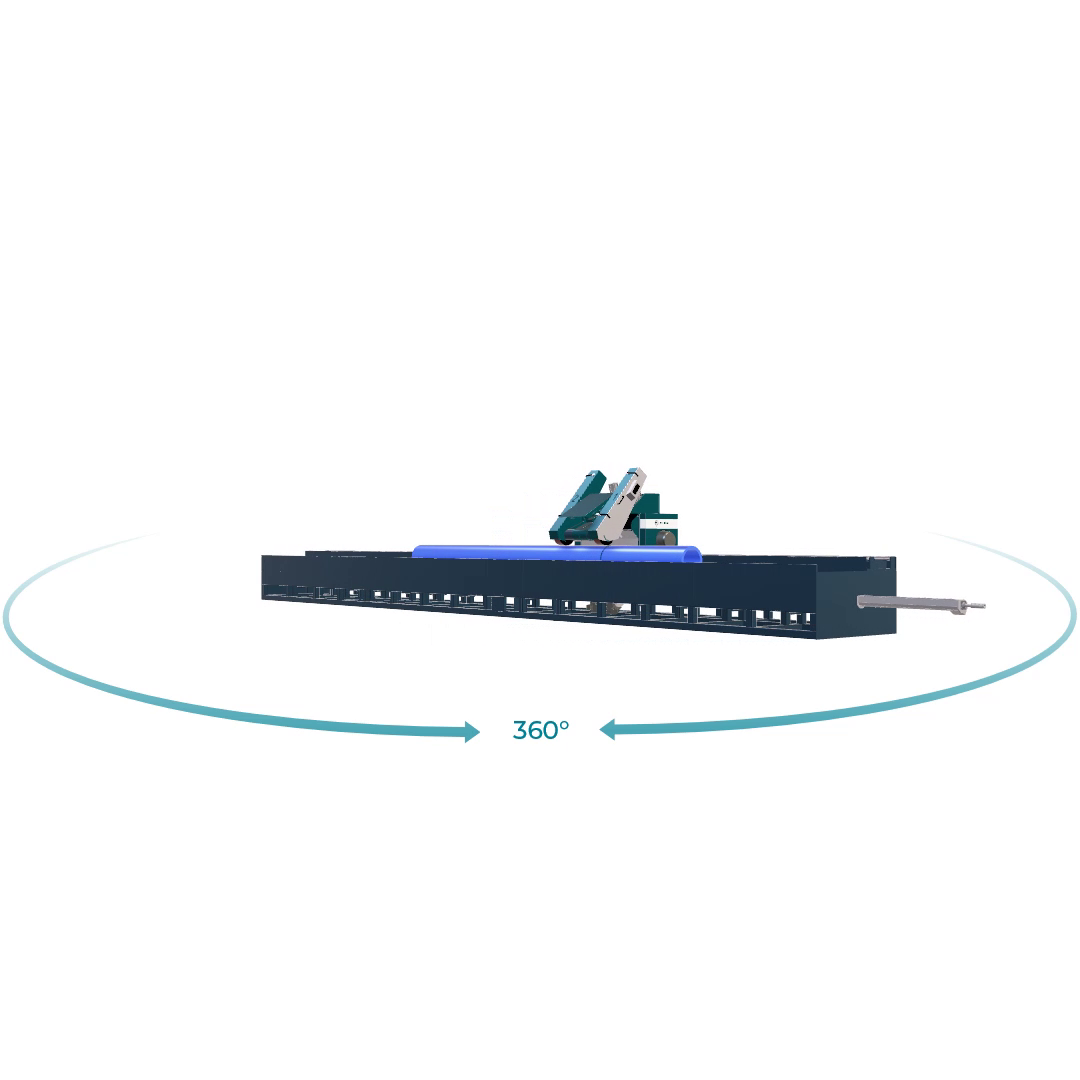

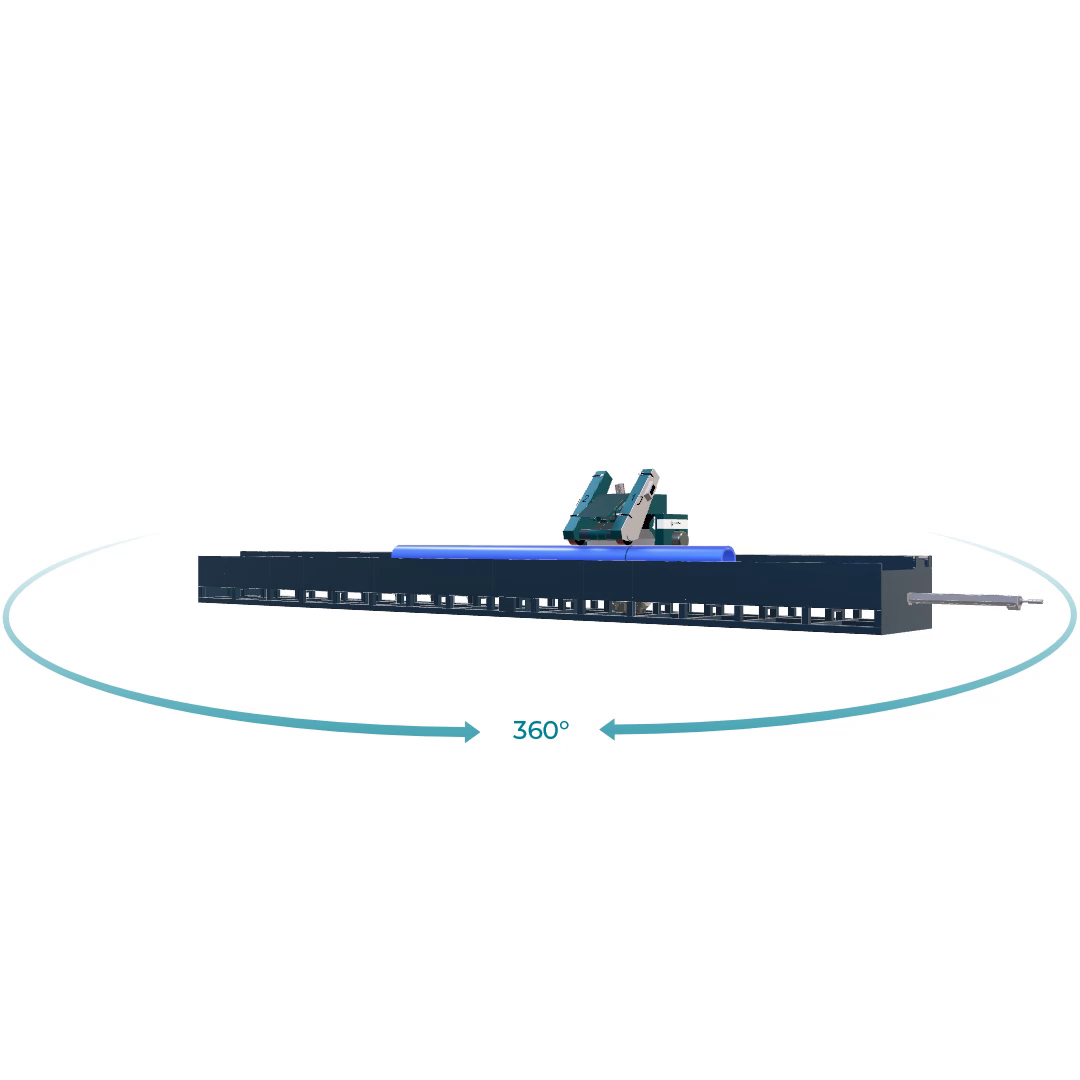

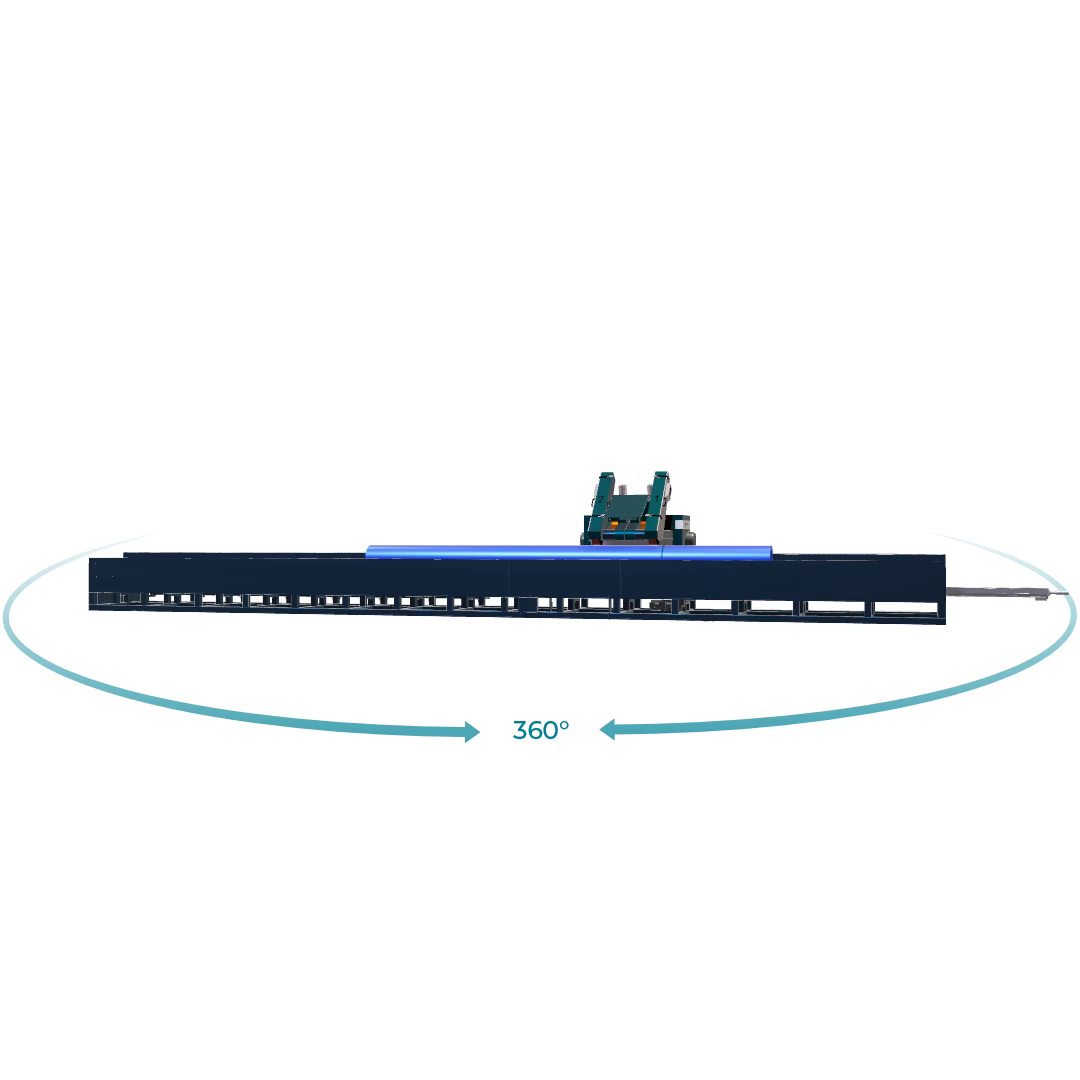

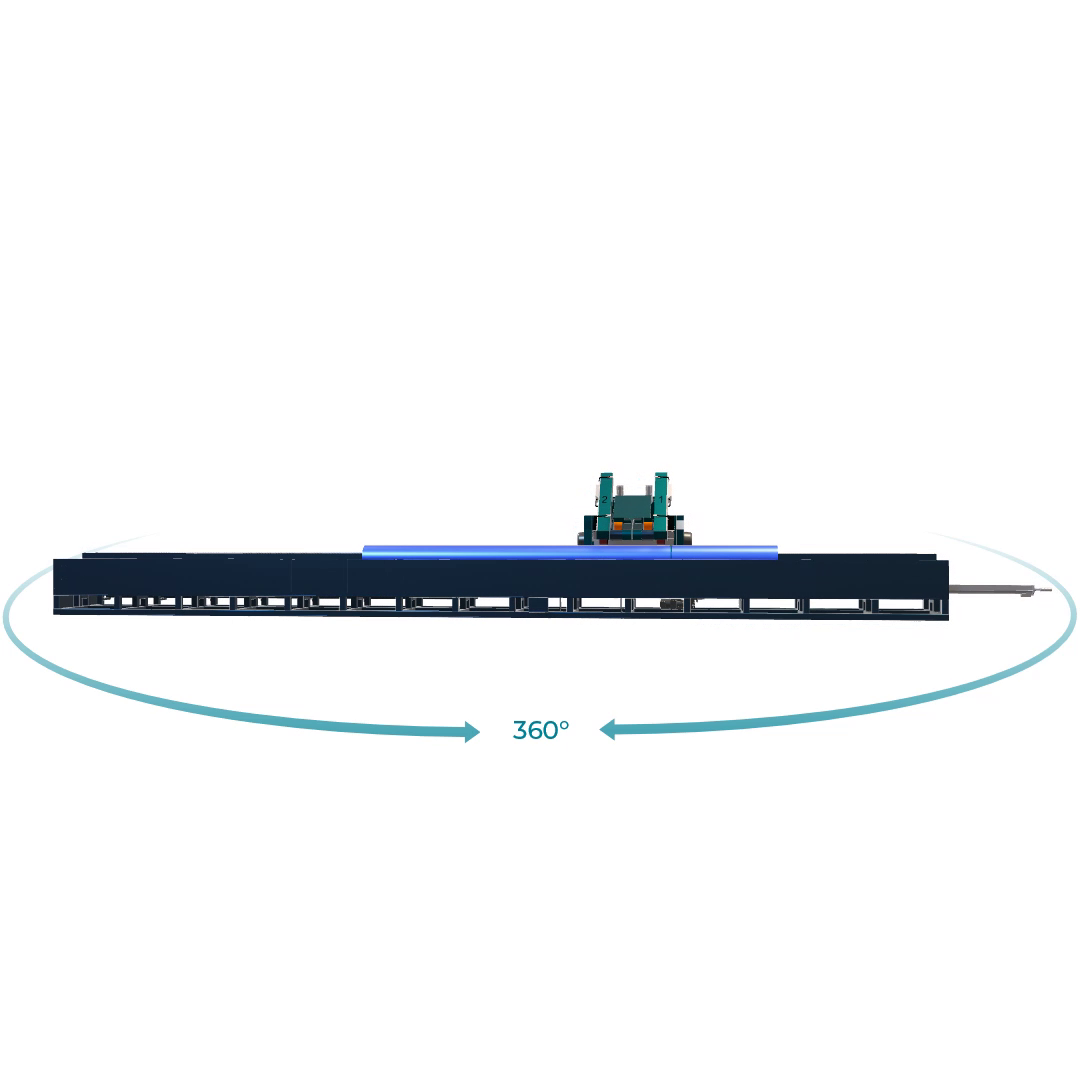

External stationary pipe grinder

Description of the device

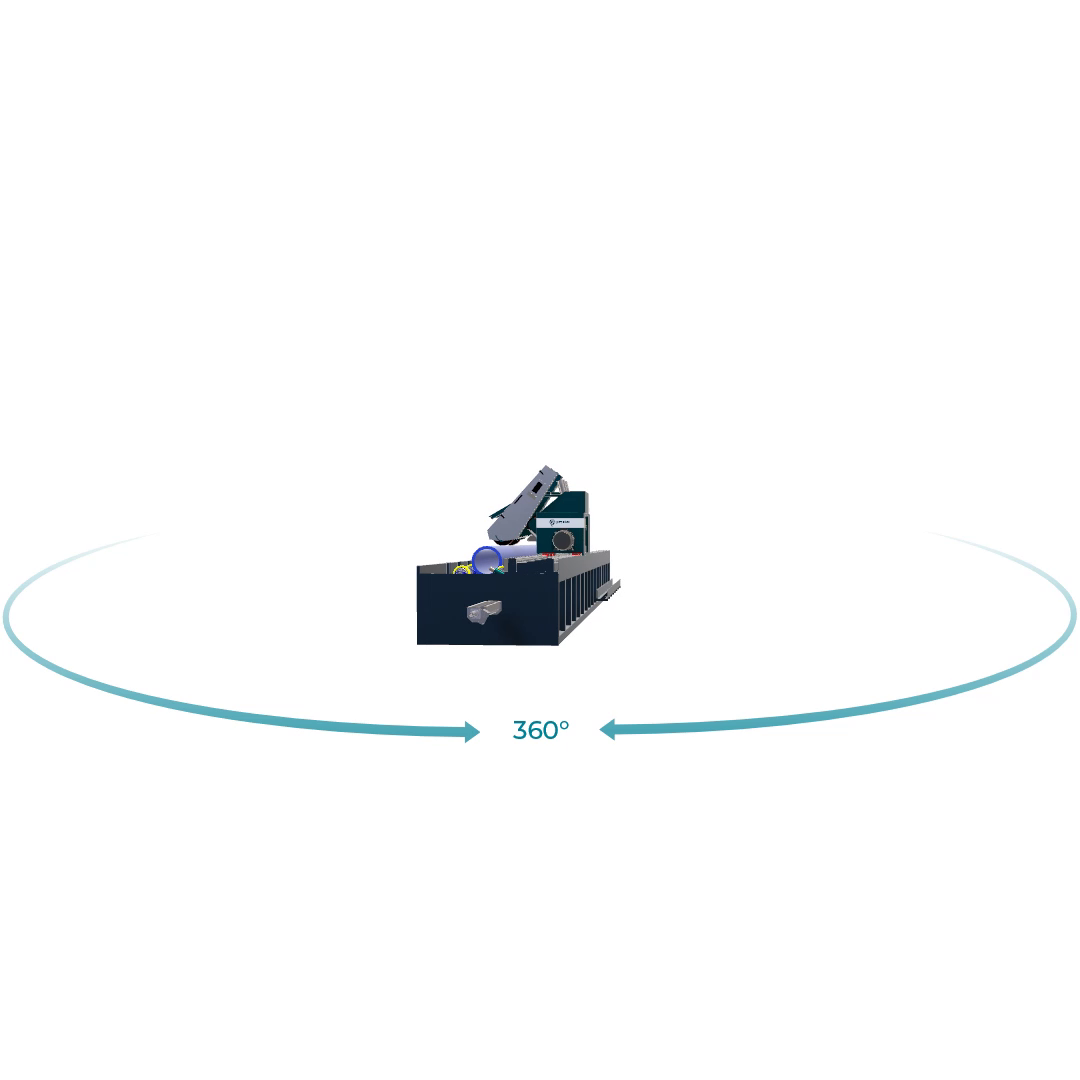

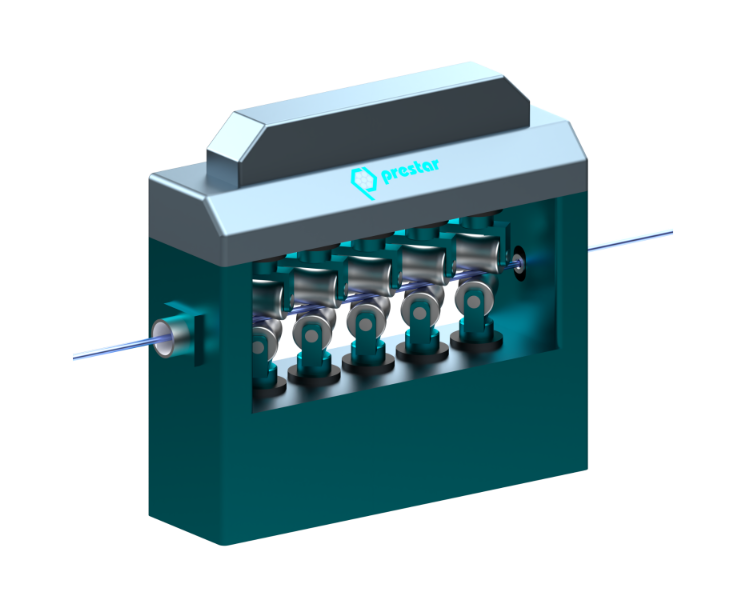

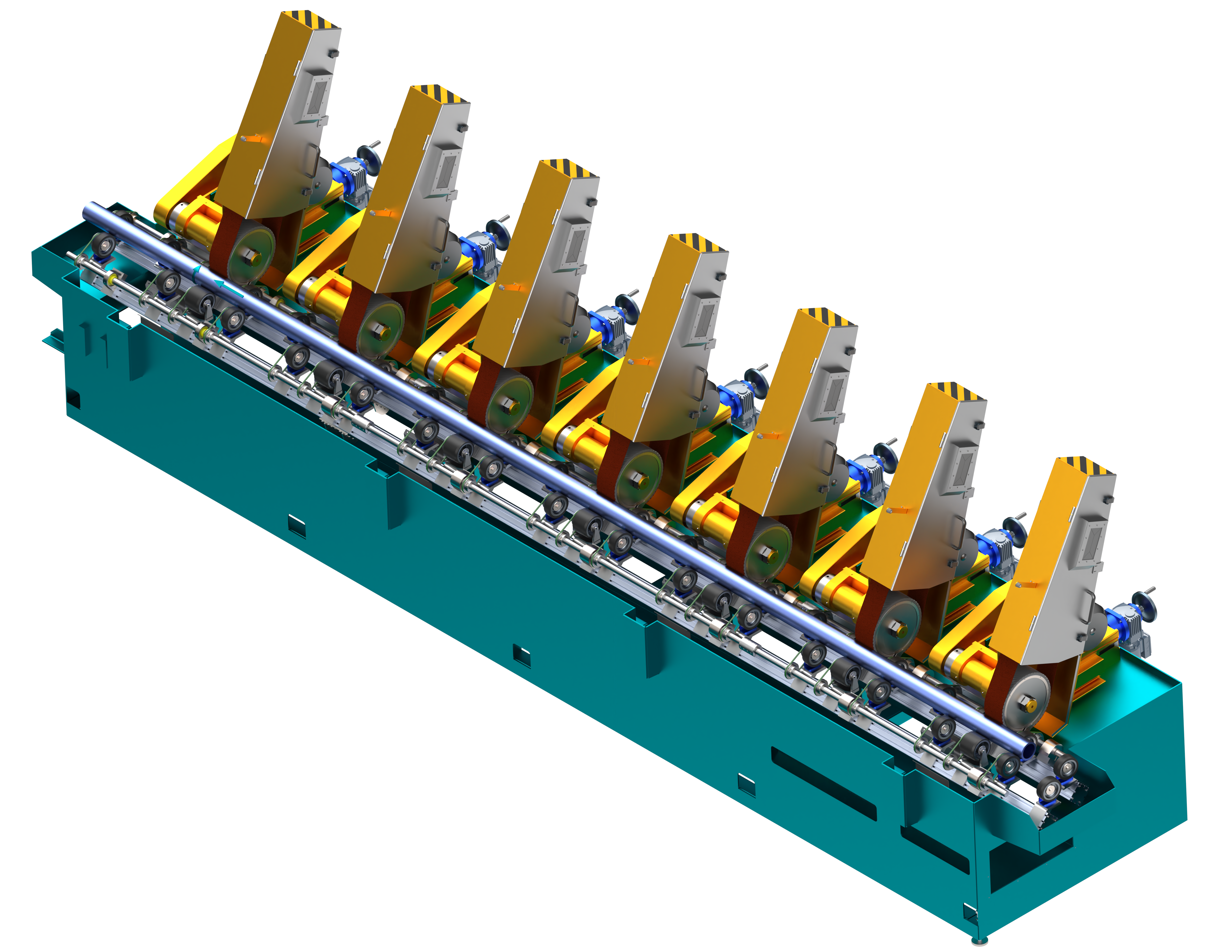

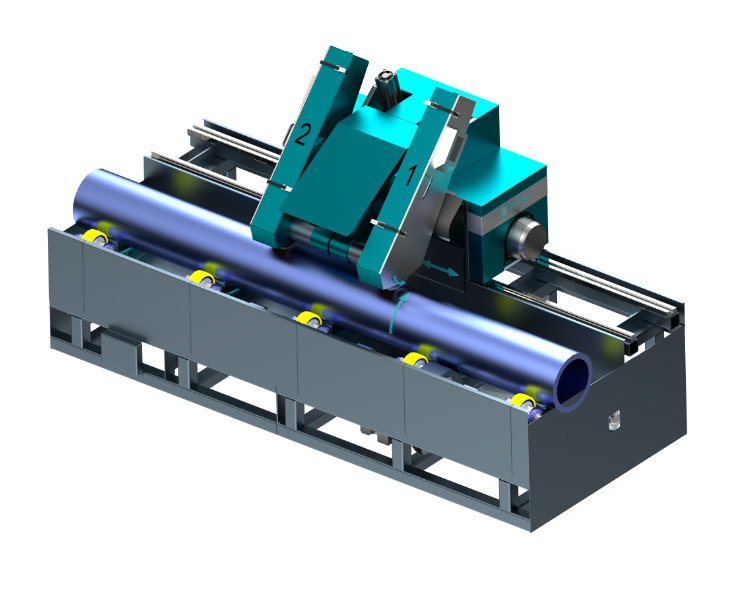

Larger diameter tubes require the outer surface to be sanded to remove scale, remove surface defects and to improve the appearance of the tubes. The pipe is loaded into the machine on driven radial rollers that are placed in a catch basin. A mobile grinding unit equipped with grinding belts is ready in the parking position next to the pipe. After start-up, the grinding unit cycles along the rotating tube and grinds the material with a constant supply of coolant. The machined material is rinsed into the tub and conveyed out of the tub by a worm shaft. Water with abraded material is filtered in three stages. Magnetic filter, fabric filter and mechanical separator. The solid residues are stored in an attached pallet and the filtered water is reused for grinding.

Technical parameters of the machine

|

Diameter of pipes: |

200 – 600 mm |

|

Pipe lengths: |

3 000 – 16 000 mm |

|

Material removal per cycle: |

up to 0,5 mm in one cycle |

|

Grinding belts: |

150 x 3 000 mm |

|

Pressure of grinding belts: |

pneumatic |

|

Tensioning of grinding belts: |

pneumatic |

|

Belt grinding speed |

30 m/s |

|

Replacement of grinding belts: |

in the parking position of the grinding unit there is a platform for easy access to the sanding belts |

|

Control panel with display: |

placed on the mobile grinding unit |

Other equipment of the machine

- Continuously variable belt grinding speed control

- Handling girder for inserting and removing pipes into and out of the machine.

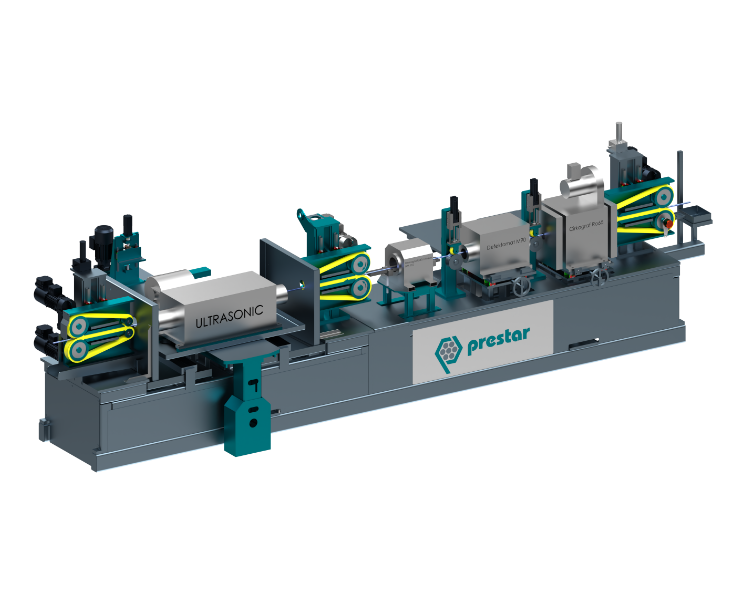

- Manual ultrasound tube wall thickness measurement.

- Extended visualization with an emphasis on intuitive and detailed display of operating states and the place of failure of the grinder.

- Enhanced service with the ability to display manuals, service guides and other necessary documentation on the machine HMI to minimize service times

- Collection of agreed production parameters with automatic saving, display and data export.

Straightening machines

Internal pipe grinder

Centerless pipe grinder

External stationary pipe grinder

Flying saw

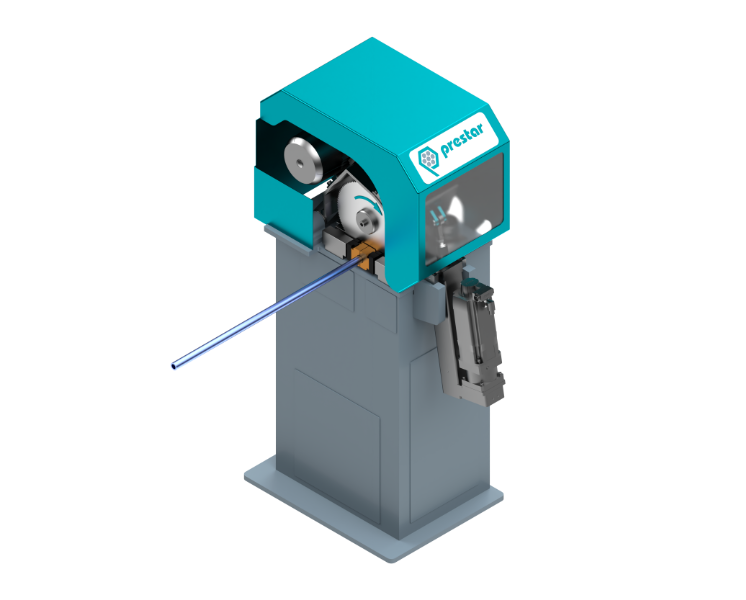

Circular saw

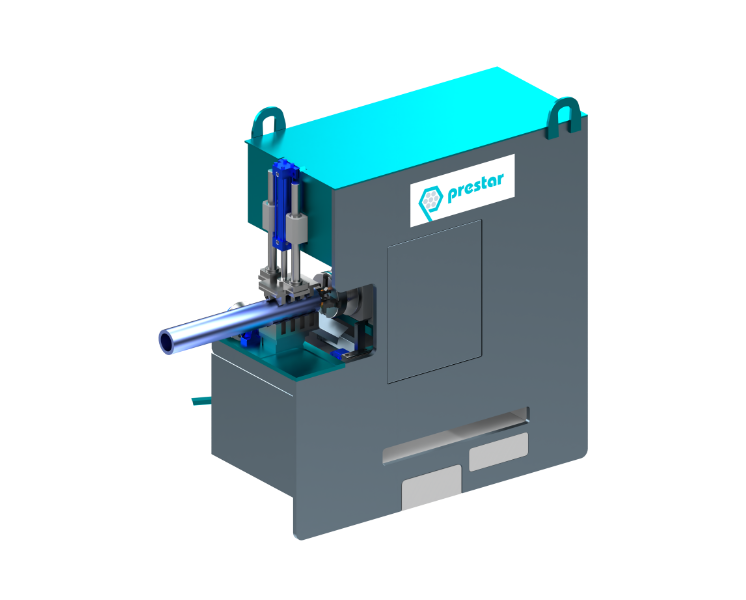

Chamfering of pipes

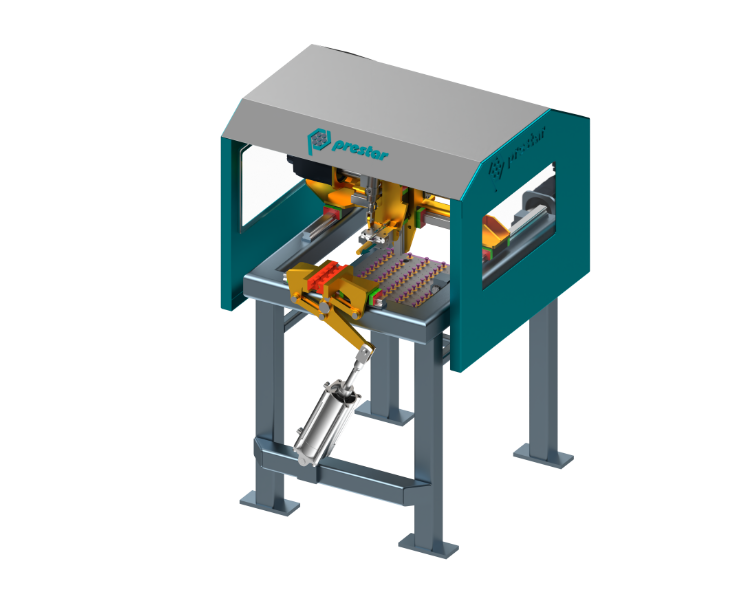

Sorting and plugging

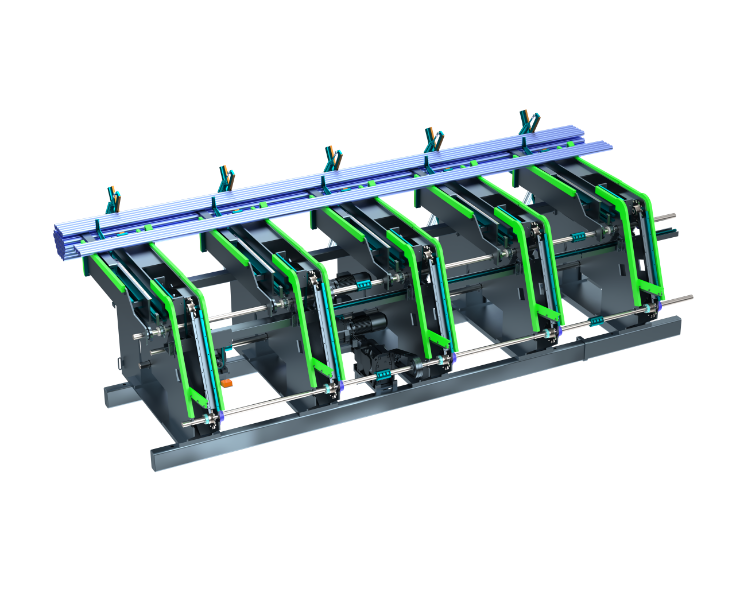

Control tables

Packaging machines

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT

90% of customers perceive Prestar's technology as highly advanced

Our solutions in industry:

Automation and modernization of tube and rod processing lines | Prestar s.r.o.

We are Prestar s.r.o., a company specializing in custom manufacturing, in-house production of handling equipment, and industrial automation. In addition, we have extensive experience...

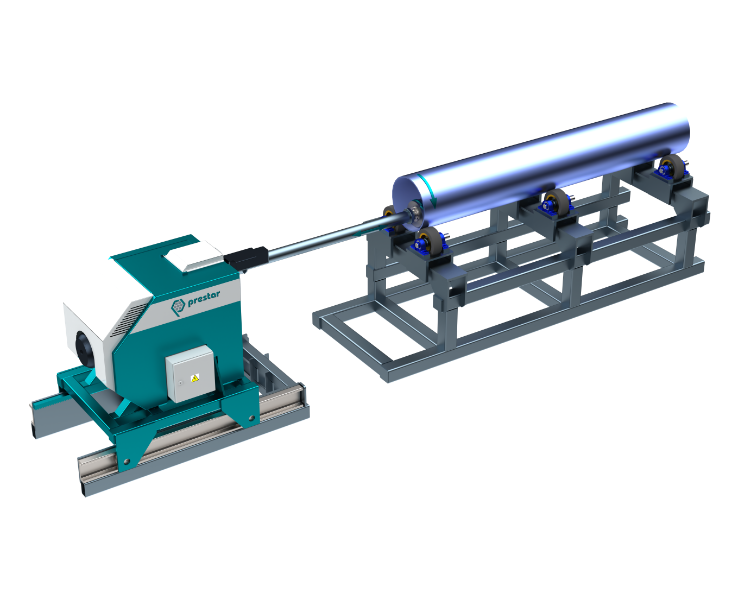

Presentation of the new equipment: Straightening machine RS50

This week at Prestar, we had the unique opportunity to introduce our RS50 straightening machine to a major player in the market - Alleima, a company specialising in the production of advanced, high value-added...

Pipe Transport Automation: A Successful Project by Prestar s.r.o.

Modern requirements for production processes include not only high speed and precision, but also adaptability to individual customer needs.We, Prestar s.r.o., successfully implement such...