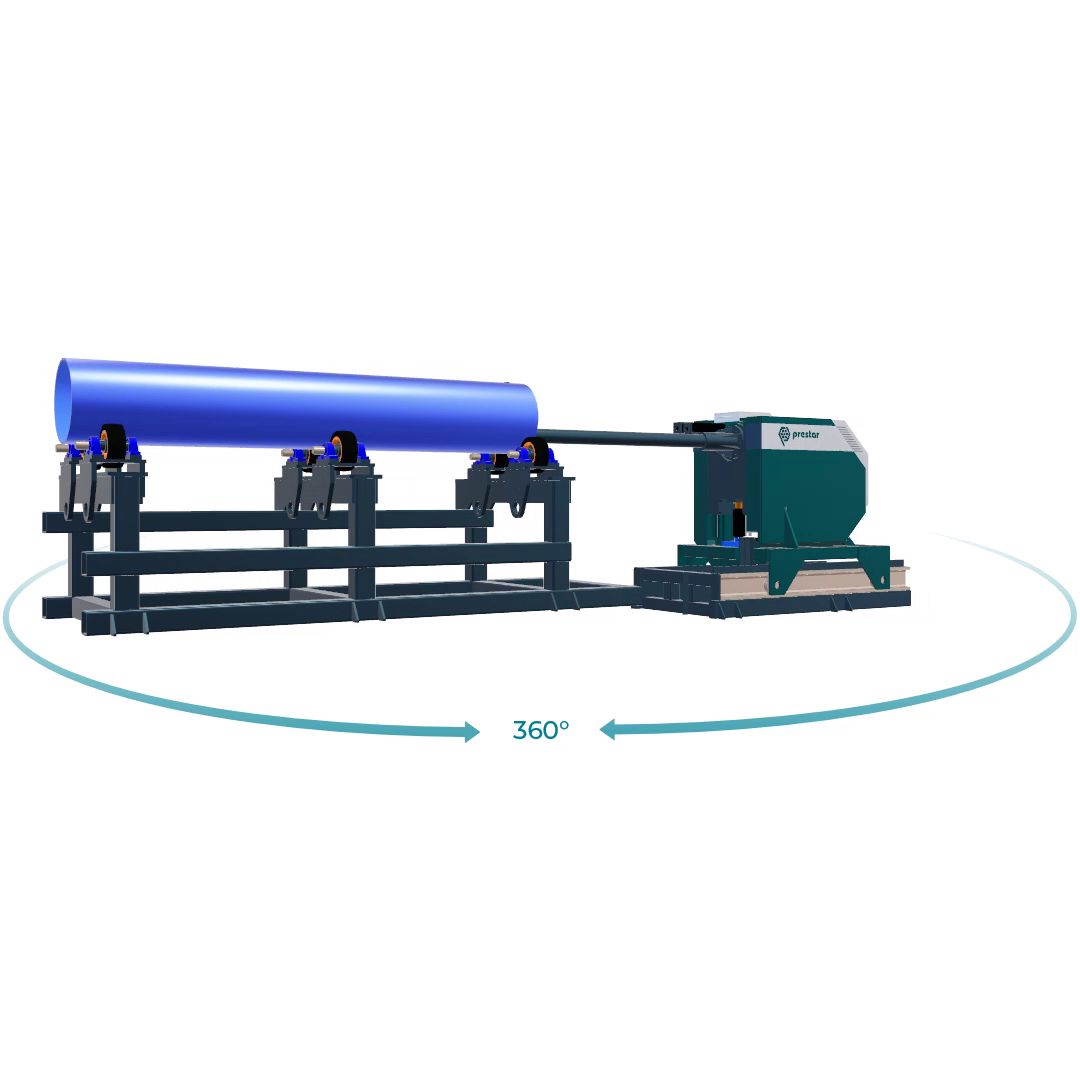

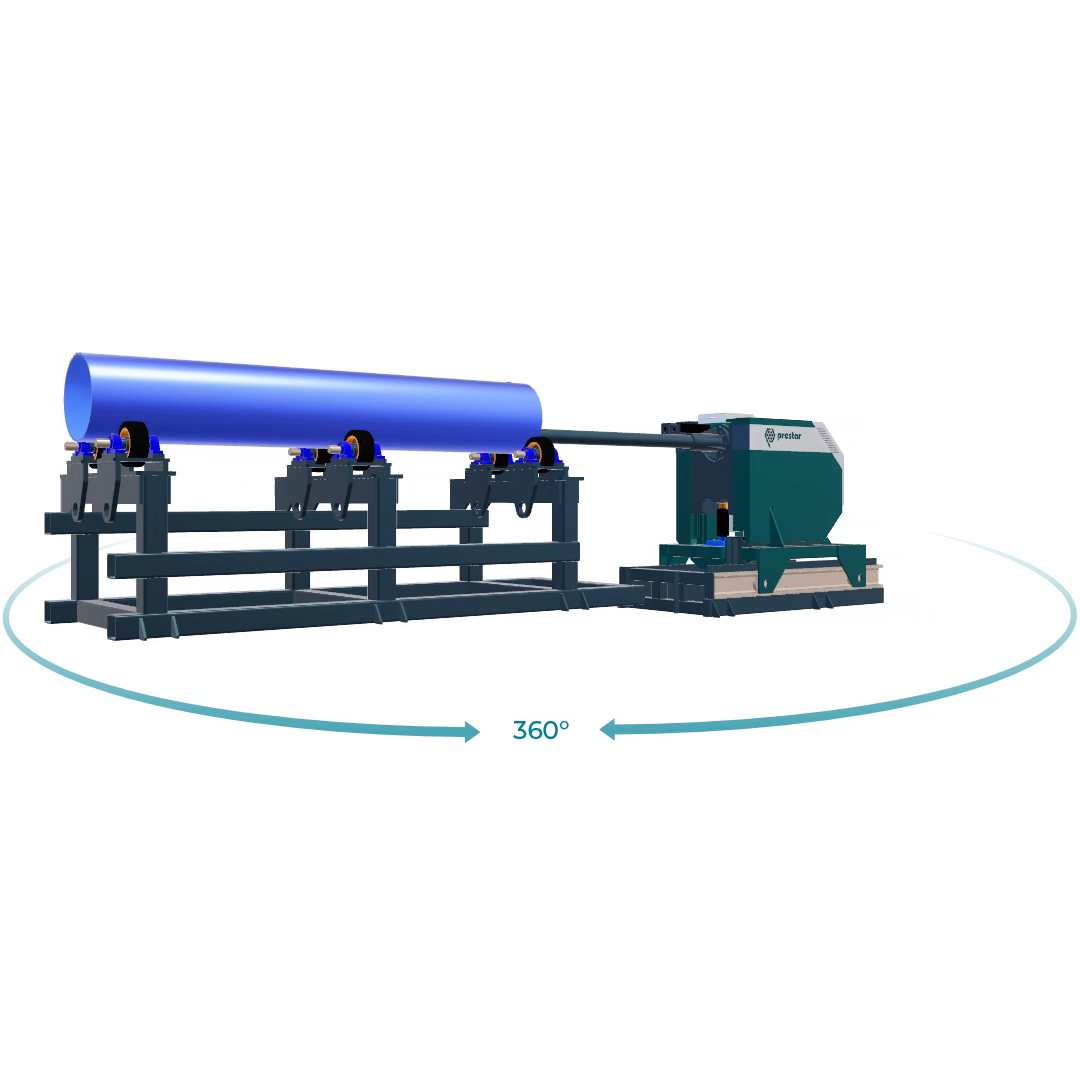

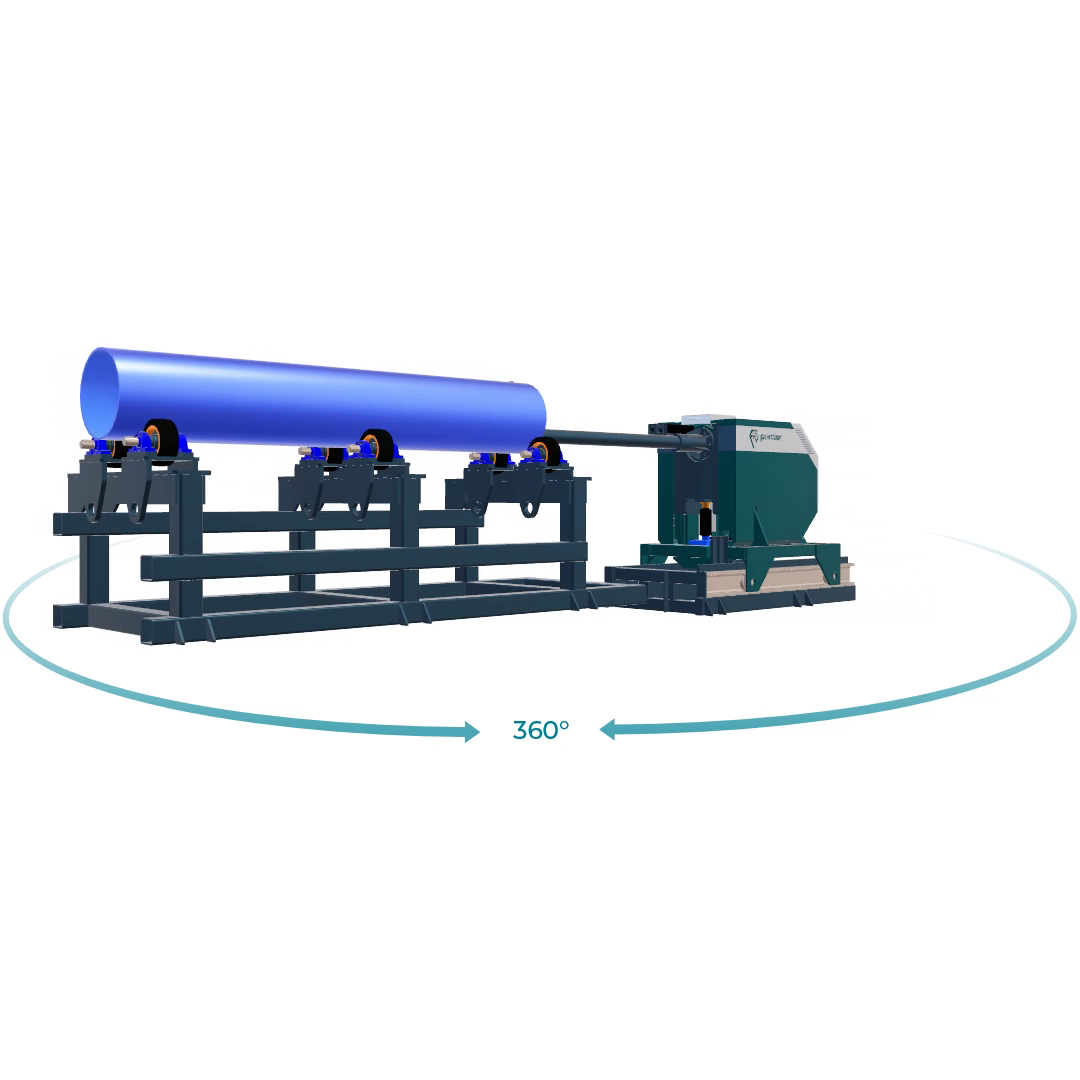

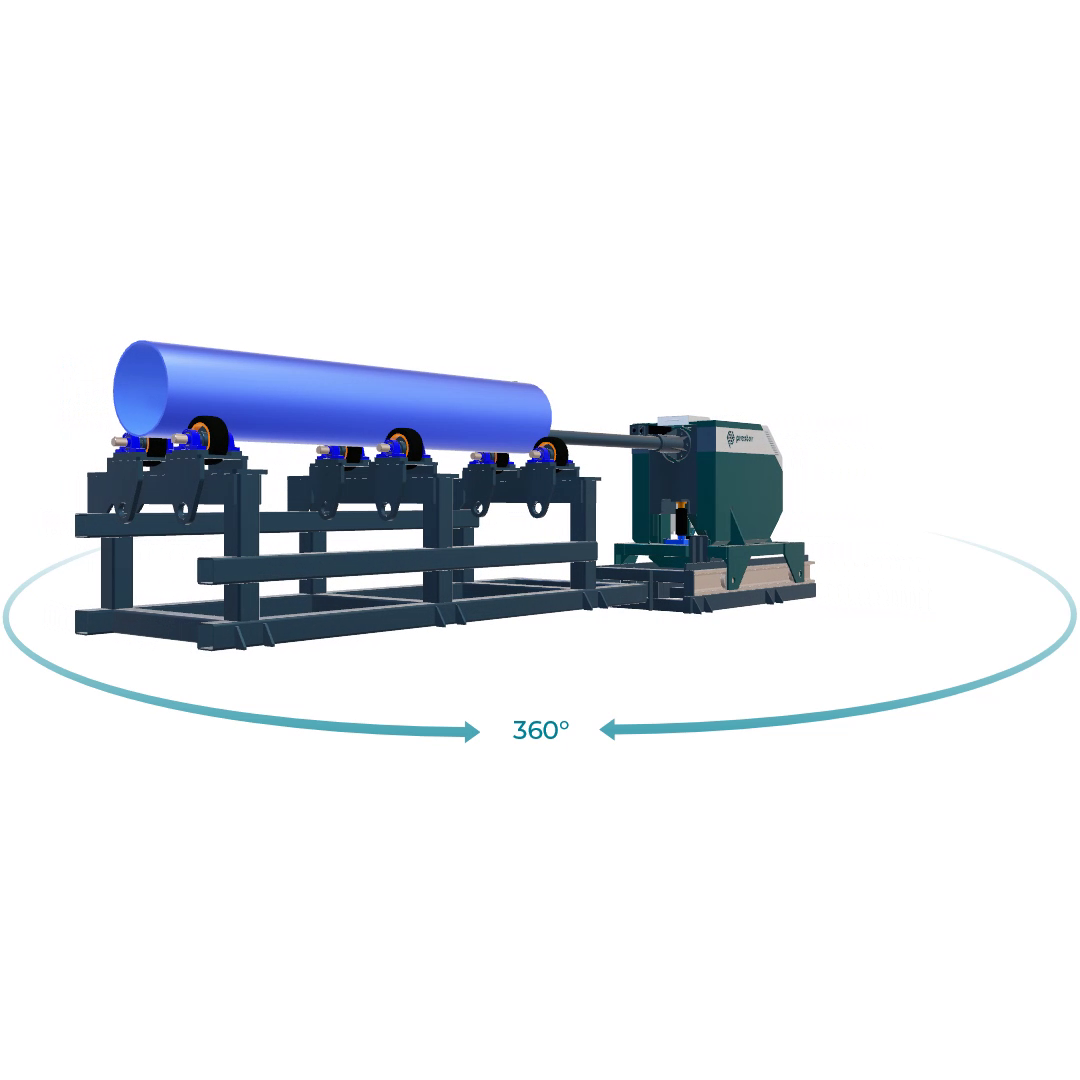

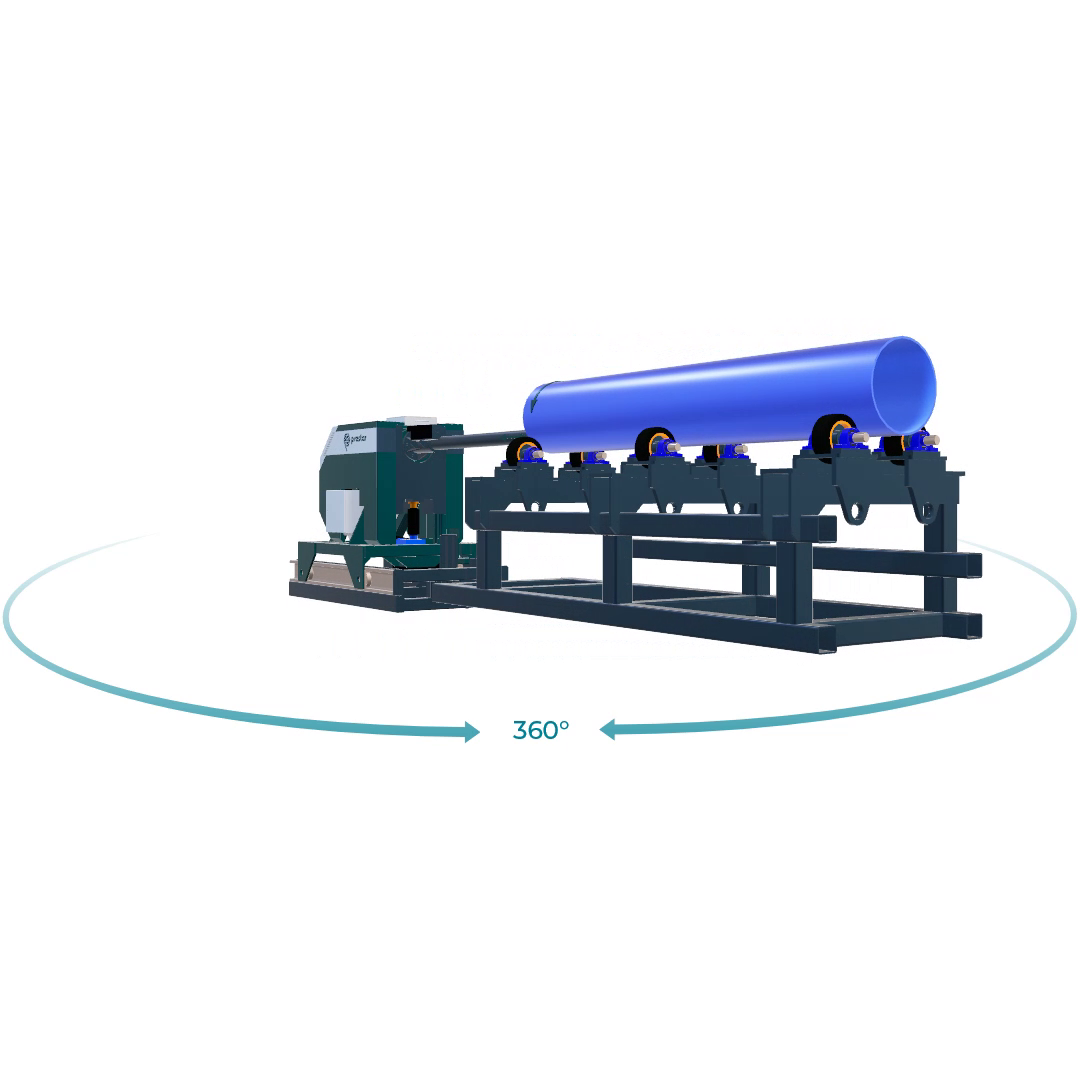

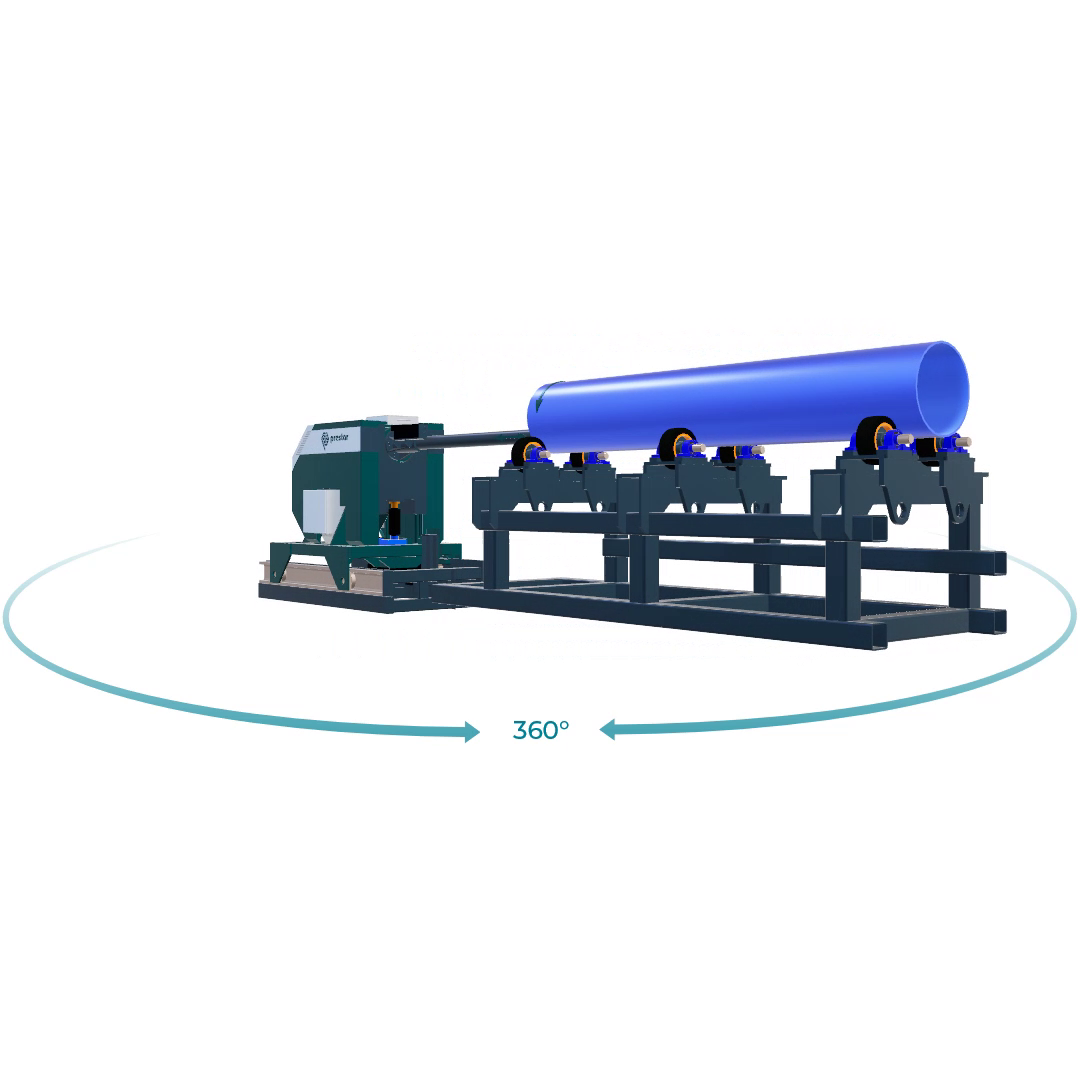

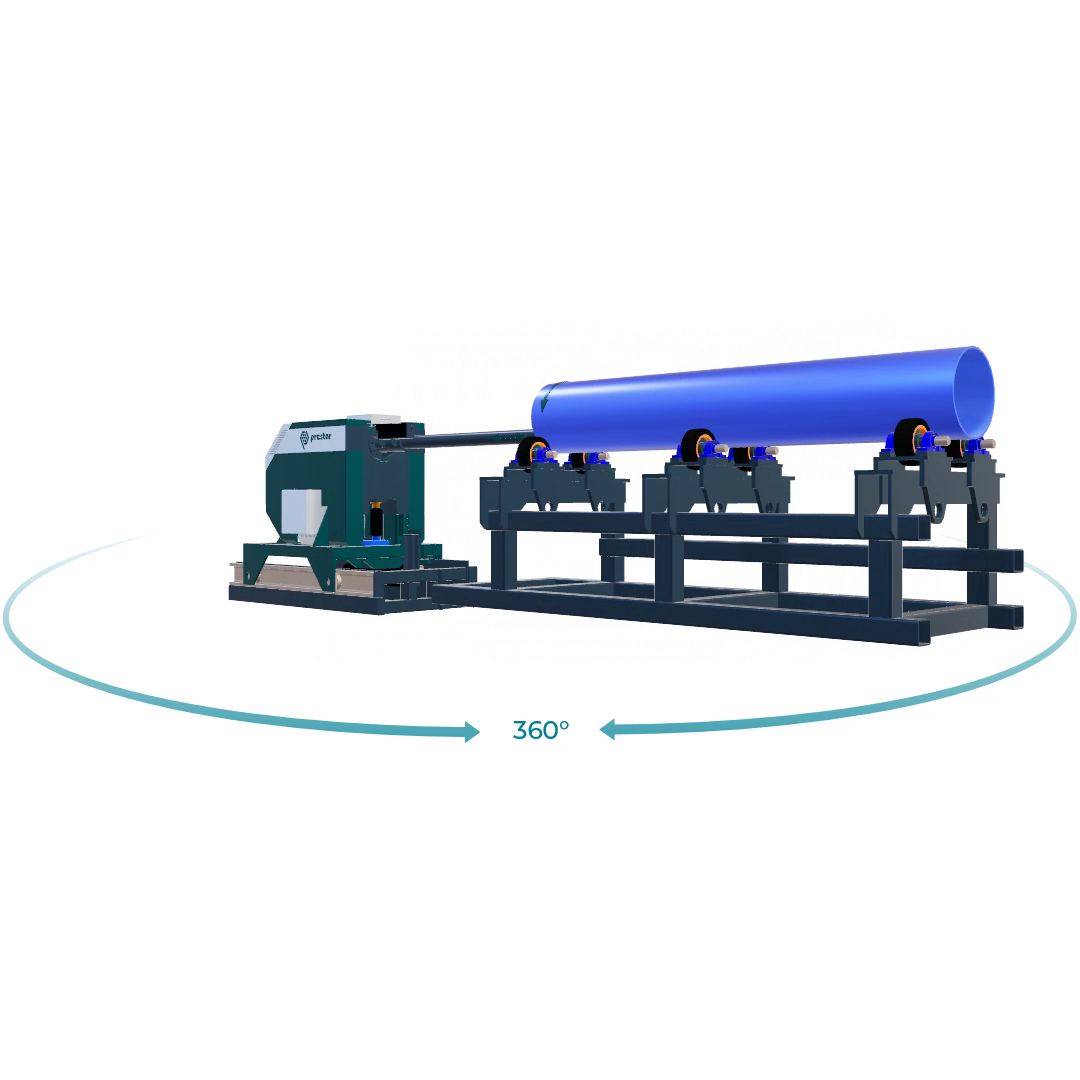

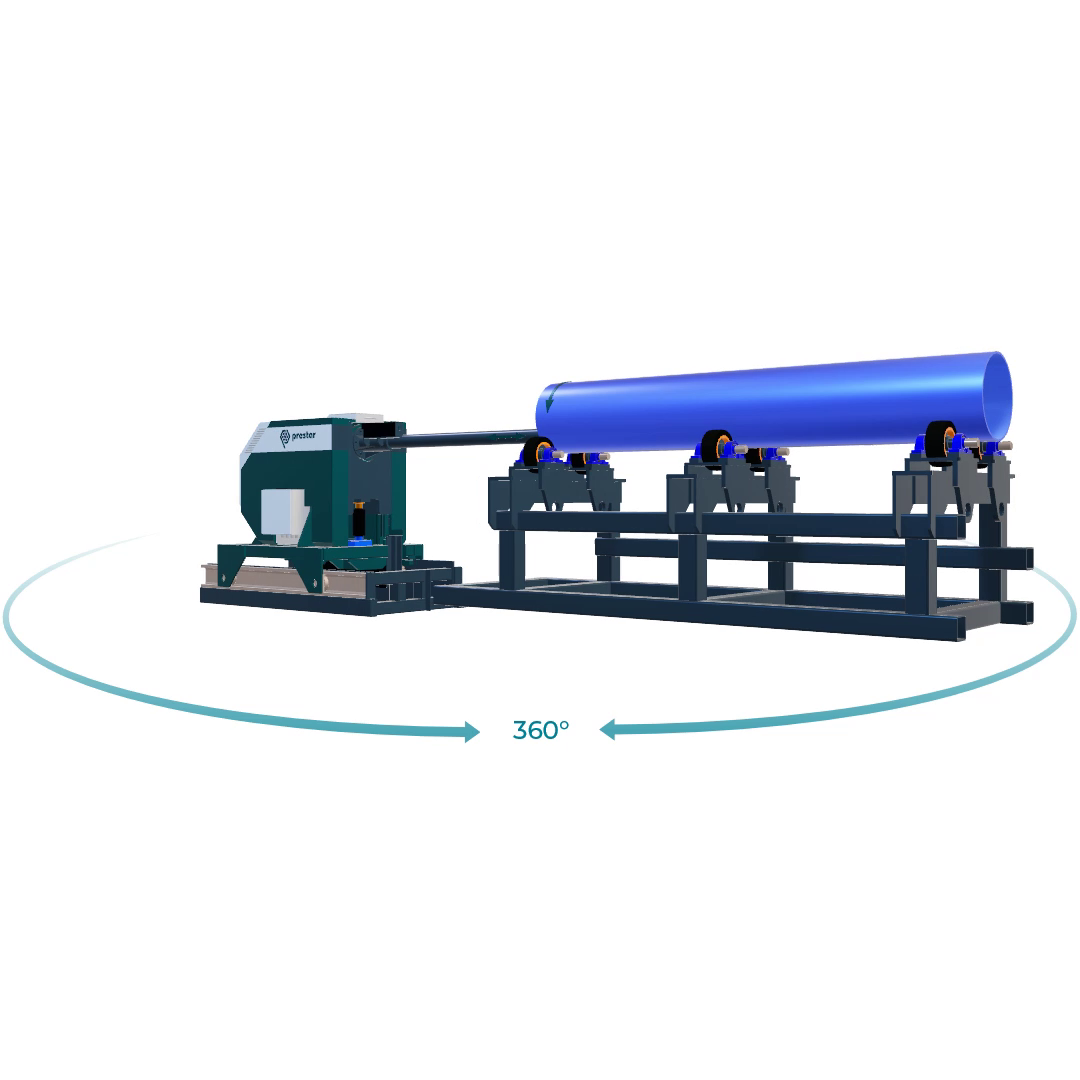

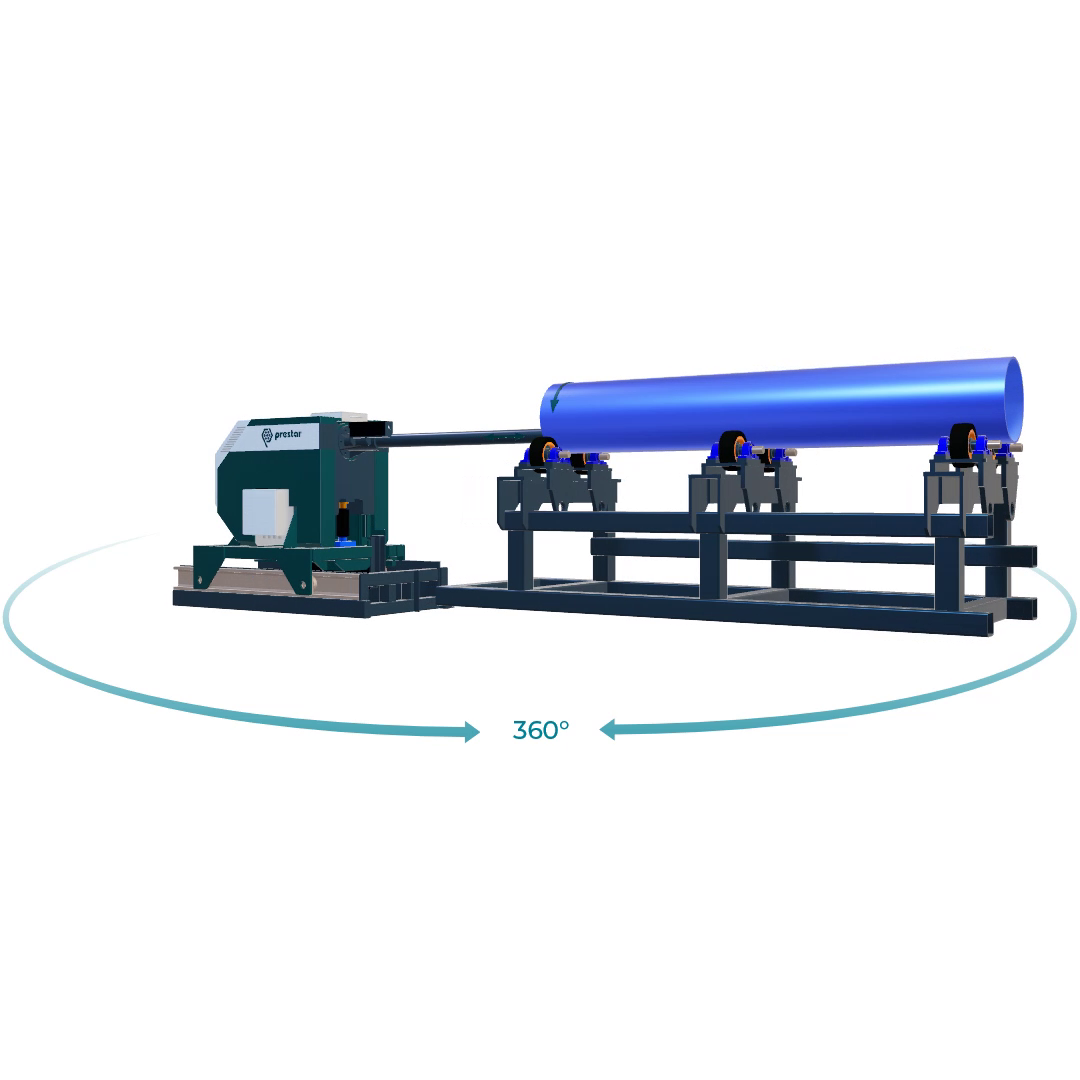

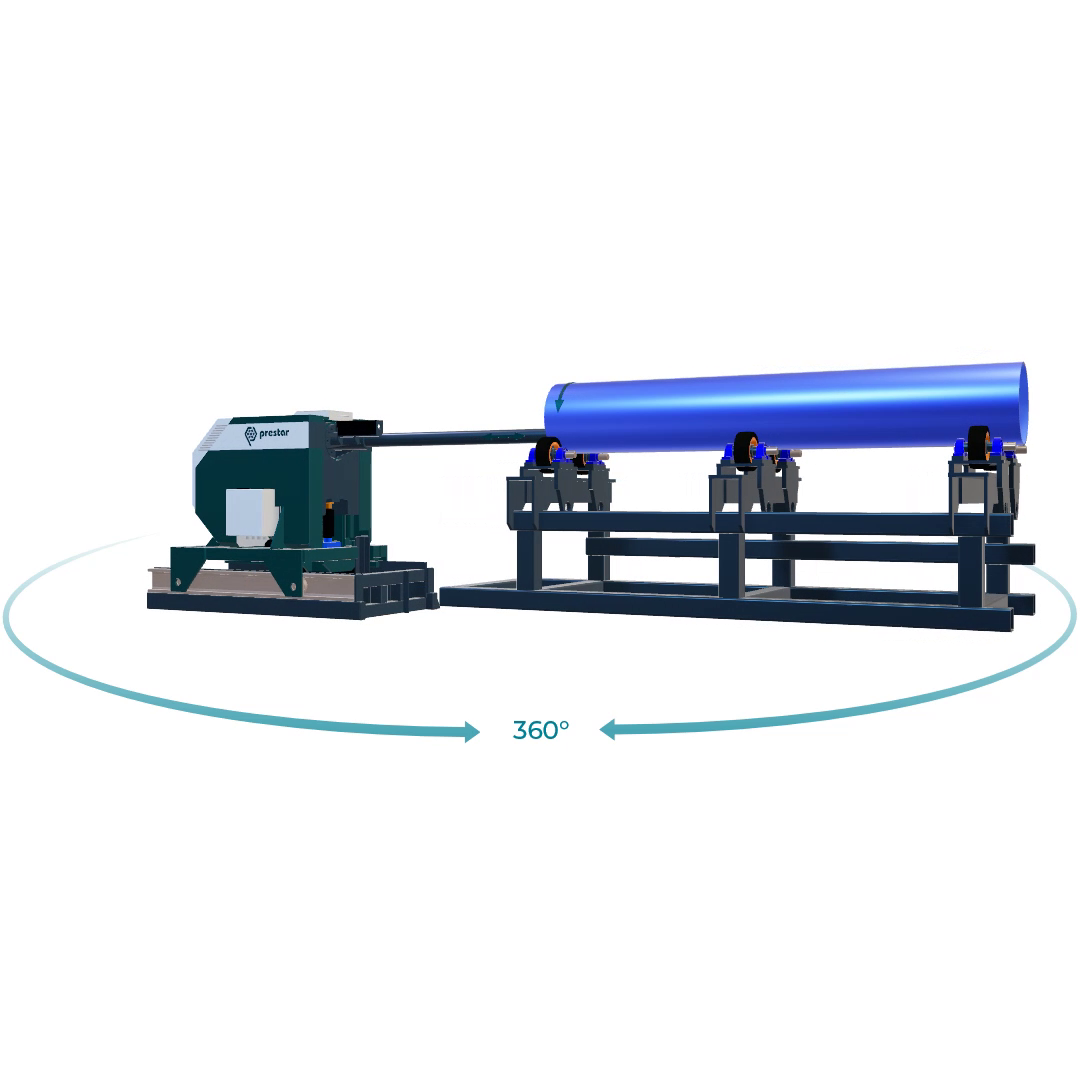

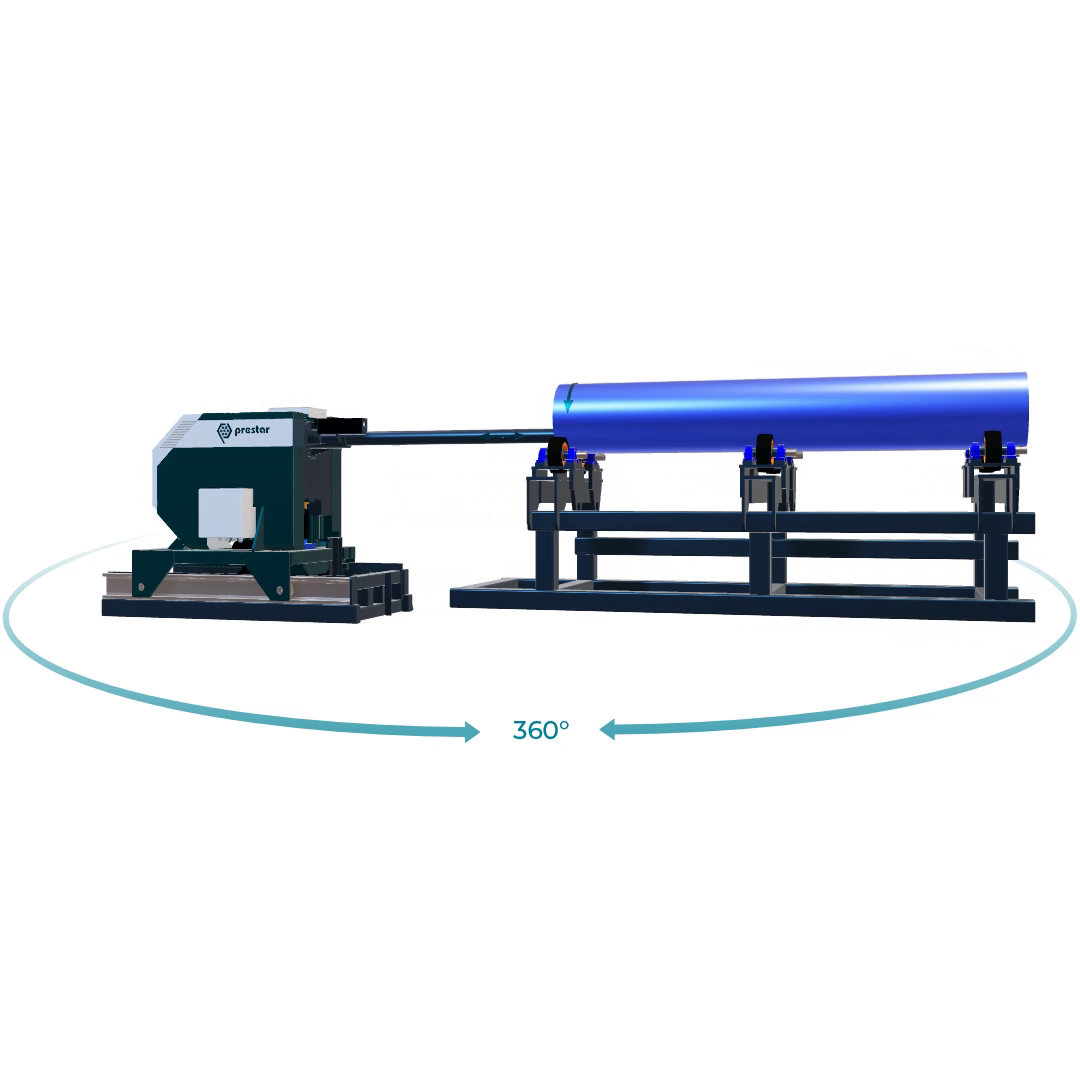

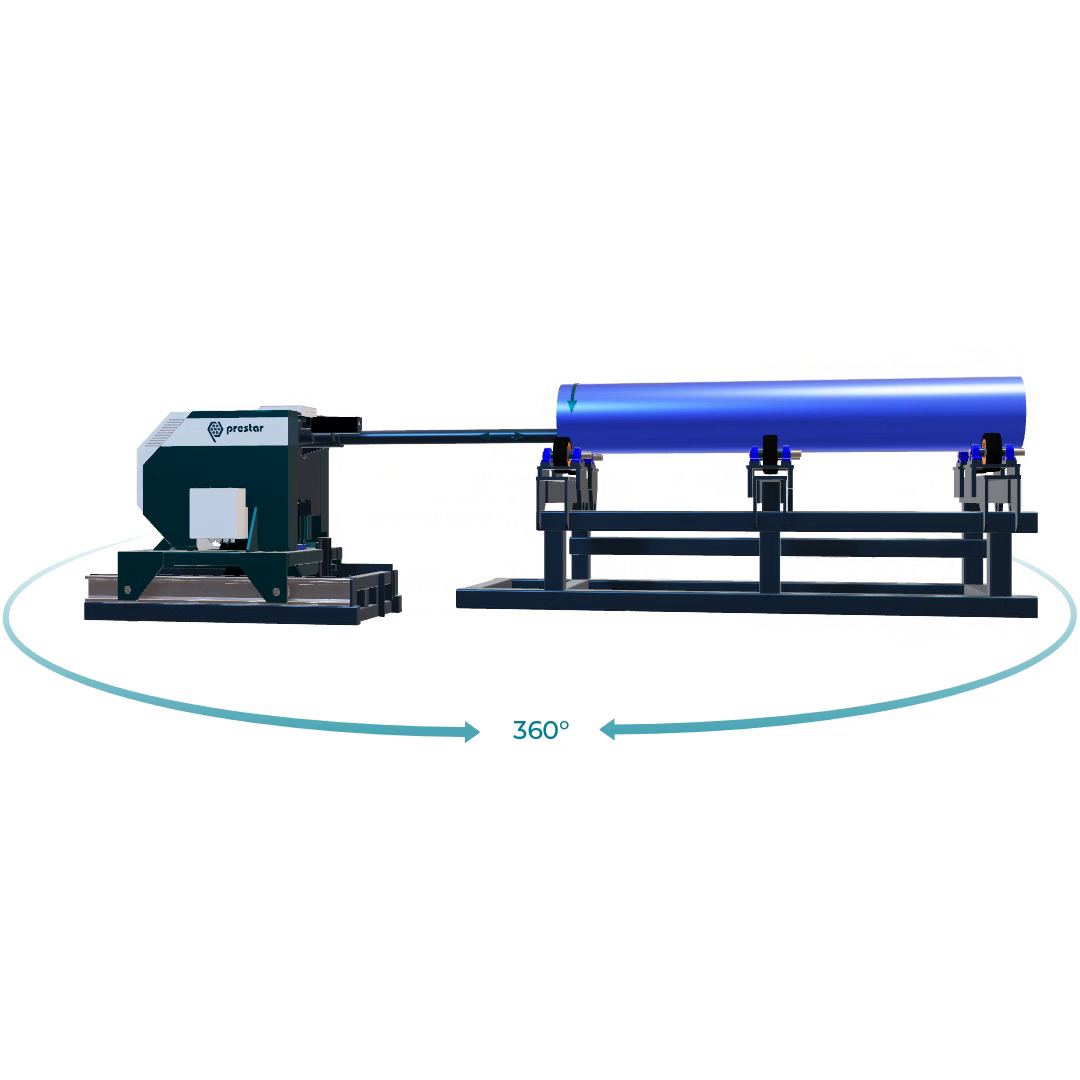

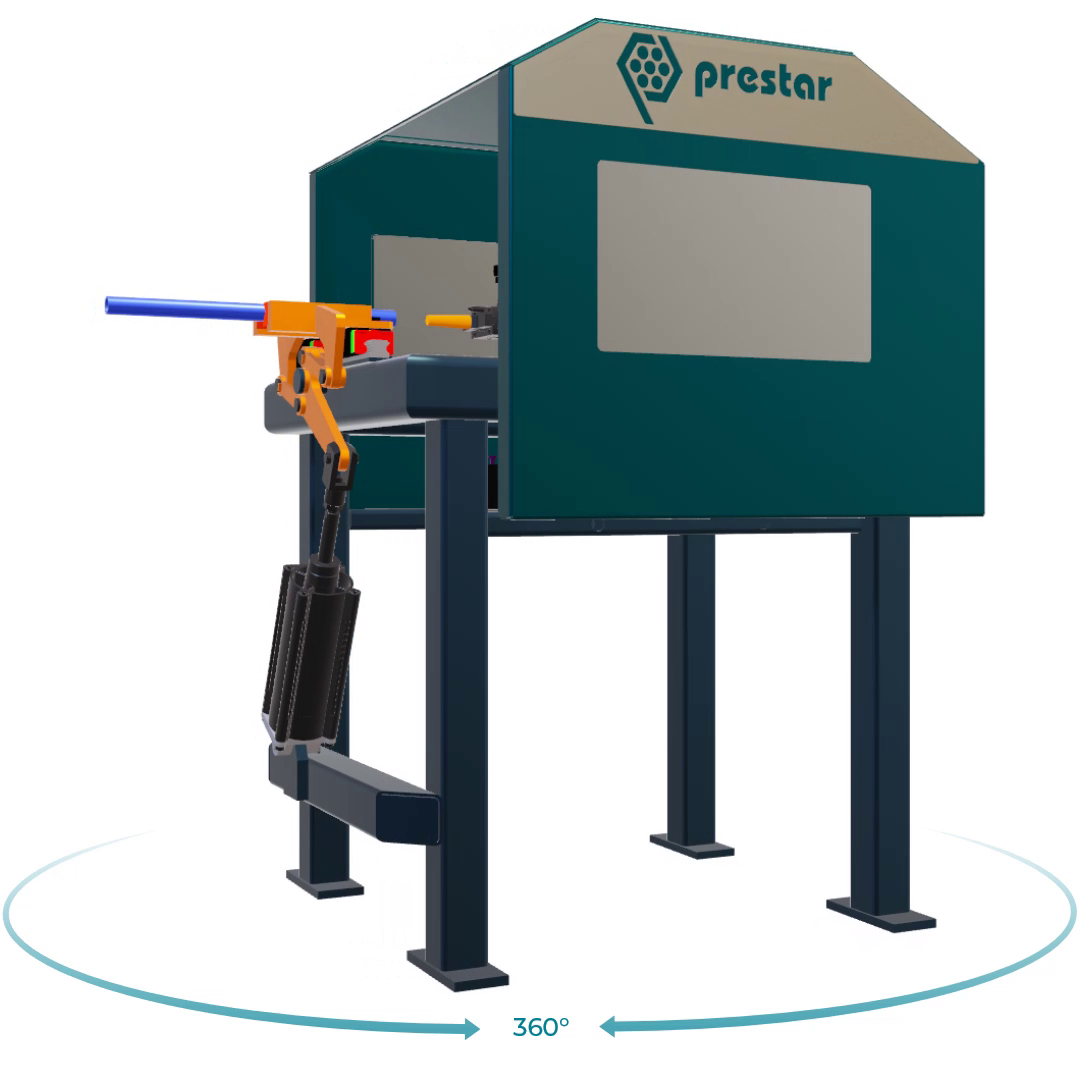

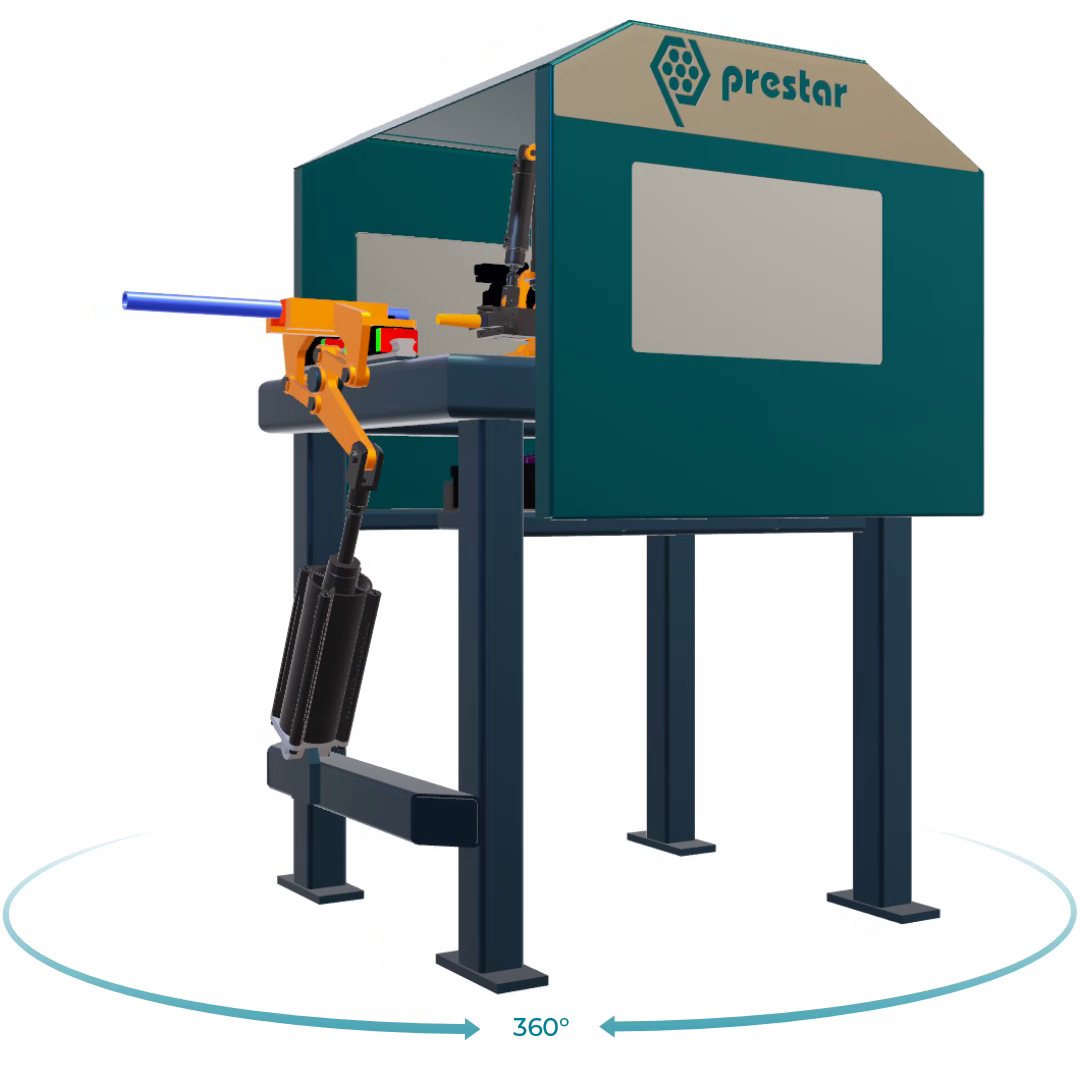

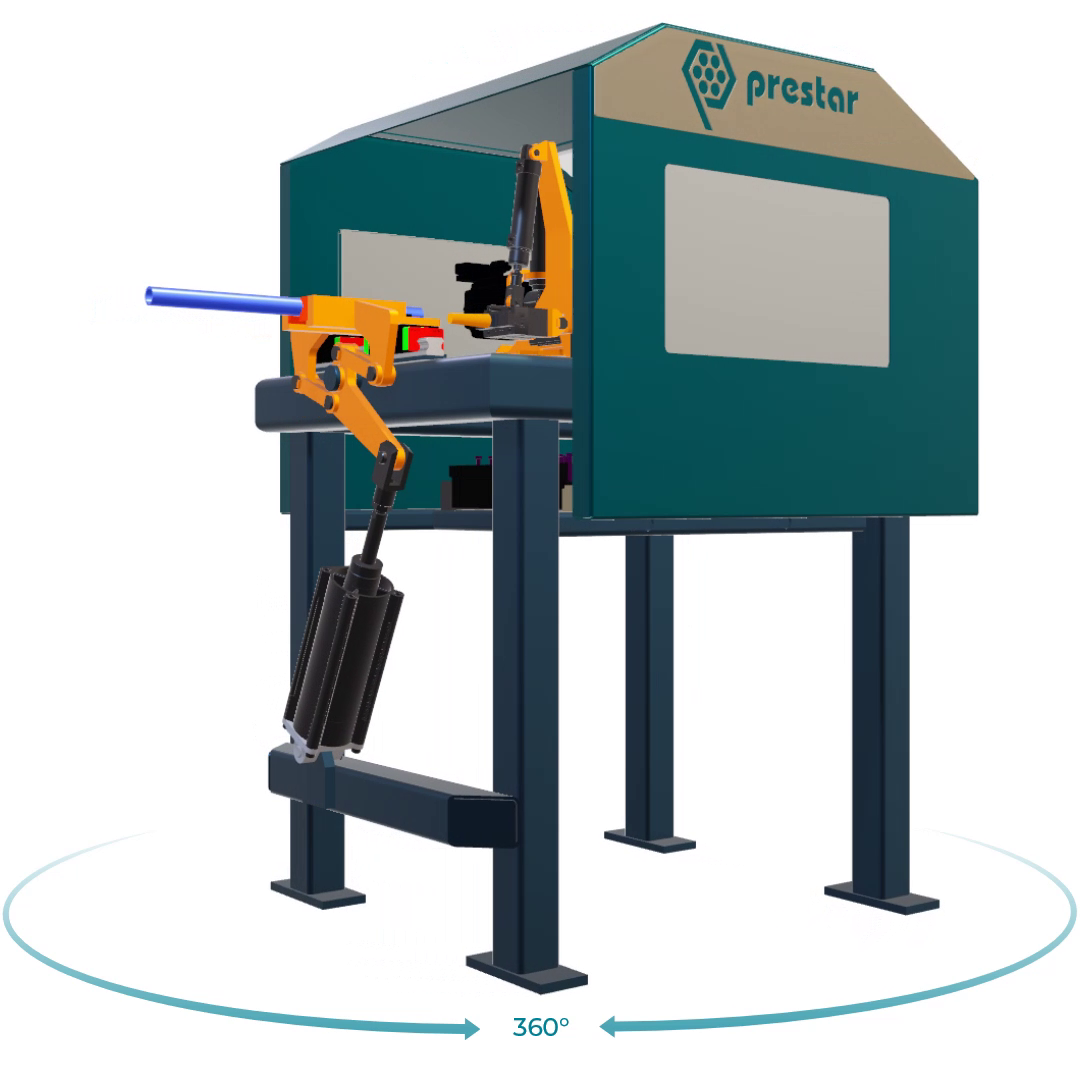

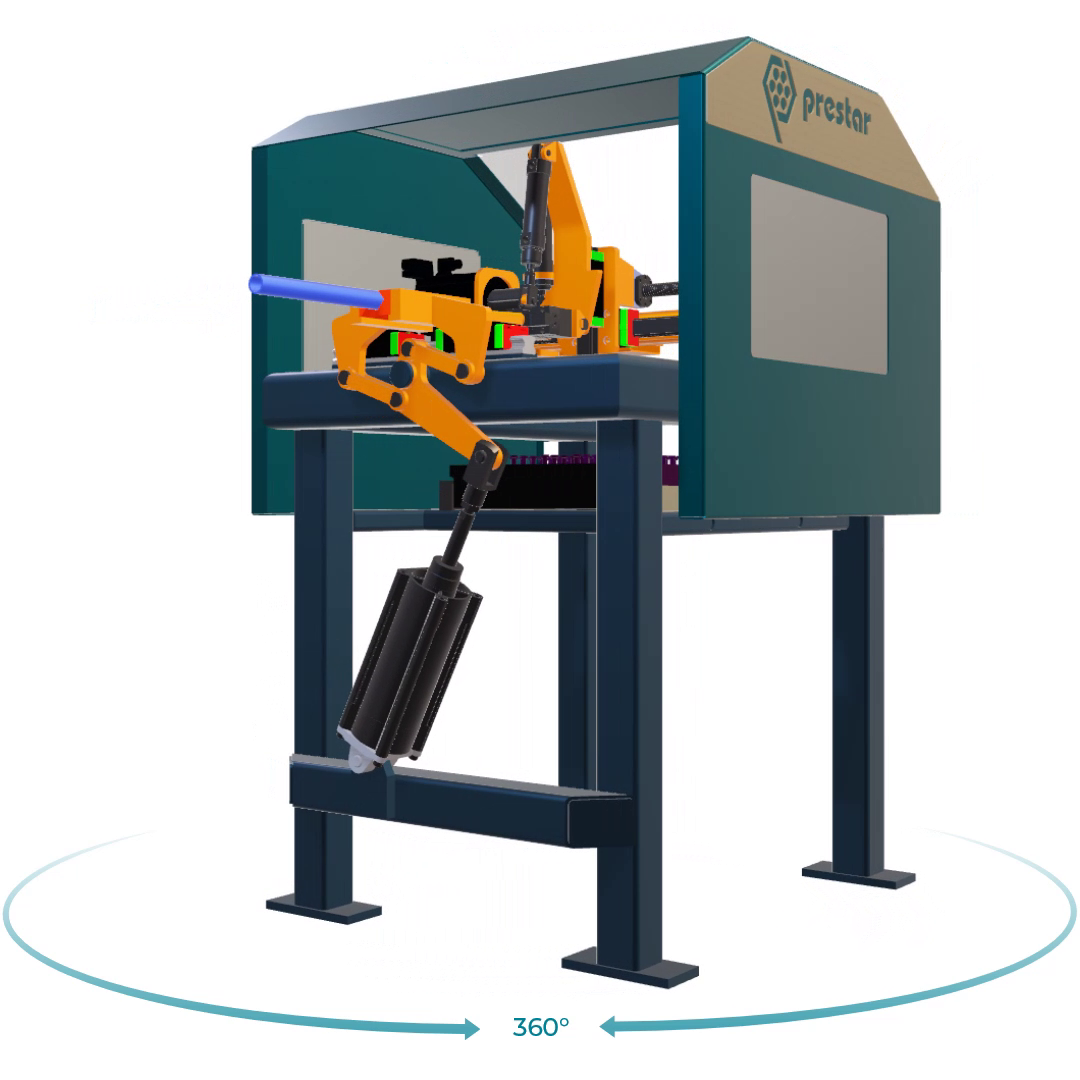

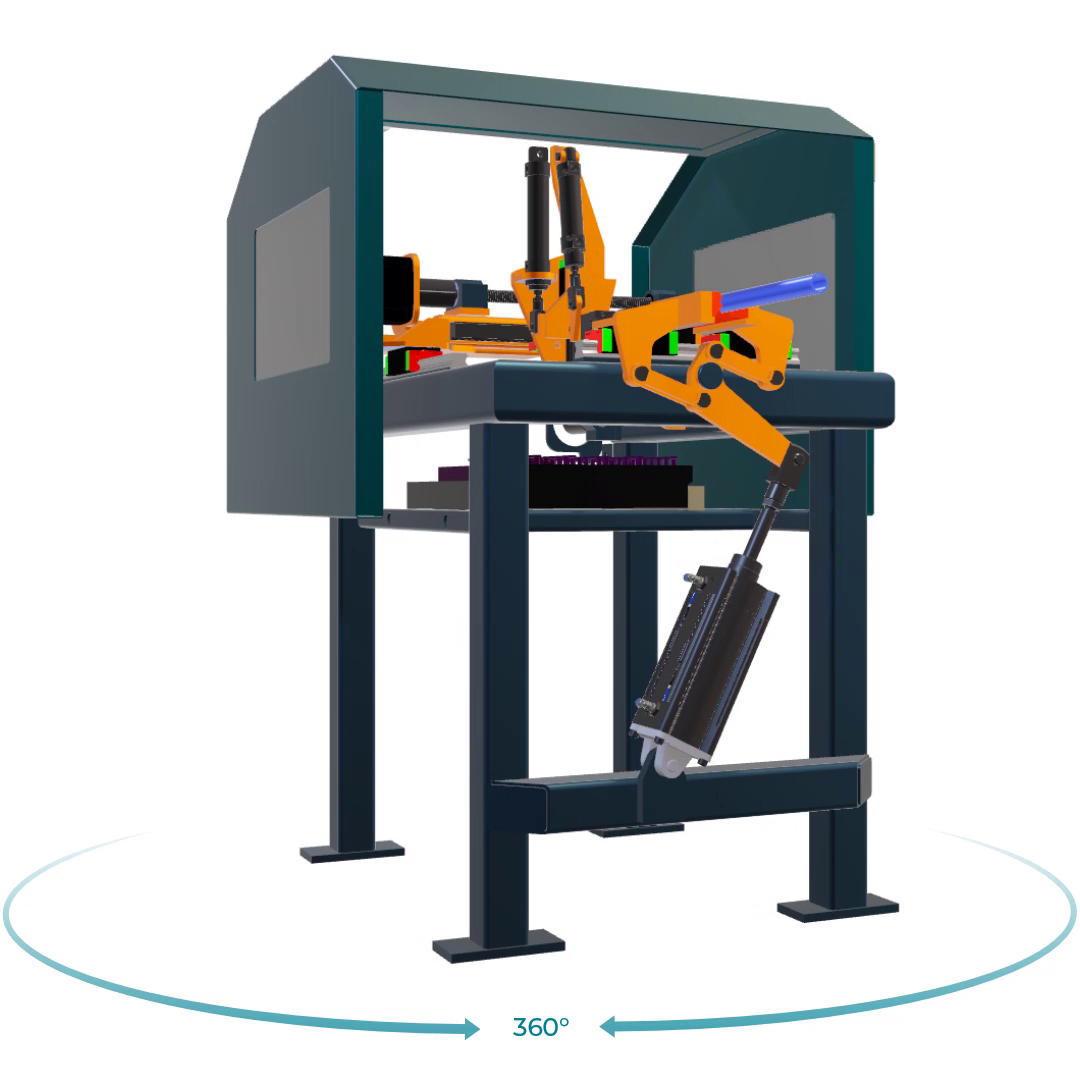

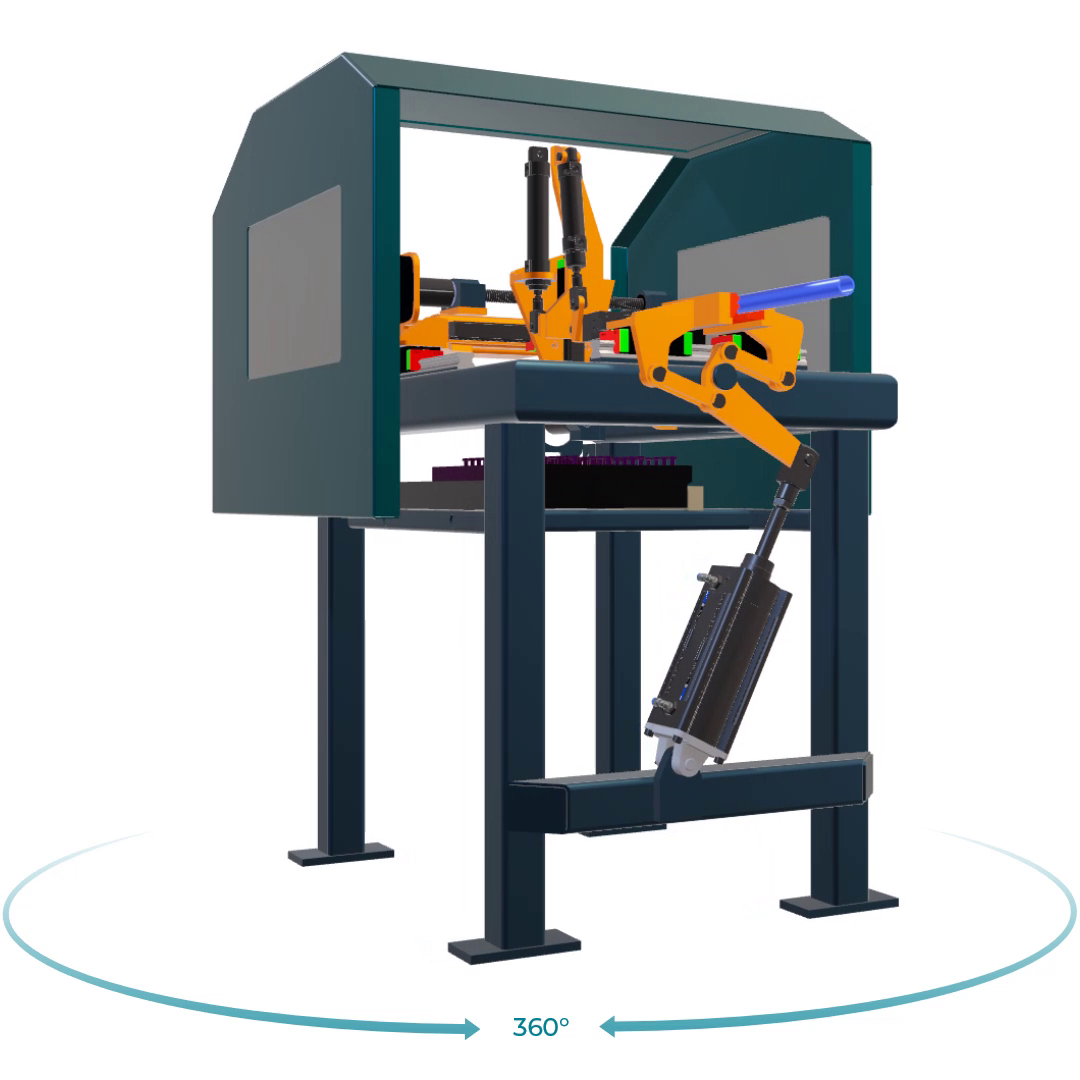

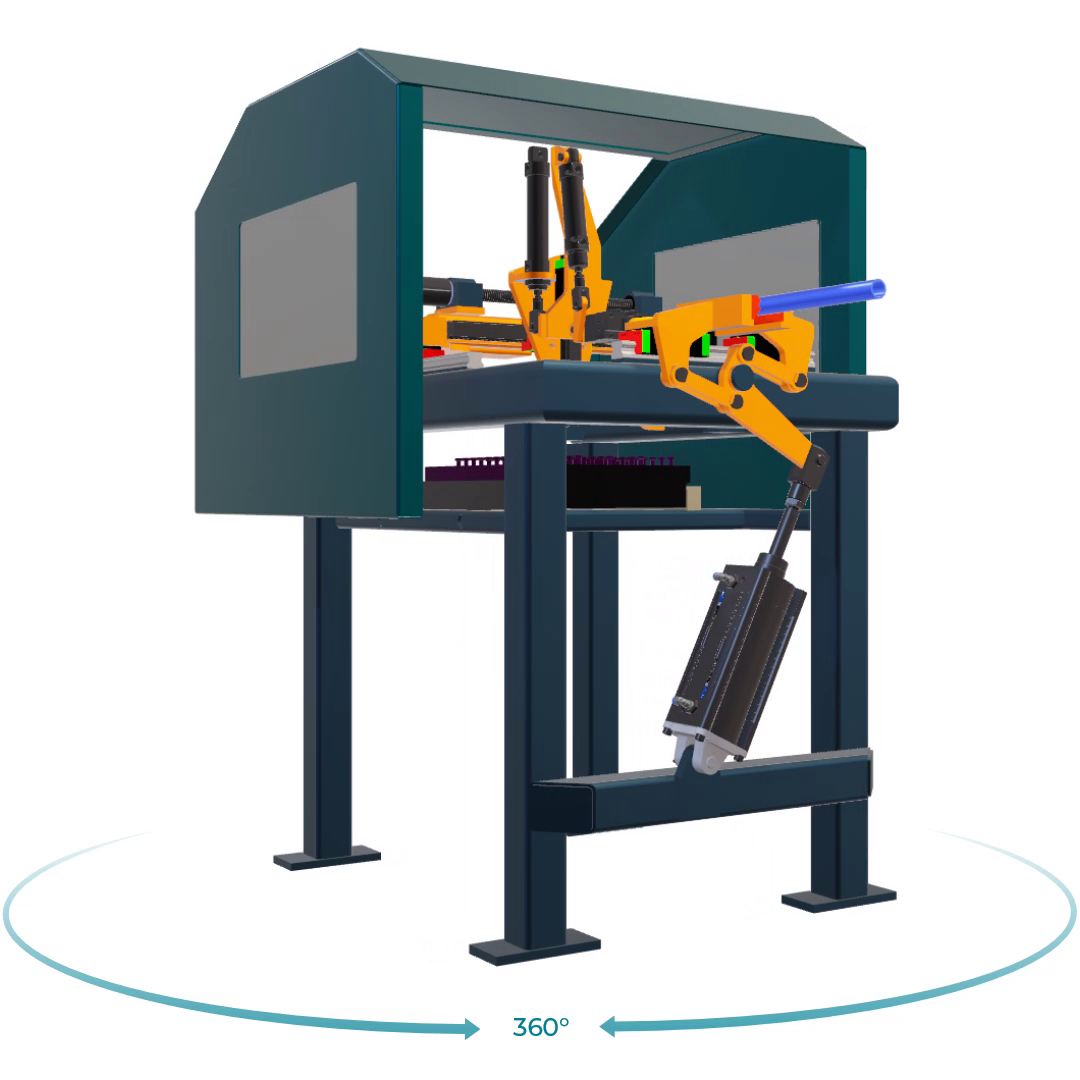

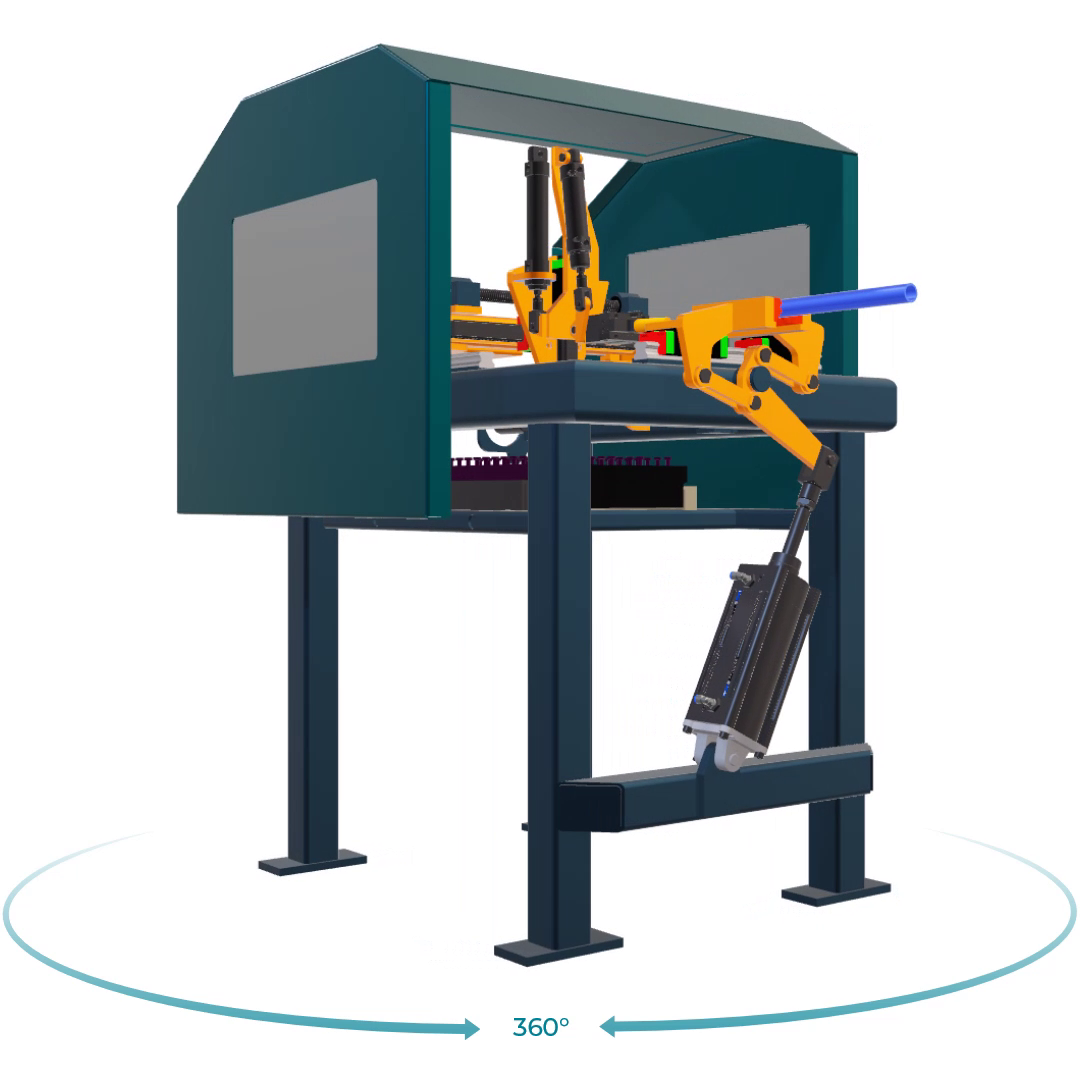

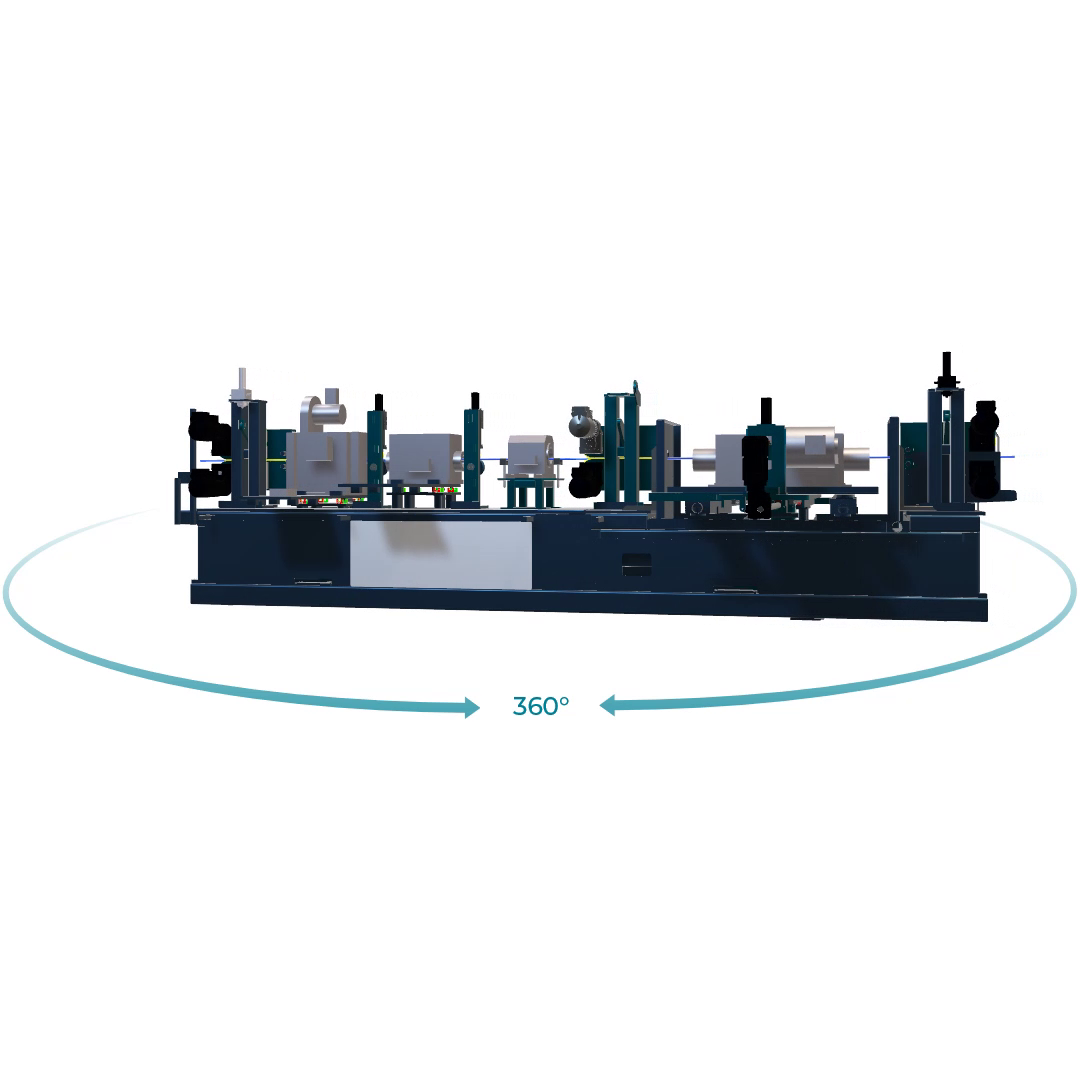

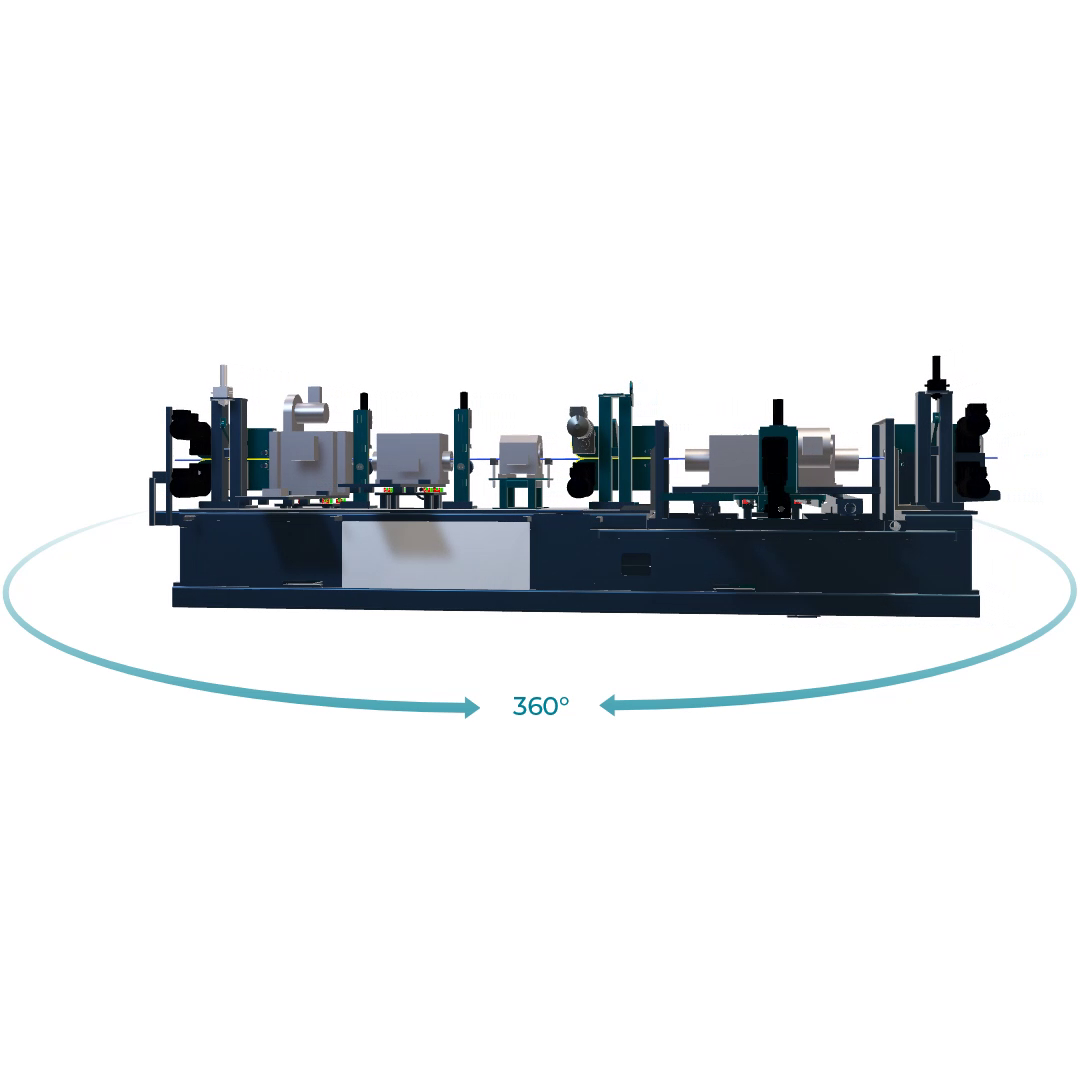

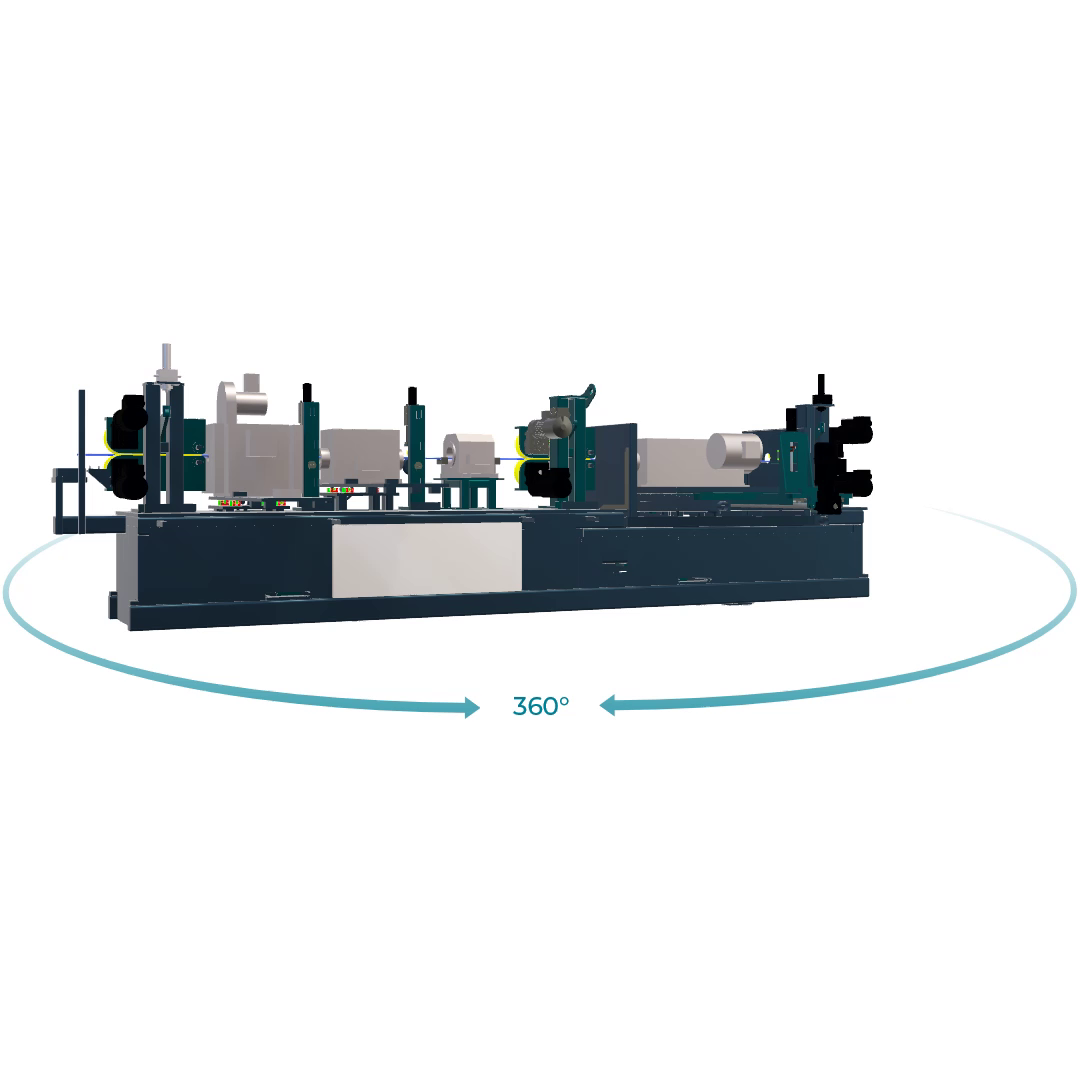

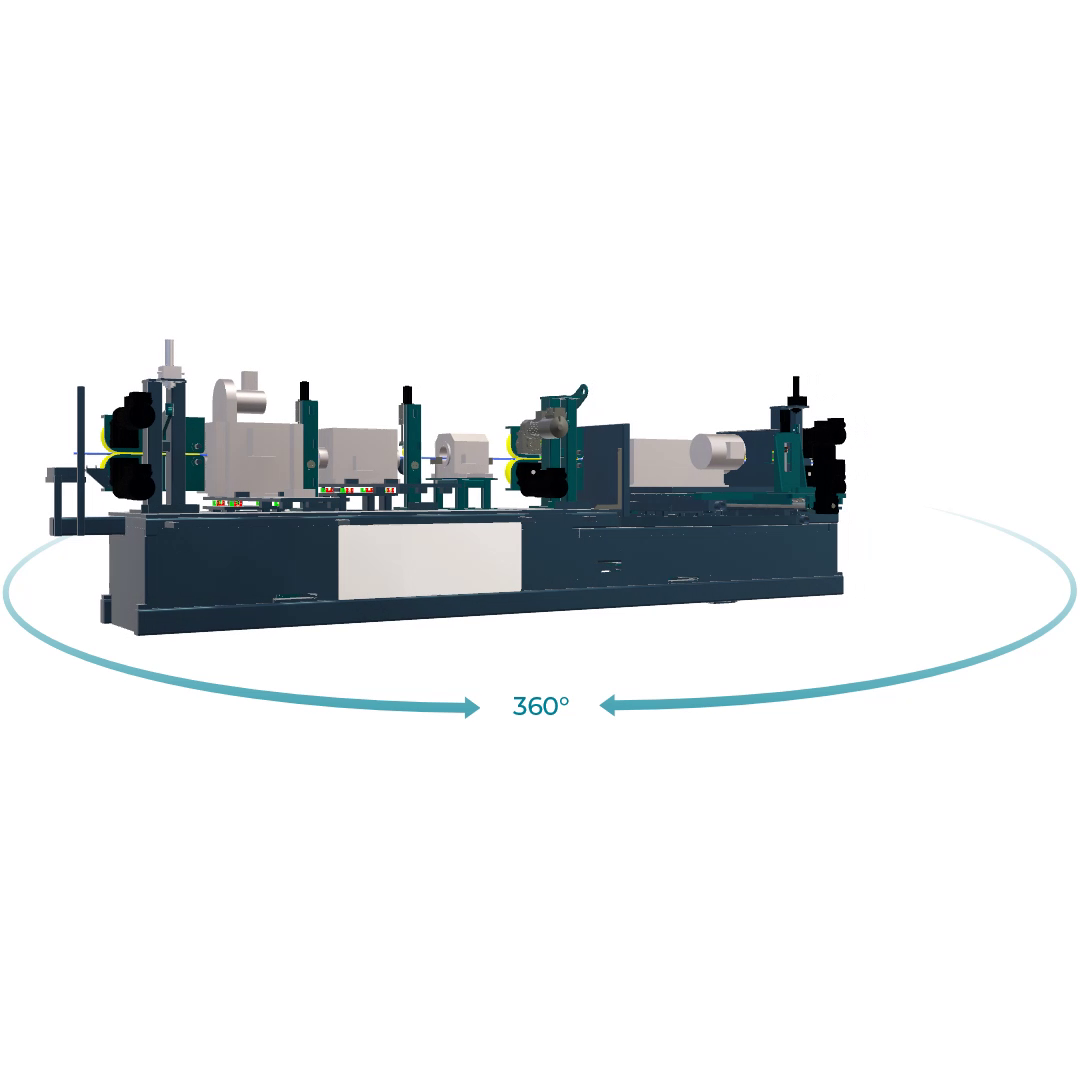

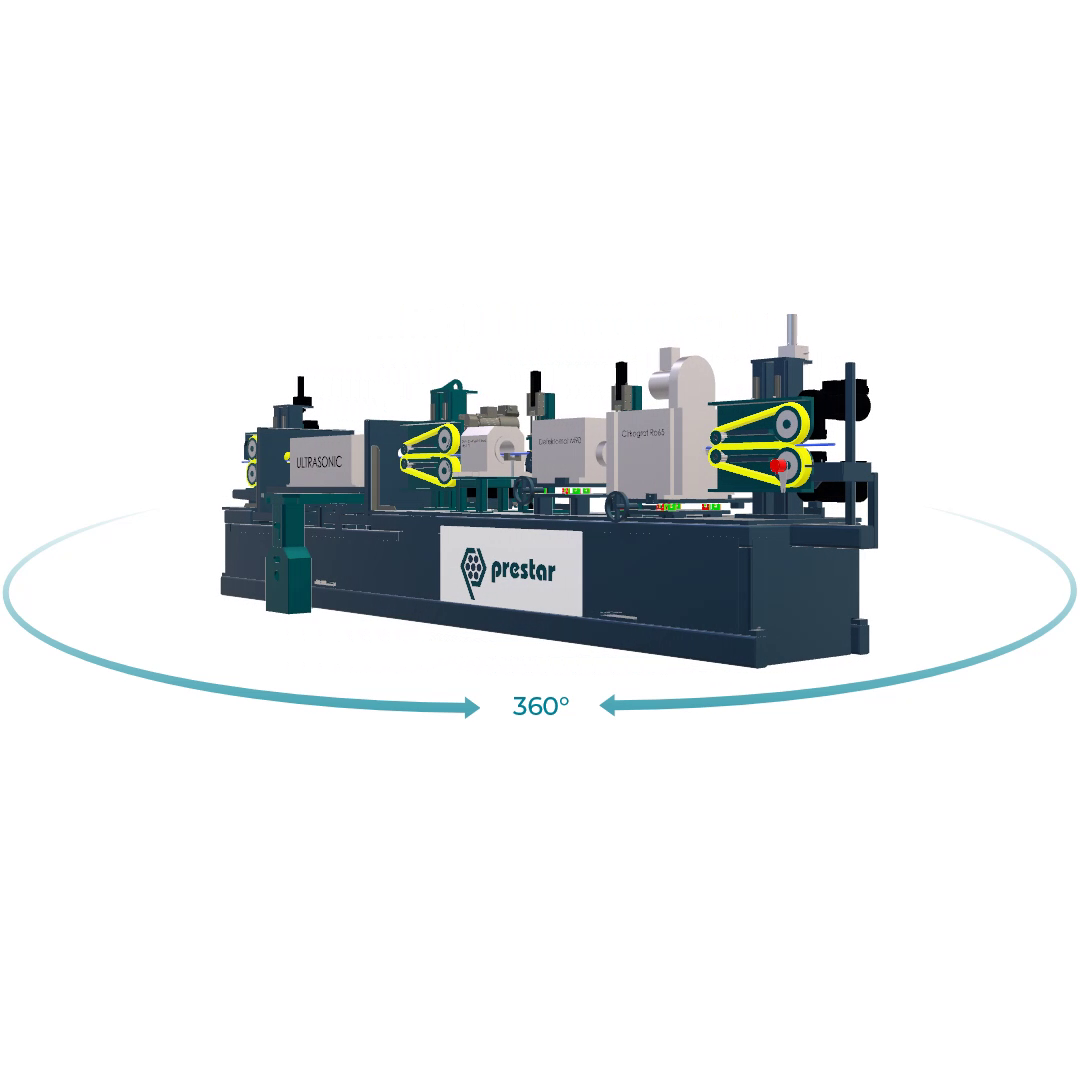

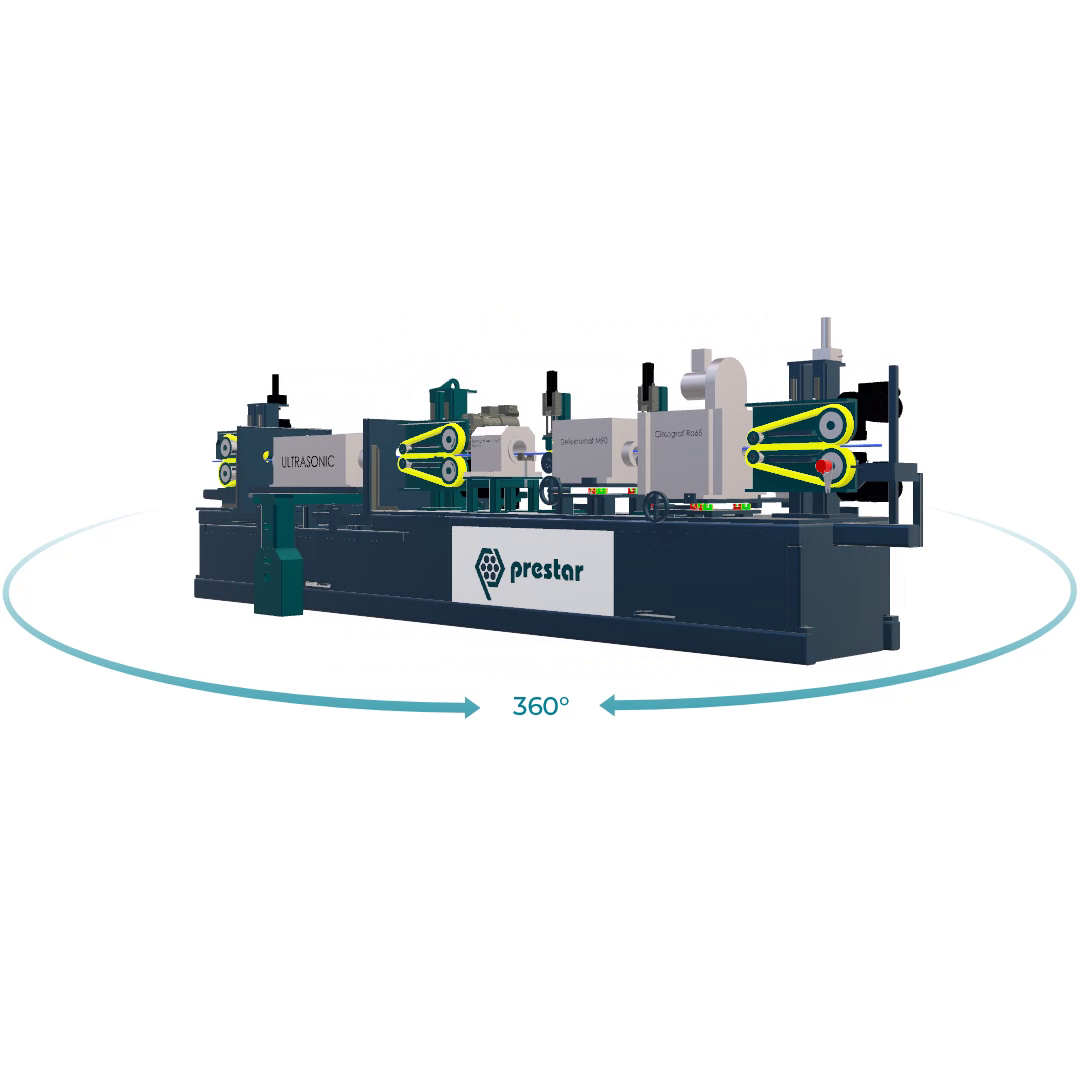

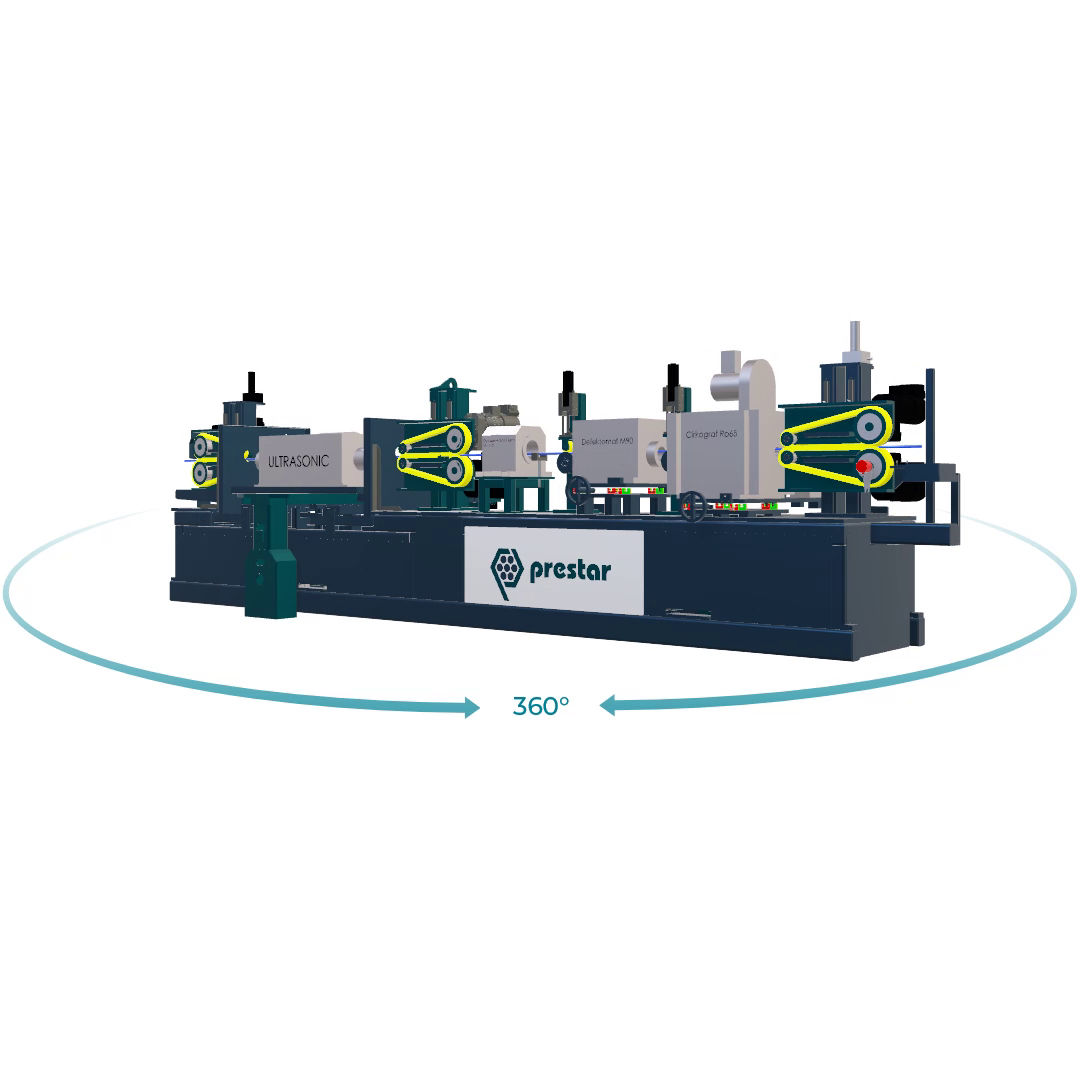

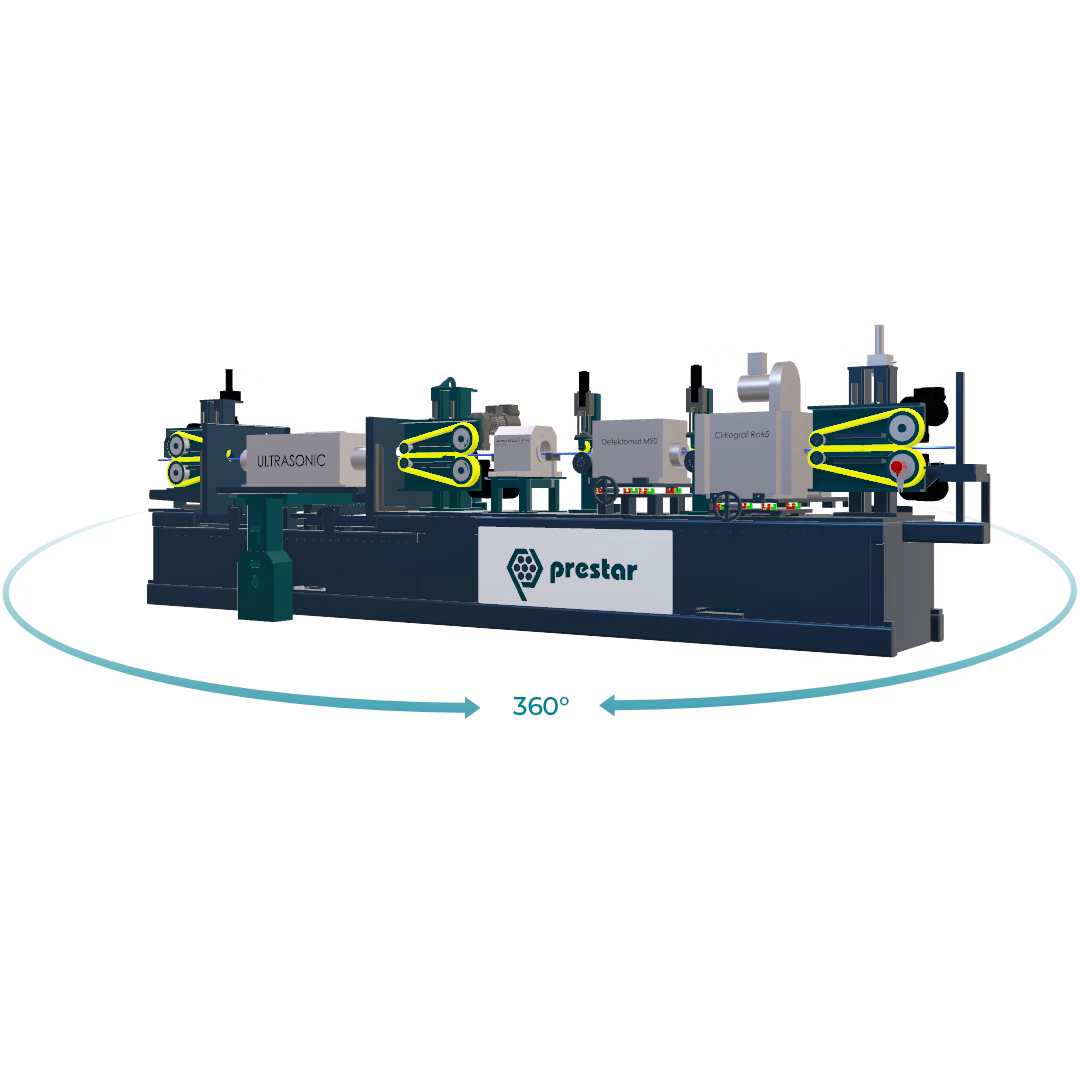

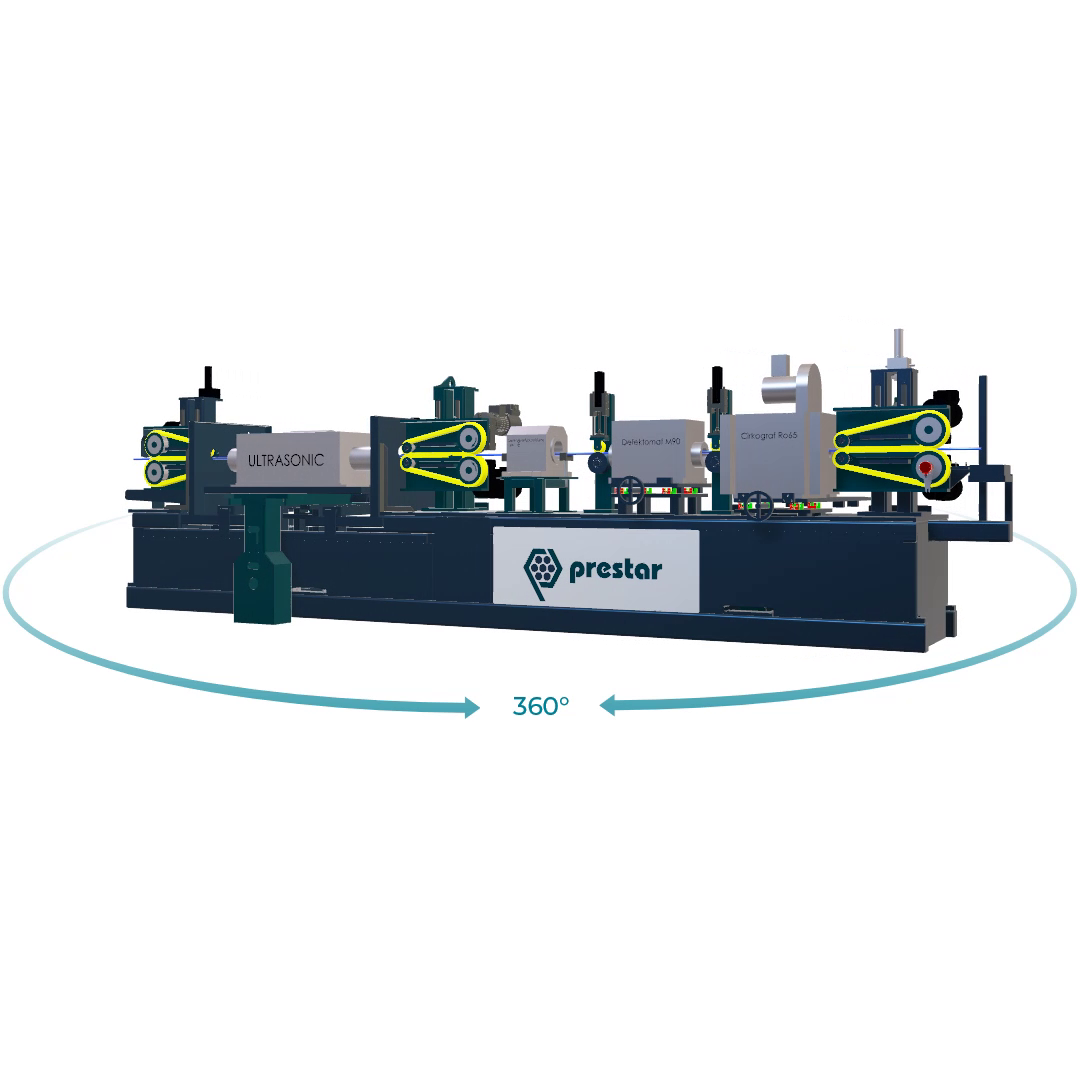

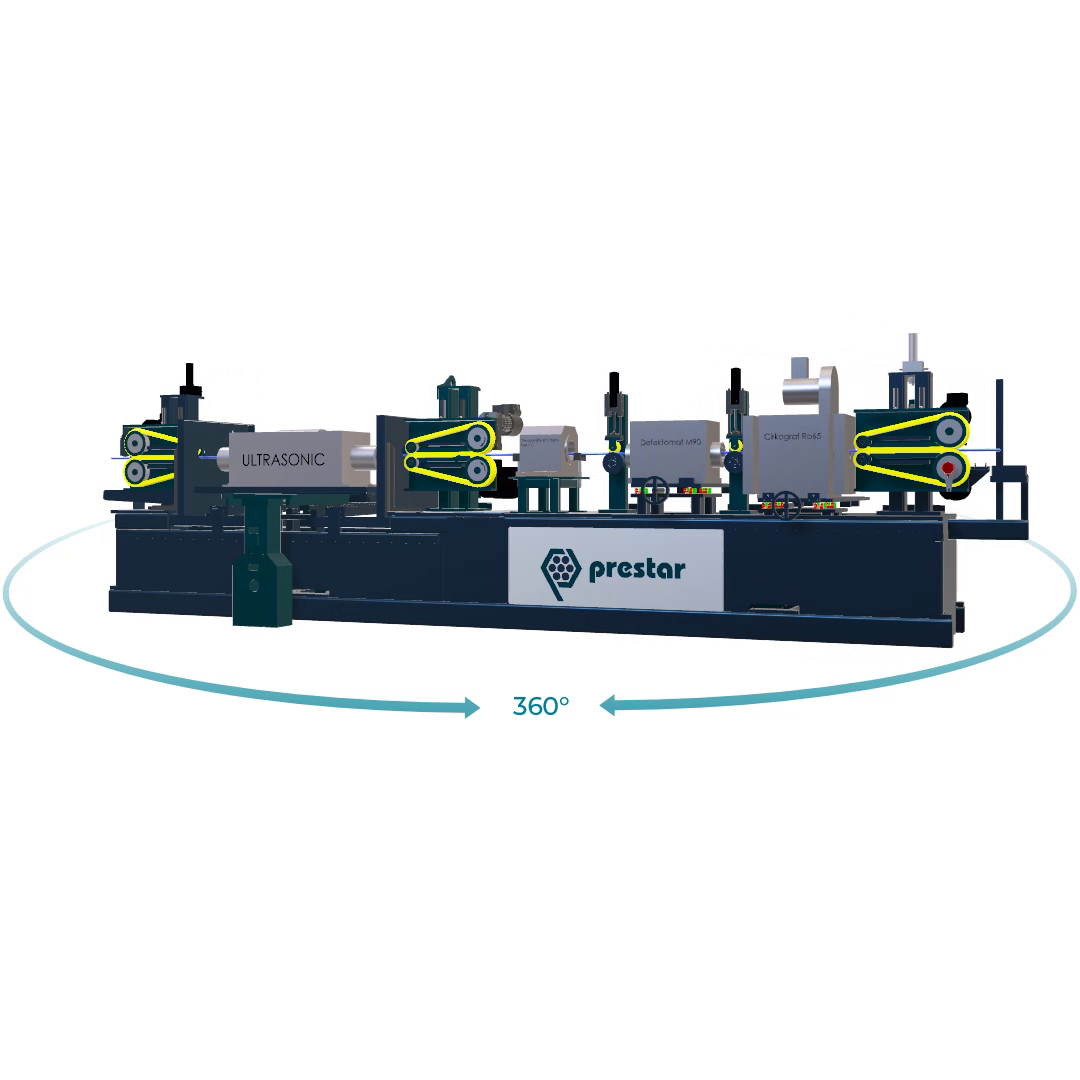

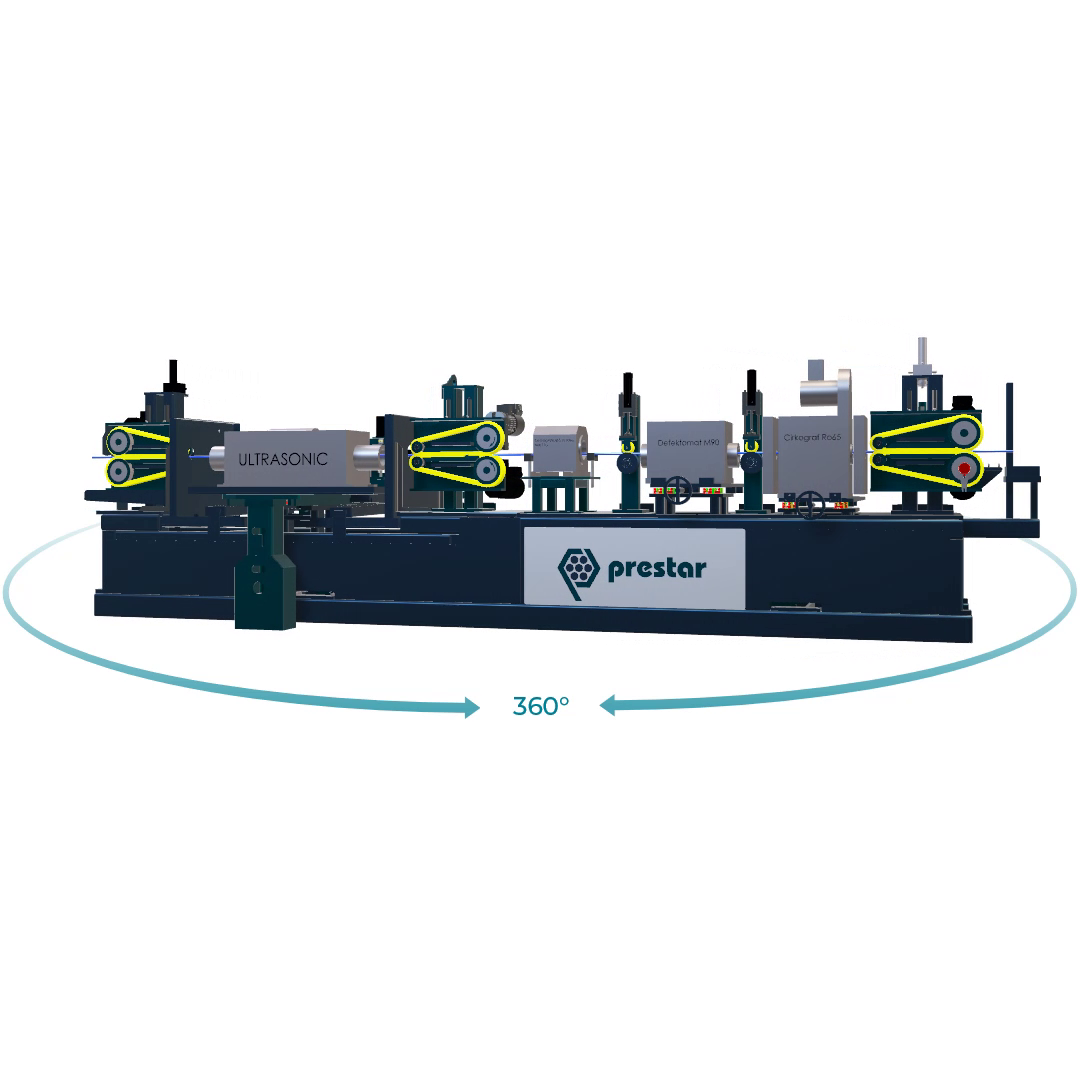

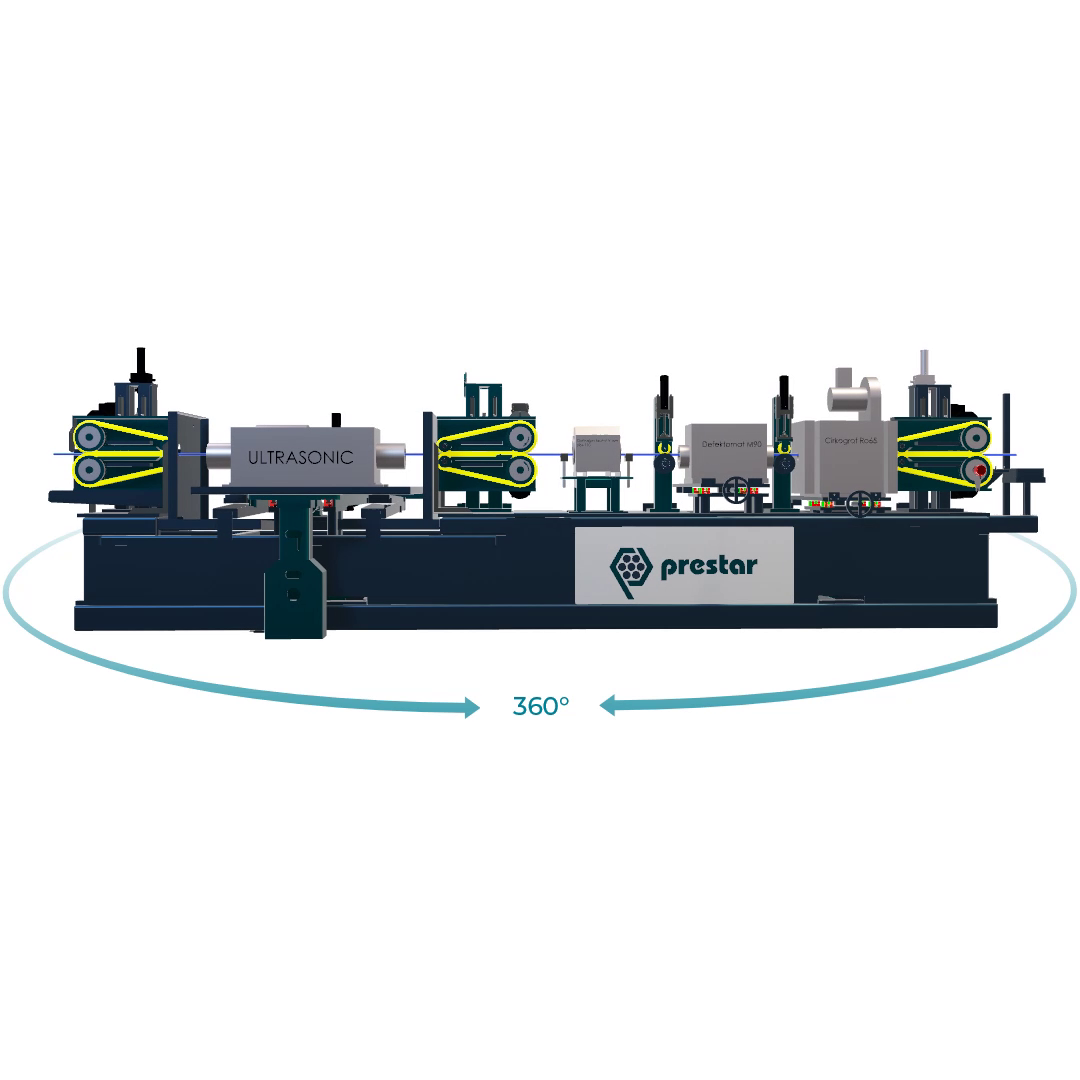

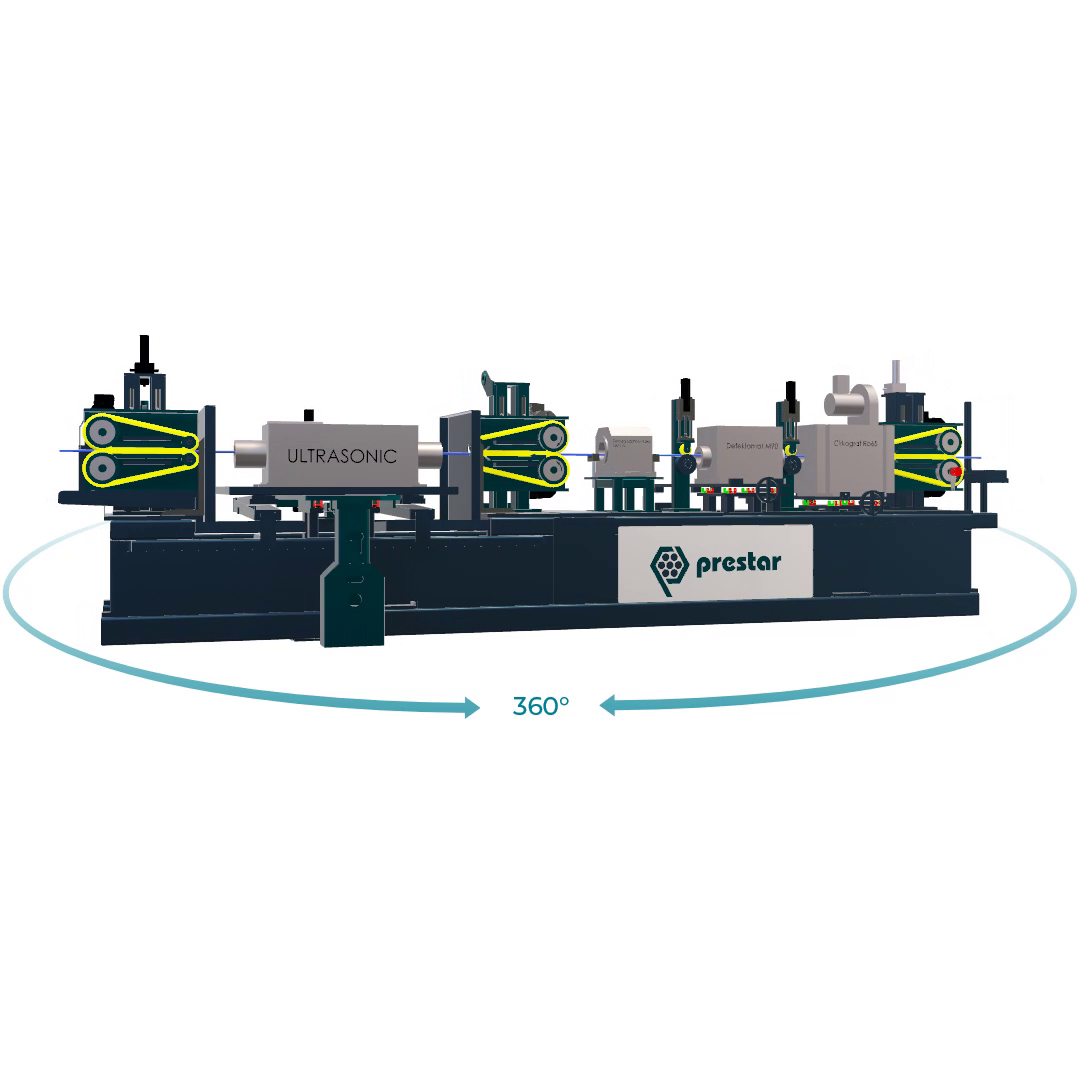

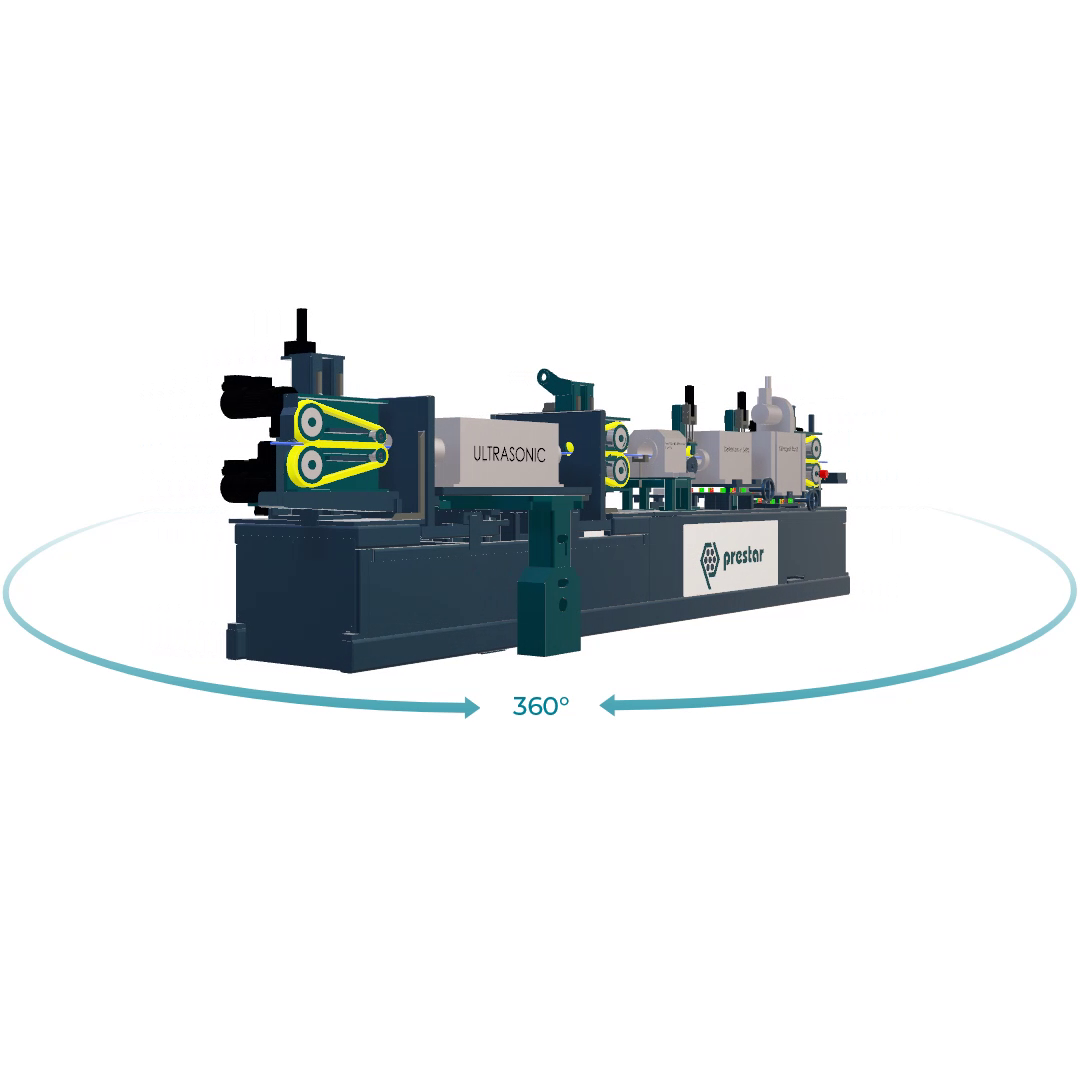

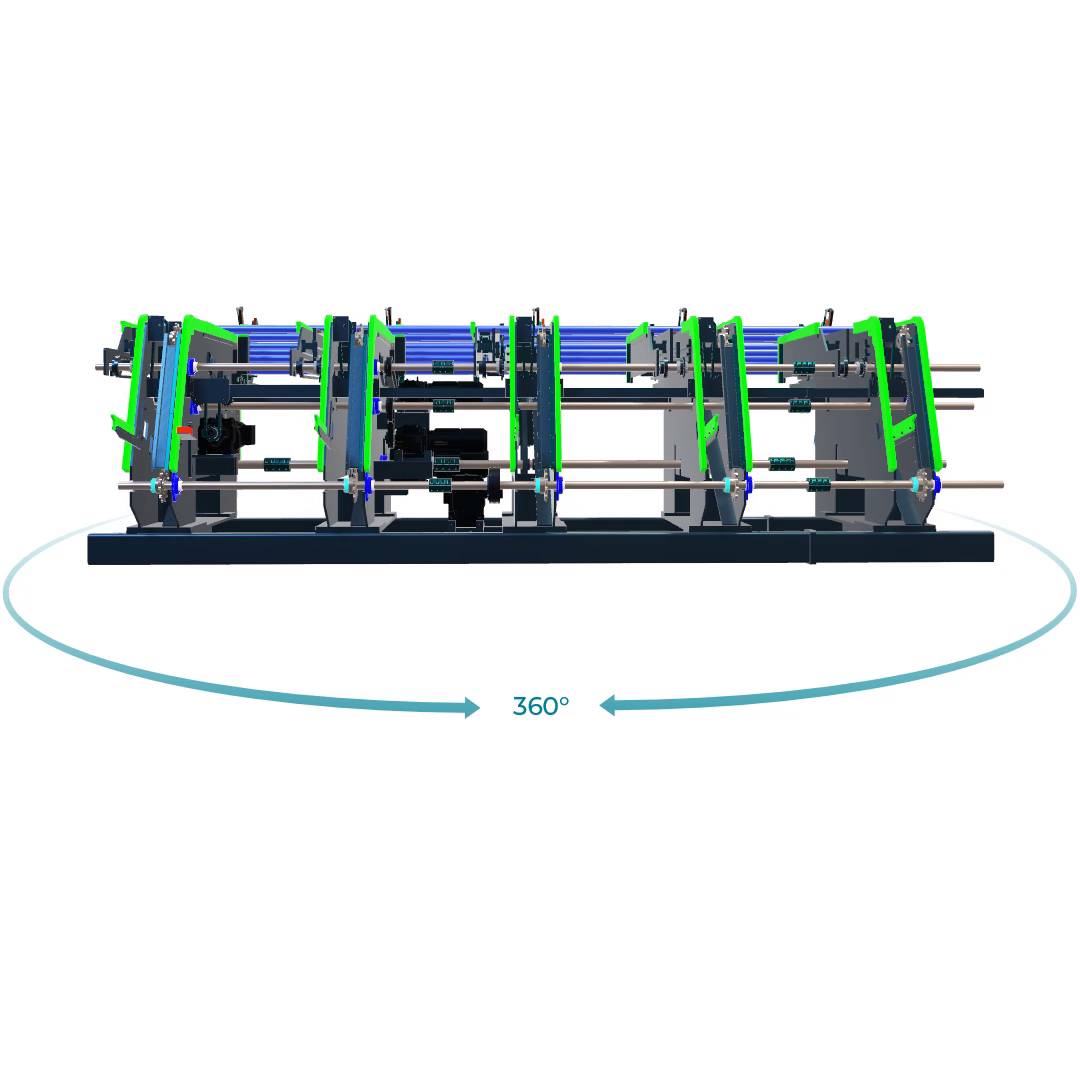

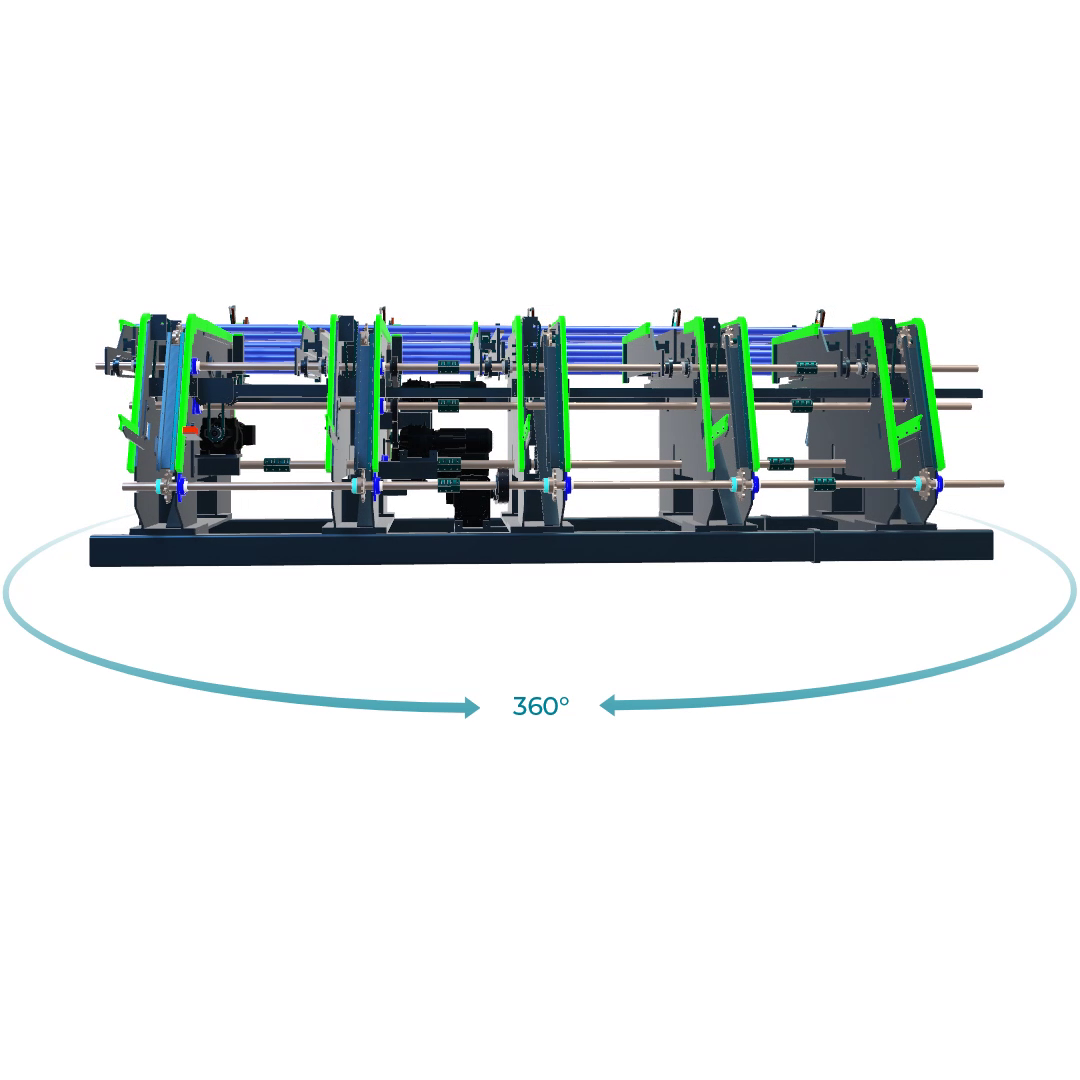

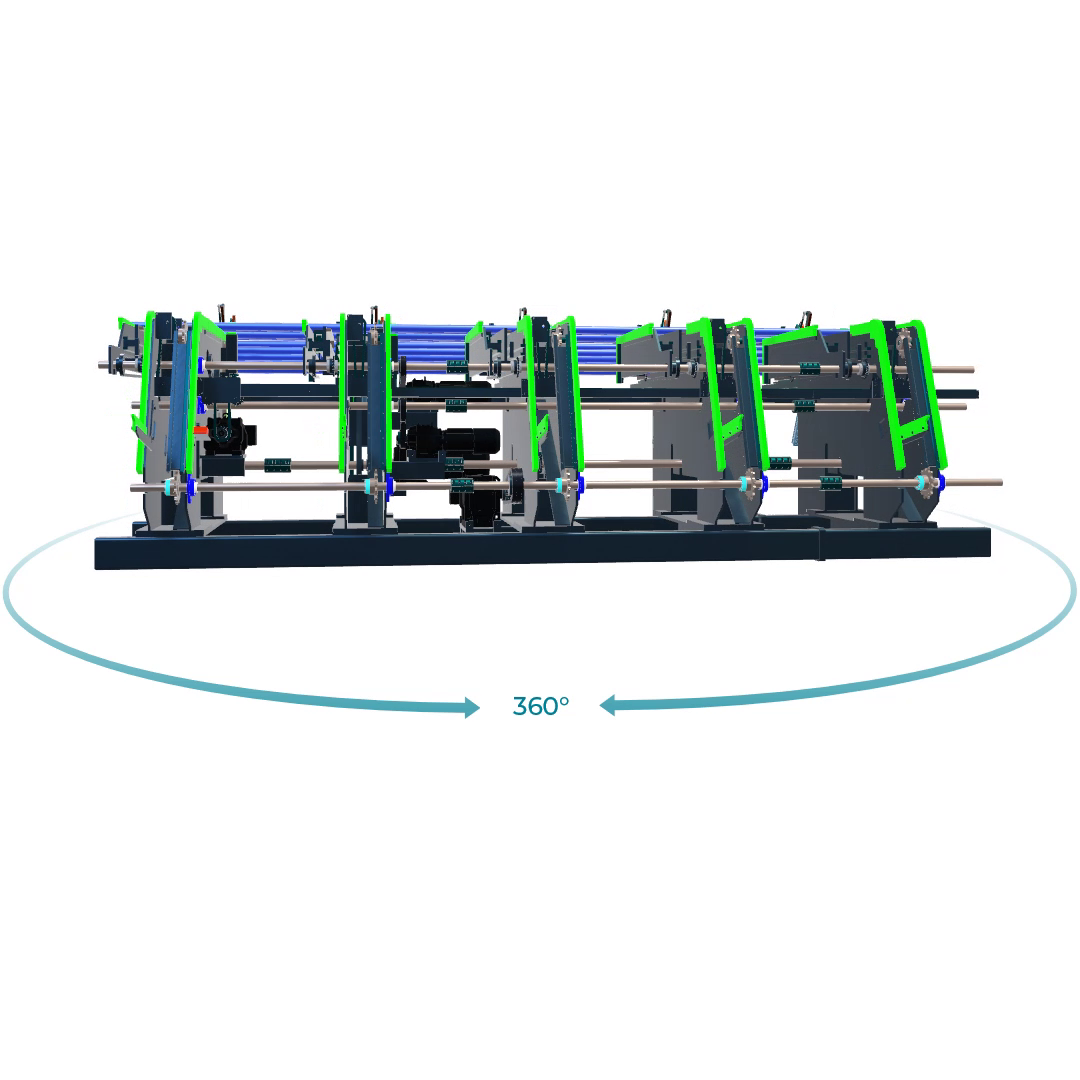

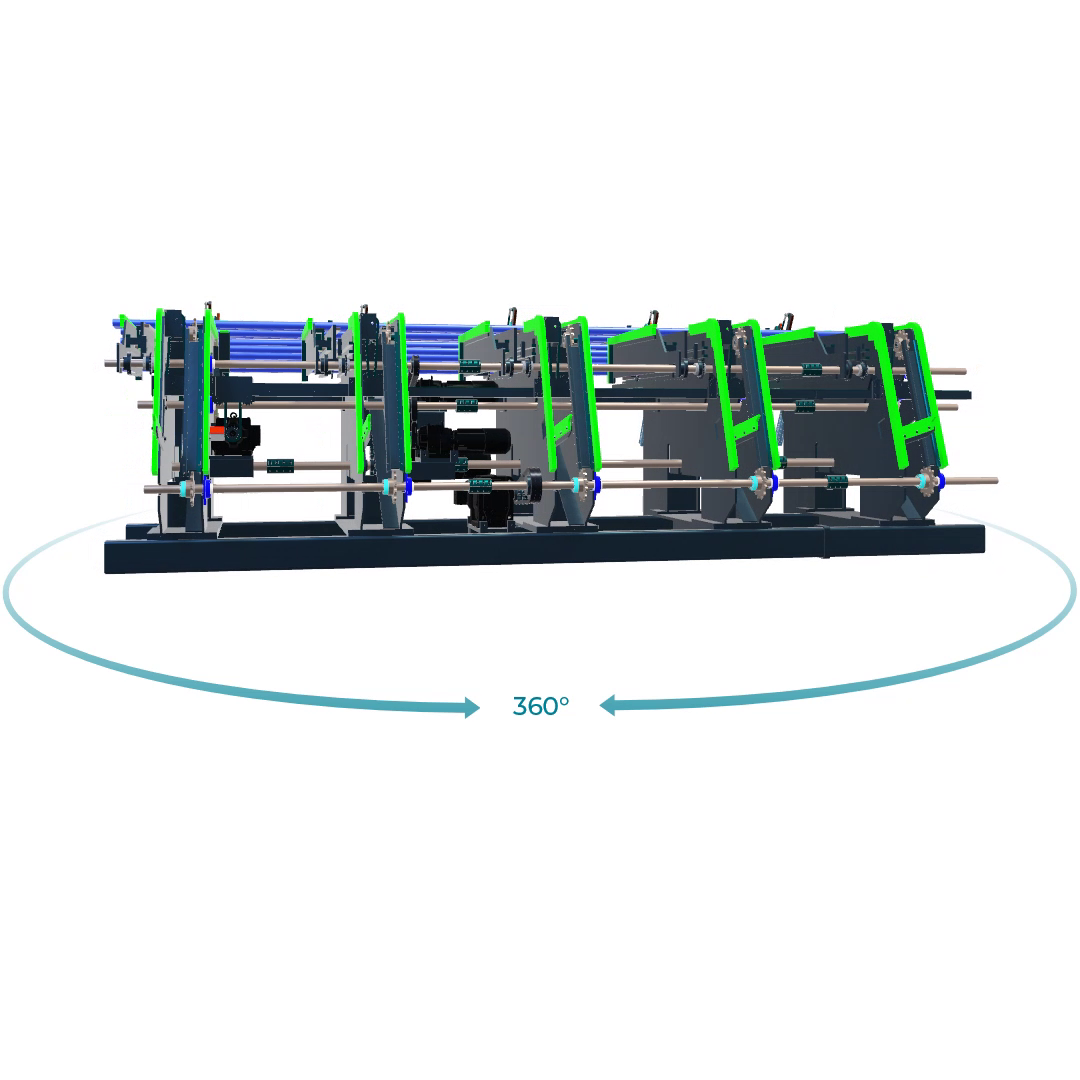

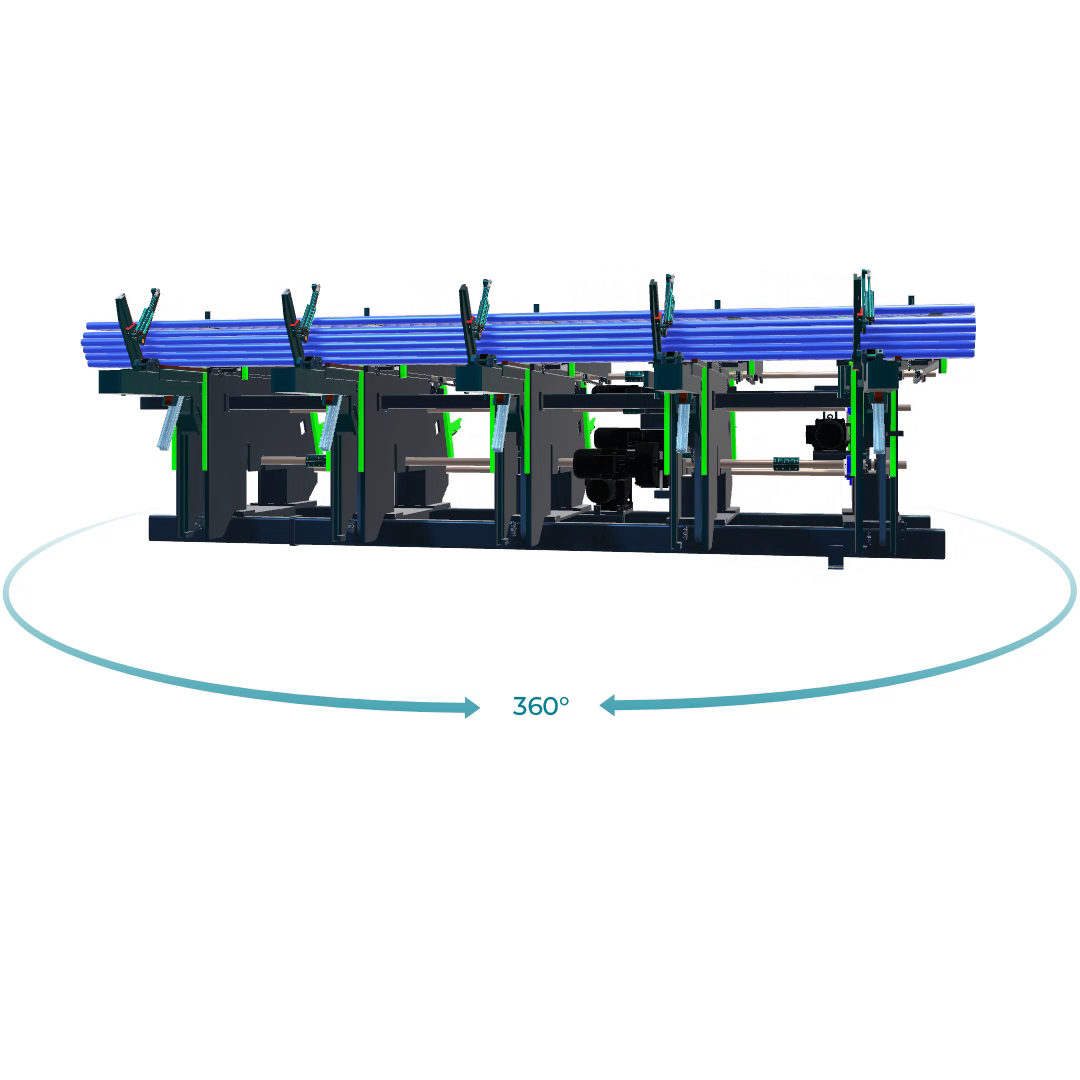

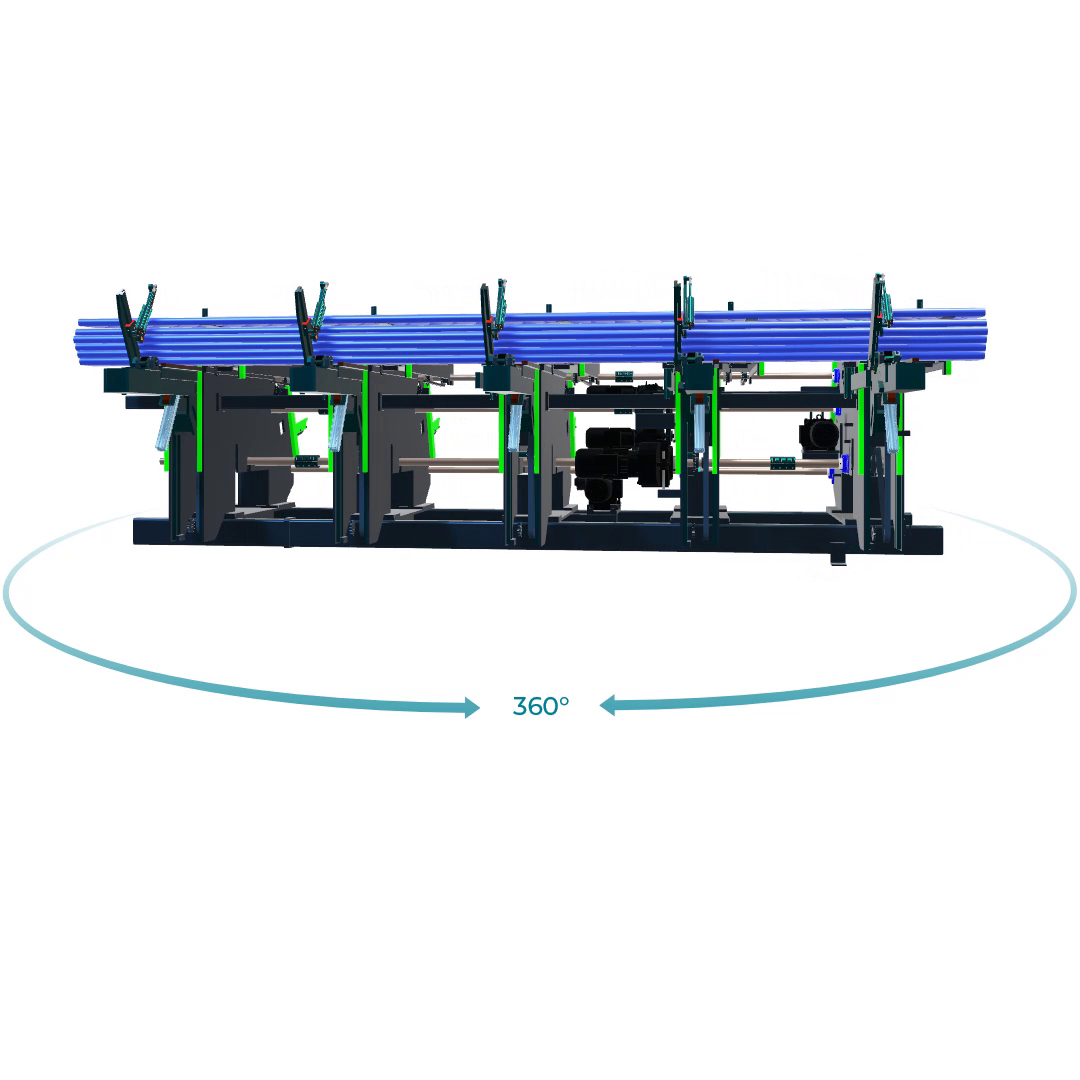

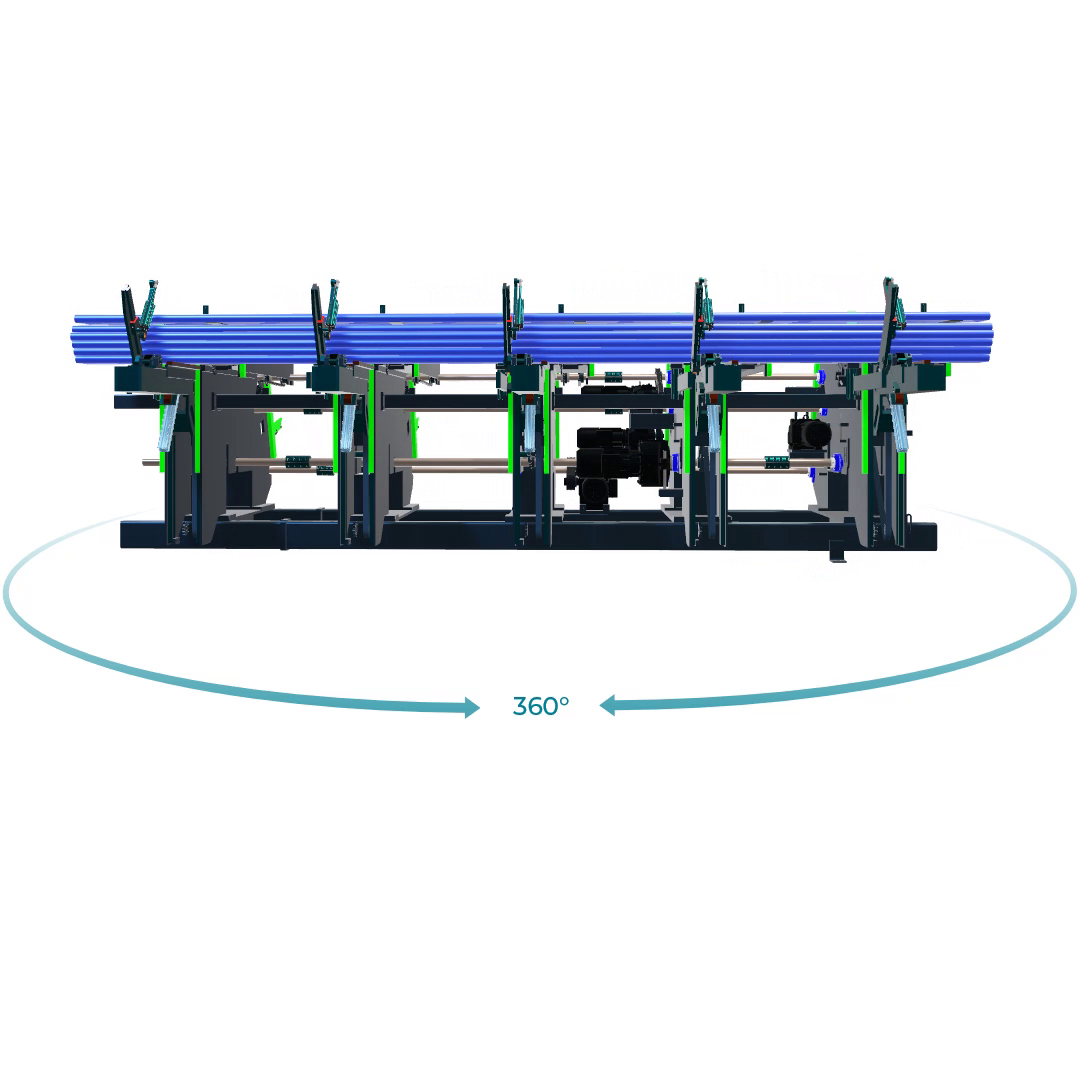

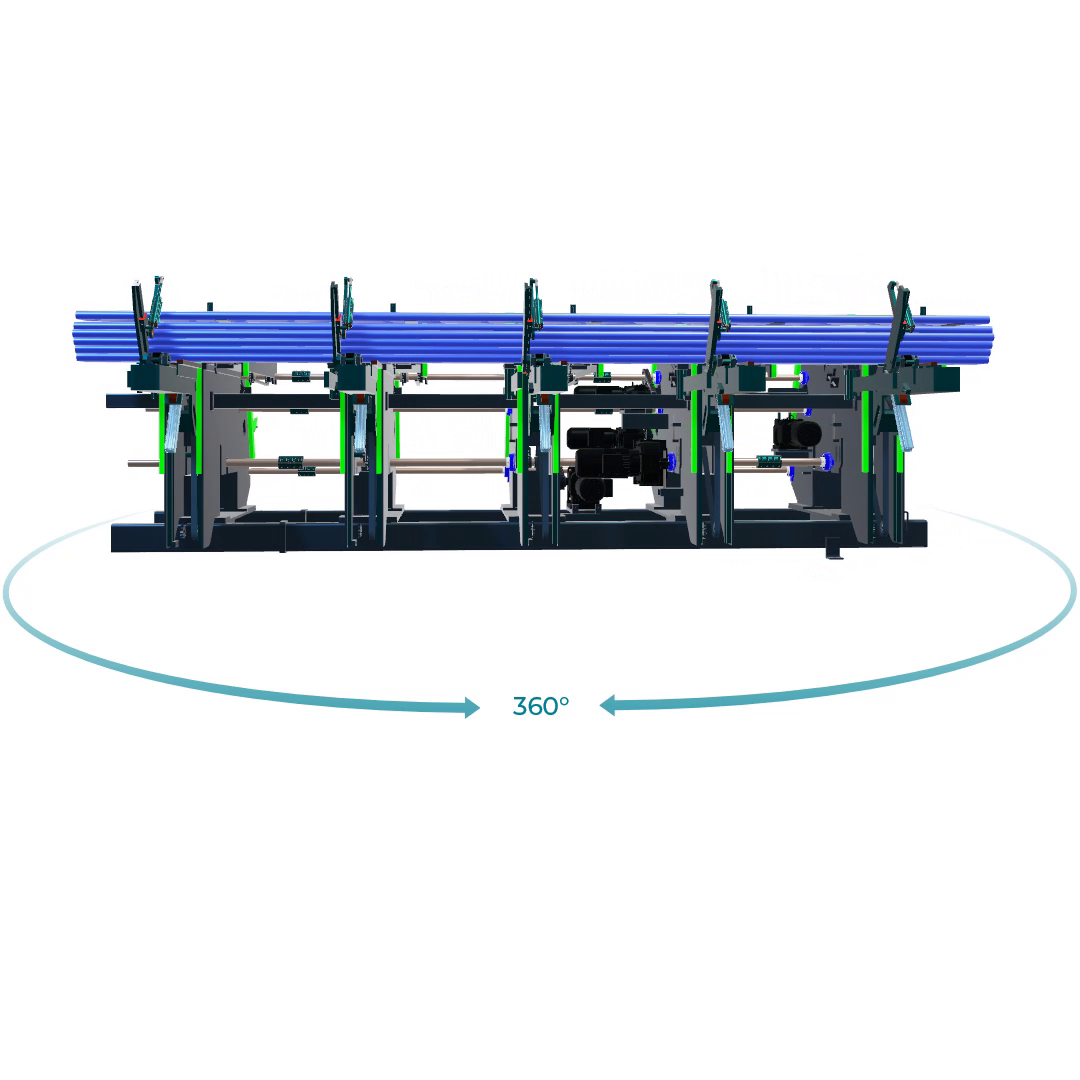

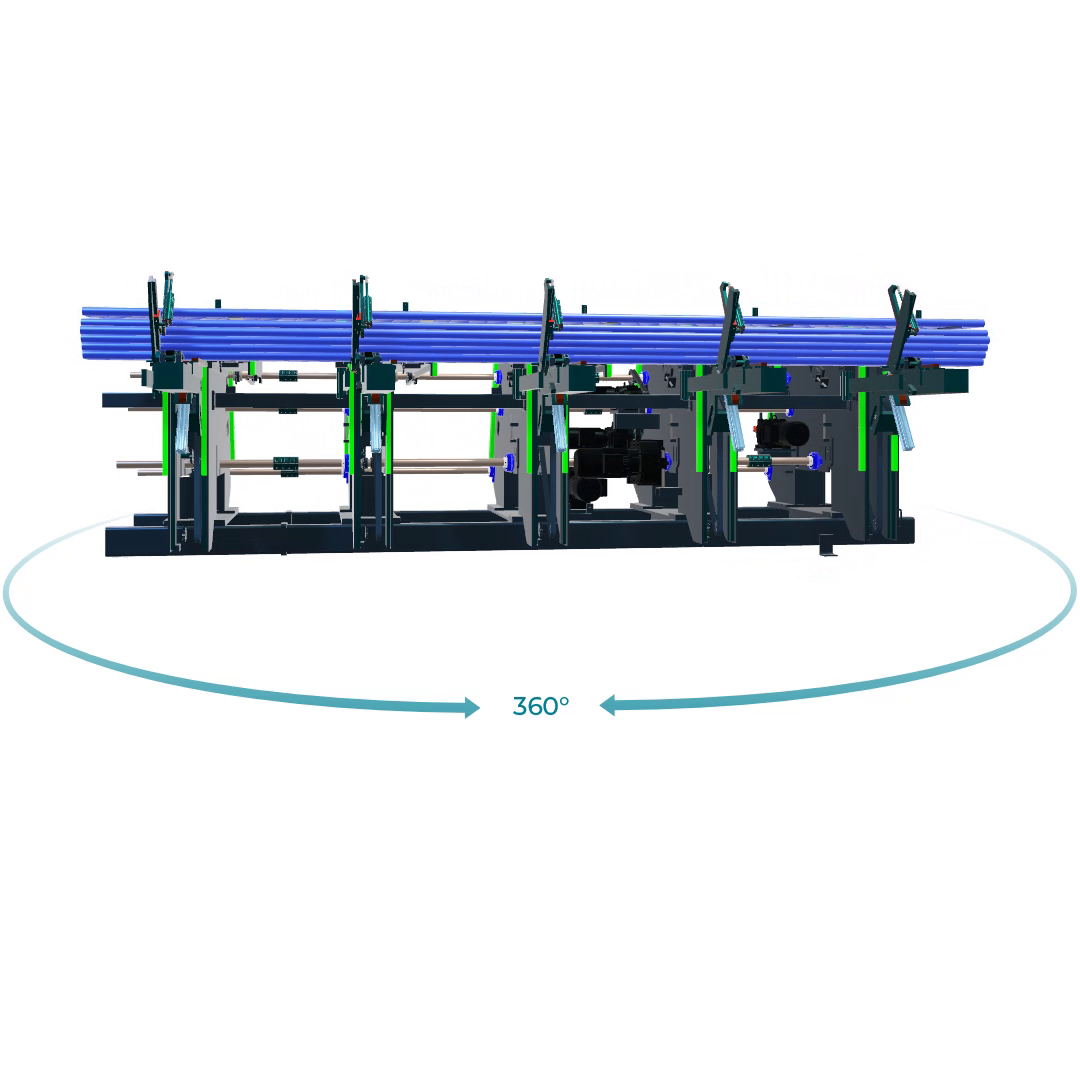

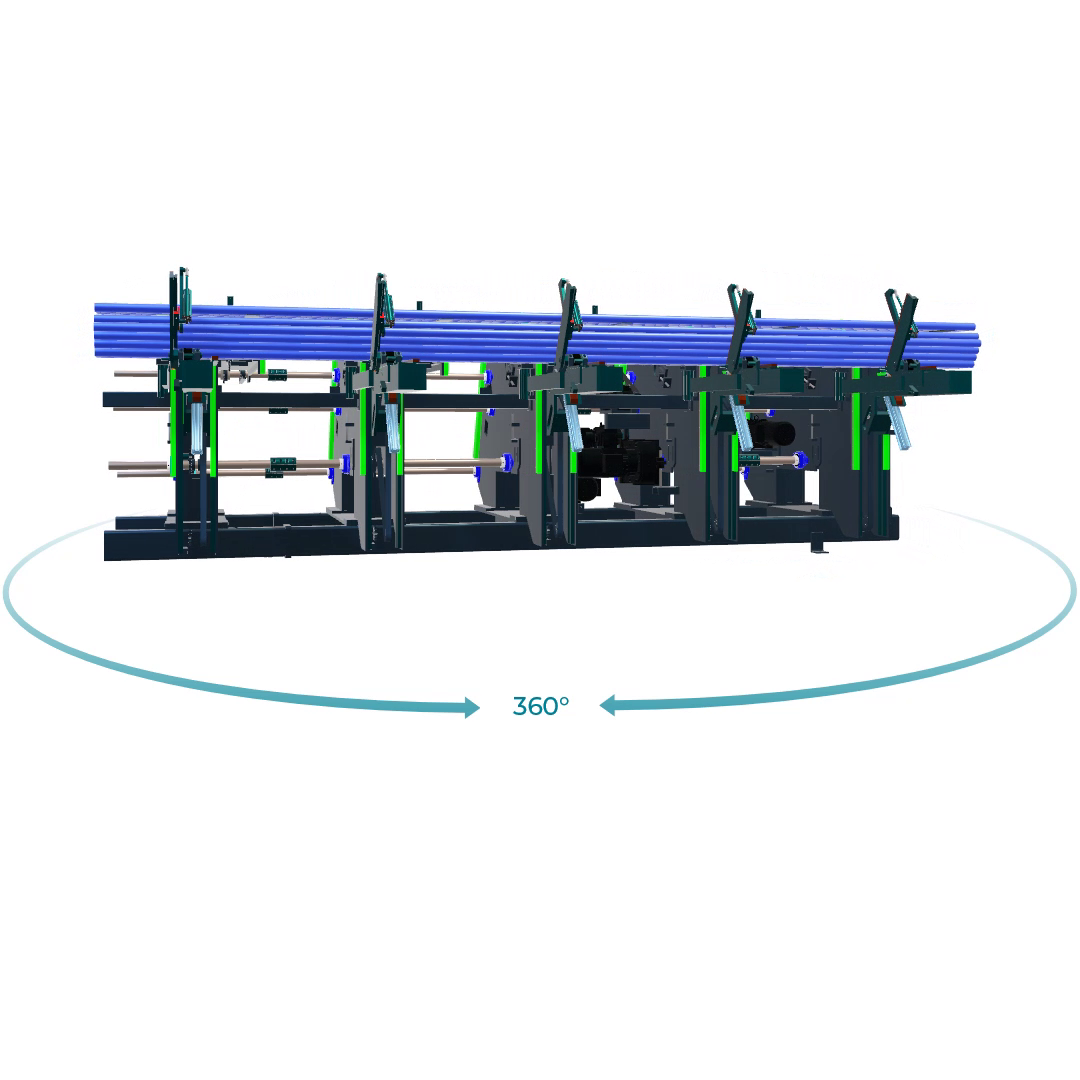

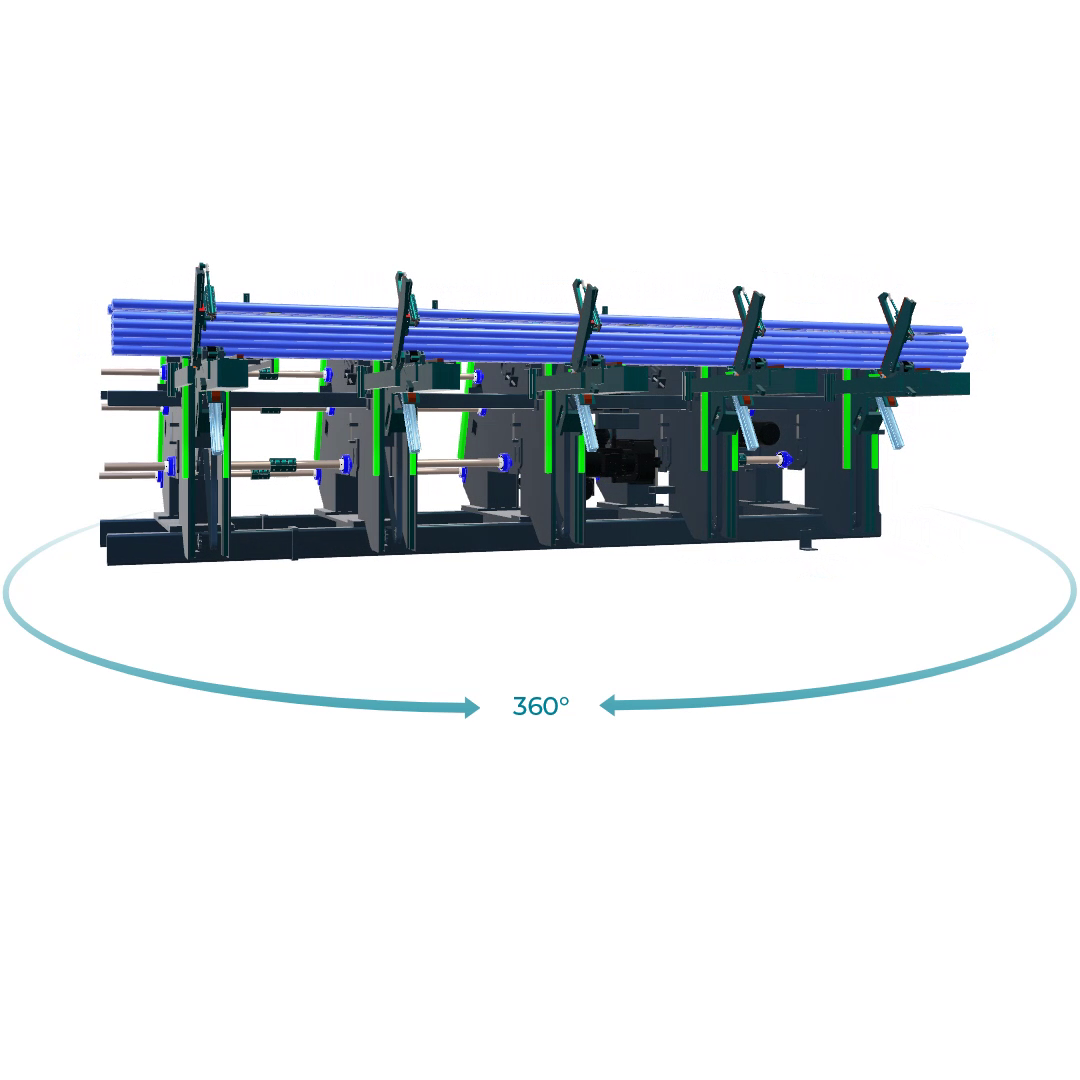

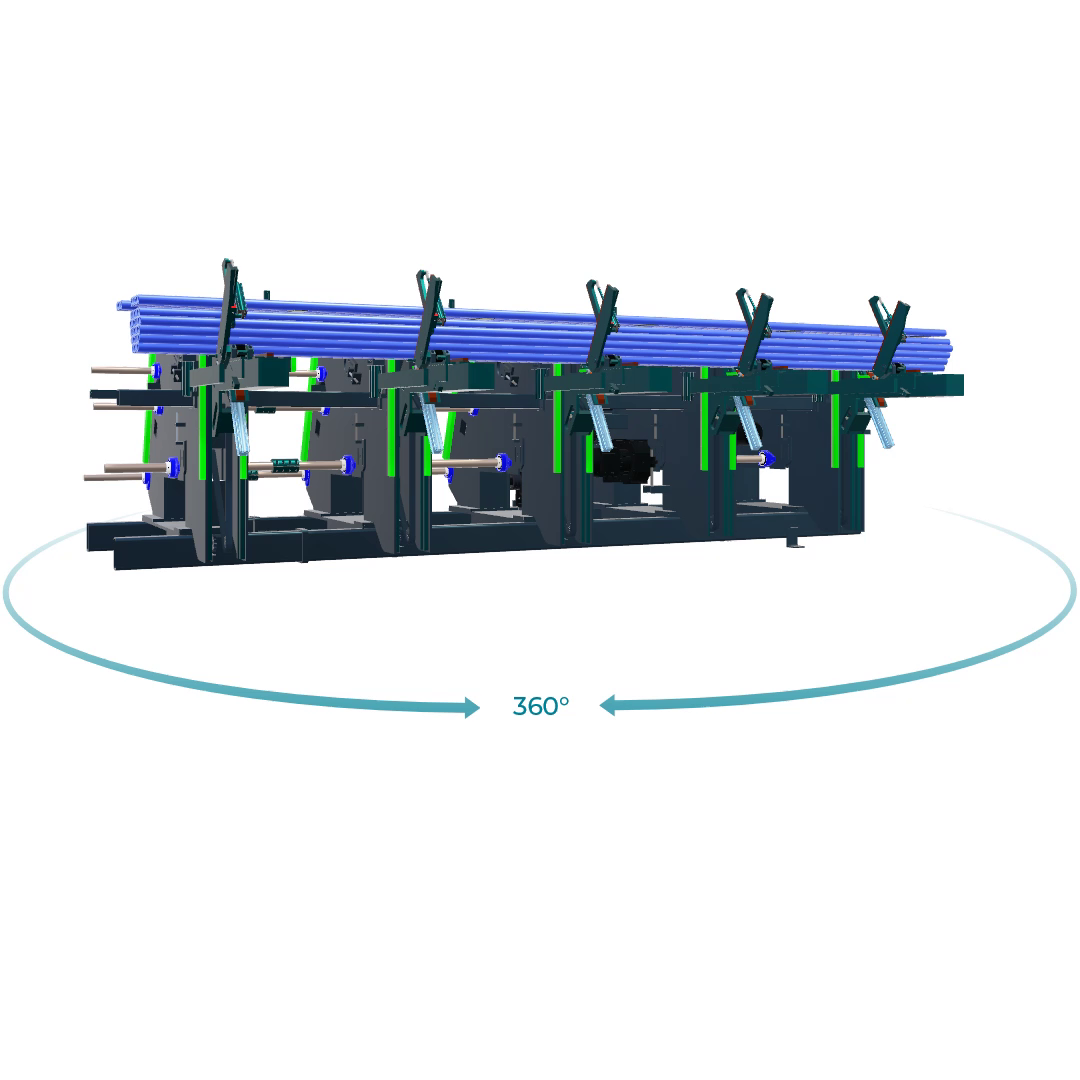

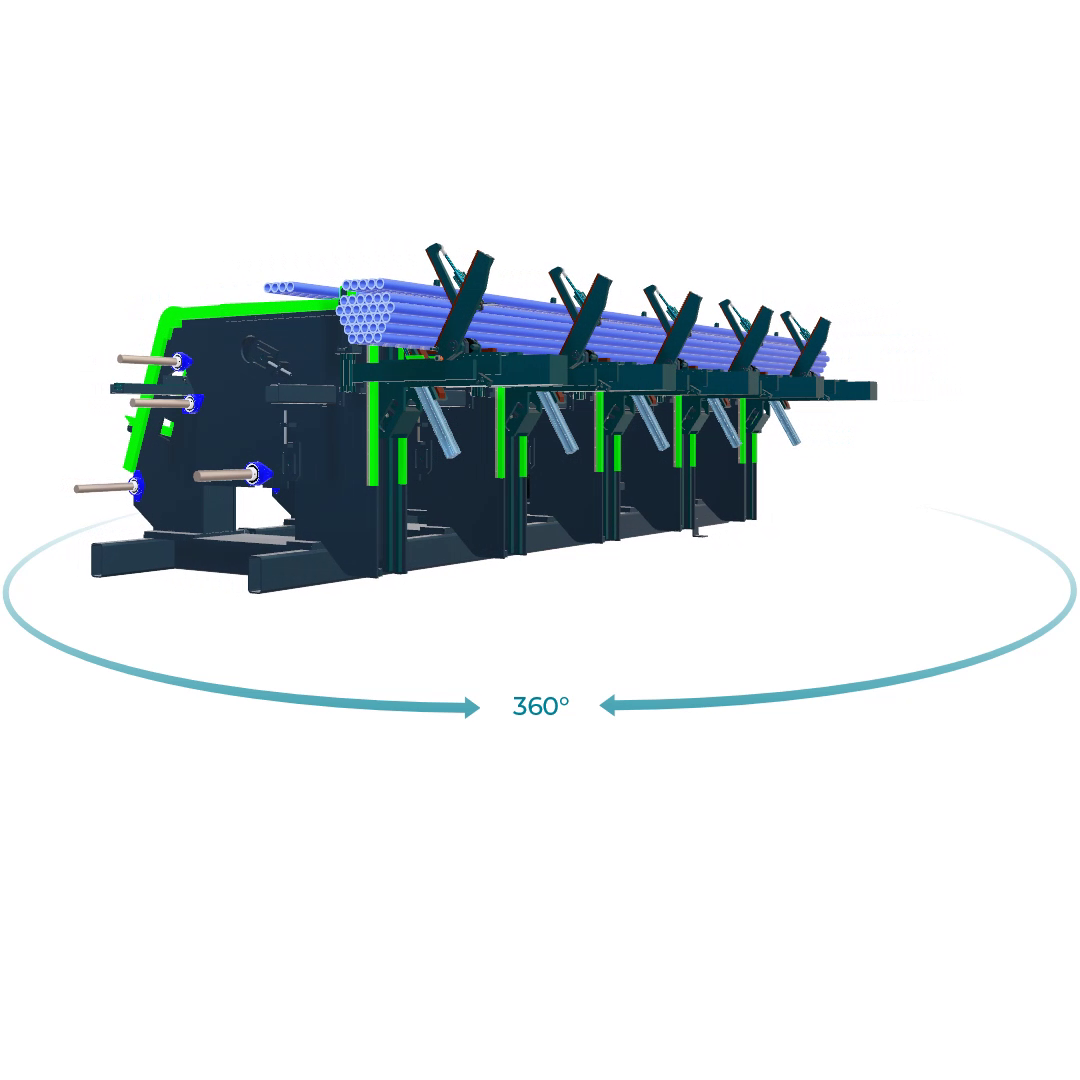

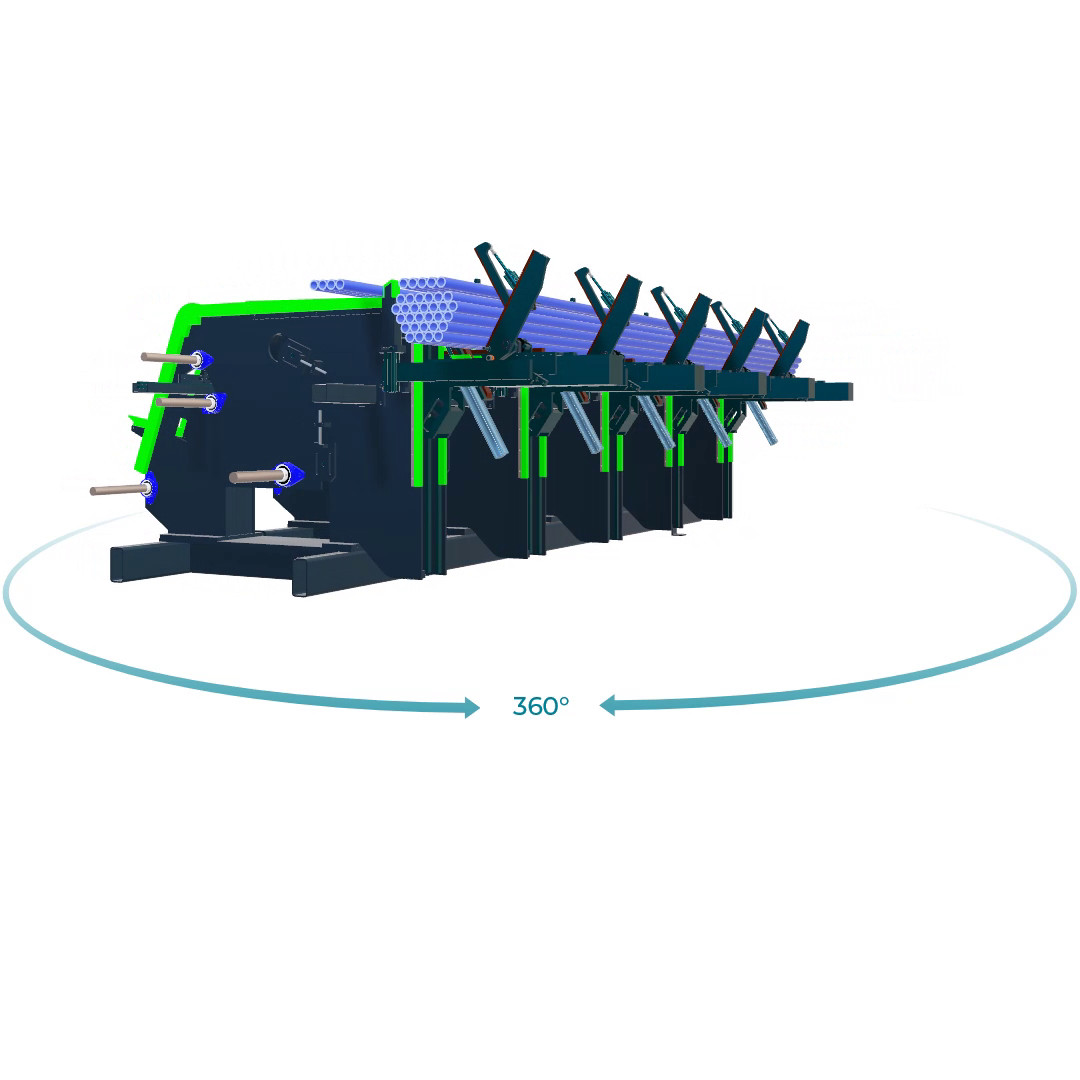

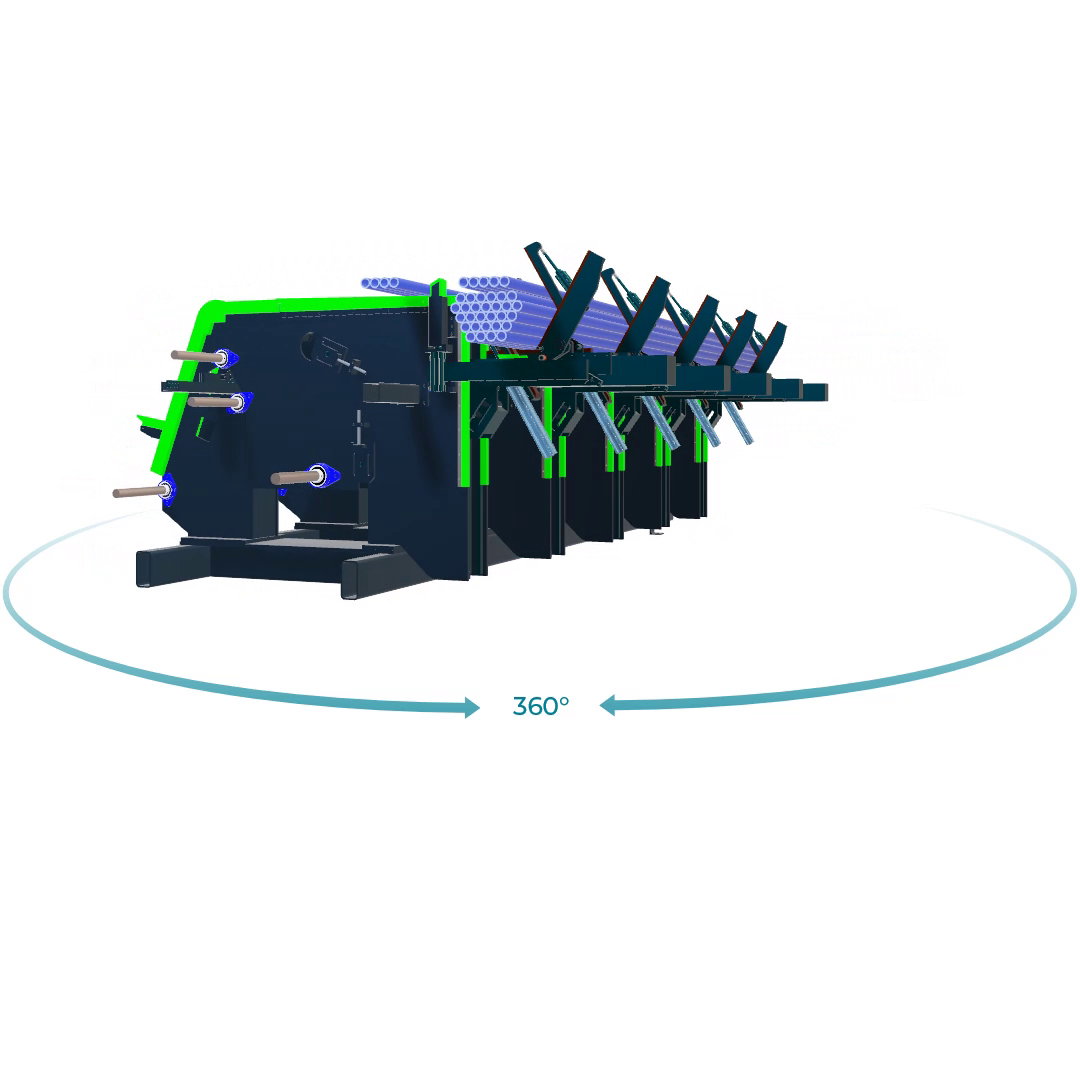

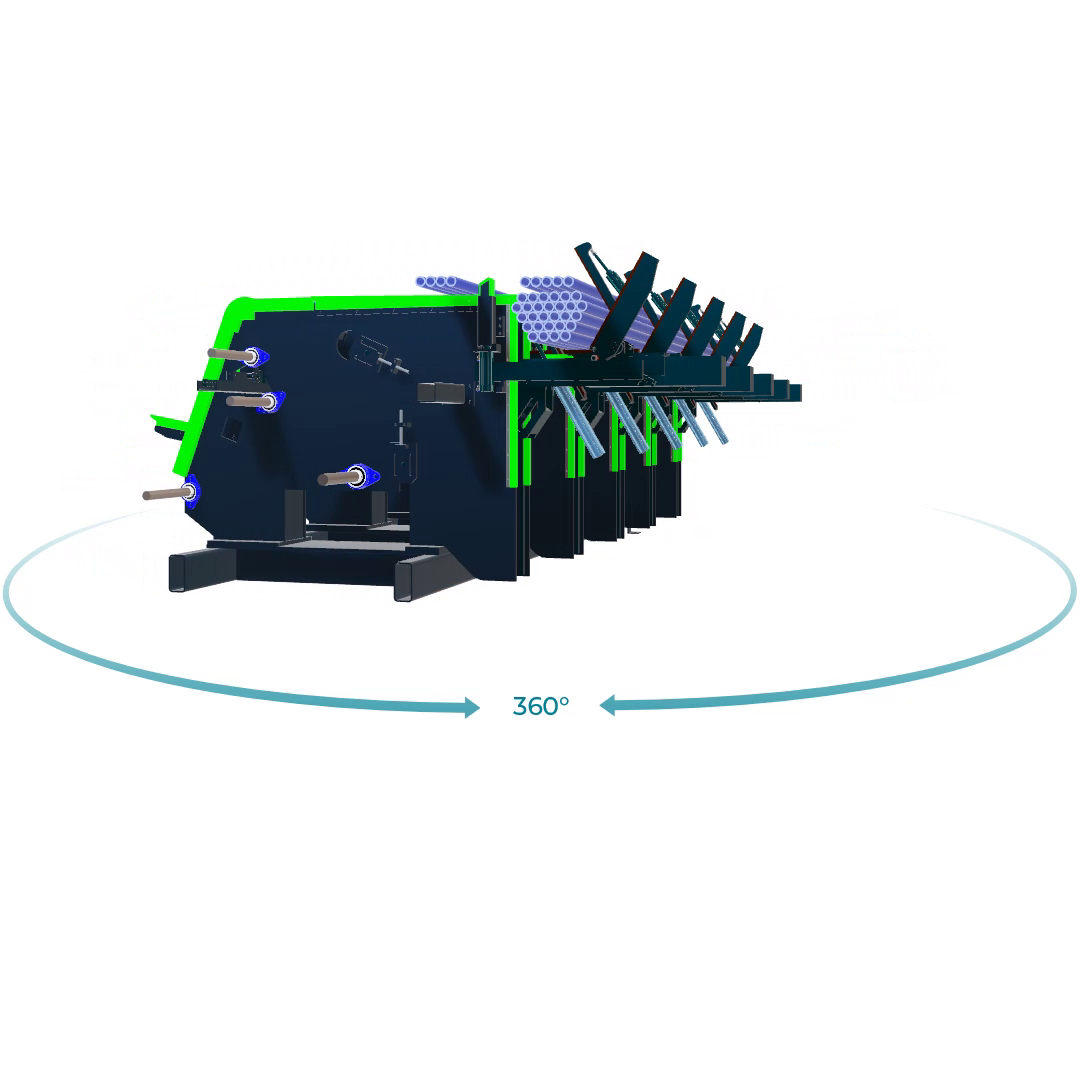

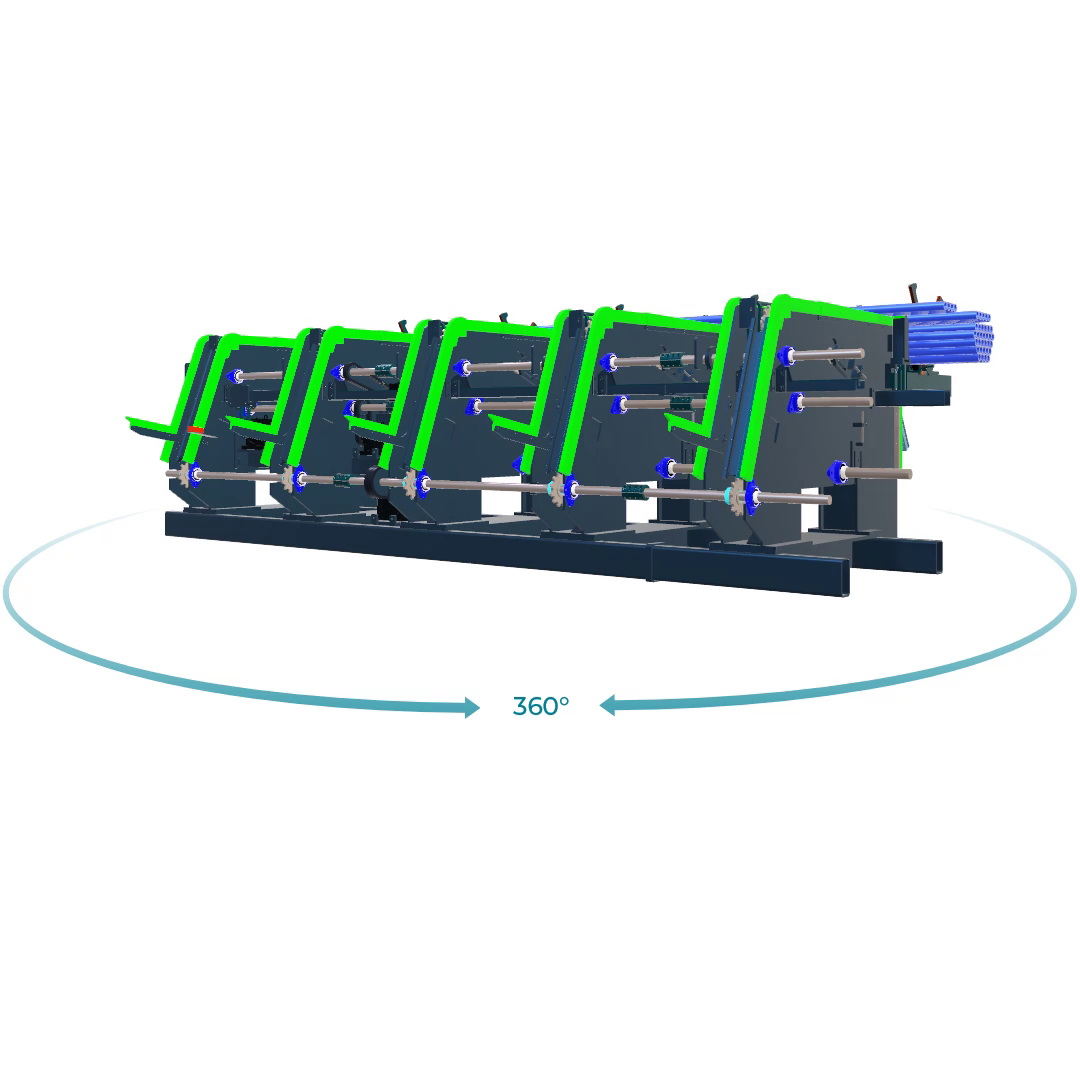

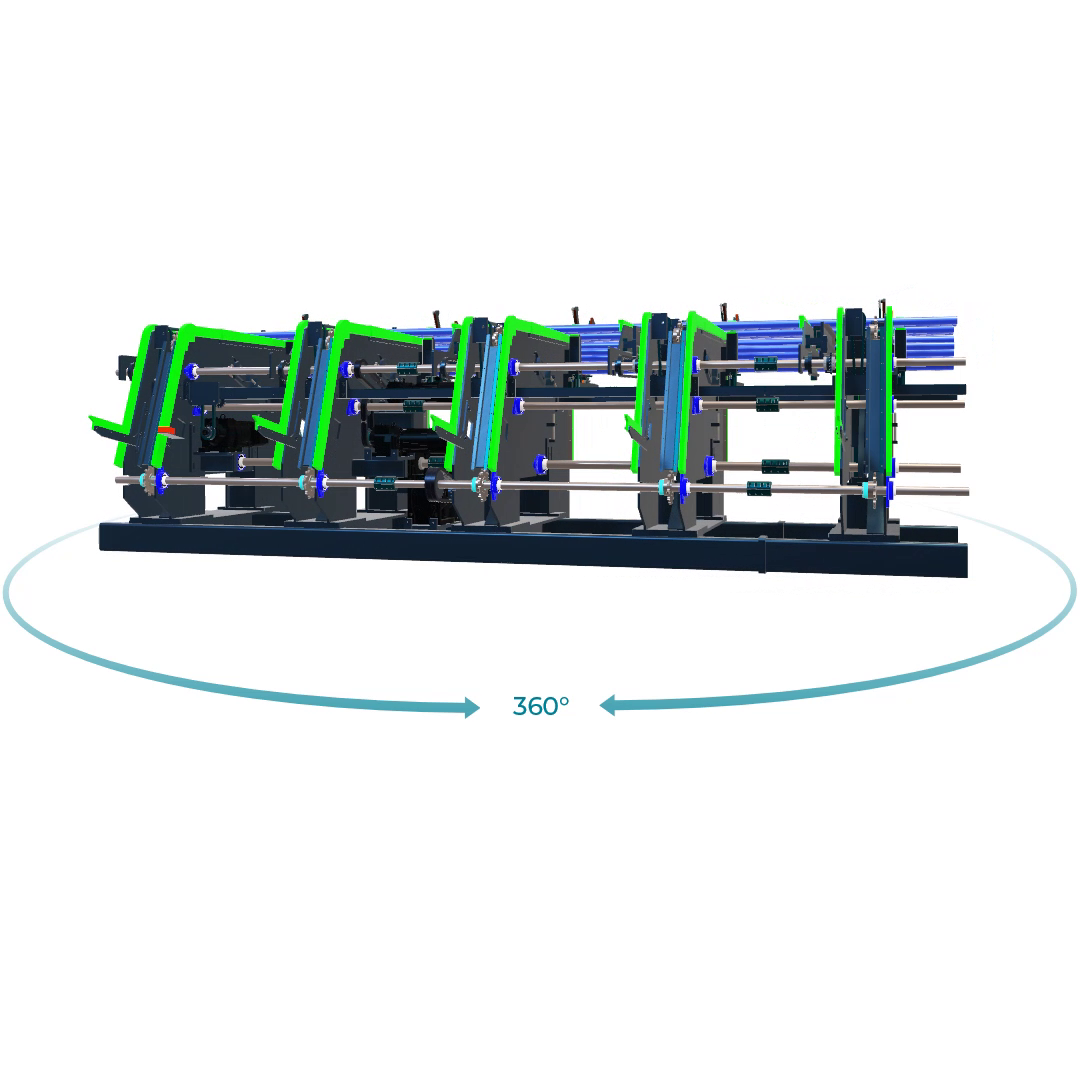

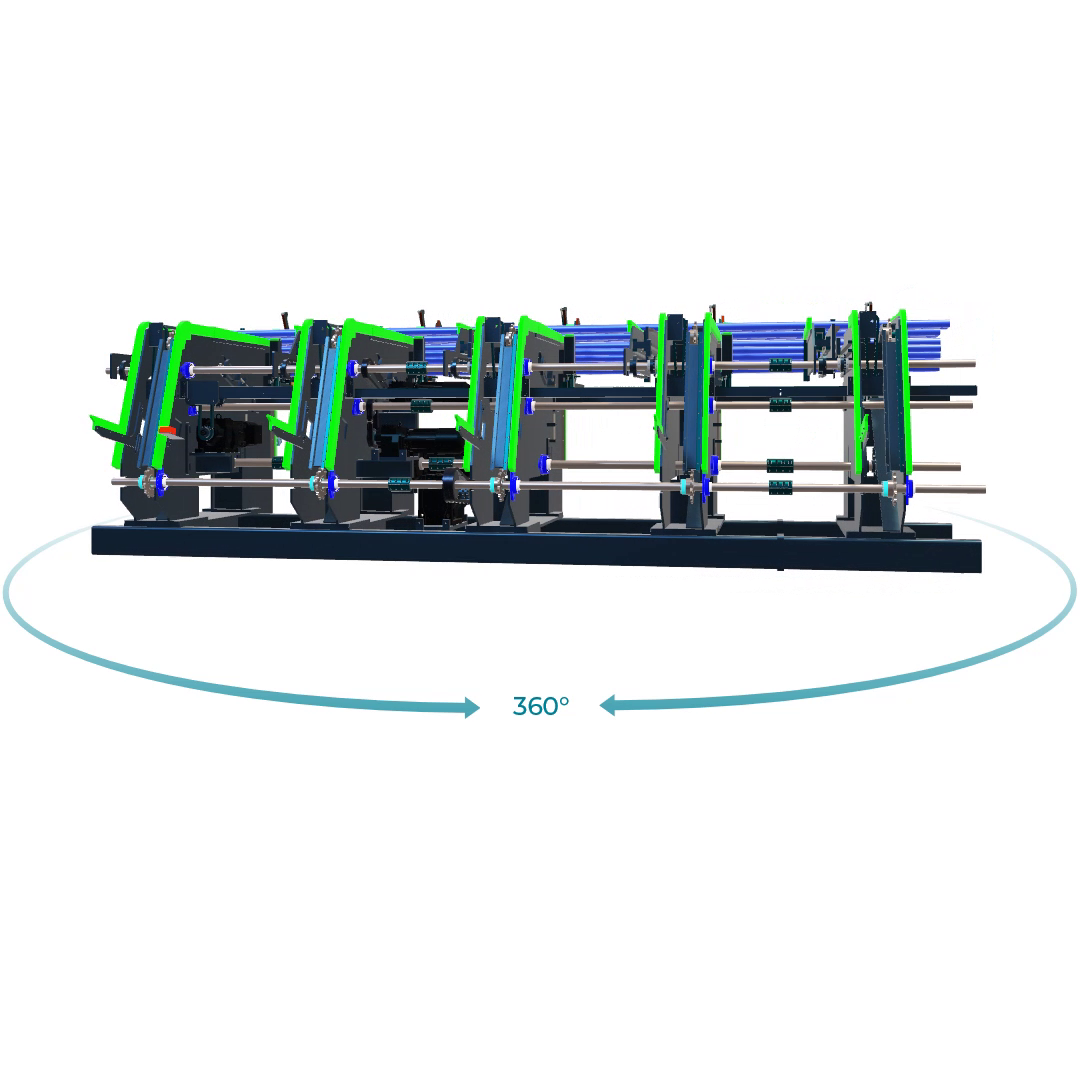

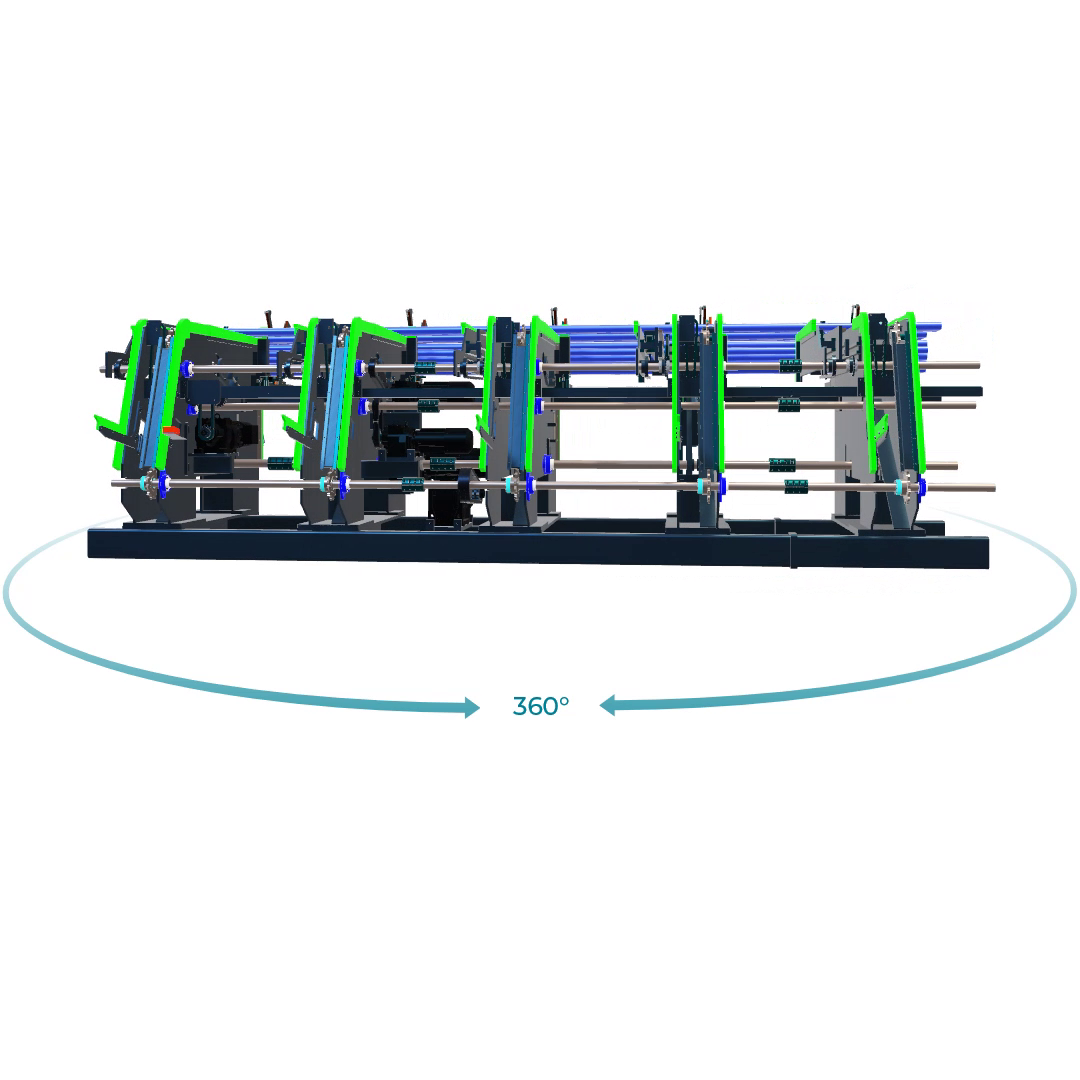

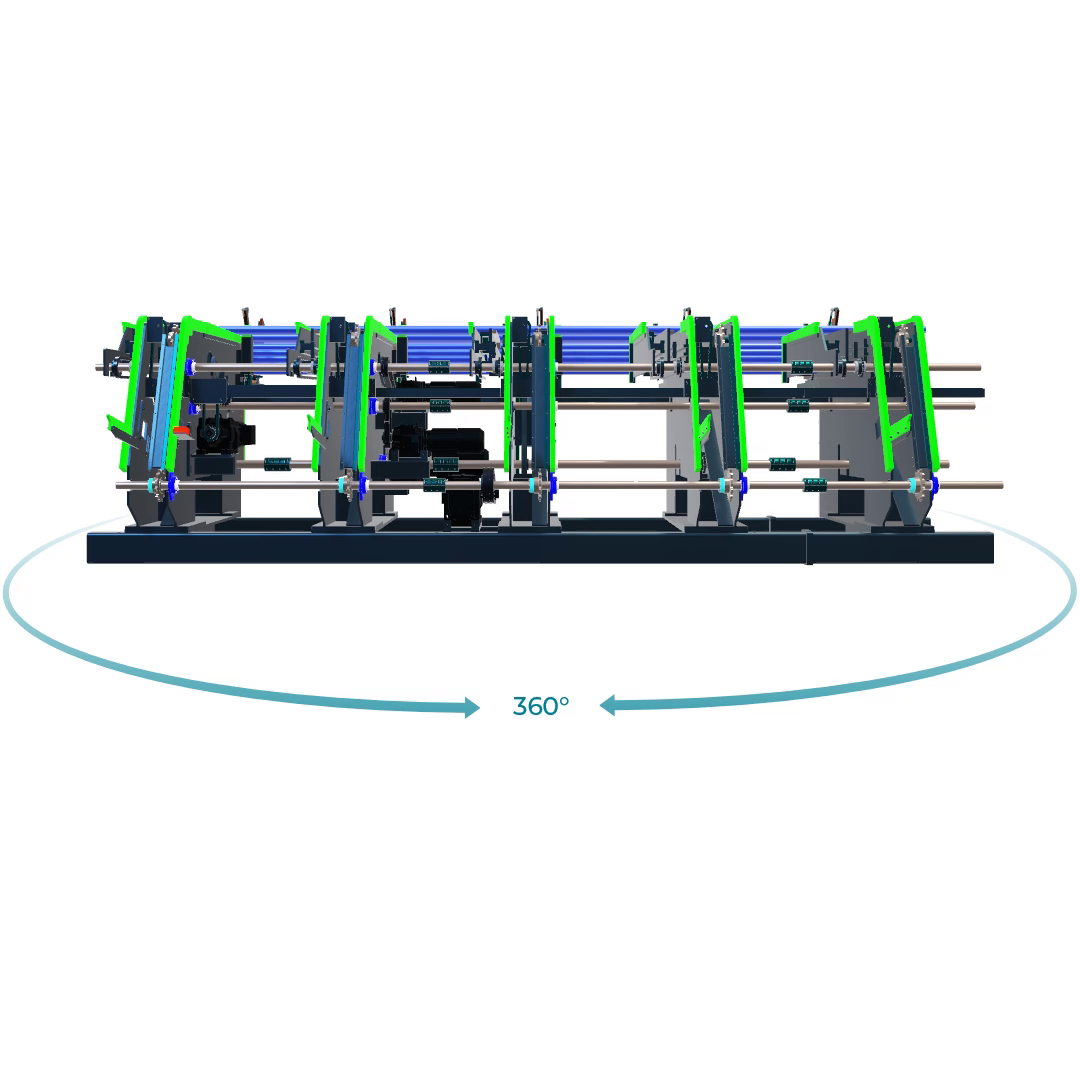

Pipes processing lines

We can make the production process of pipes and rods more efficient!

Automated tube and bar processing lines offer a wide range of applications for tubes of different sizes and materials. With our automation lines, you can make the handling and conditioning of tubes and bars in your plant several times more efficient.

Straightening machines

Internal pipe grinder

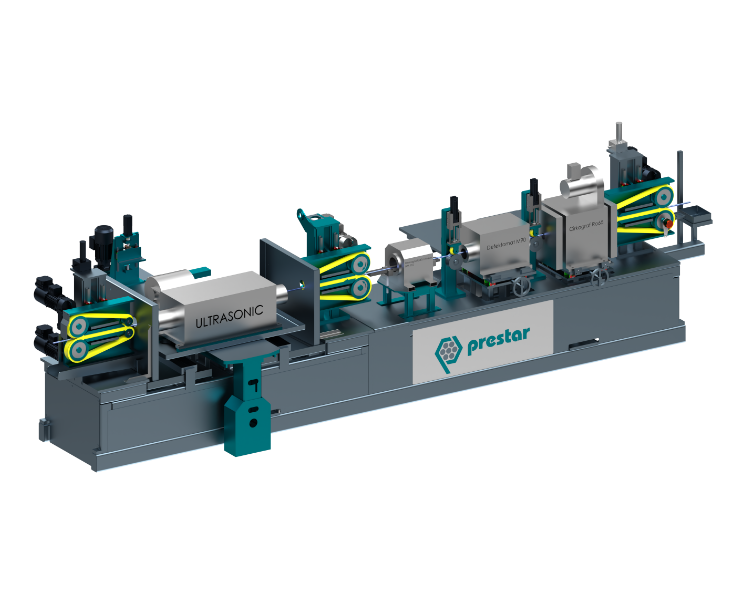

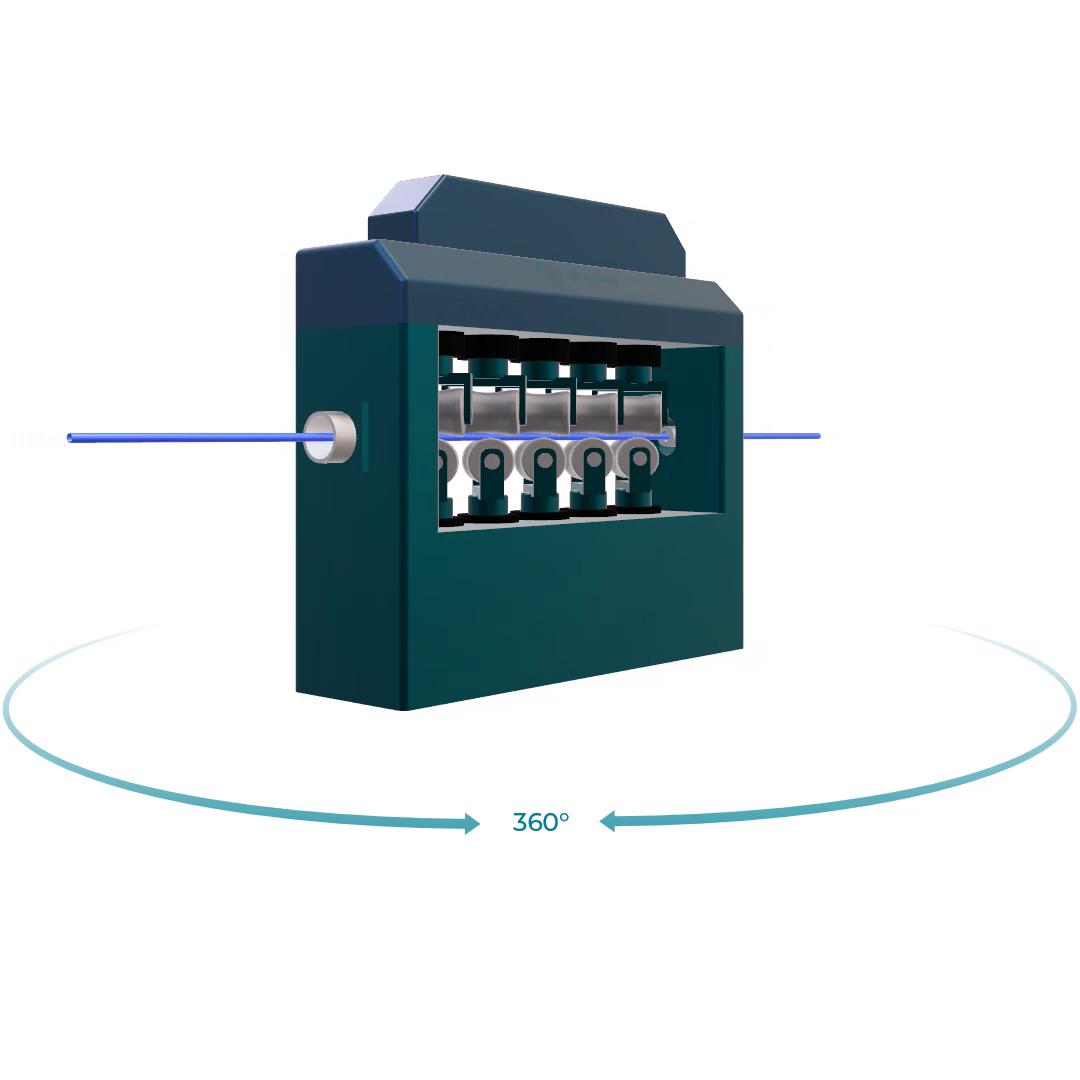

Centerless Pipe Grinder

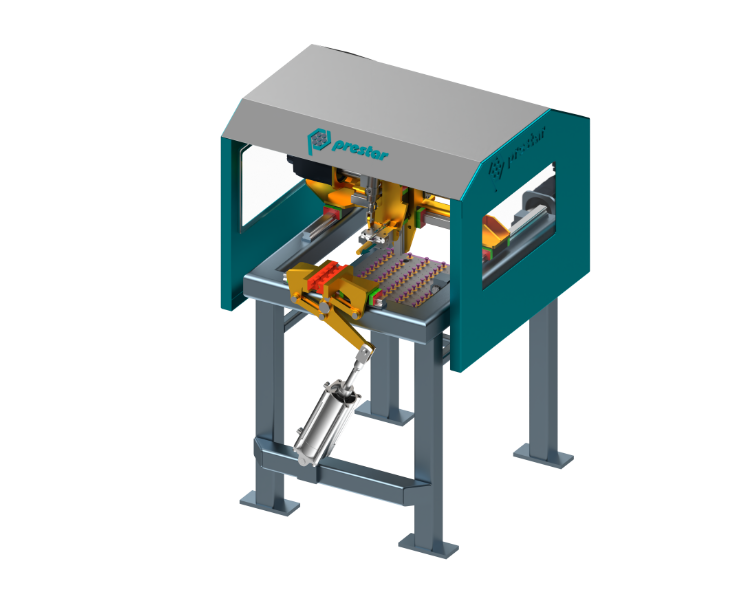

Flying saw

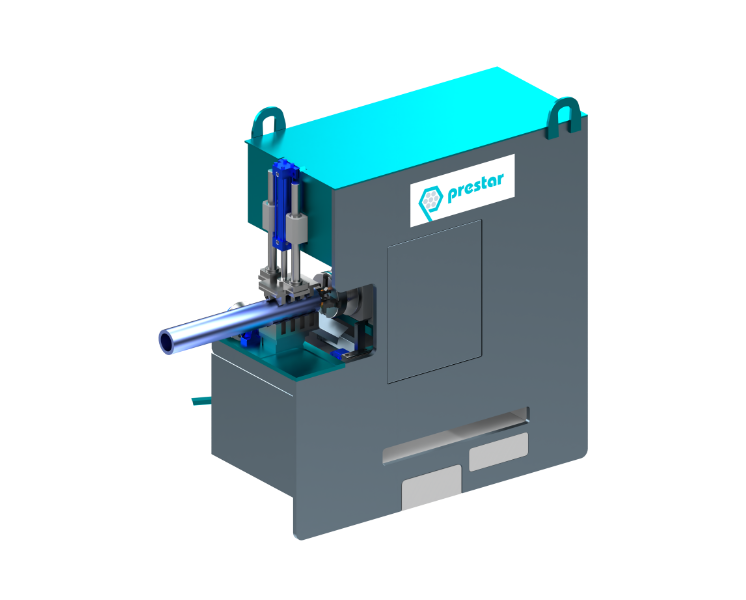

Circular saw

Chamfering of pipes

Sorting and plugging

Control tables

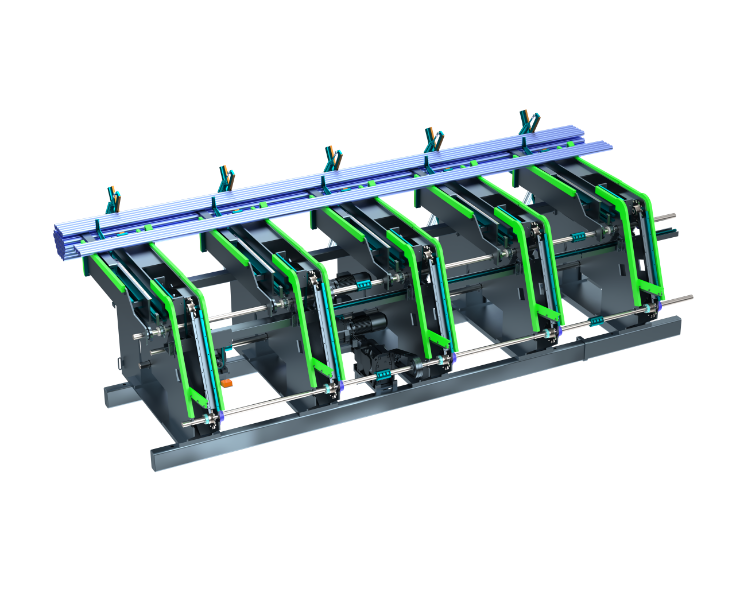

Packaging machines

![Untitled-3 [resumed]](https://www.prestar.cz/wp-content/uploads/2022/08/Bez-nazvu-3-obnoveny.png)

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT

90% of customers perceive Prestar's technology as highly advanced

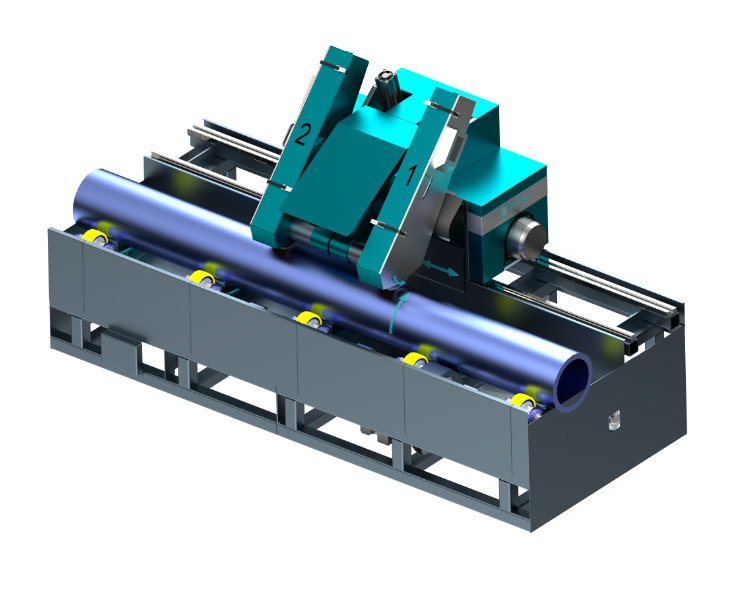

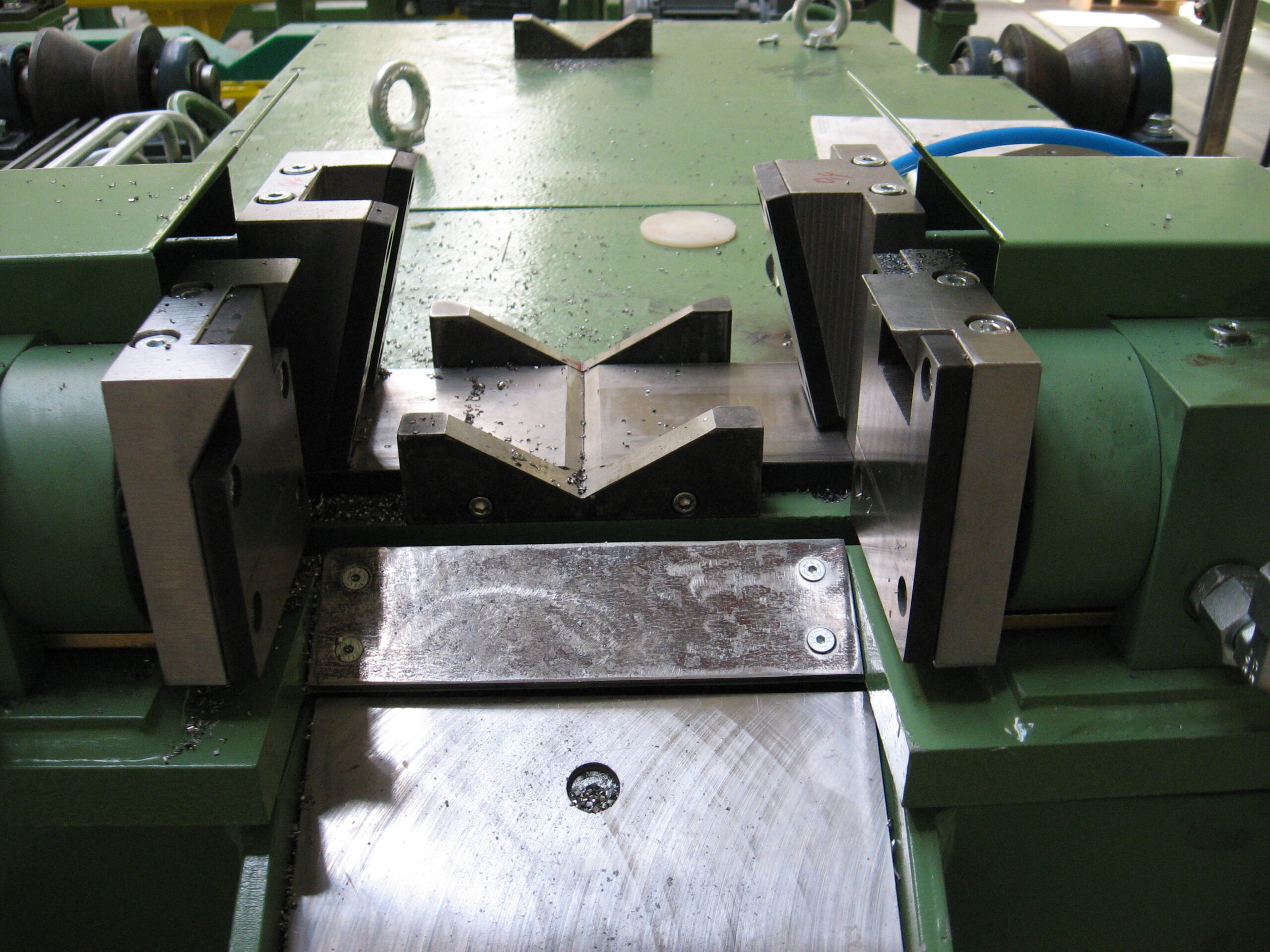

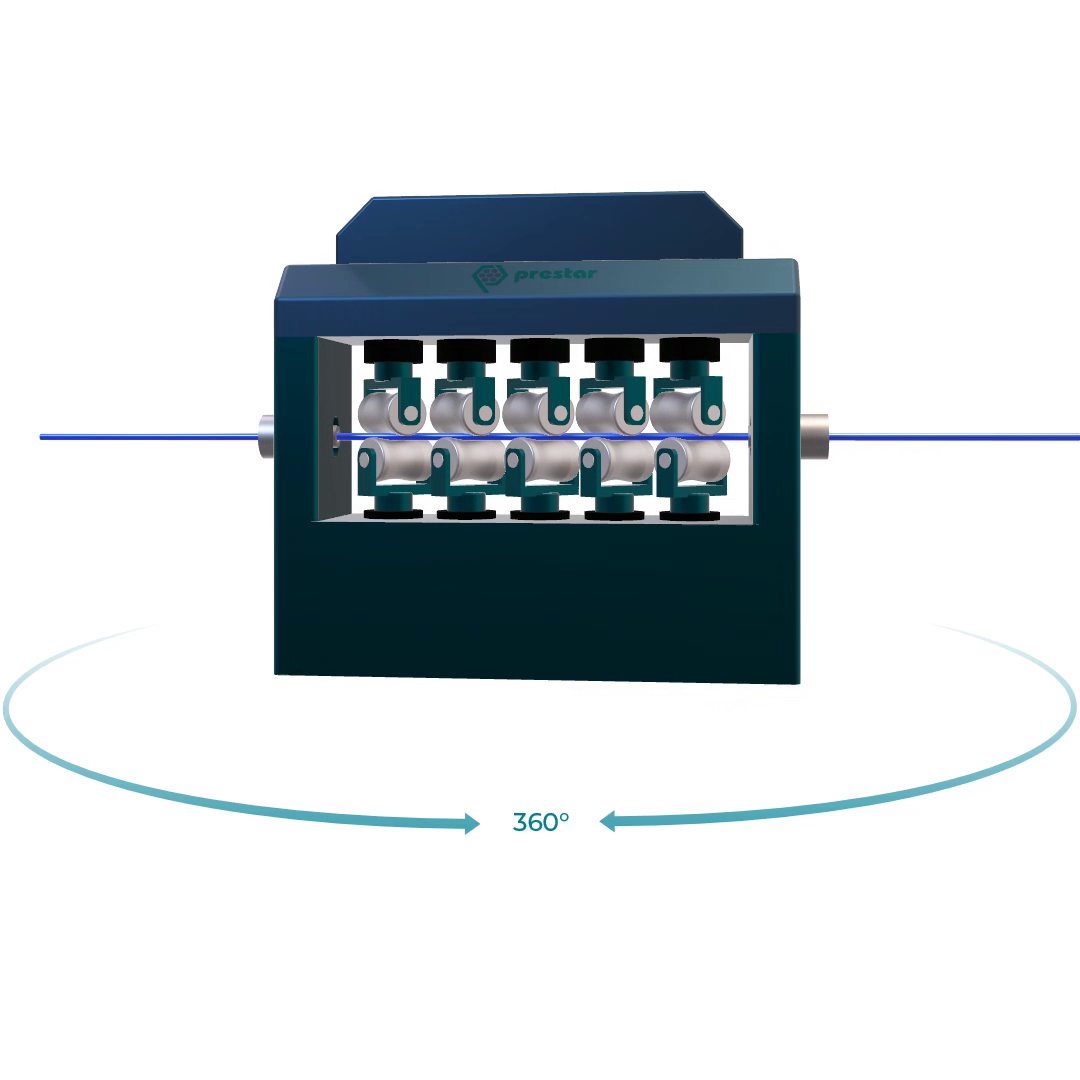

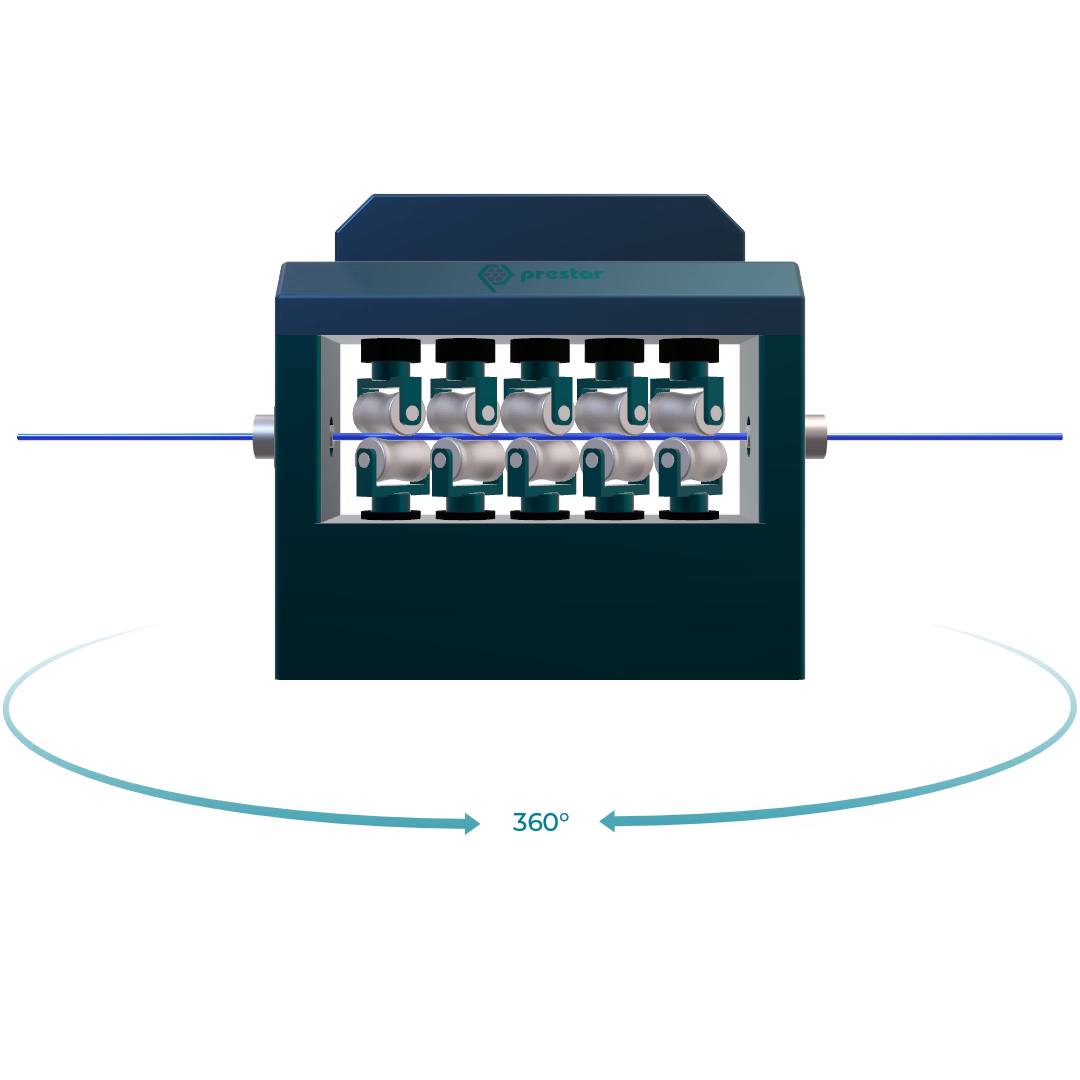

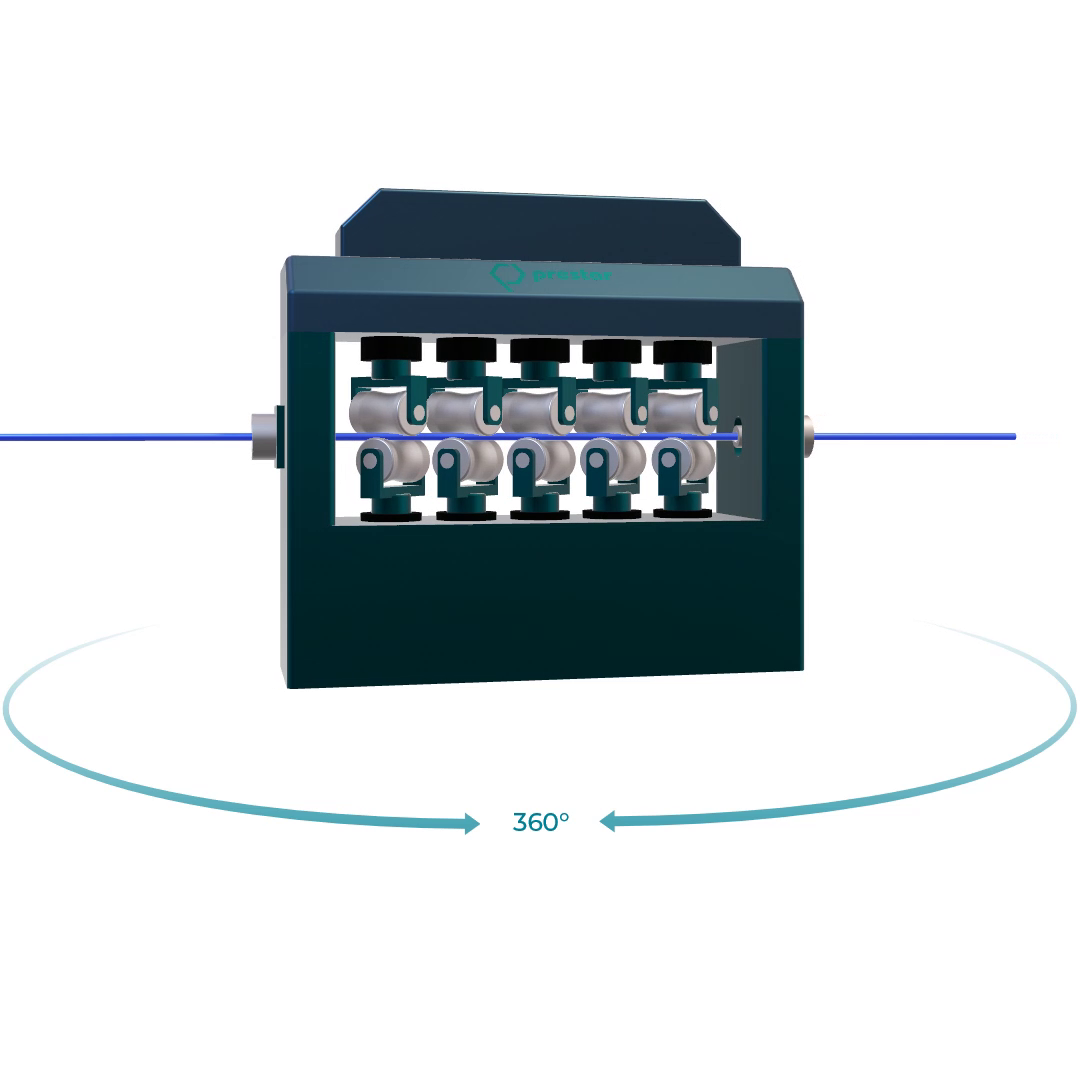

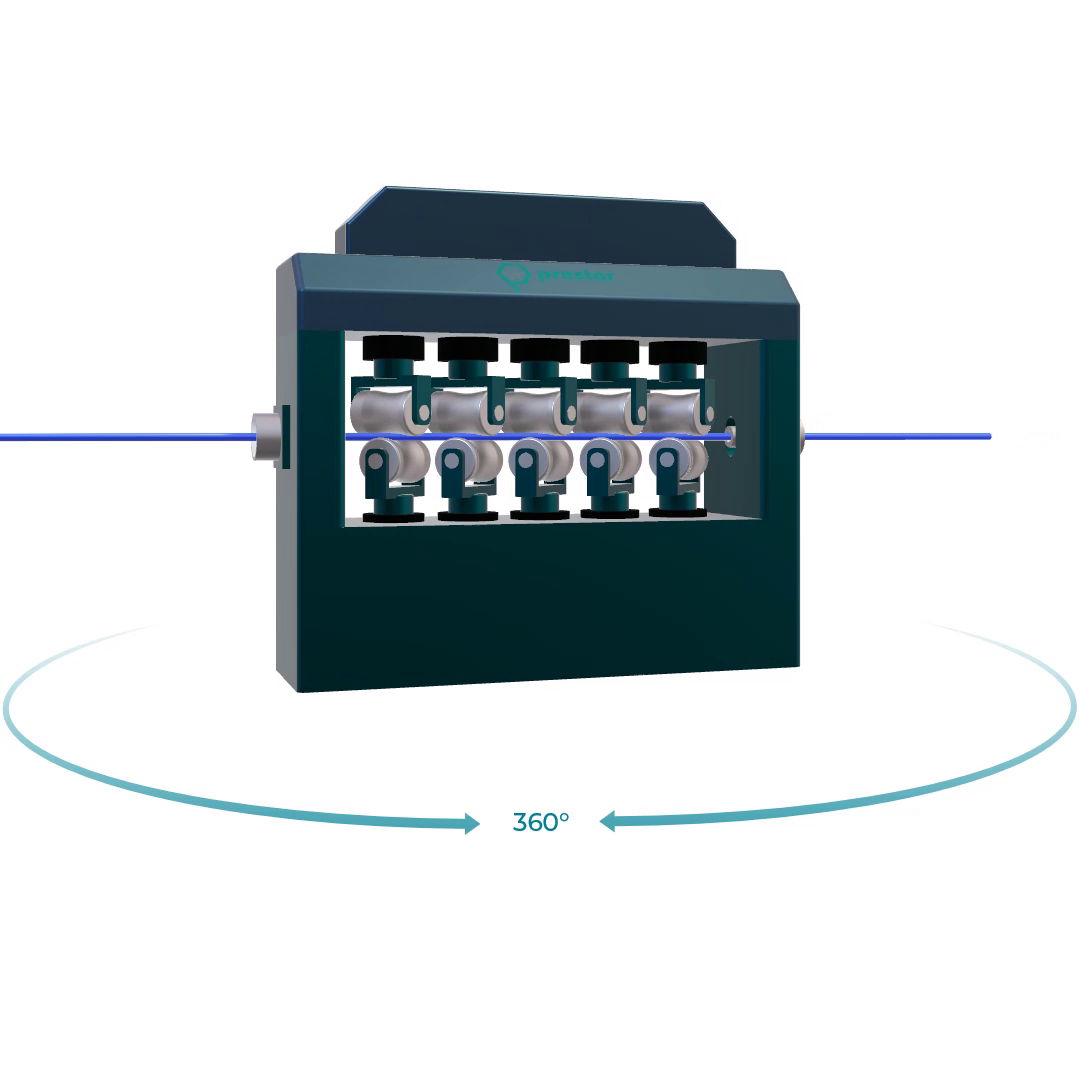

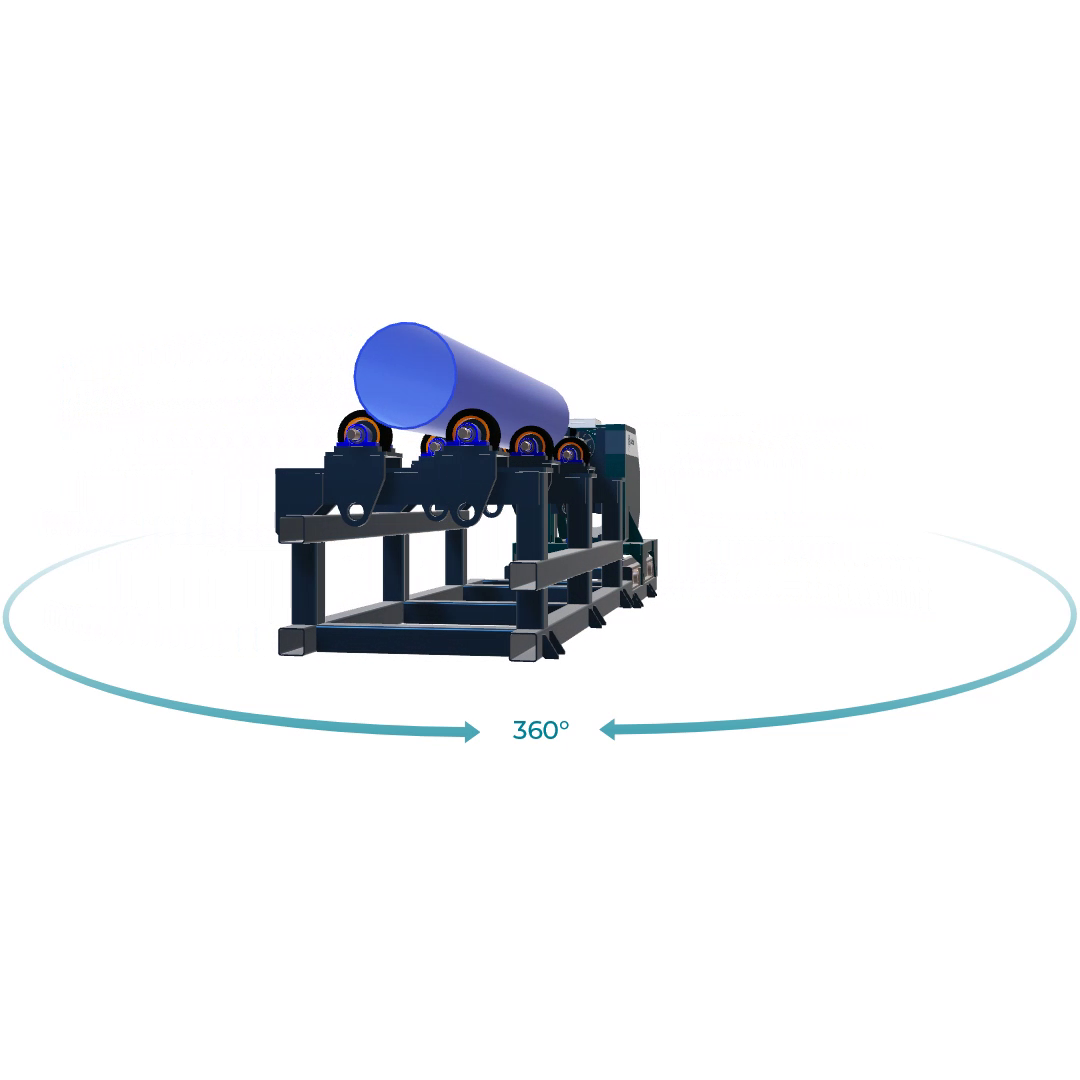

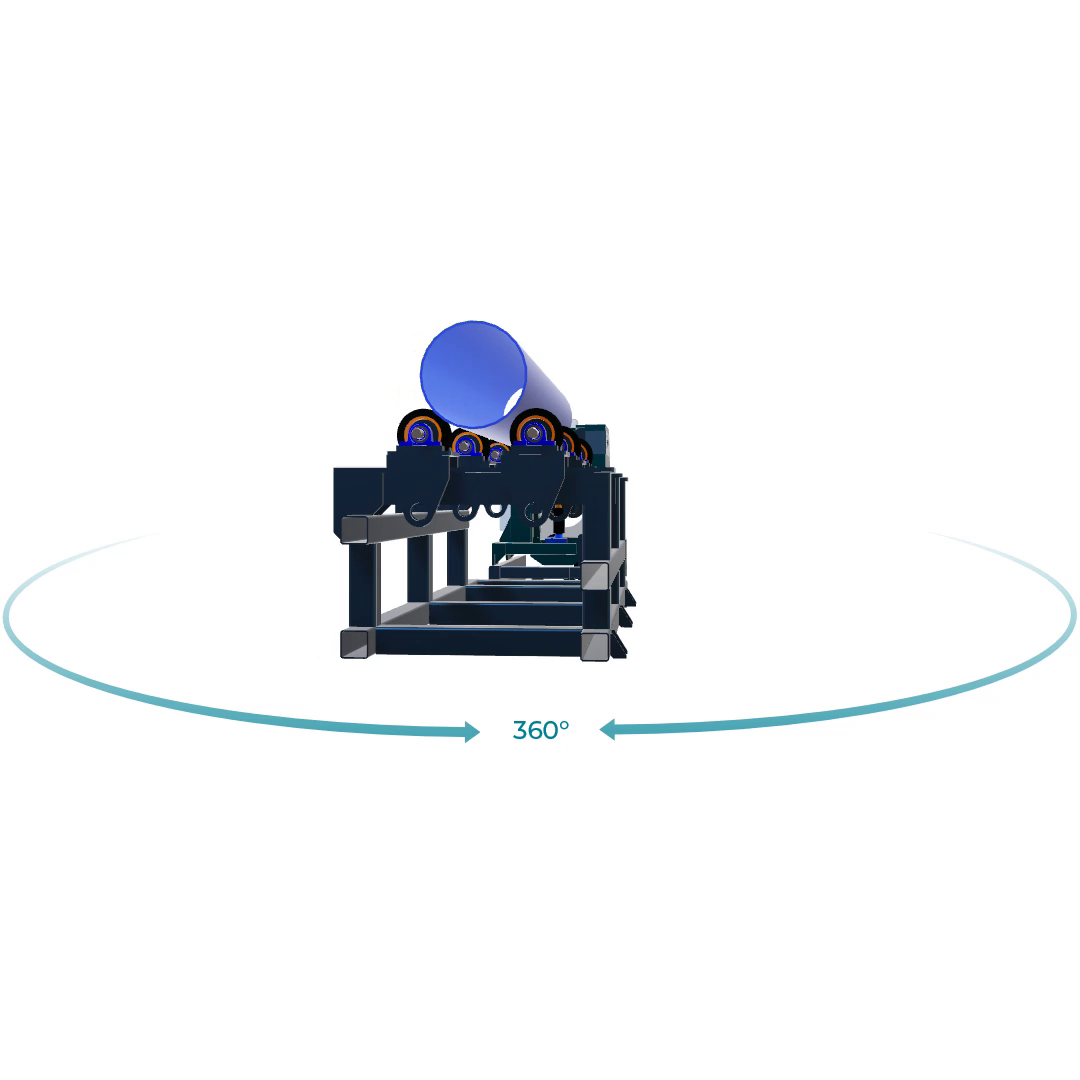

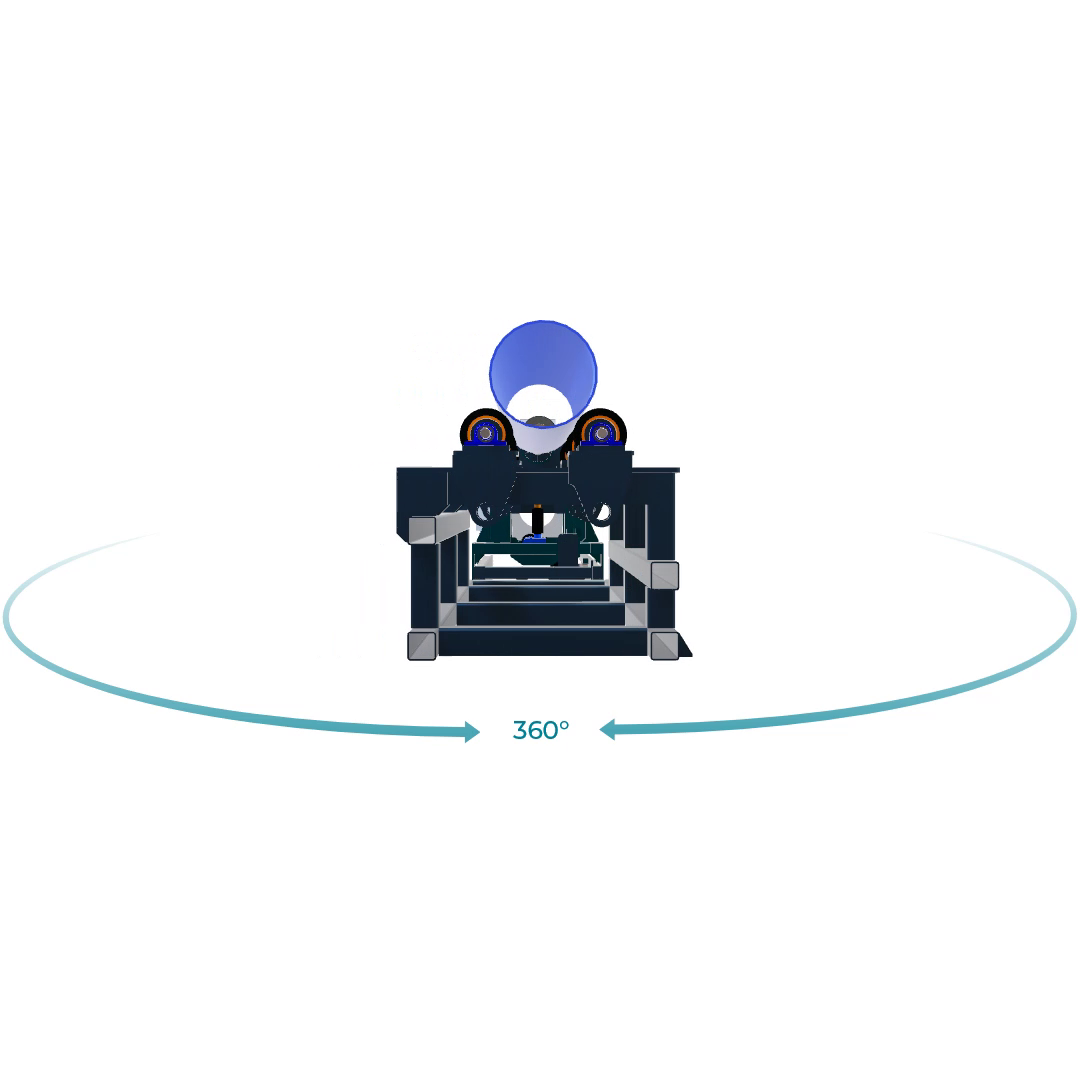

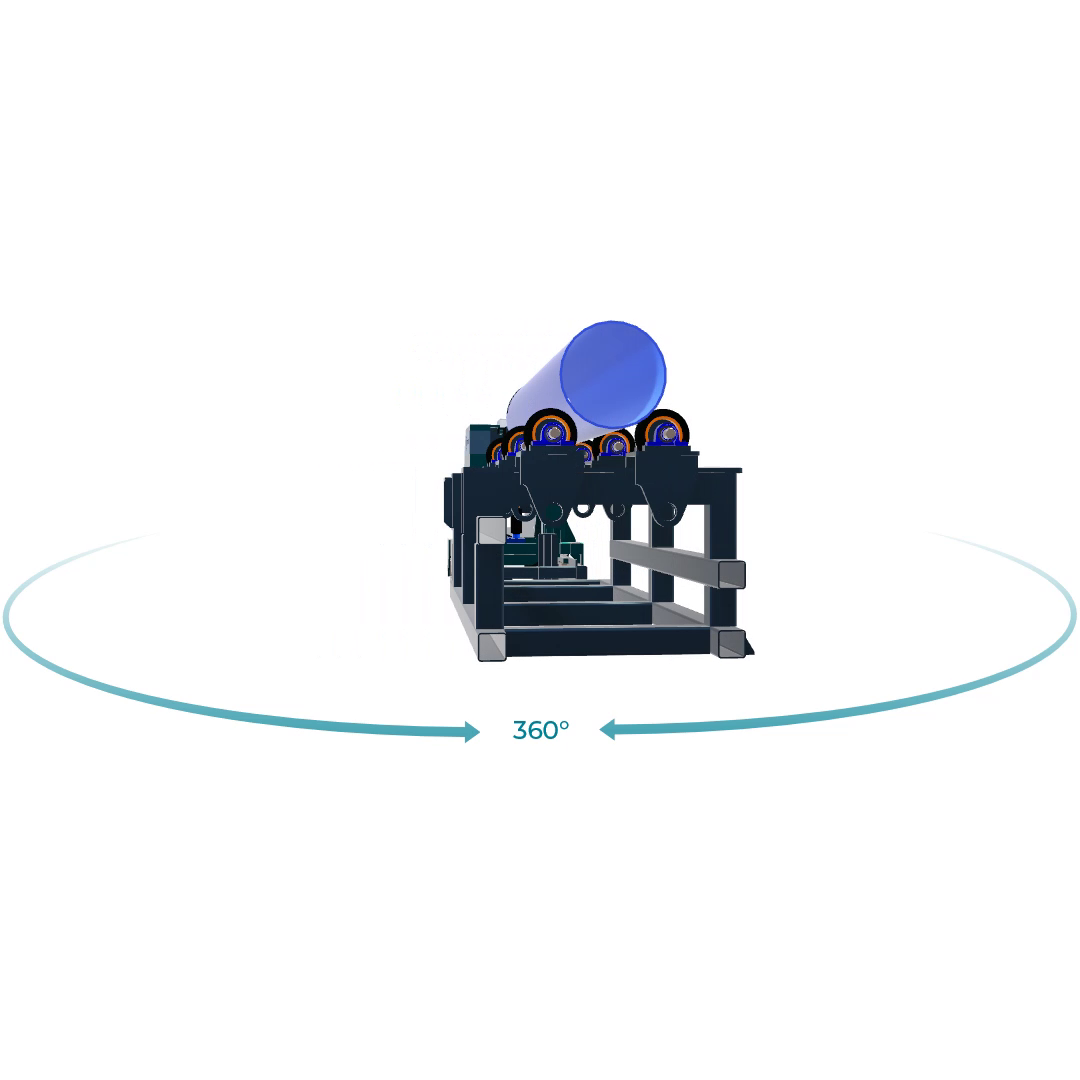

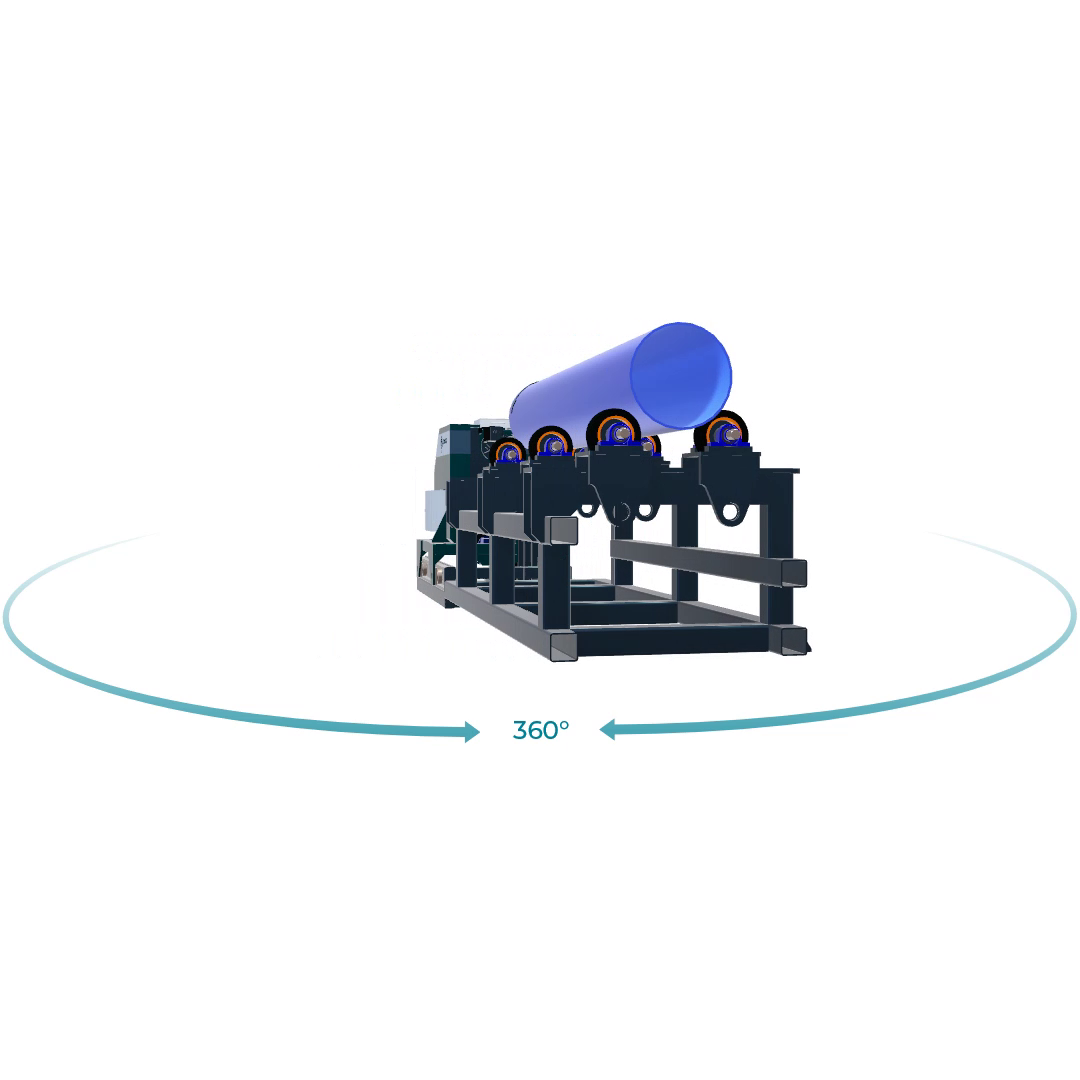

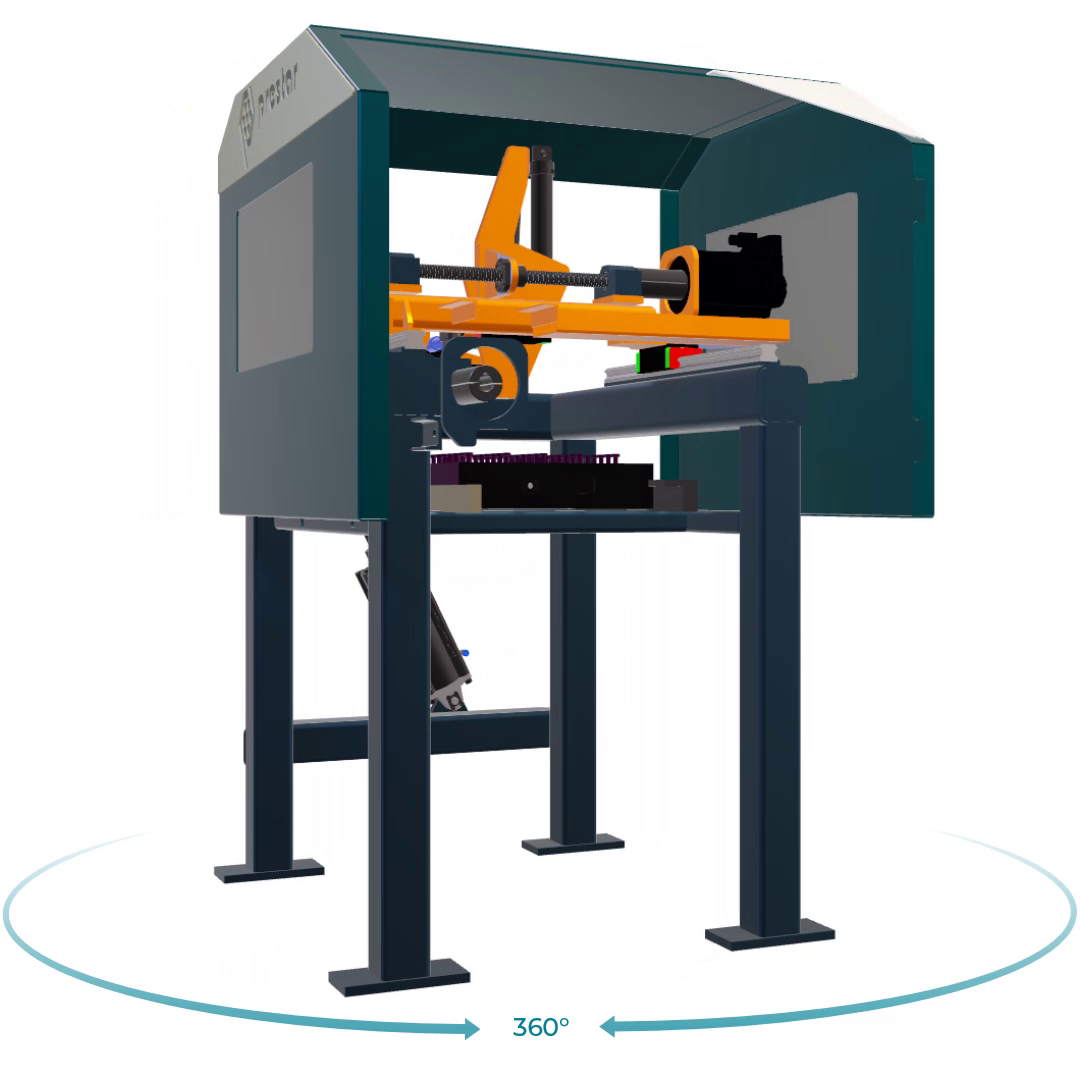

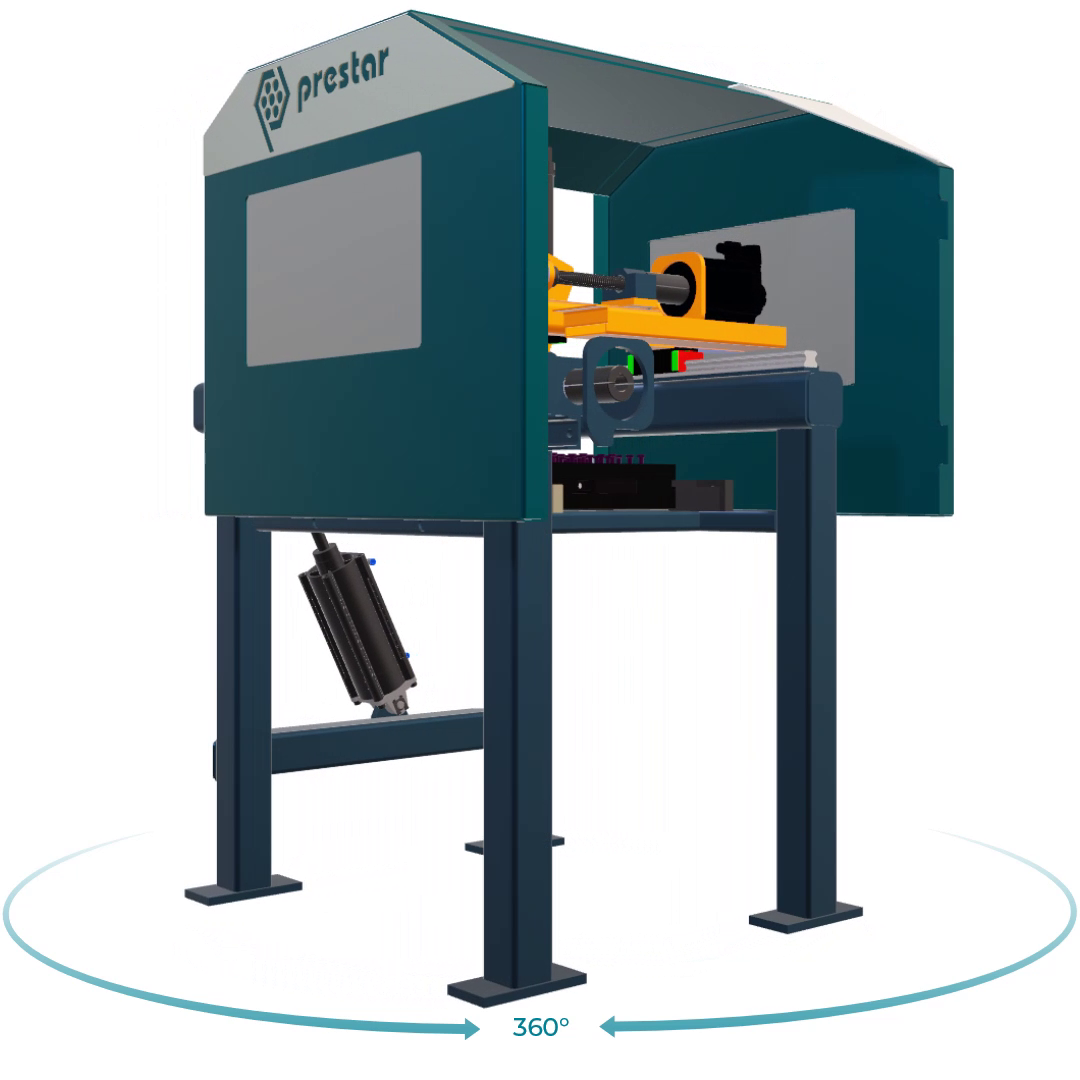

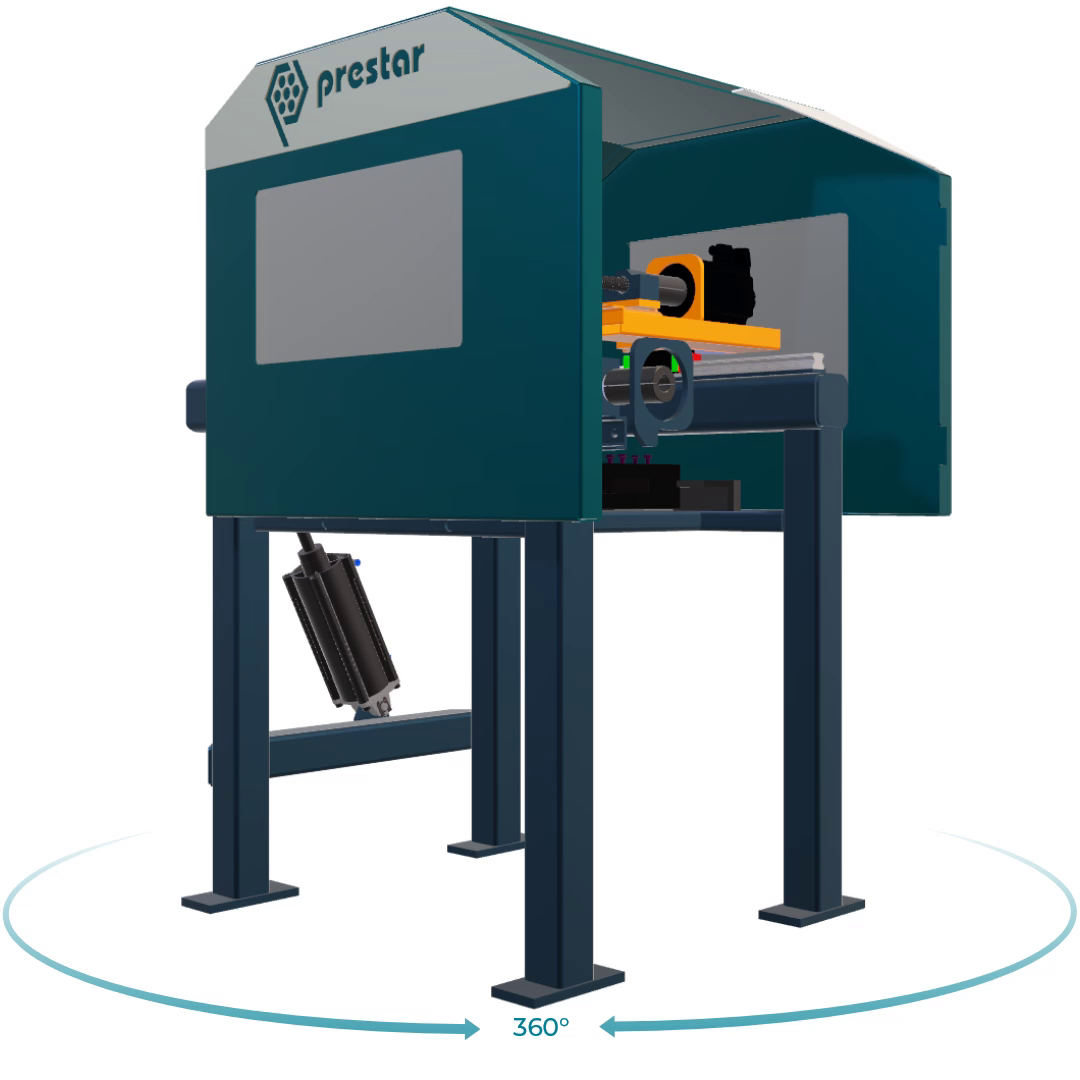

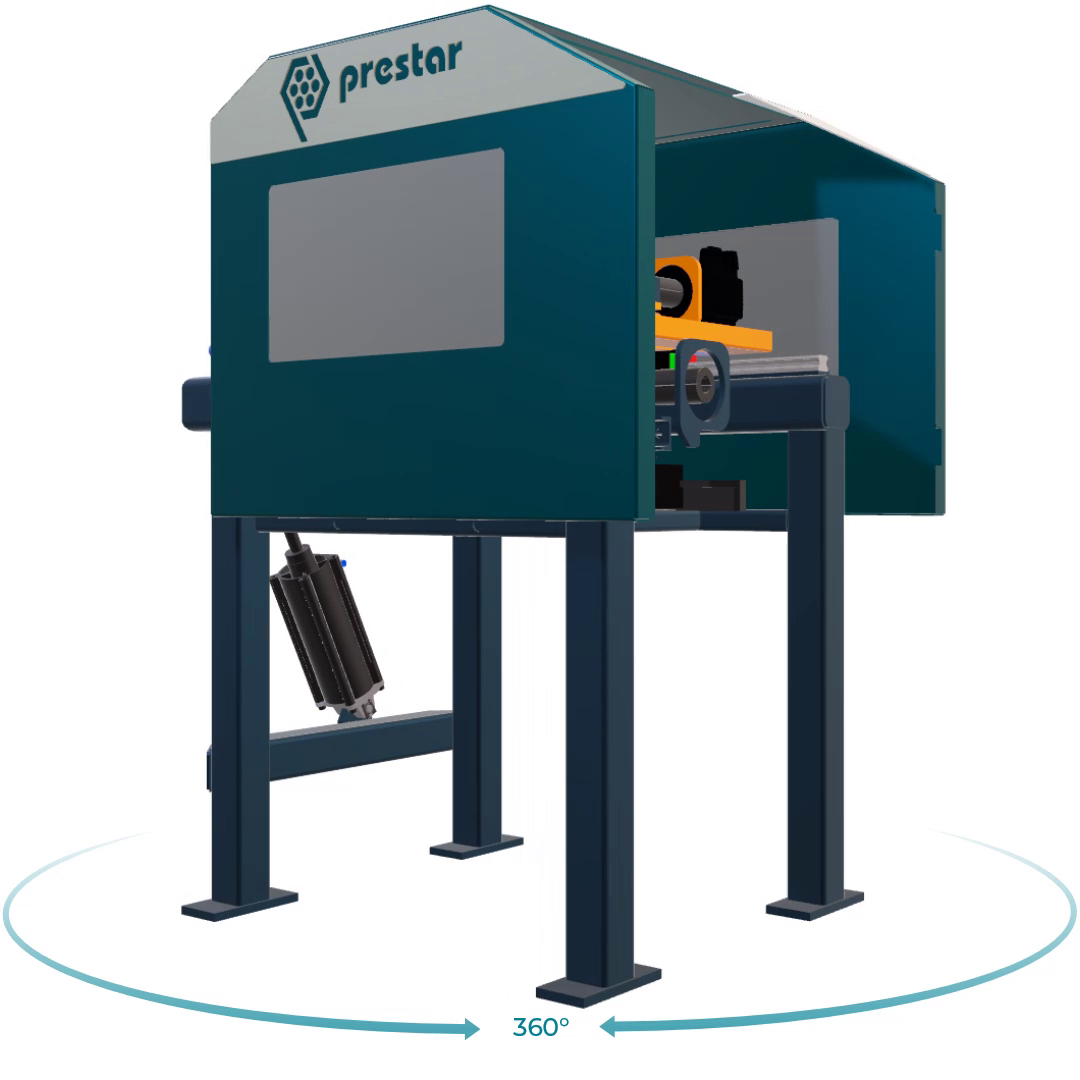

Straightening machines

Description of the device

A 6-roll or fully automated 10-roll straightening machine is used for straightening tubes

Technical parameters of the machine

- The deployment of a 10-cylinder straightening machine enables quality straightening results

- Quick conversion to a new pipe dimension

- Manual correction of settings, storage of settings in recipes and clarity of manual control from the control panel.

Other equipment of the machine

- Inlet guidance VARIO trough

- Rotary tube carrier for straightening machine

- Ejection chute

- Protective safety cover for the straightening machine

- Pressure measurement per cylinder

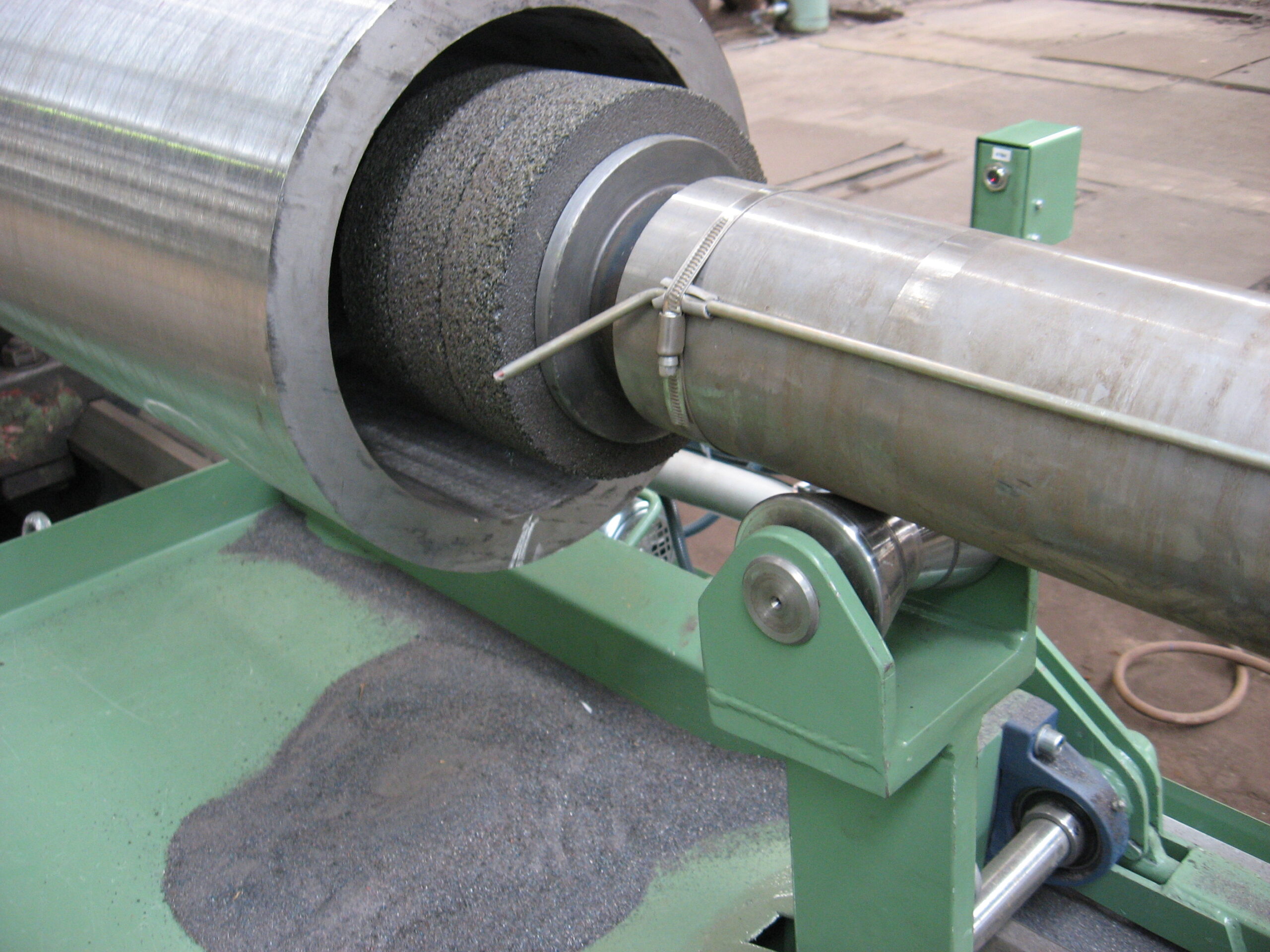

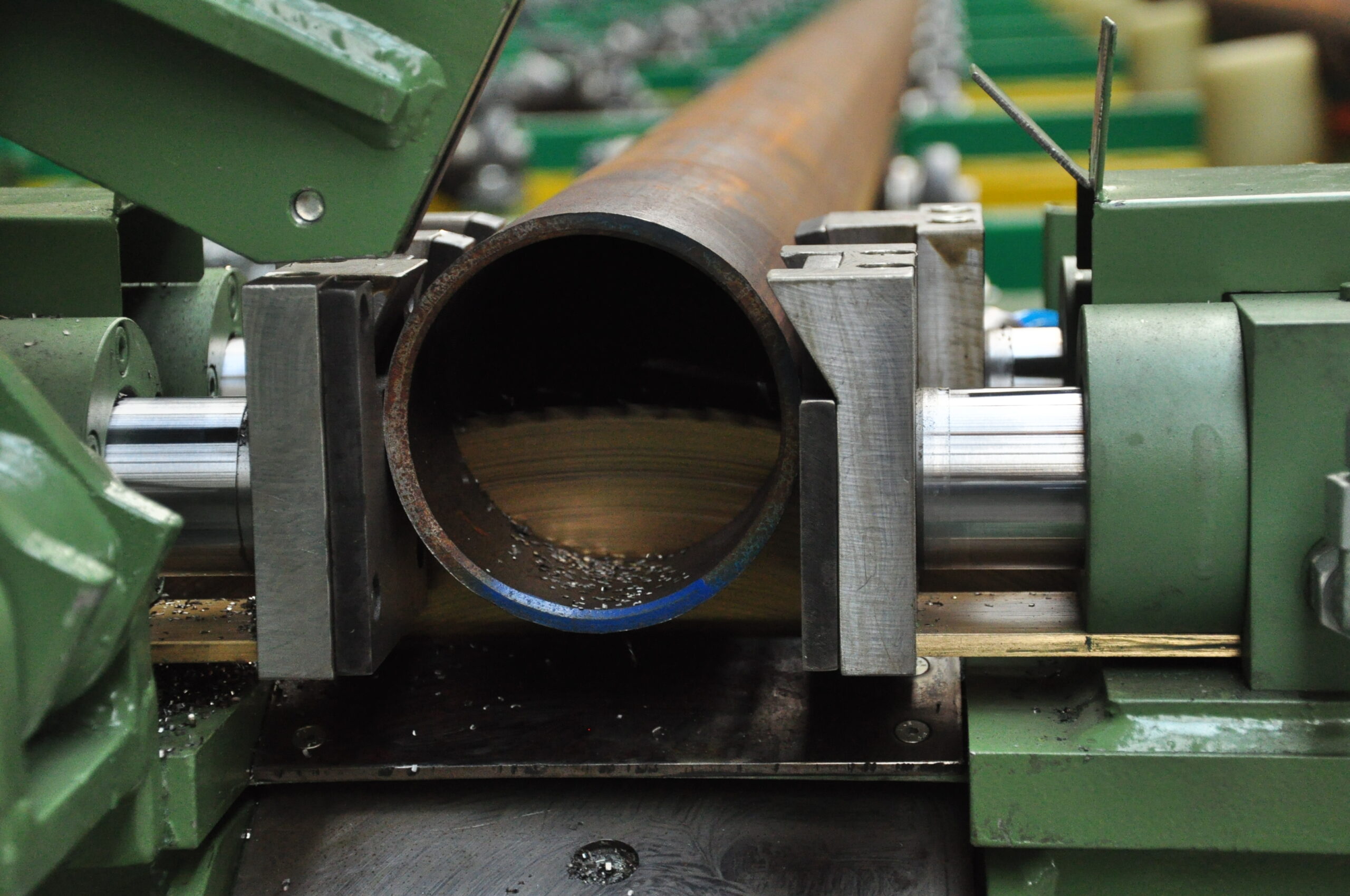

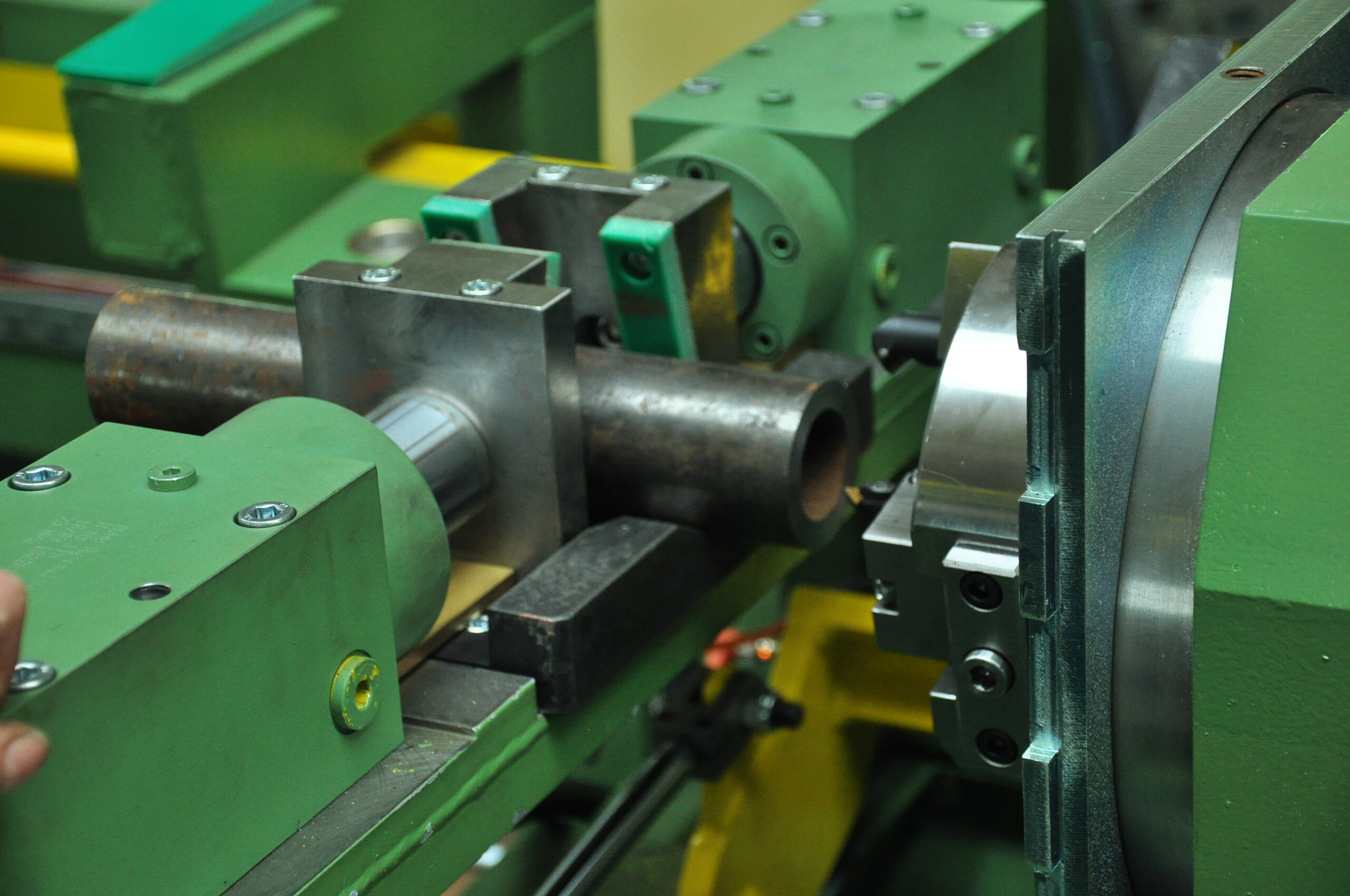

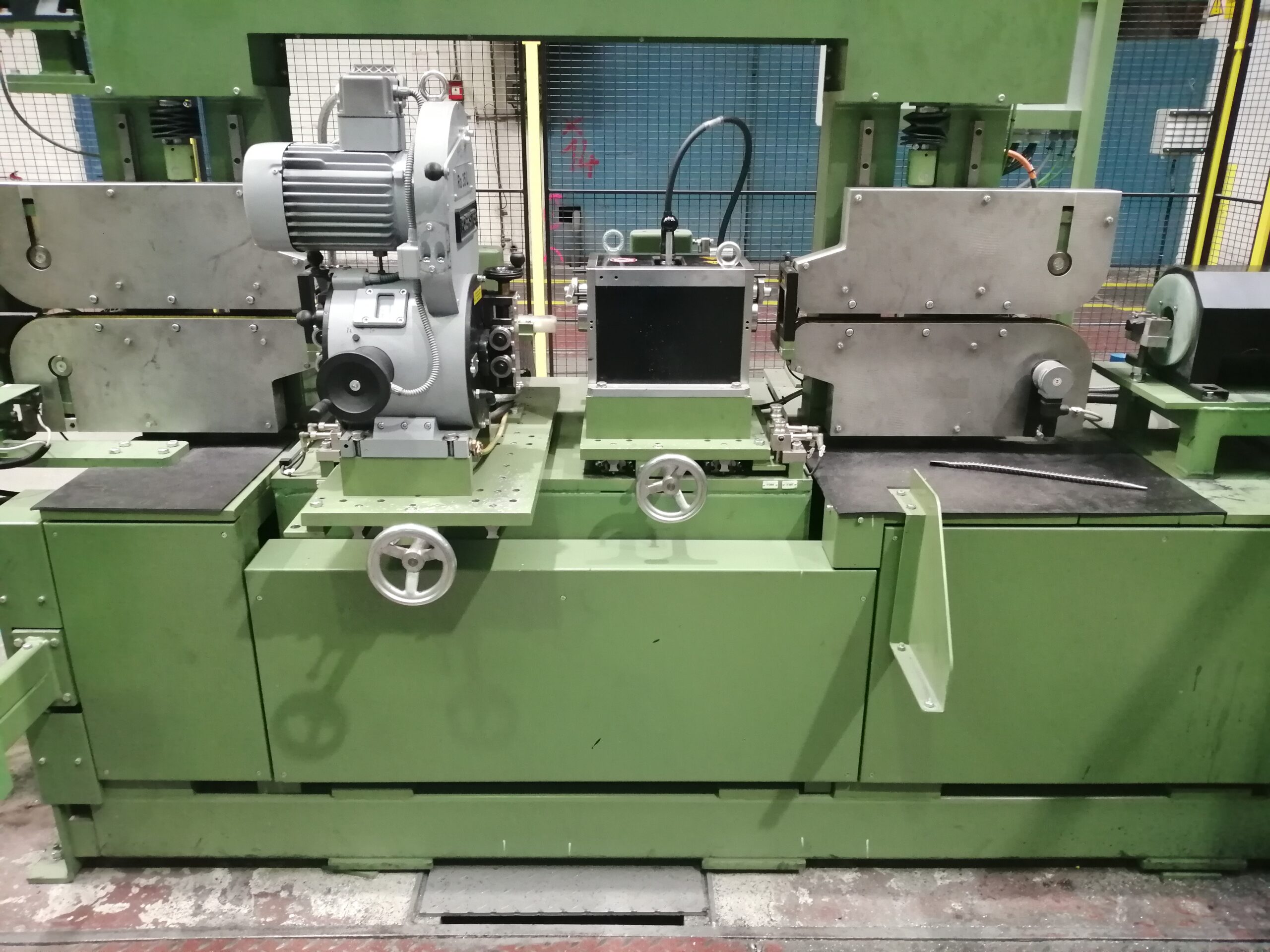

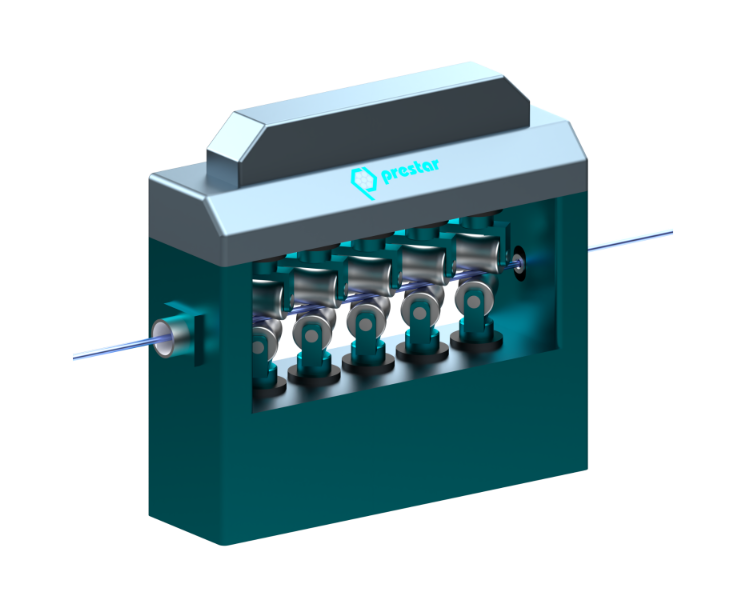

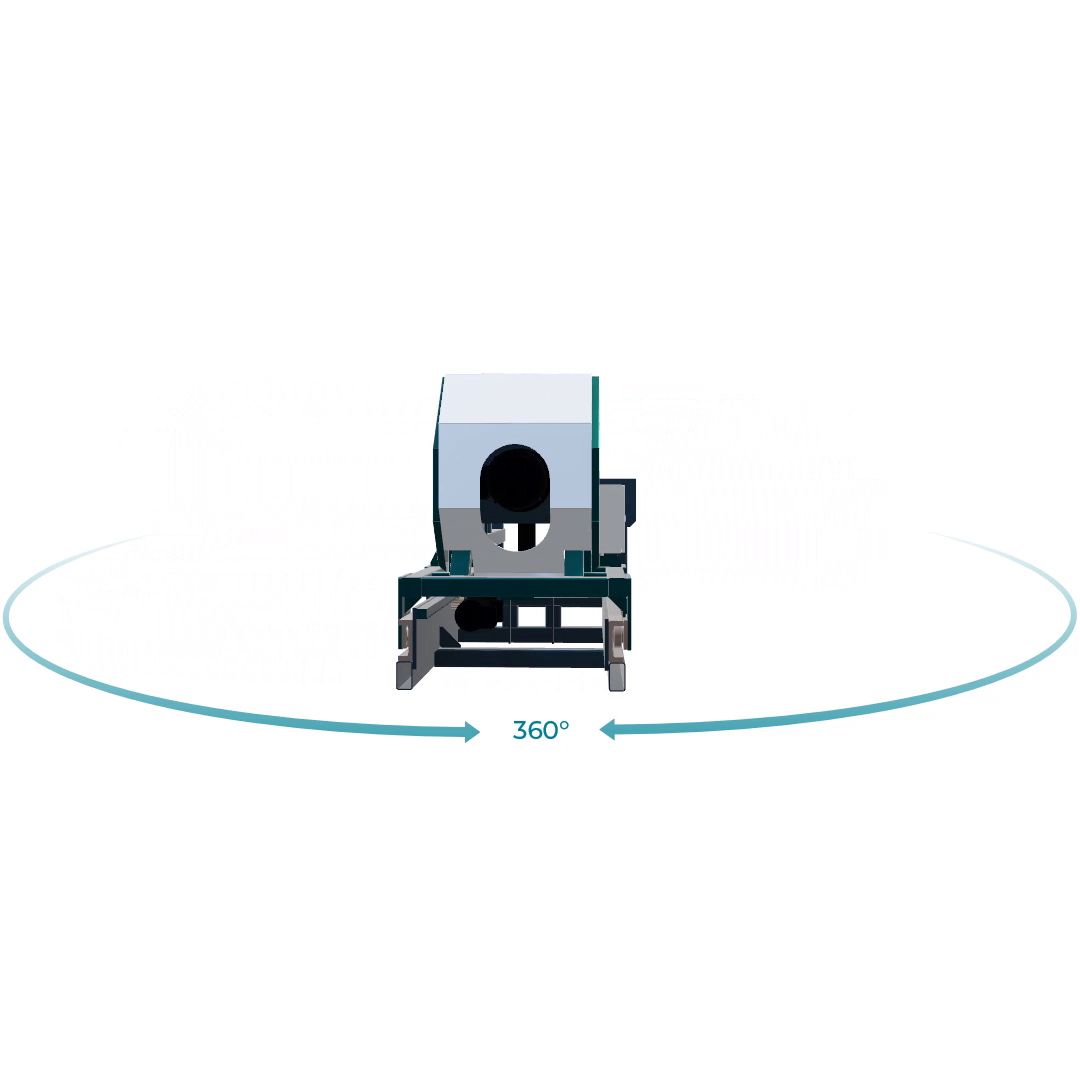

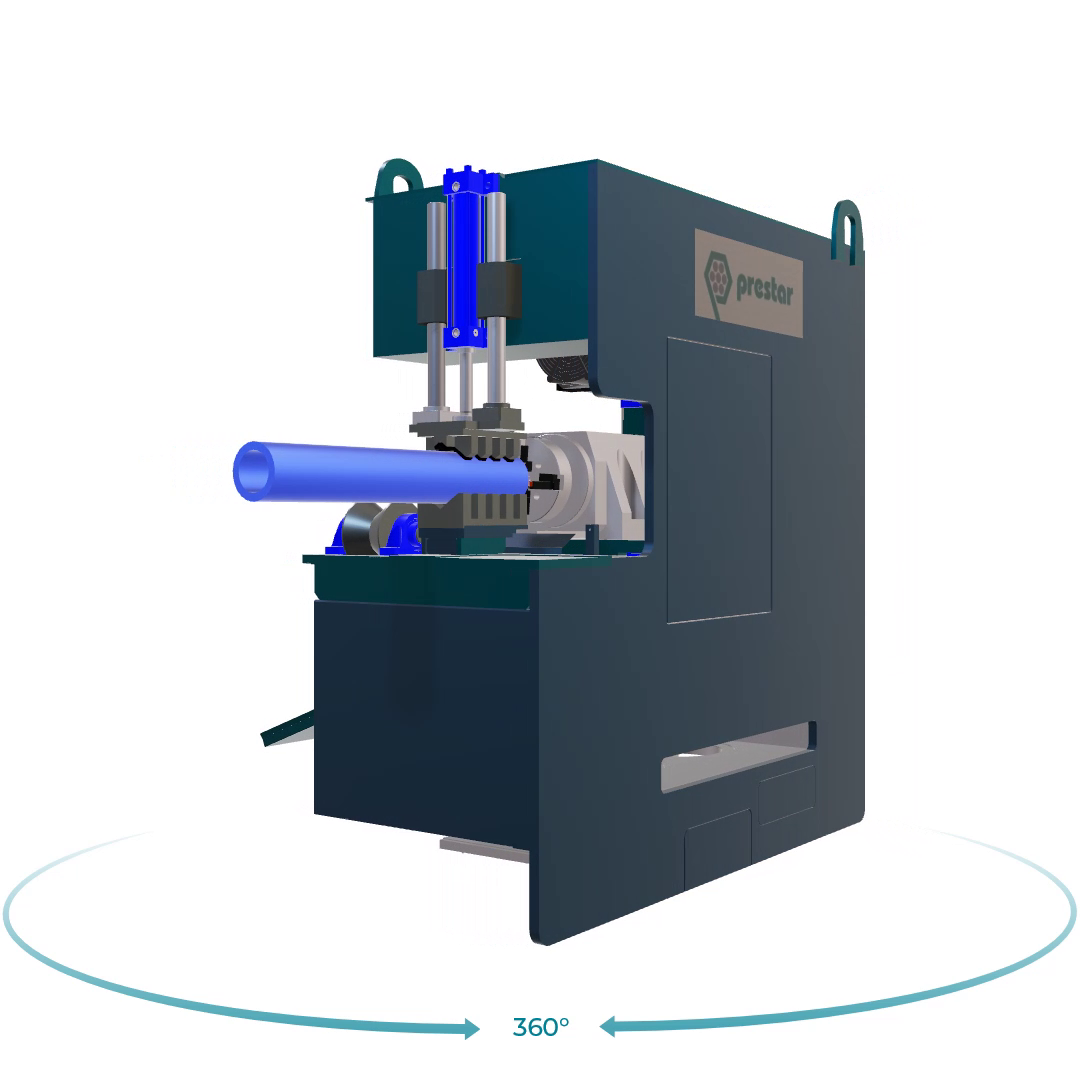

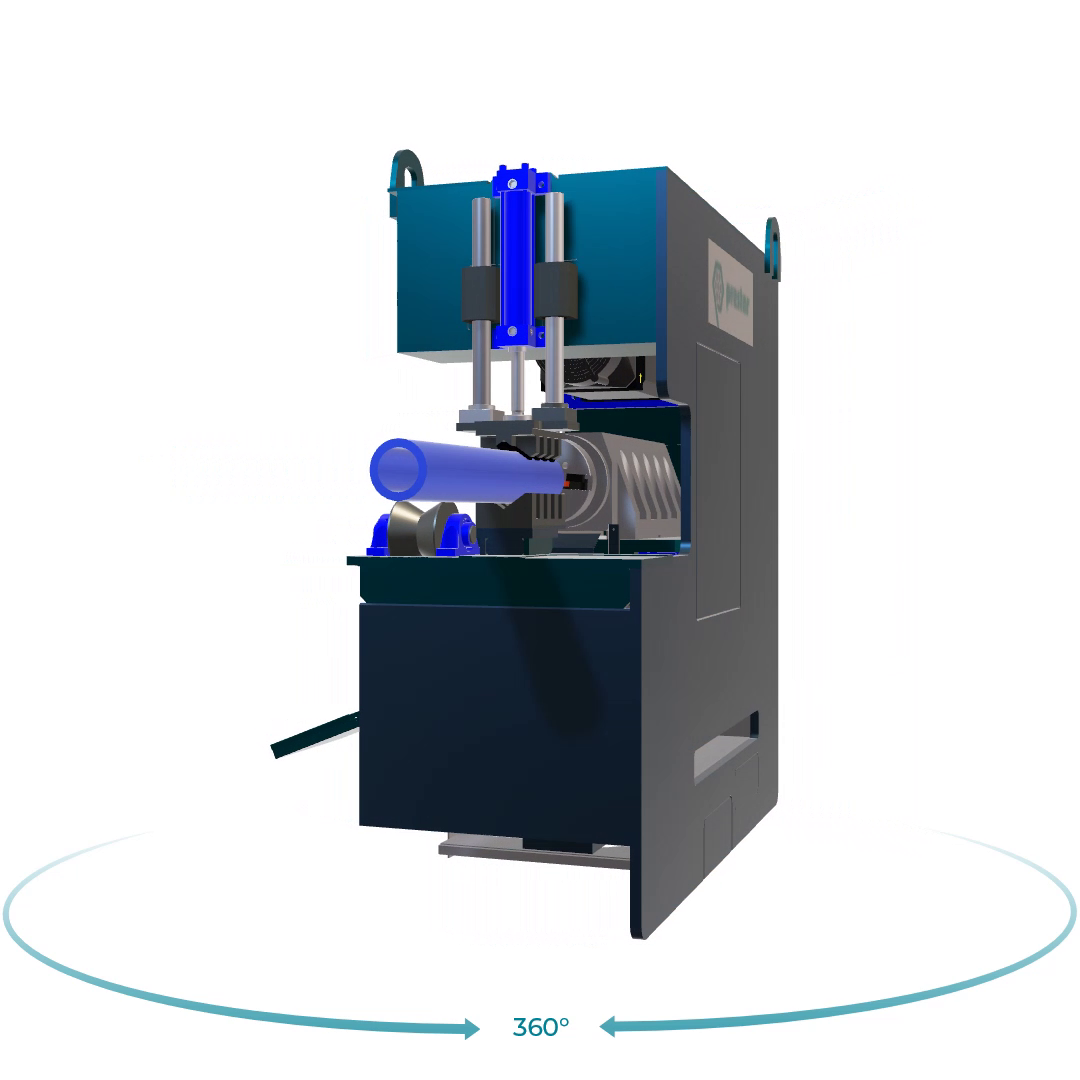

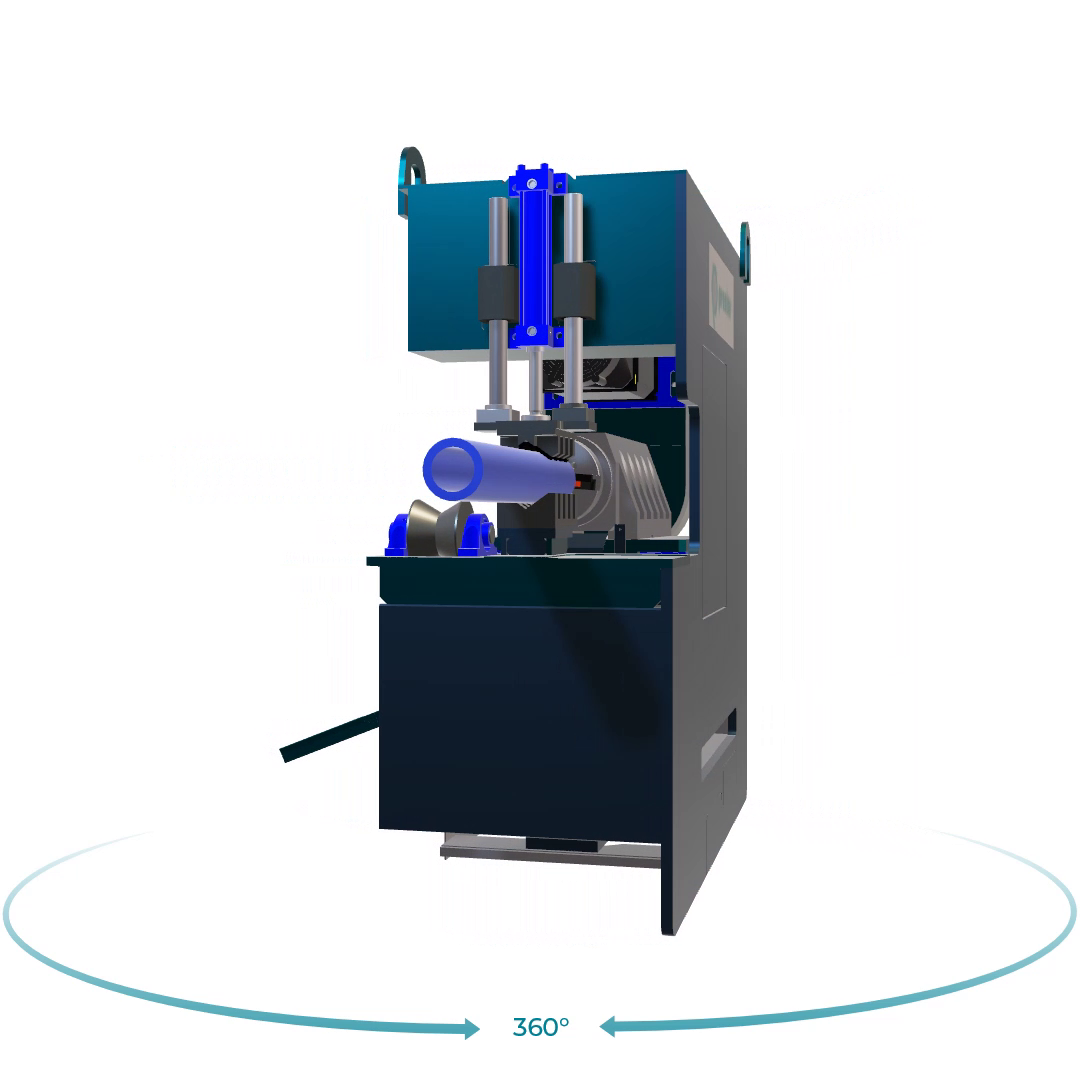

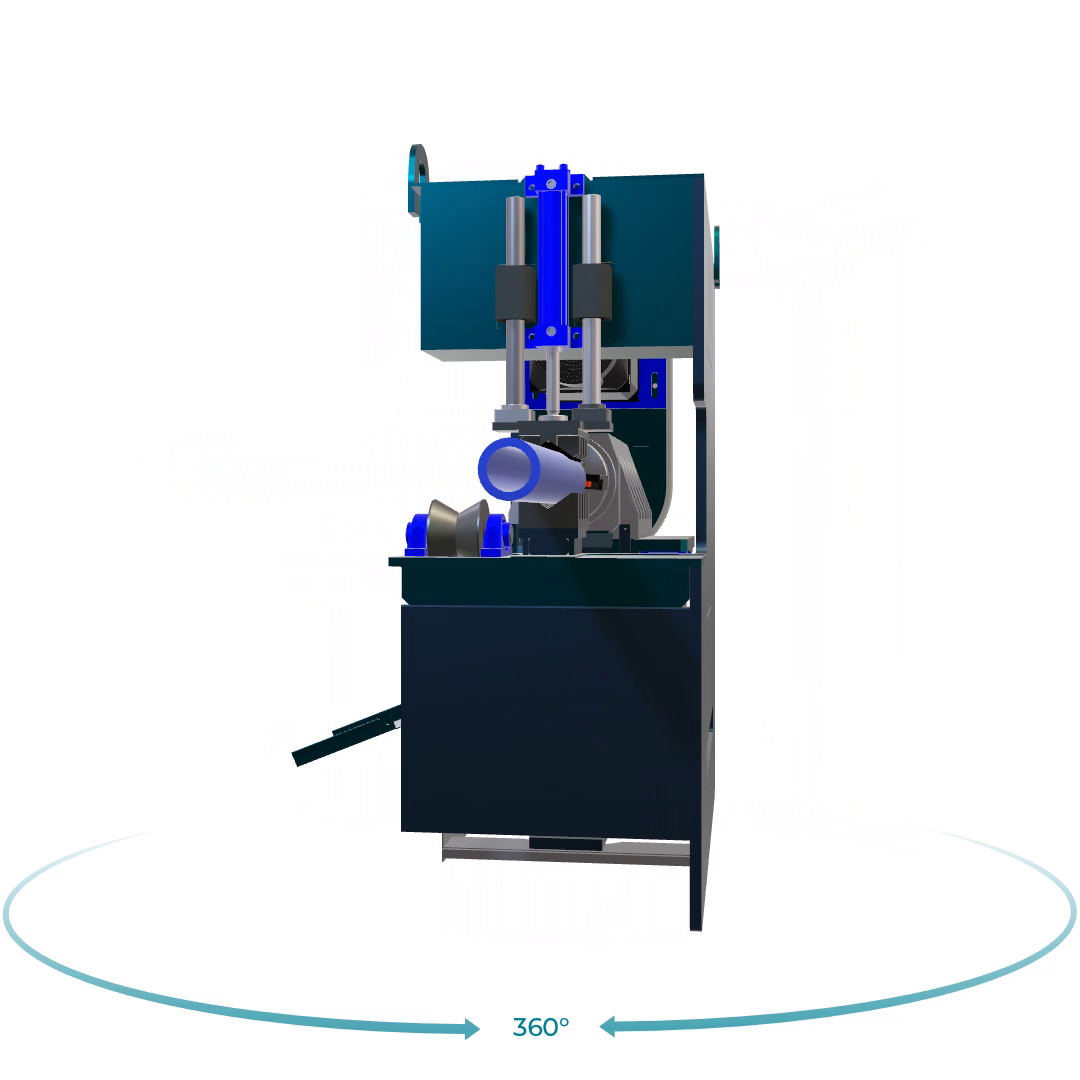

Internal pipe grinder

Description of the device

It is used to remove surface defects and to remove scale from the inner diameter of pipes.

The tube rotates by means of driven radial lunettes and a guide mandrel with a grinding wheel is inserted into the tube. The disc is made up of a set of grinding stones.

Technical parameters of the machine

| Inner diameter of pipes: | 180 – 600 mm |

| Length of pipes for single sided grinding: | to 8 000 mm |

| Max. Max. length of pipes when grinding from both sides: | up to 16 000 mm |

| Material removal in one cycle of passage: | up to 0,20 mm |

| Quality of the internal surface after grinding | up to 1,6 Ra |

| Automatic mode allows for: |

|

| Abrasion extraction: | by connecting the flexible, abrasion-resistant hose to the end of the pipe using the interchangeable conical socket |

Other equipment of the machine

- Input tray tables with automatic loaders The loaders move the pipe from the table to the radial rollers to the grinding axis The loaders move the pipe from the table to the radial rollers to the grinding axis.

- Translators for unloading pipe from rollers onto a table

- Filtration device with a fan for suction of particles after grinding. Filtration device can be set up in the production hall.

- Semi automatic insertion of the suction hose to the suction end of the pipe.

- For long pipes over 8 m, two mirror grinders are set up to grind the pipe from both ends. This solution increases the productivity of long pipe production and saves handling times, including 180° pipe rotation.

- Manual ultrasound tube wall thickness measurement.

- Extended visualization with an emphasis on intuitive and detailed display of operating states and the place of failure of the grinder.

- Enhanced service with the ability to display manuals, service guides and other necessary documentation on the machine HMI to minimize service times

- Collection of agreed production parameters with automatic saving, display and data export.

External stationary pipe grinder

Description of the device

Technical parameters of the machine

|

Diameter of pipes: |

200 – 600 mm |

|

Pipe lengths: |

3 000 – 16 000 mm |

|

Material removal per cycle: |

up to 0,5 mm in one cycle |

|

Grinding belts: |

150 x 3 000 mm |

|

Pressure of grinding belts: |

pneumatic |

|

Tensioning of grinding belts: |

pneumatic |

|

Belt grinding speed |

30 m/s |

|

Replacement of grinding belts: |

in the parking position of the grinding unit there is a platform for easy access to the sanding belts |

|

Control panel with display: |

placed on the mobile grinding unit |

Other equipment of the machine

- Continuously variable belt grinding speed control

- Handling girder for inserting and removing pipes into and out of the machine.

- Manual ultrasound tube wall thickness measurement.

- Extended visualization with an emphasis on intuitive and detailed display of operating states and the place of failure of the grinder.

- Enhanced service with the ability to display manuals, service guides and other necessary documentation on the machine HMI to minimize service times

- Collection of agreed production parameters with automatic saving, display and data export.

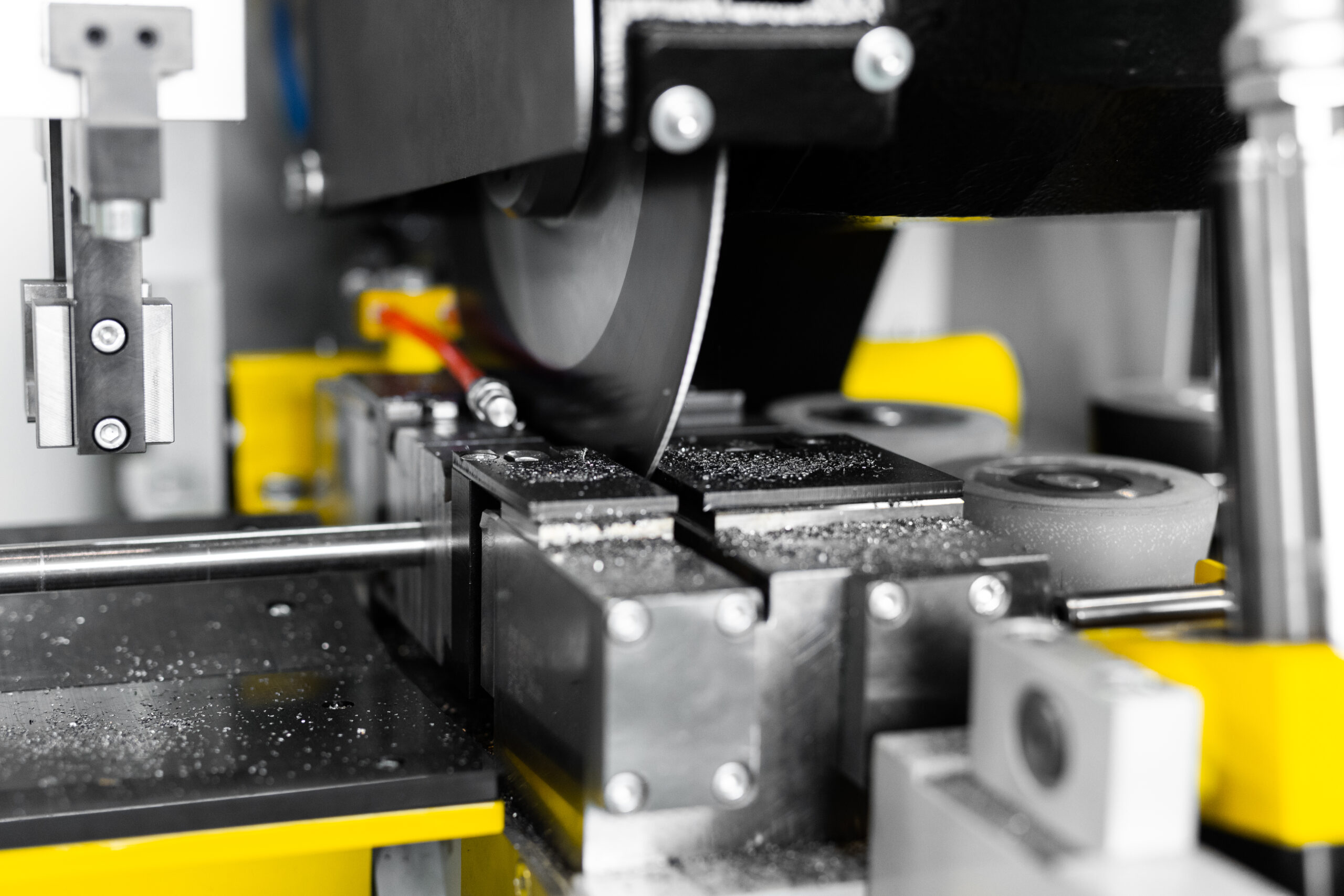

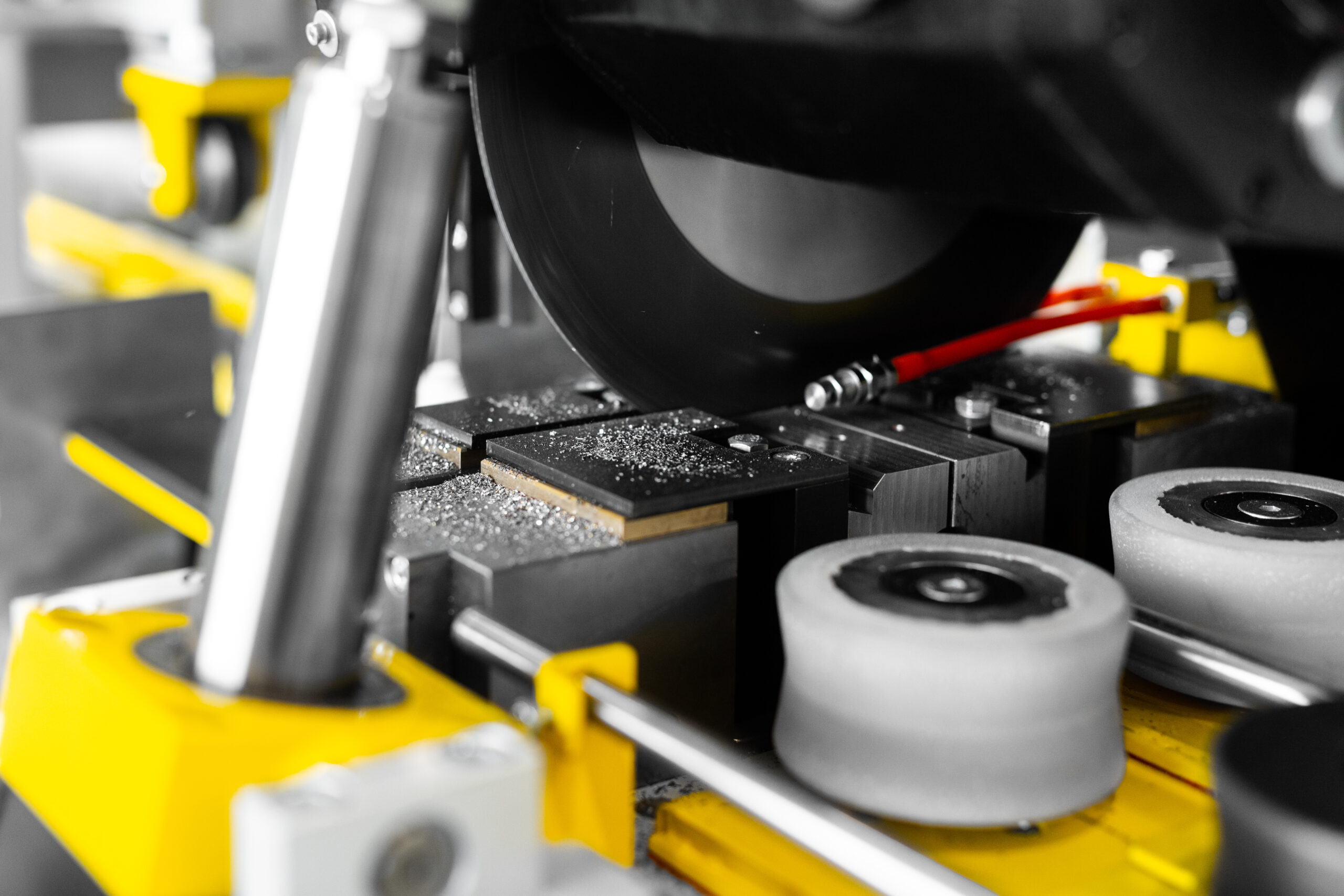

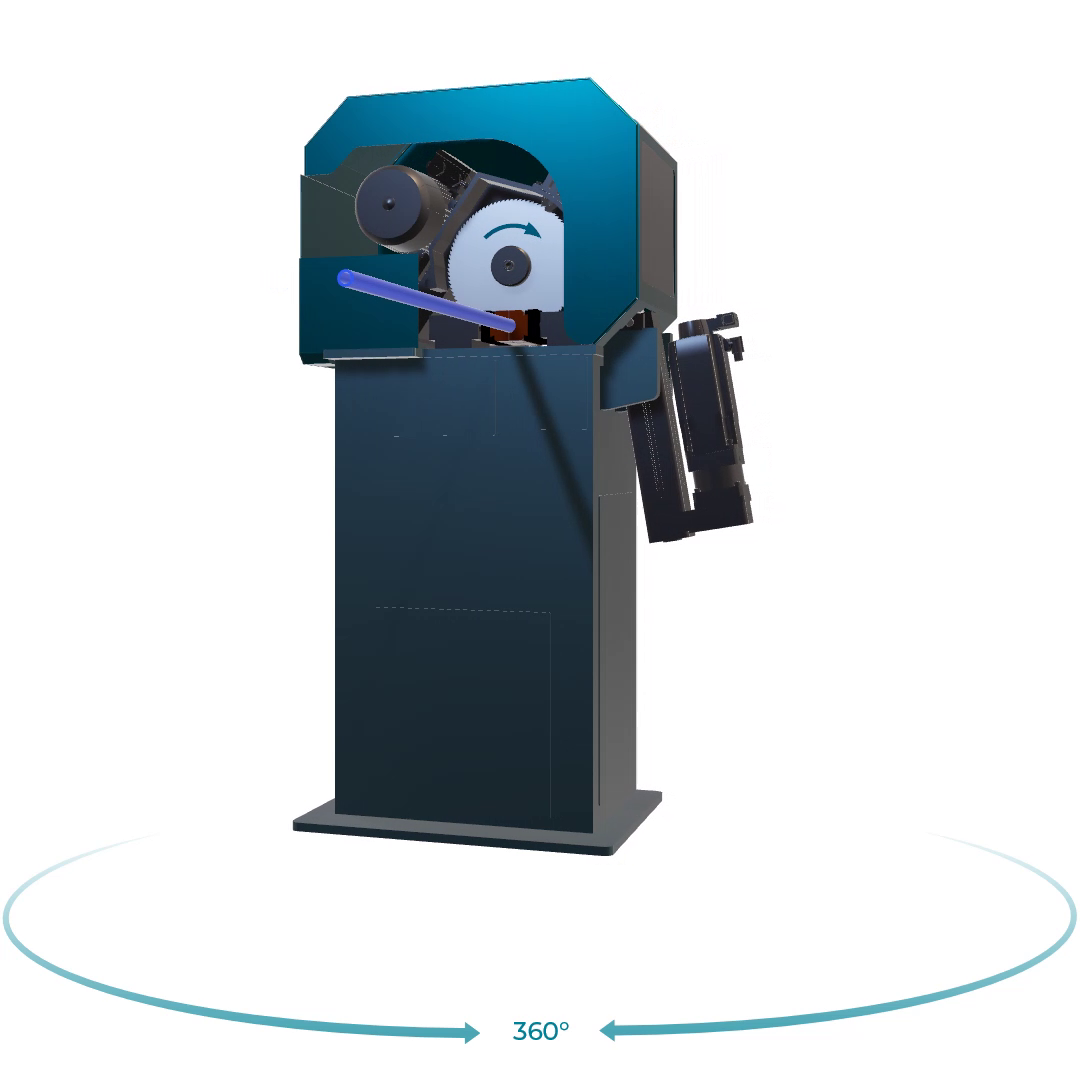

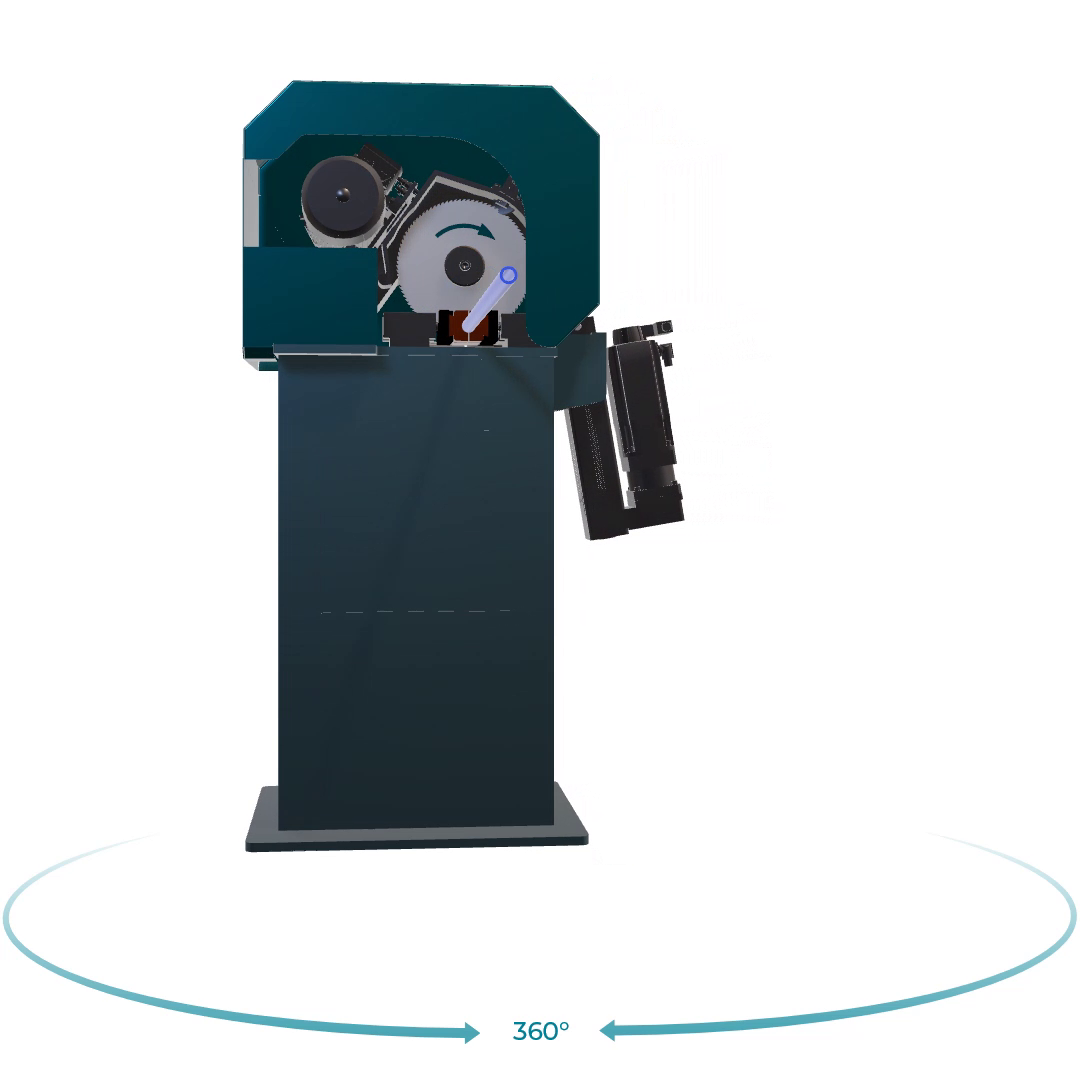

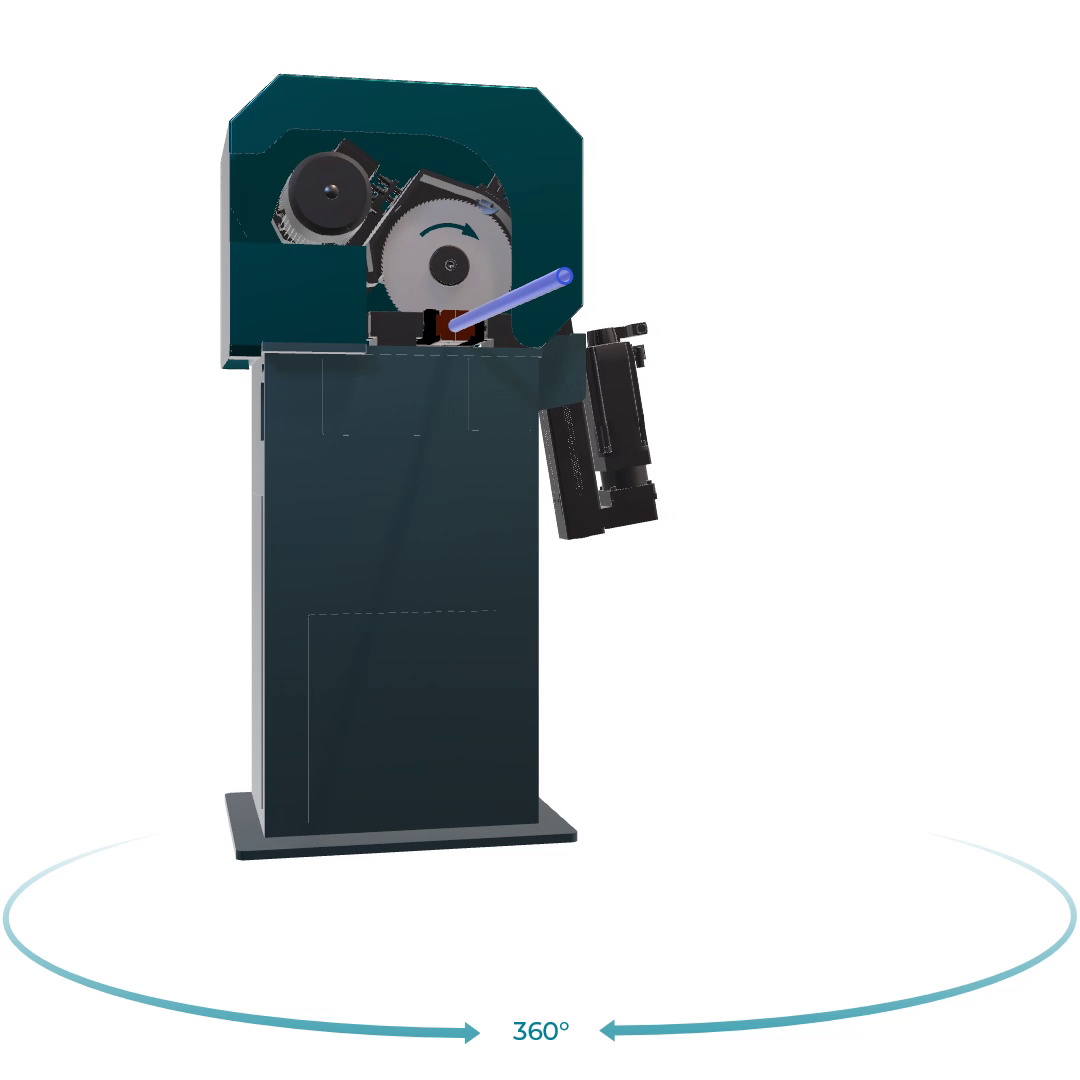

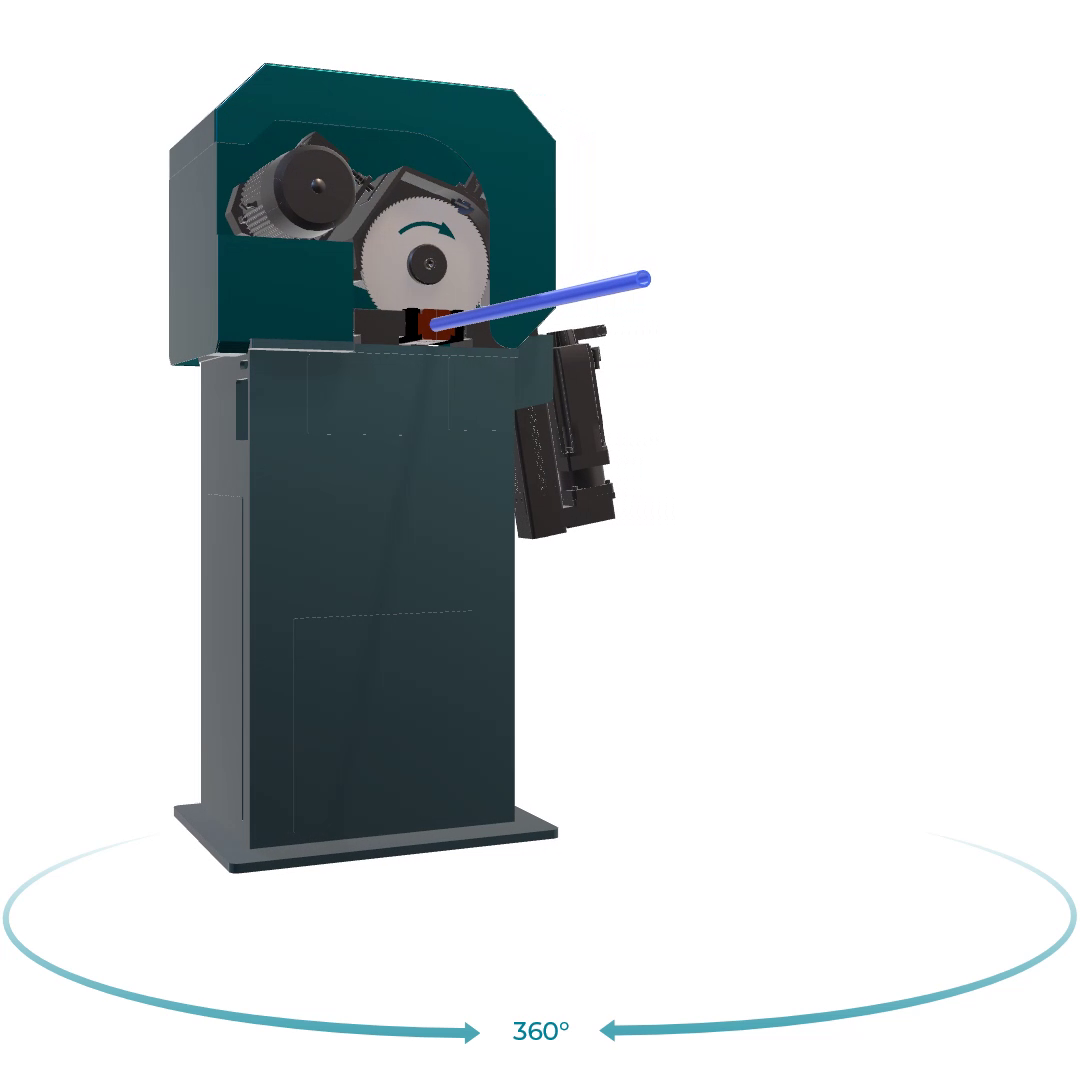

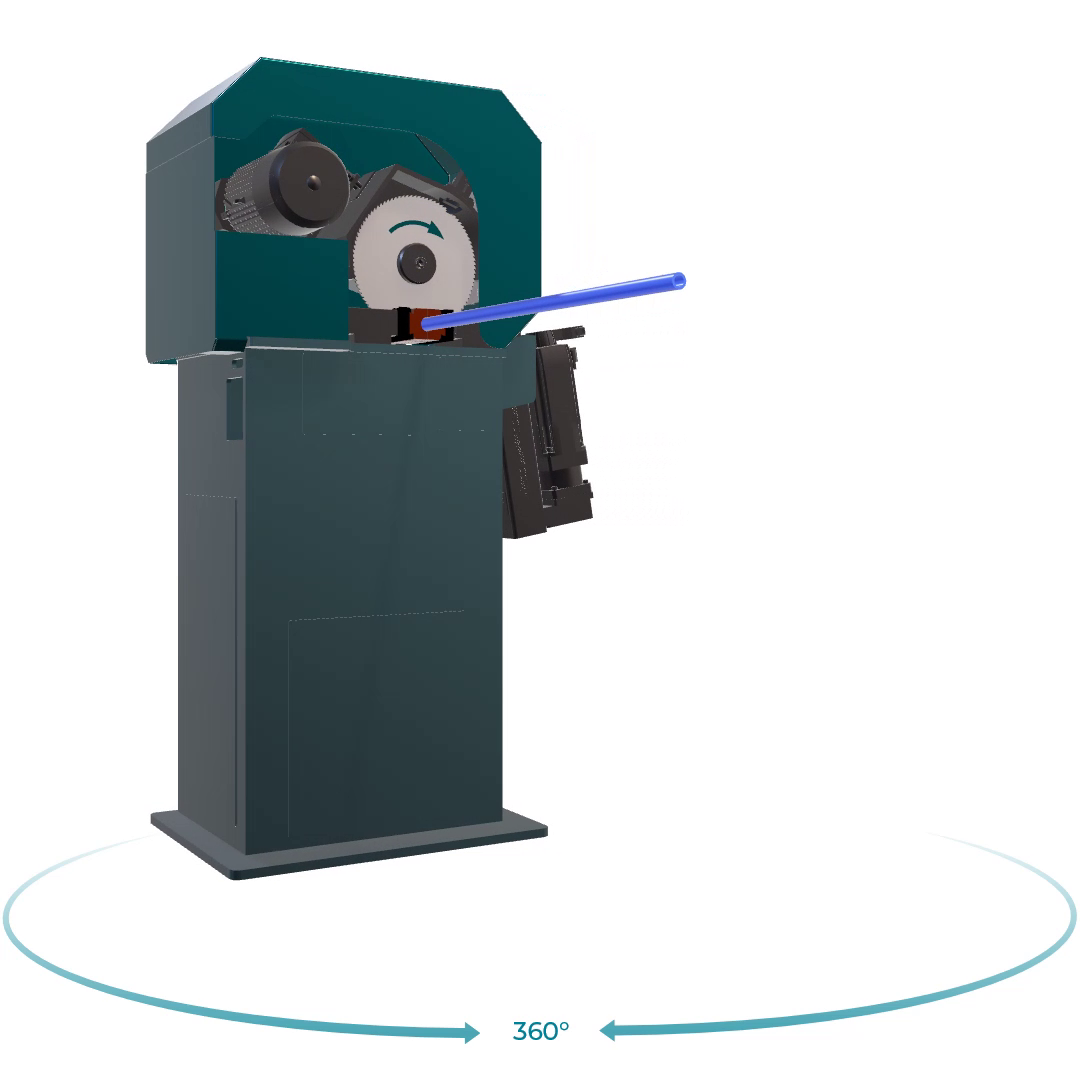

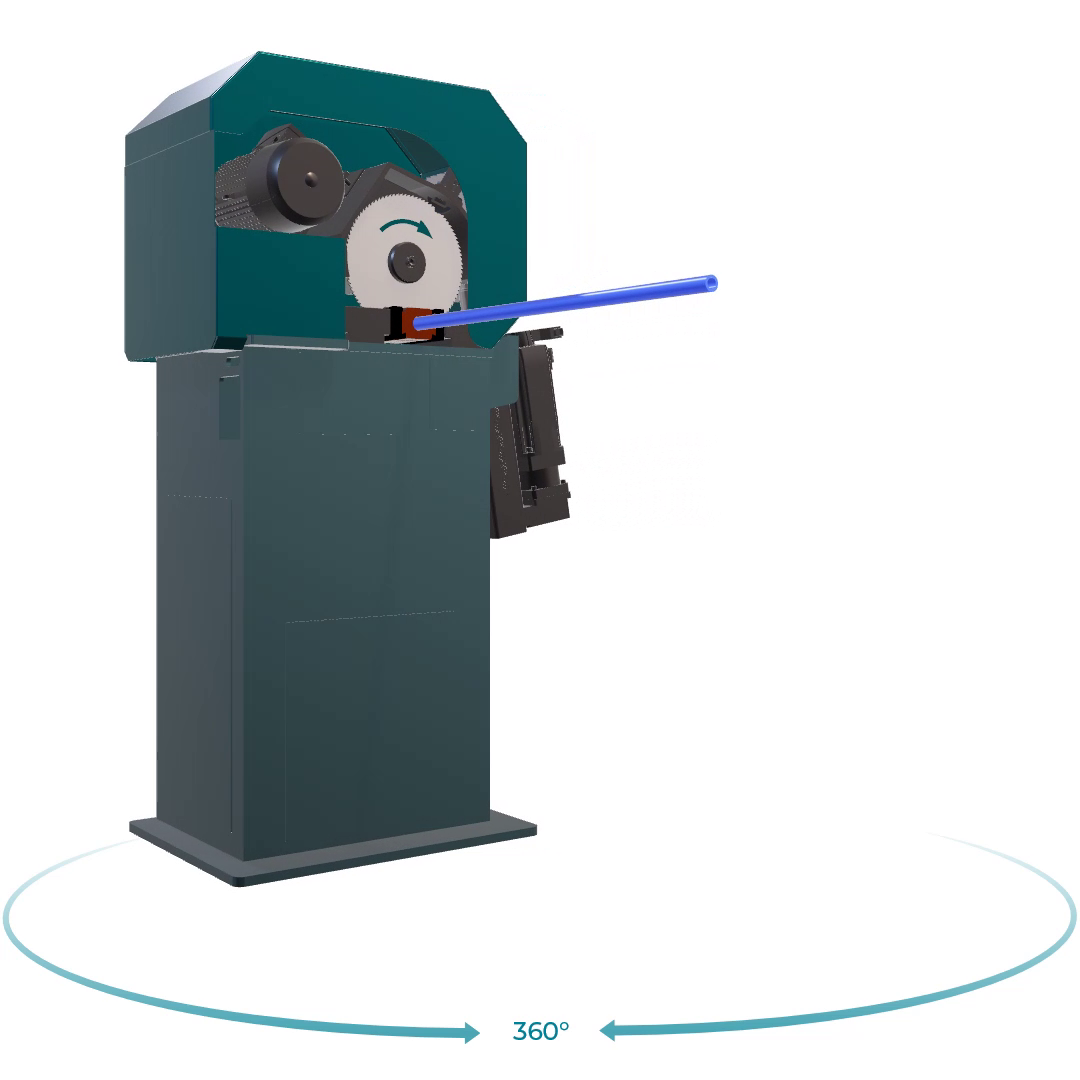

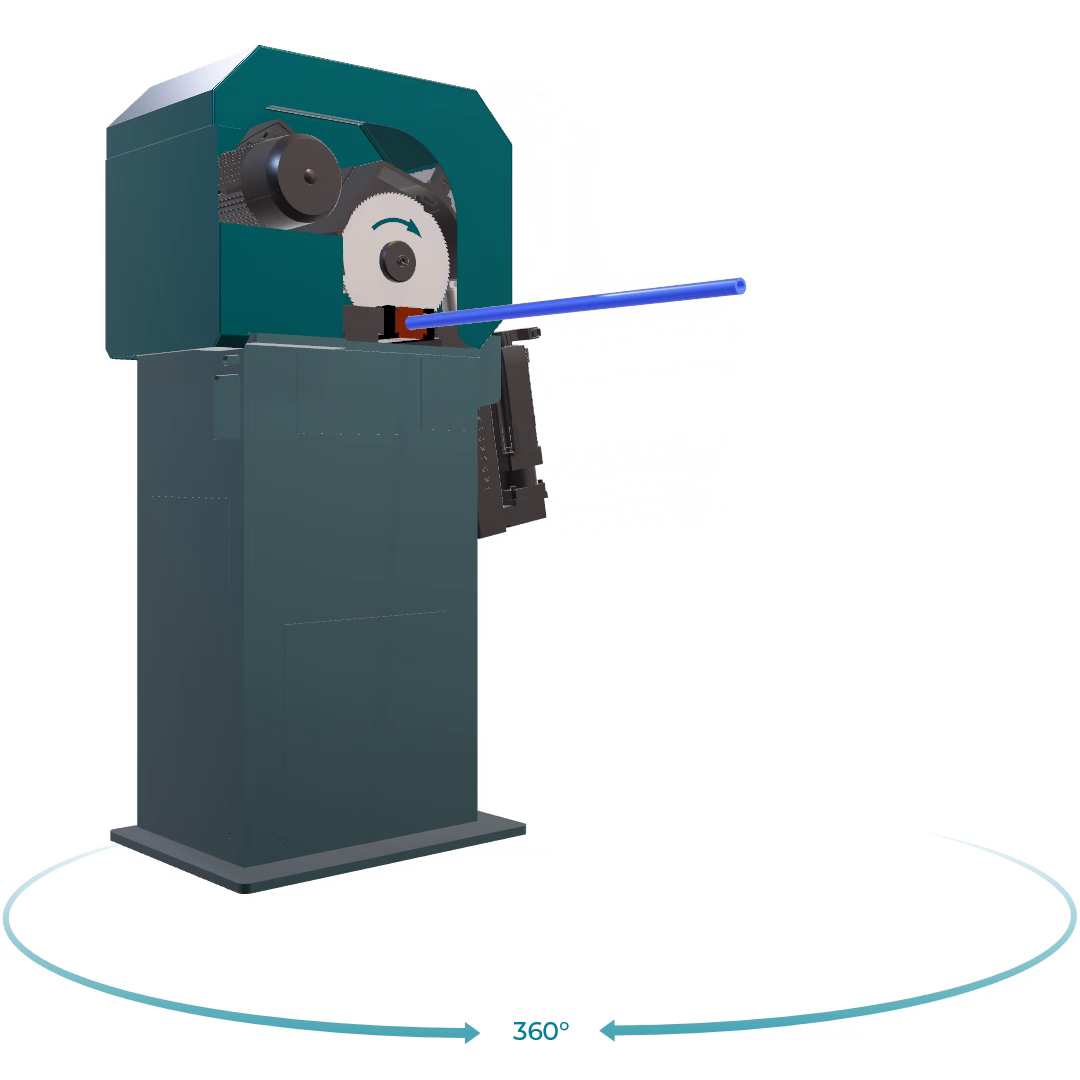

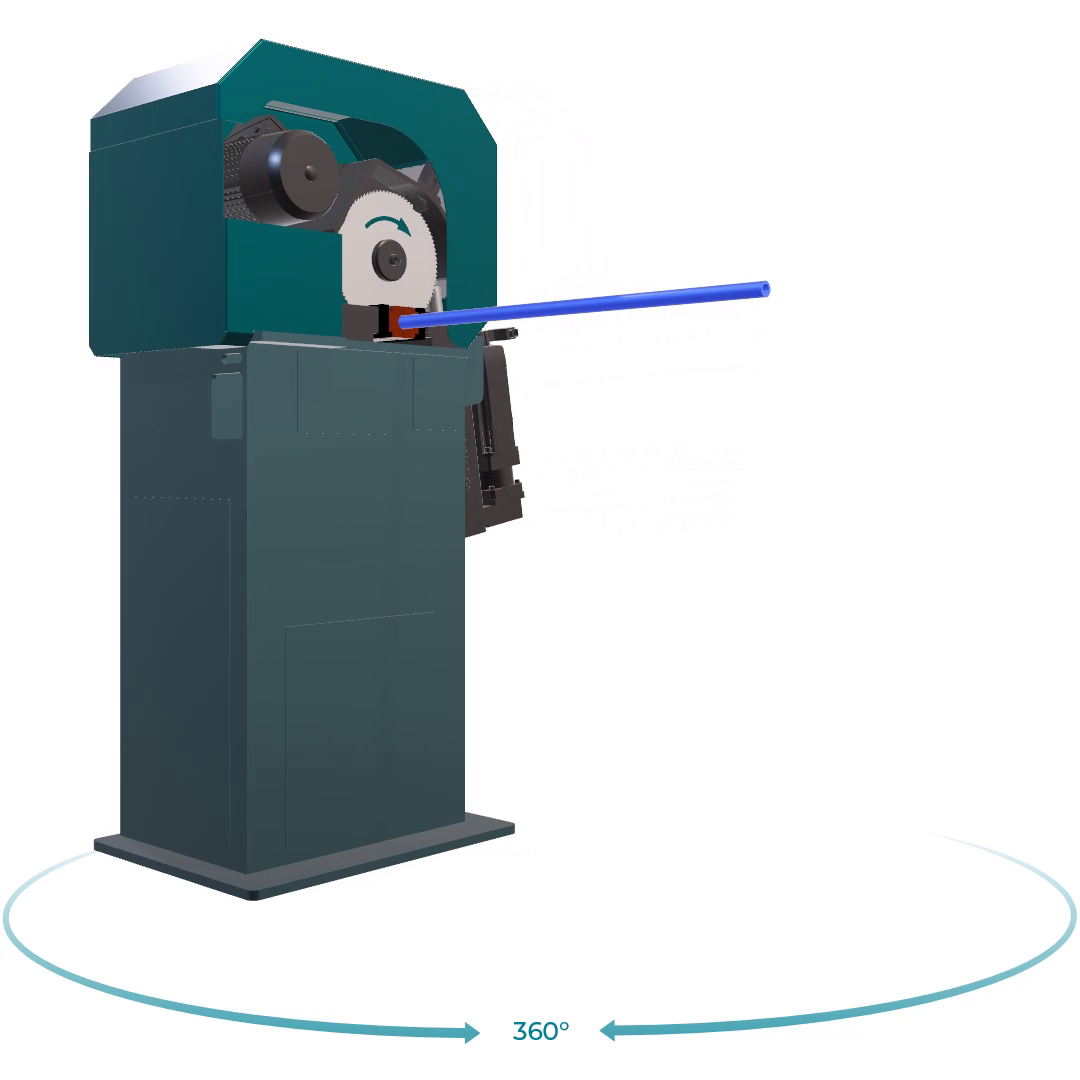

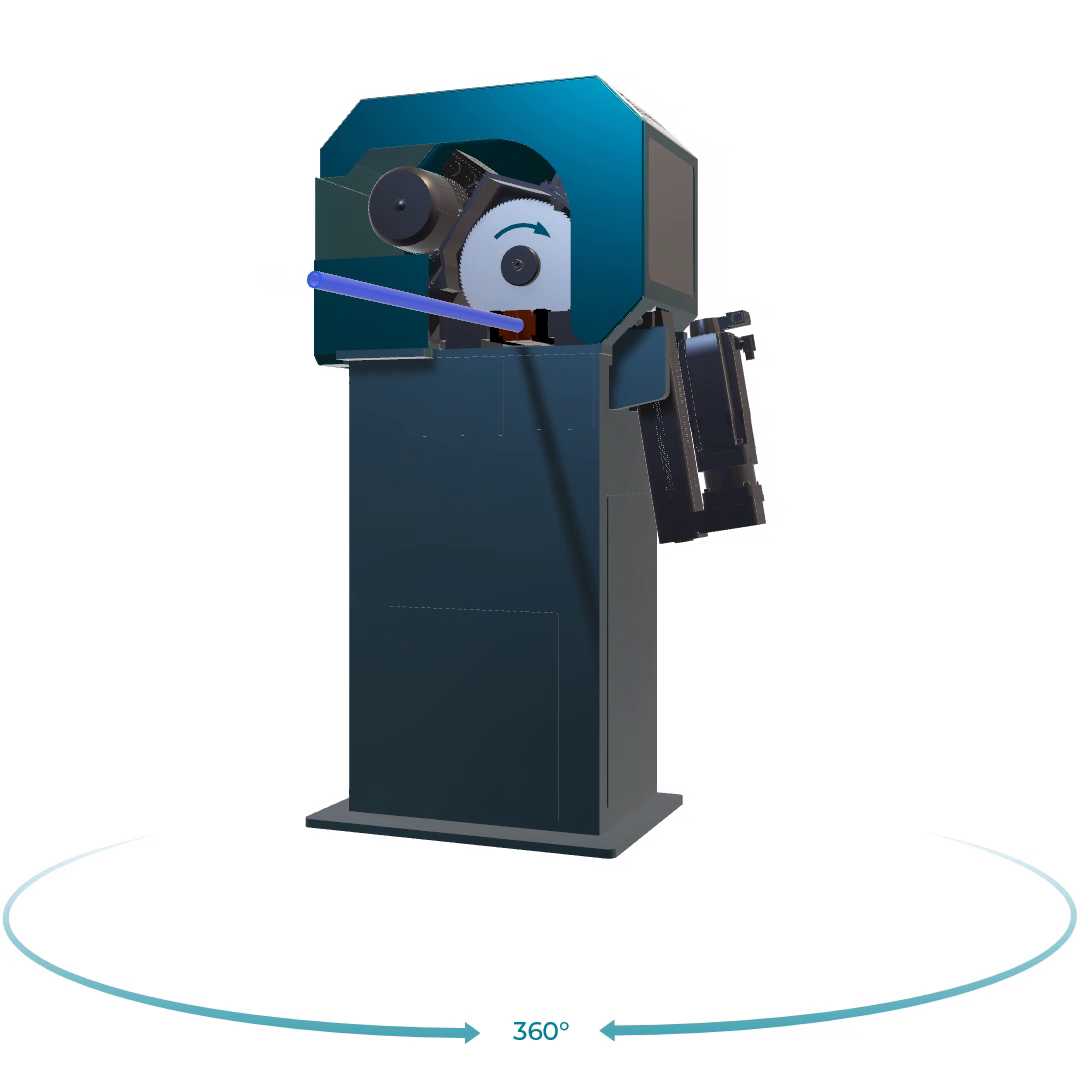

Circular saw

Description of the device

Circular saws are designed to cut tubes and bars to precise lengths. The range of tubes is from 6 to 140 mm. Cutting with HSS discs or discs with HM inserts.

Technical parameters of the machine

- Cutting pipes into lengths with an accuracy of + - 0.5 mm/ 6 m length.

- For continuous cutting, a circular saw can be used with a feed rate of up to 1.0 m/sec.

- To clean up the ends after cutting, the circular saw can be supplemented by brushing or chamfering the pipe ends

Other equipment of the machine

- optimization of the blade feed with respect to the diameter and wall thickness of the pipe

- emulsion spray on the dividing disc

- cleaning the disc

- jaw chips from chips after cutting

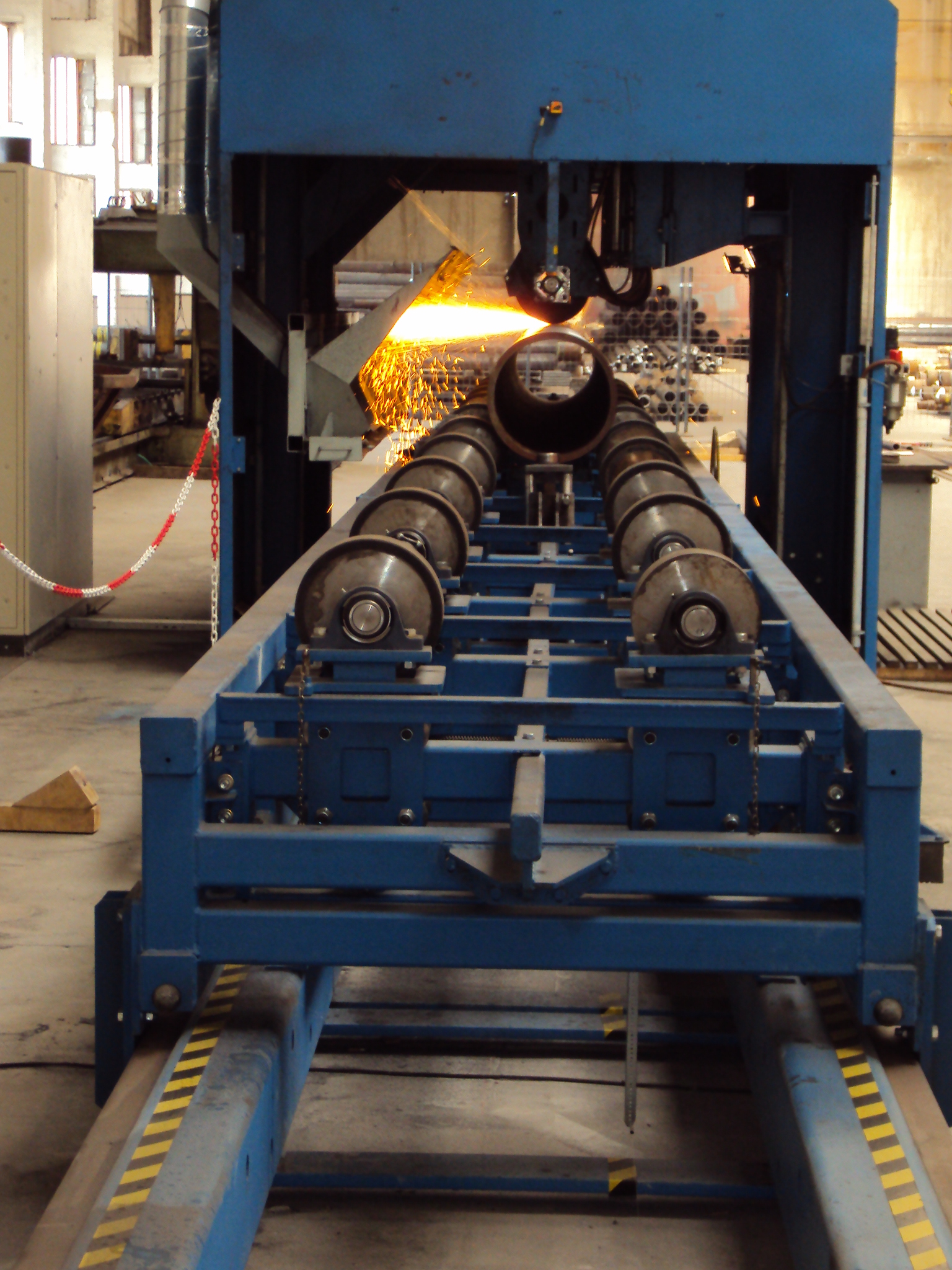

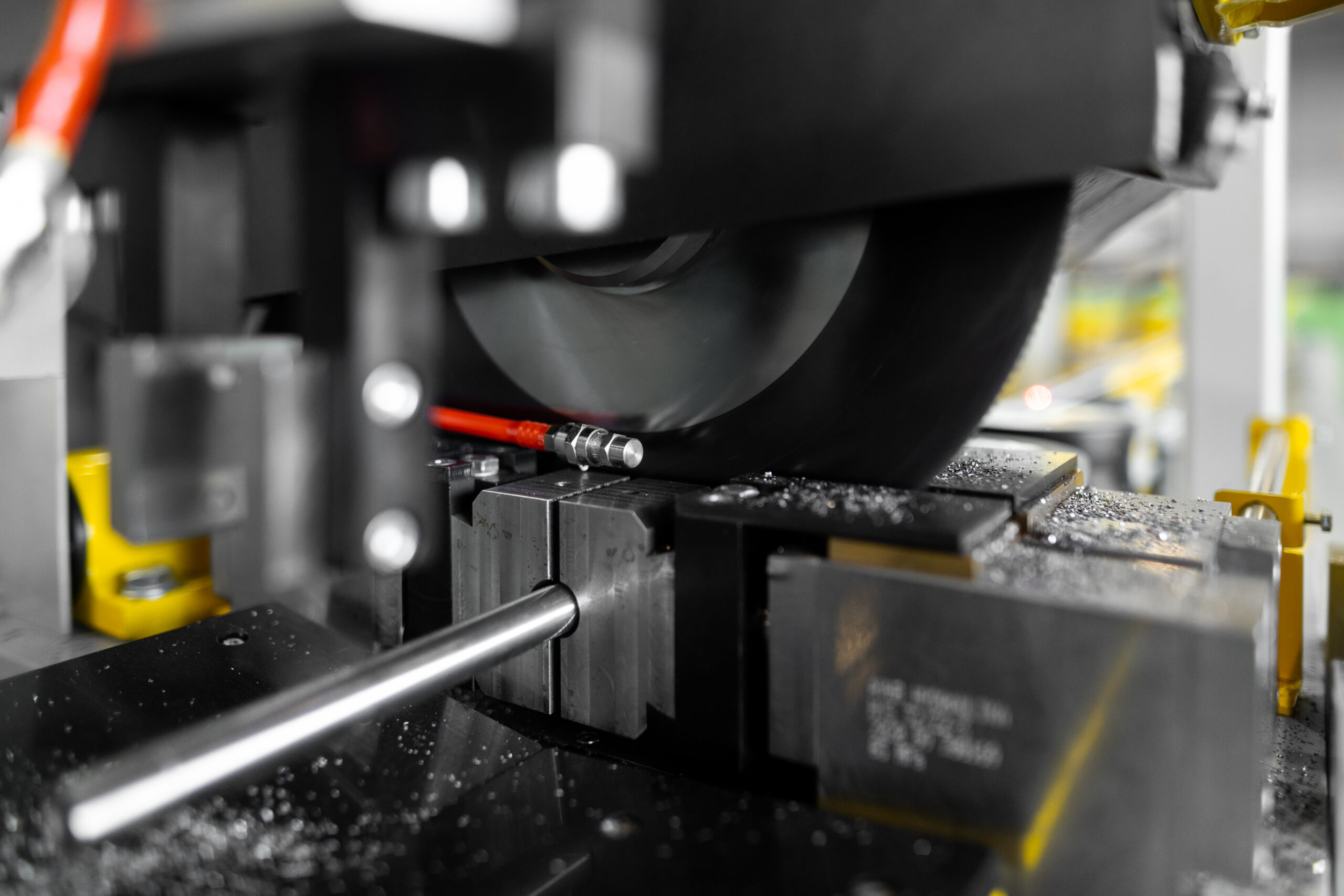

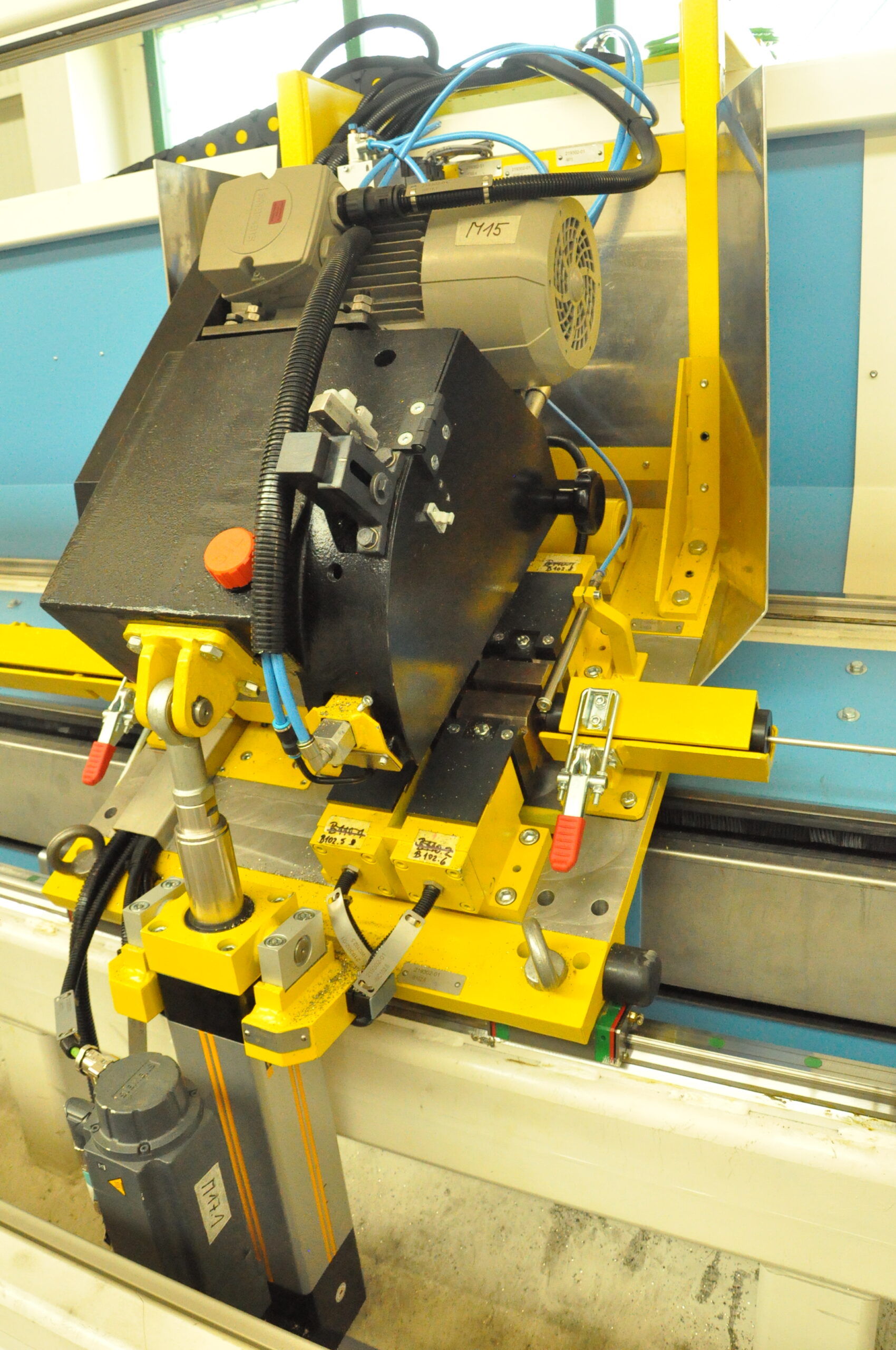

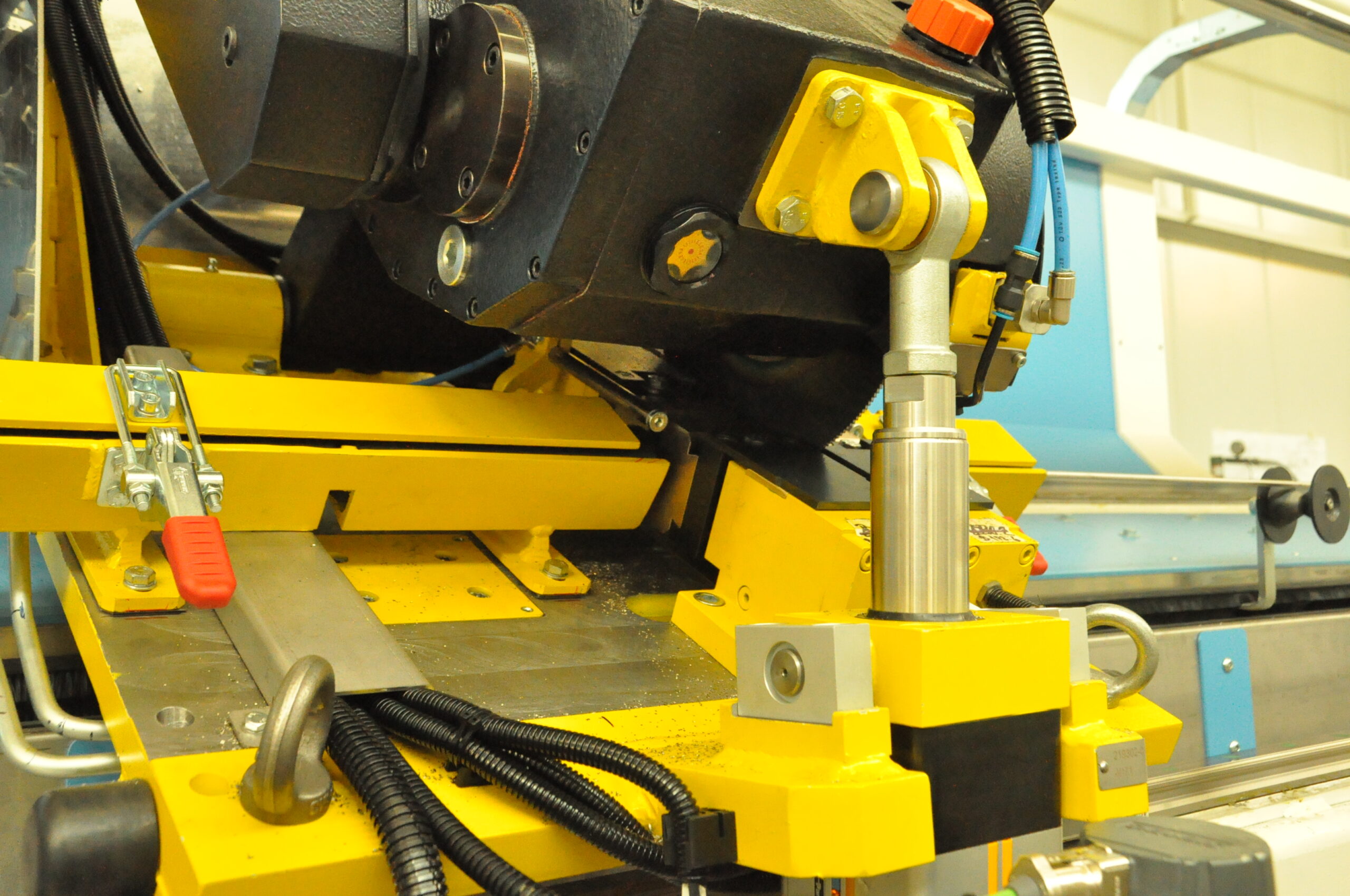

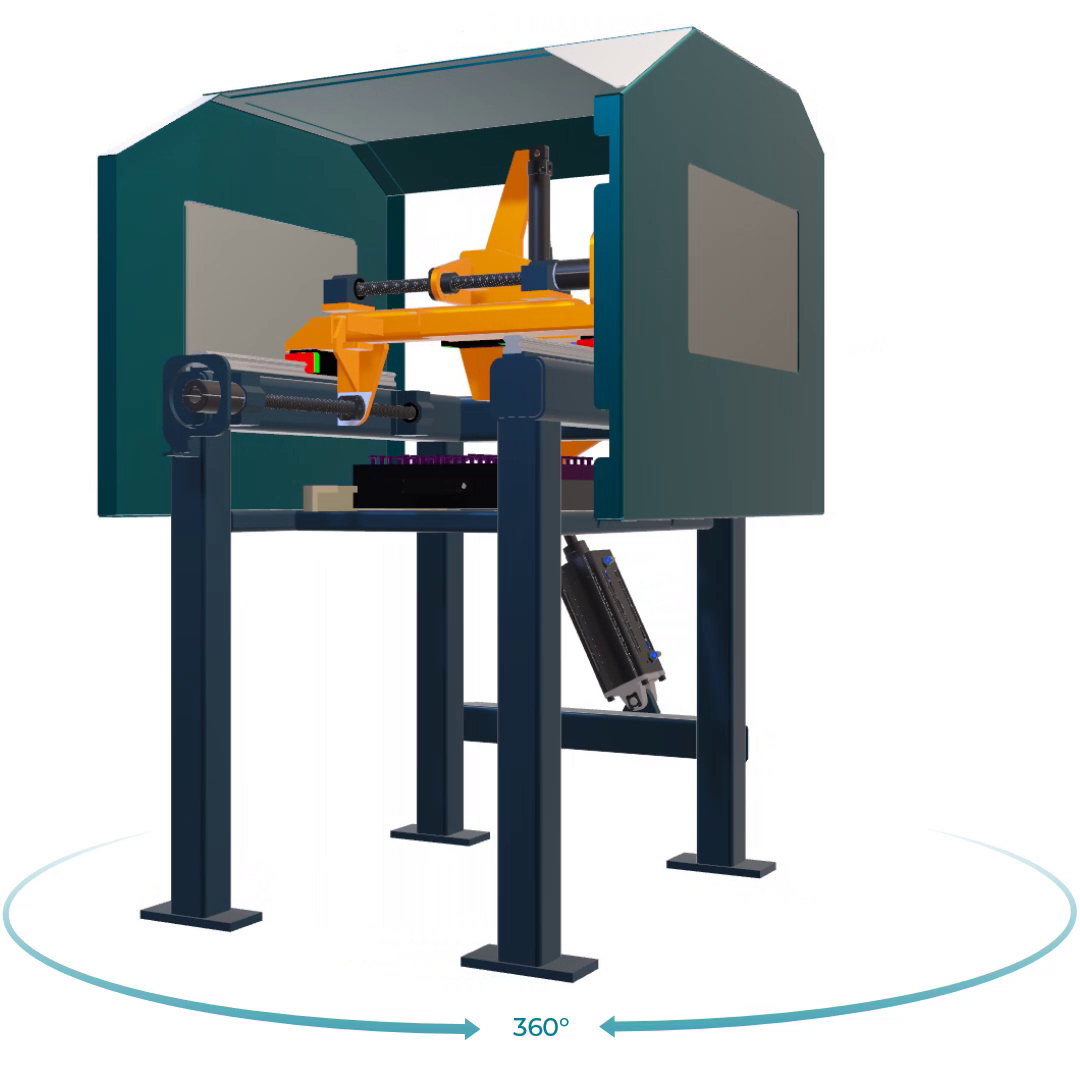

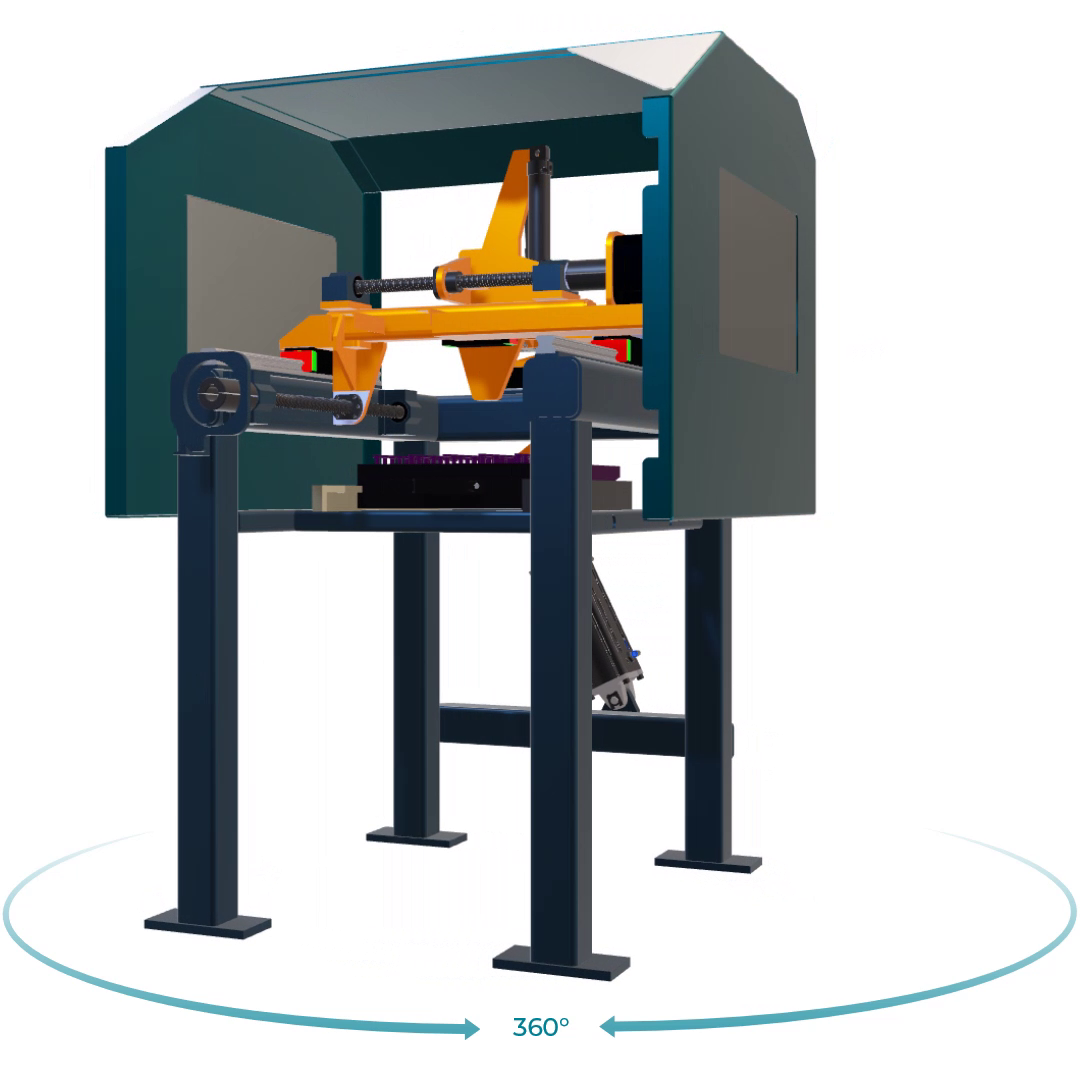

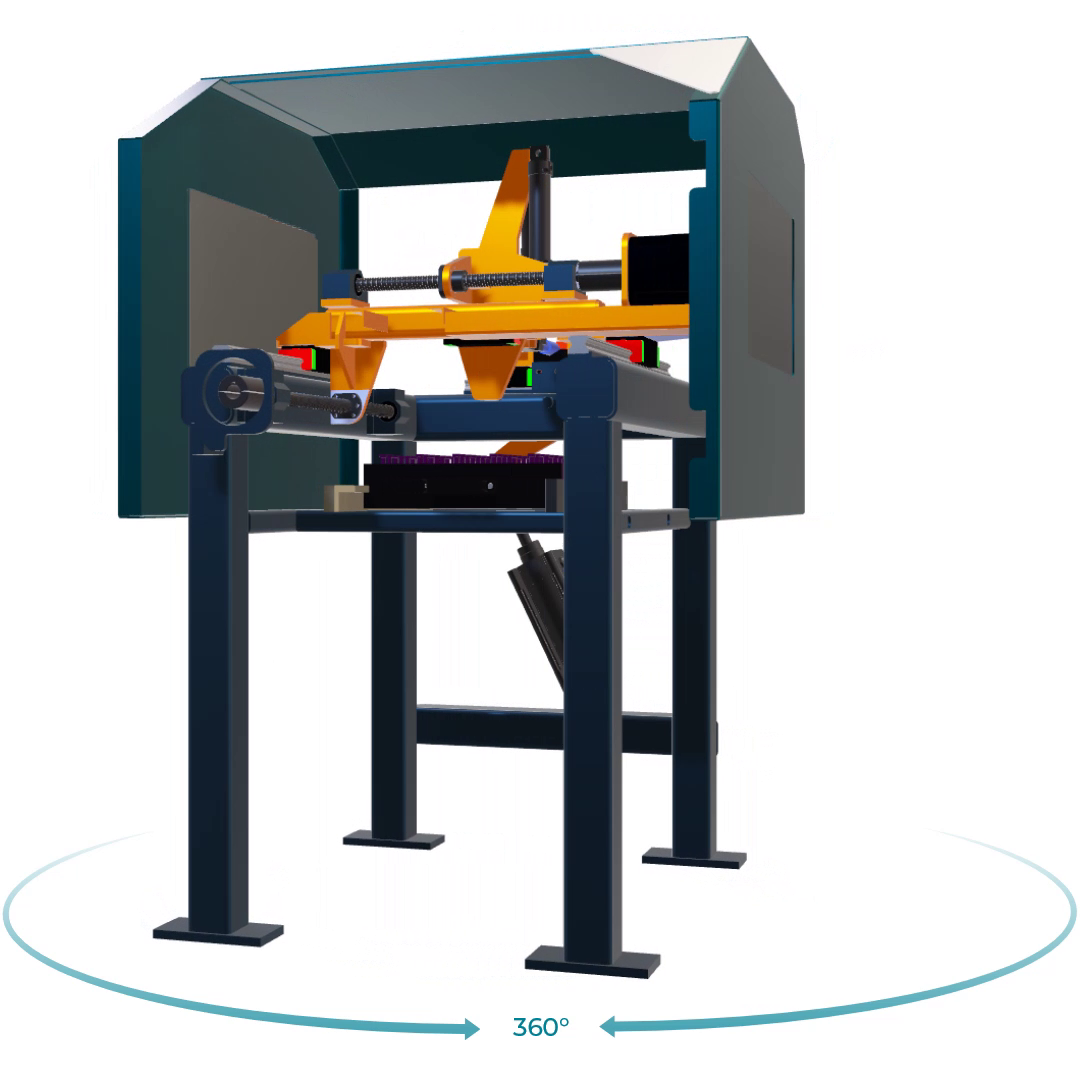

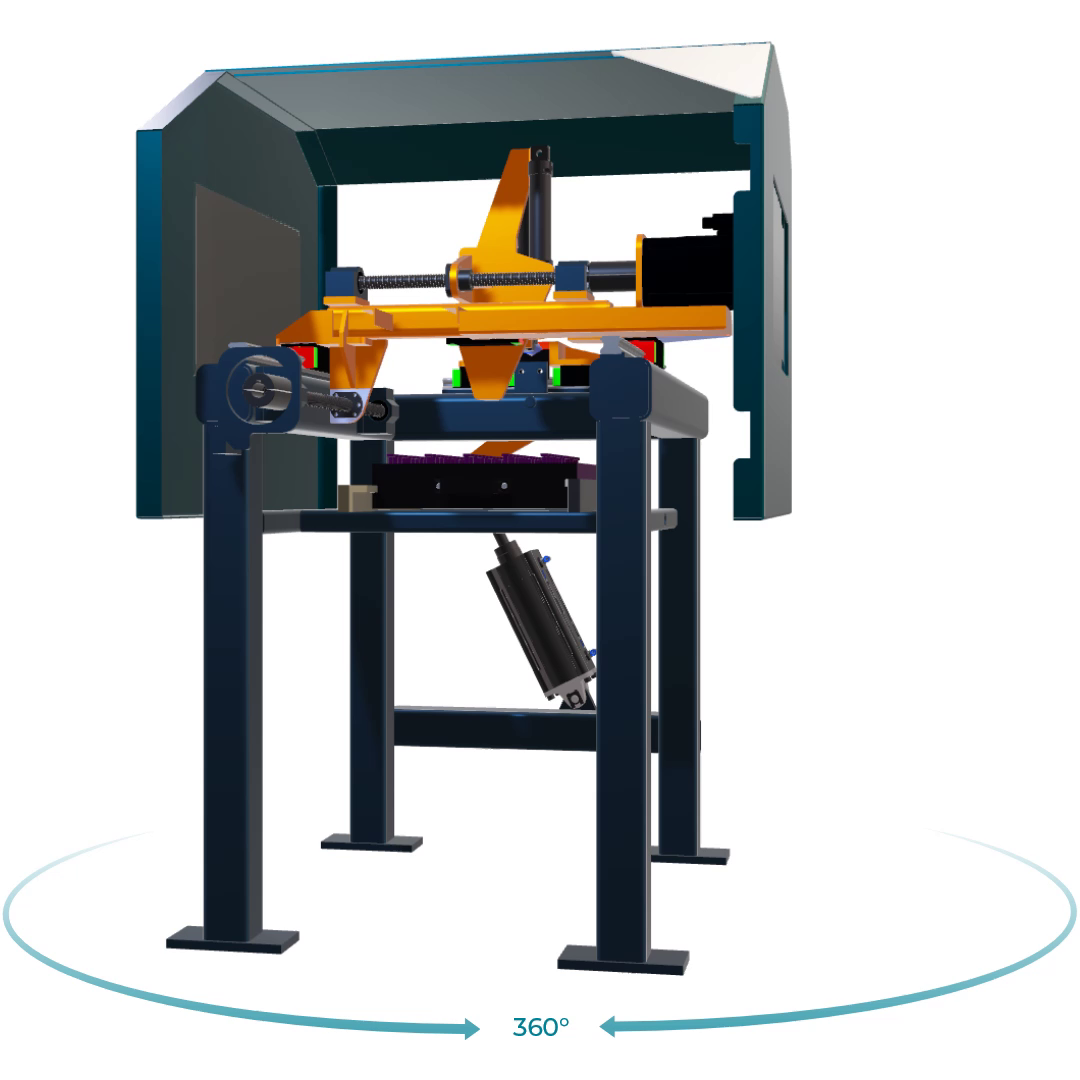

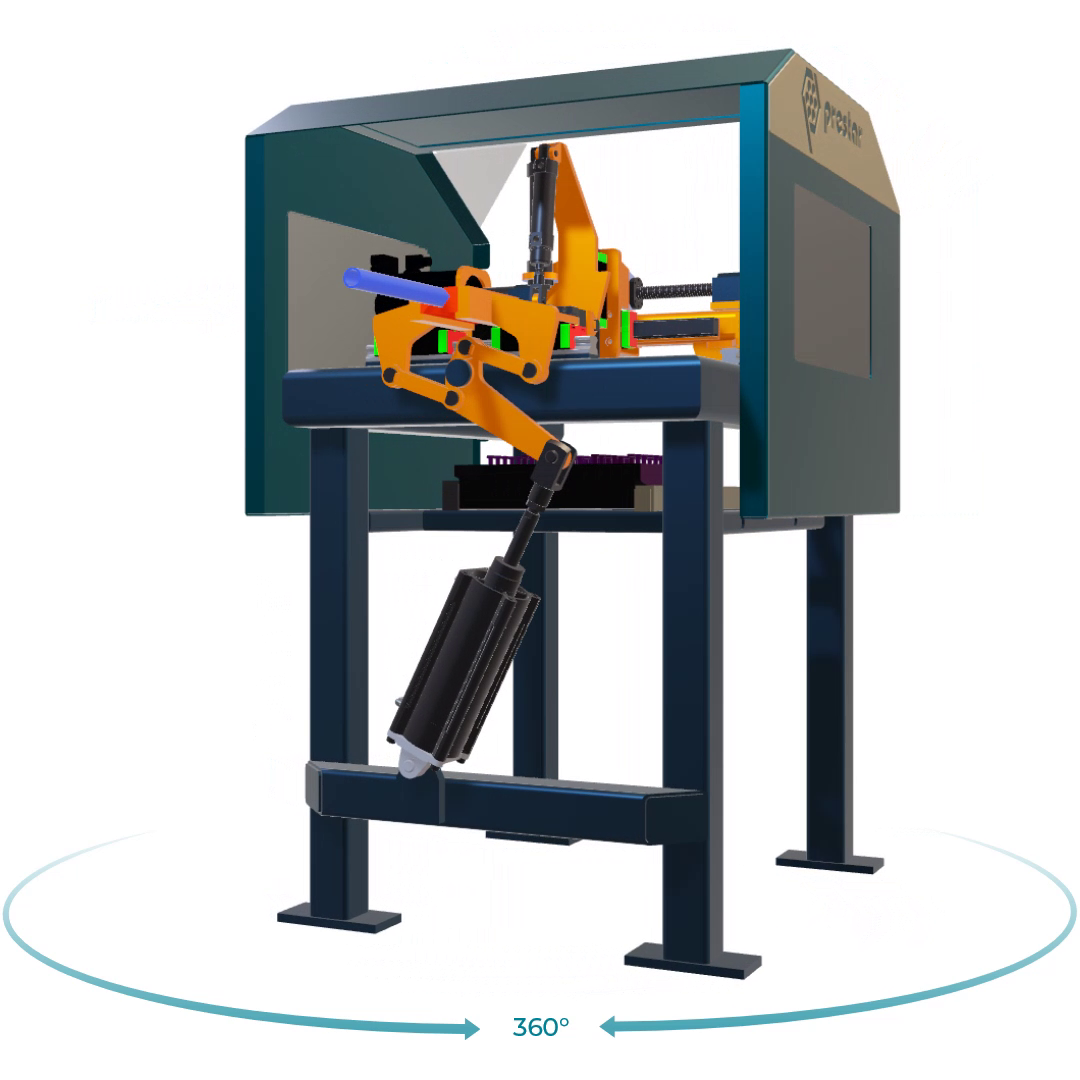

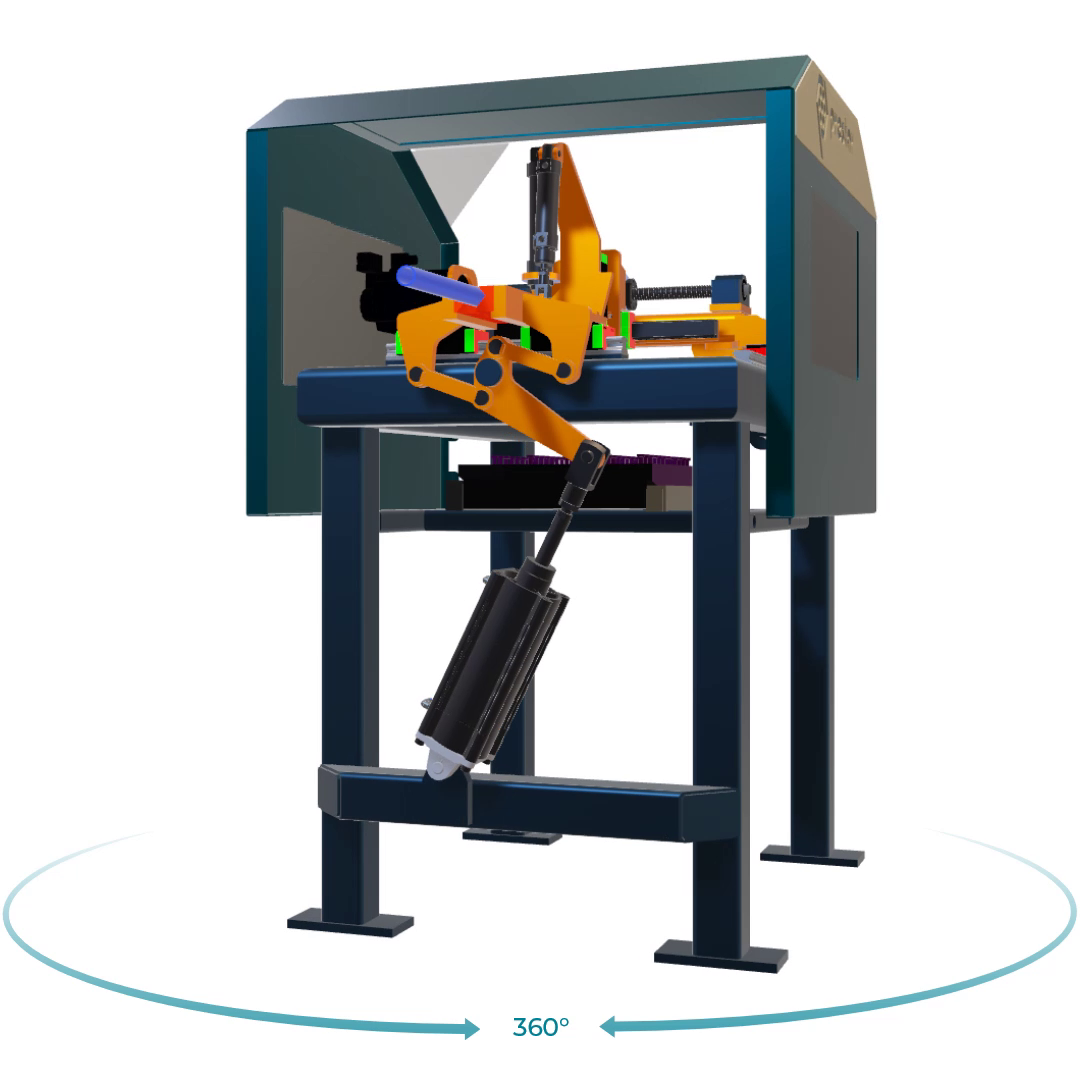

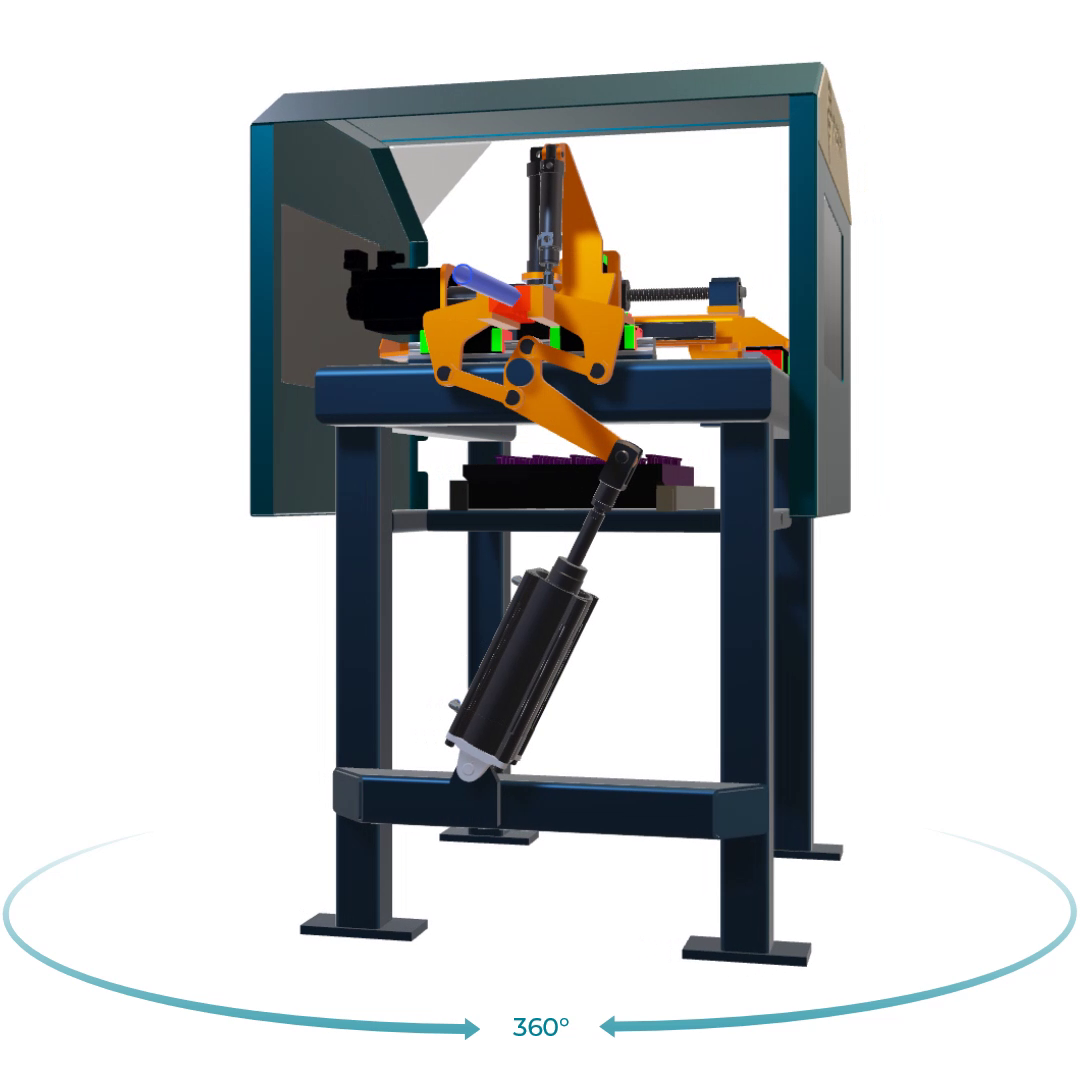

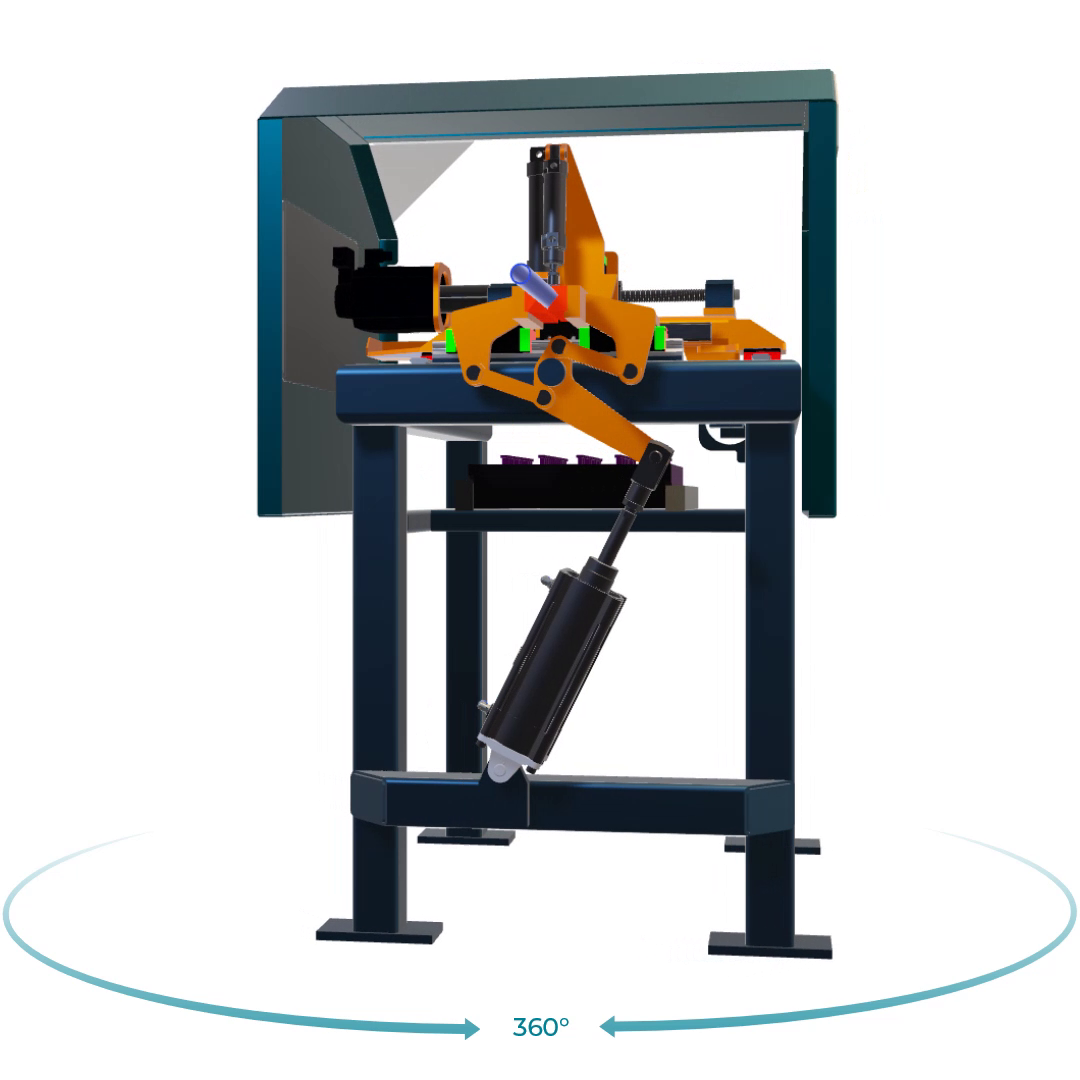

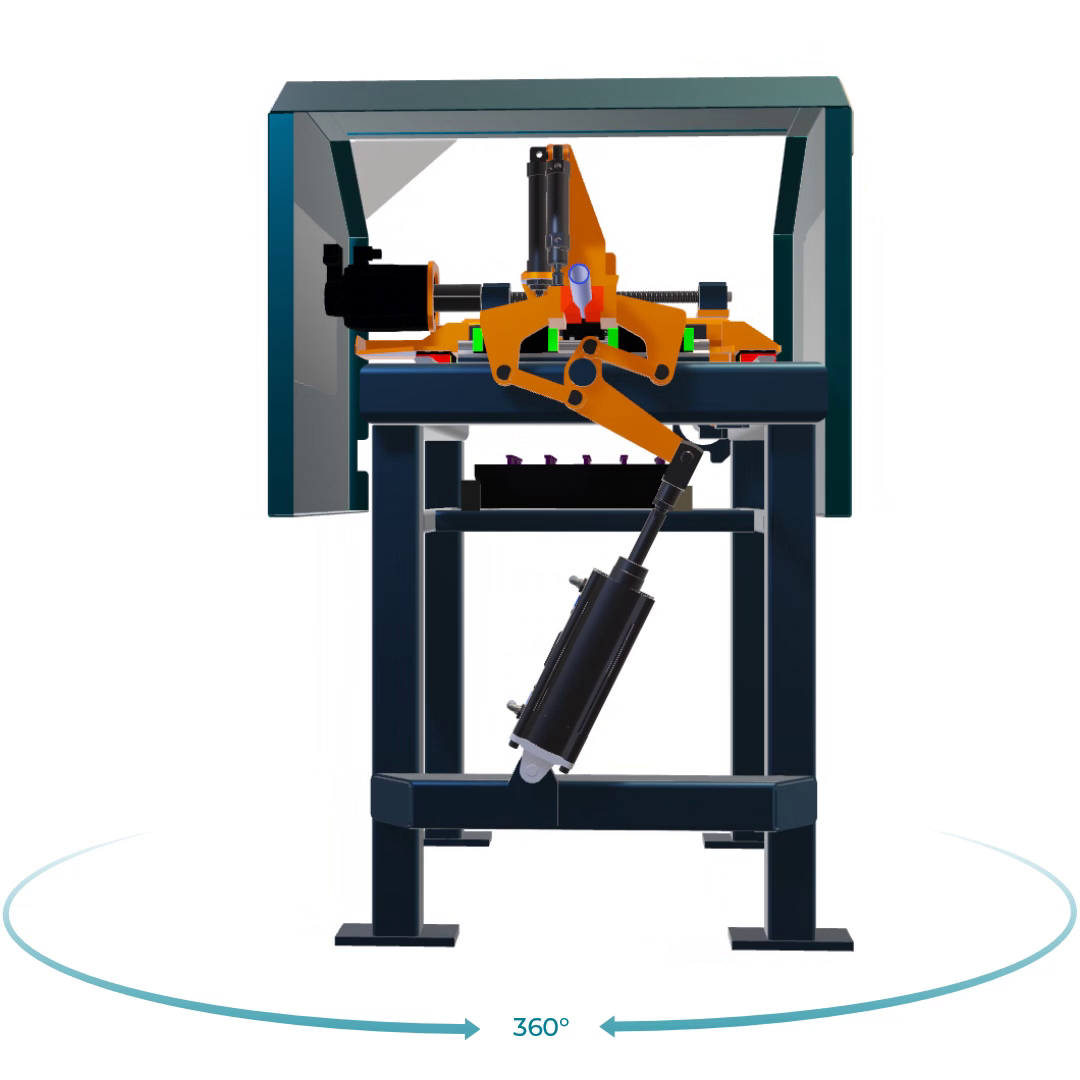

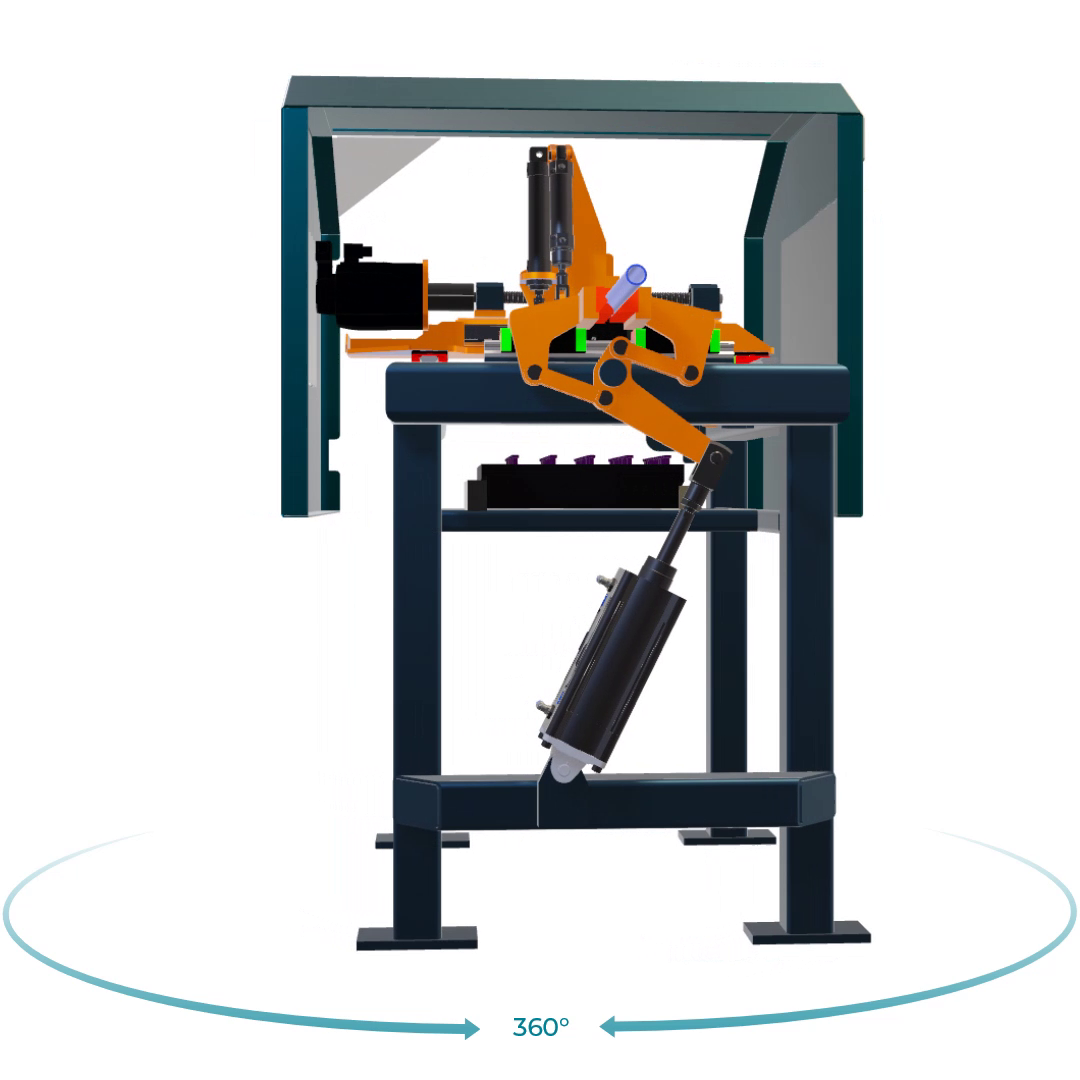

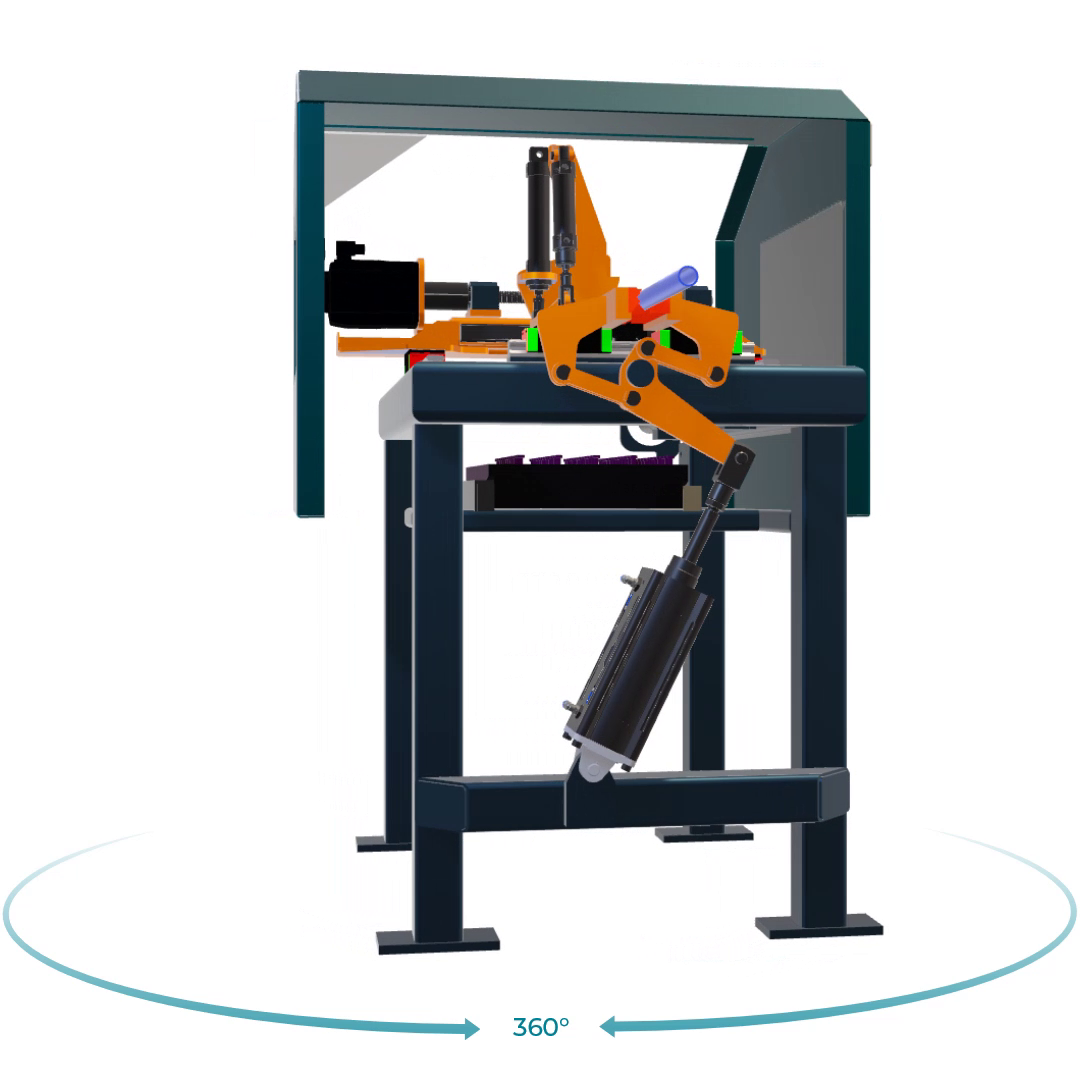

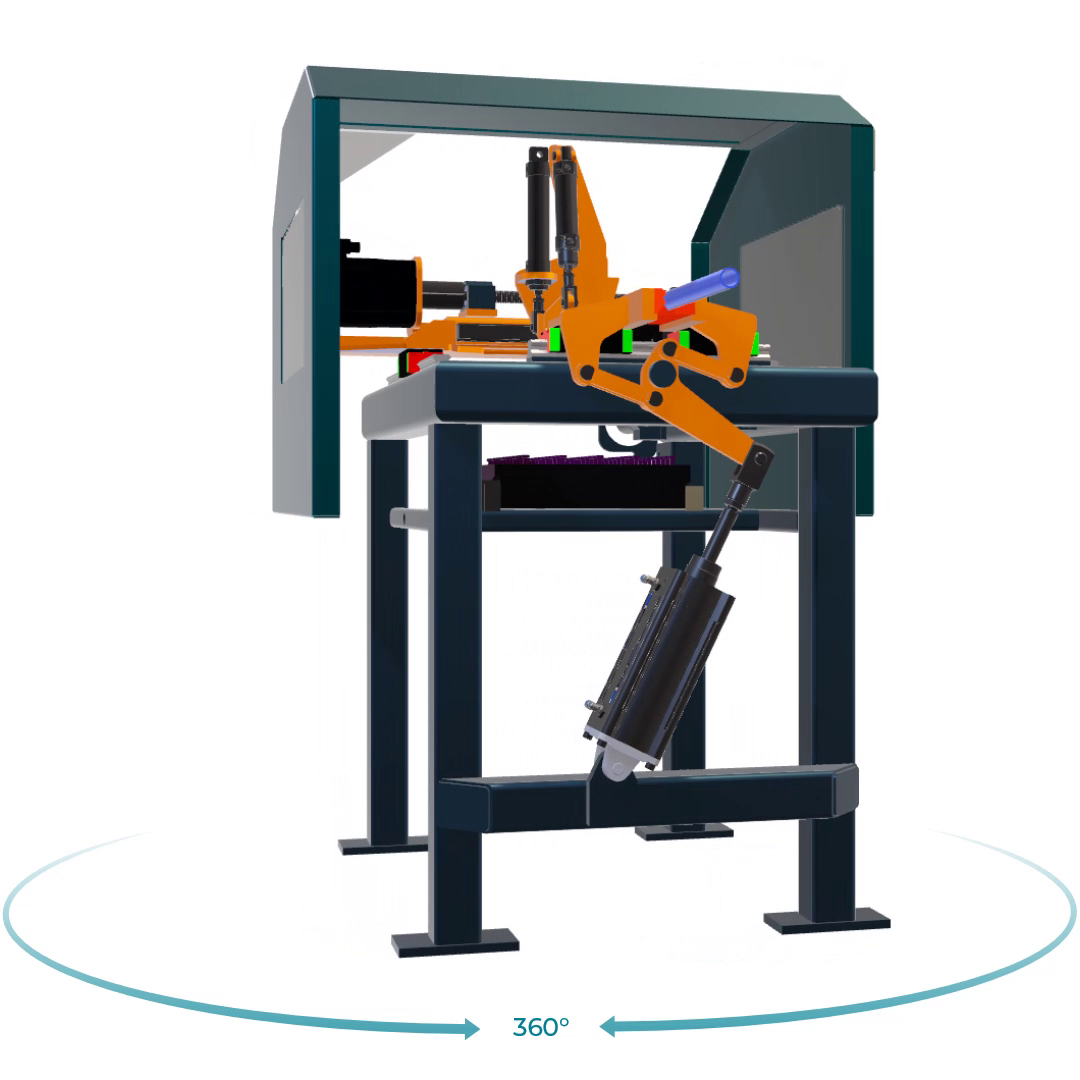

Flying saw

Description of the device

Letme saws are designed to cut pipes and bars into precise lengths with continuous movement of the pipe in the line. They are always designed for a specific range of pipes according to customer requirements.

Technical parameters of the machine

|

Split diameters, profiles: |

6 – 120 mm |

|

Length after division: |

3 –21 m |

|

Feed speed of pipe, rod: |

up to 2,0 m/sec |

|

Cutting accuracy: |

+- 1,5 mm |

|

Control system: |

Simatic S7 1500T |

|

Hydraulic jaw clamping |

|

|

Feed into the section by hydraulic cylinder or servo drive |

|

|

Variable blade feed into the cut when cutting closed profiles |

|

|

Automatic lubrication system |

|

|

Safety covering with transparent glass |

|

Other equipment of the machine

- Unwinding device before entering the flying saw with speed control.

- Pre levelling of pipes and rods after unwinding before cutting on a flying saw.

- Continuous monitoring of defects and automatic carving of identified defects.

- Storage of gifted tubes and bars in pockets according to different lengths.

- Storing carved defects in a separate pocket.

- Description and marking of profiles

- Collection of production parameters with automatic storage, display and export of data

- Enhanced service with the ability to display manuals, service guides and other necessary documentation on the machine's HMI to minimize service times

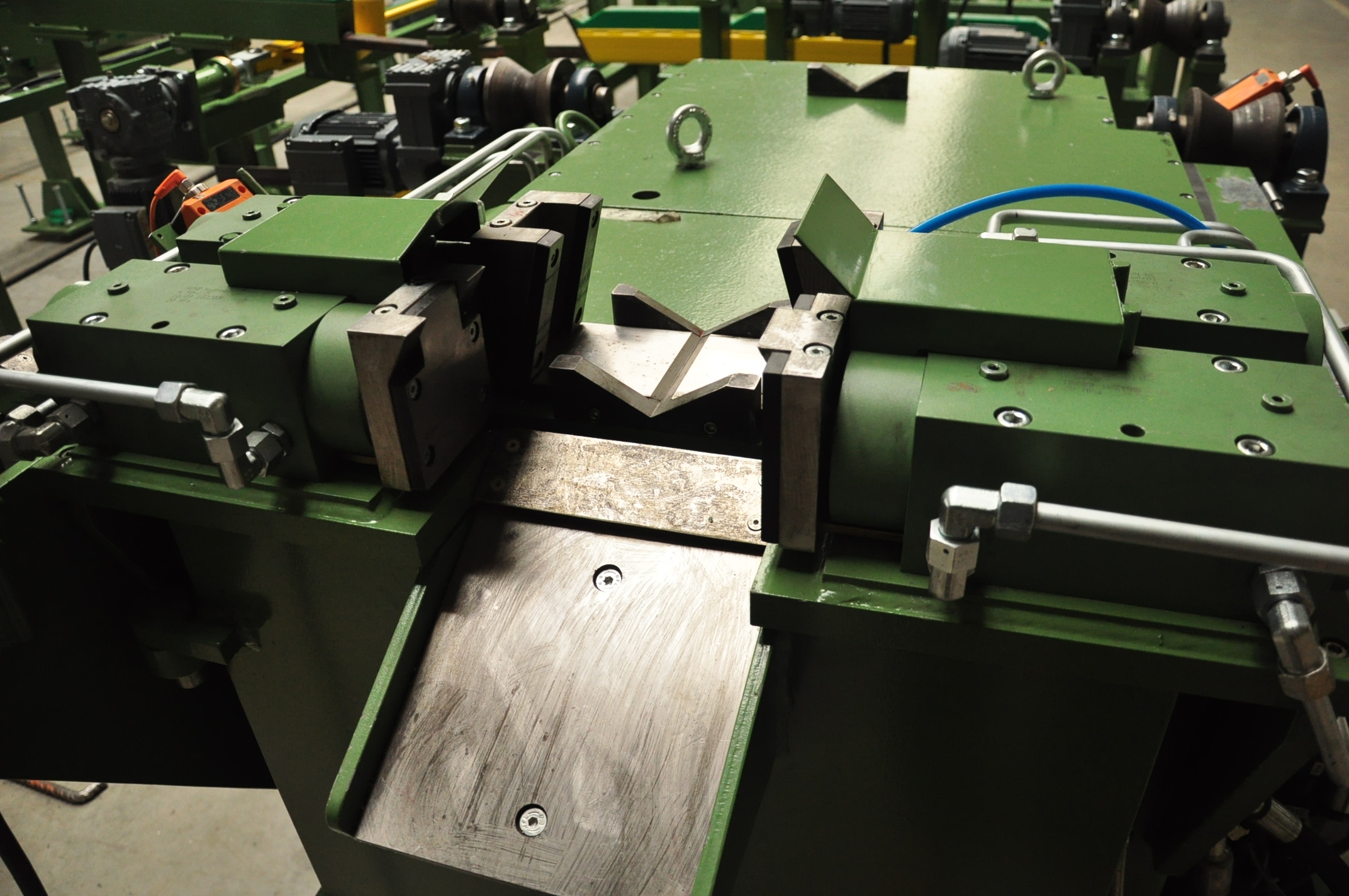

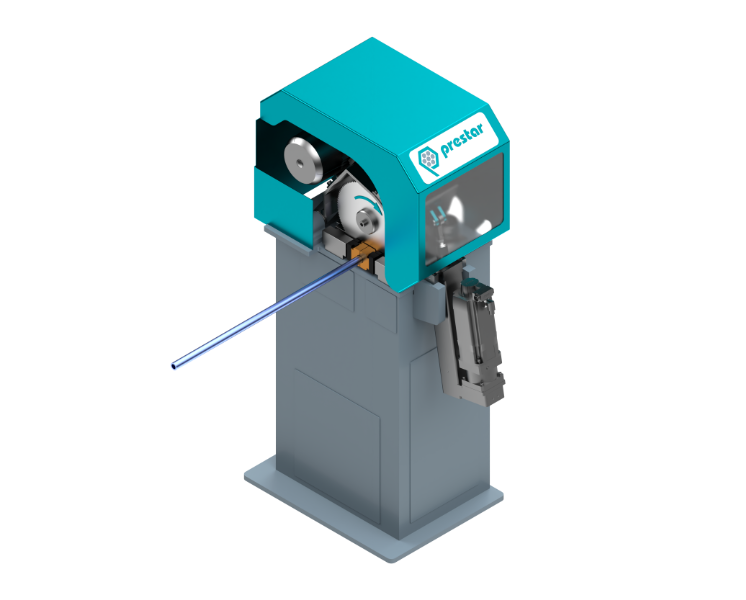

Chamfering of pipes

Description of the device

Bevelling and chamfering at the tube ends is used to remove burrs after cutting of the tubes or to make the bevels for welding of the tube ends.

Technical parameters of the machine

- Edge shrinking to prepare pipe ends for welding. The shrinkage ranges are 2 - 10 mm x 30, 45 or 60 deg.

- The chuck is equipped with two to three clamped knives with replaceable inserts for edge beveling. In one stroke, the outer edge is knocked off, the inner edge is knocked off and the pipe face is aligned.

- Hydraulic cylinders must be used to clamp the pipes. The pipe must always be centred in the axis against the chuck.

Other equipment of the machine

- Beveling machines ensure beveling of the edge on the outer and inner diameter and alignment of the pipe face.

- Edges on bars or hexagons can be knocked off in the same way.

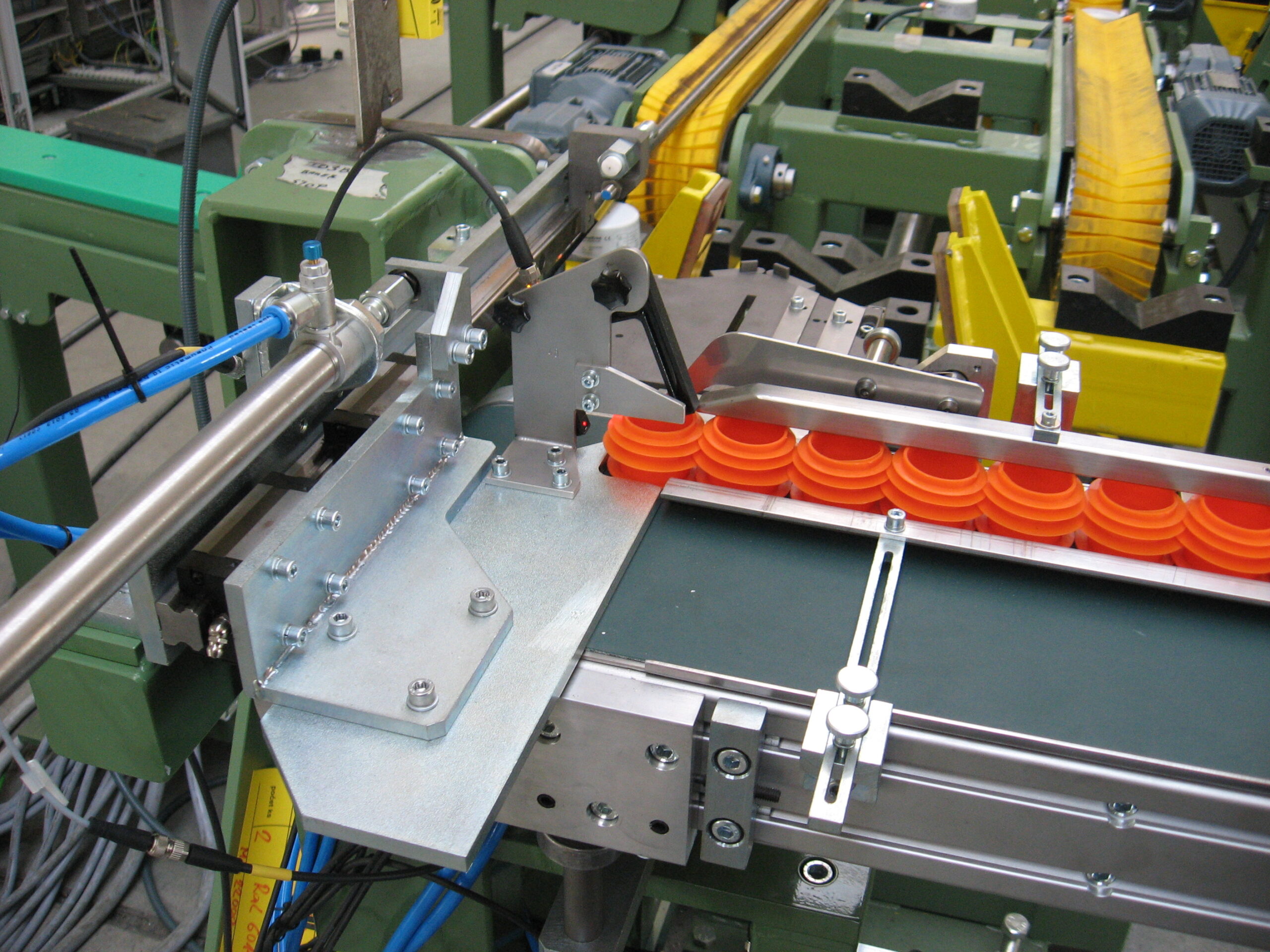

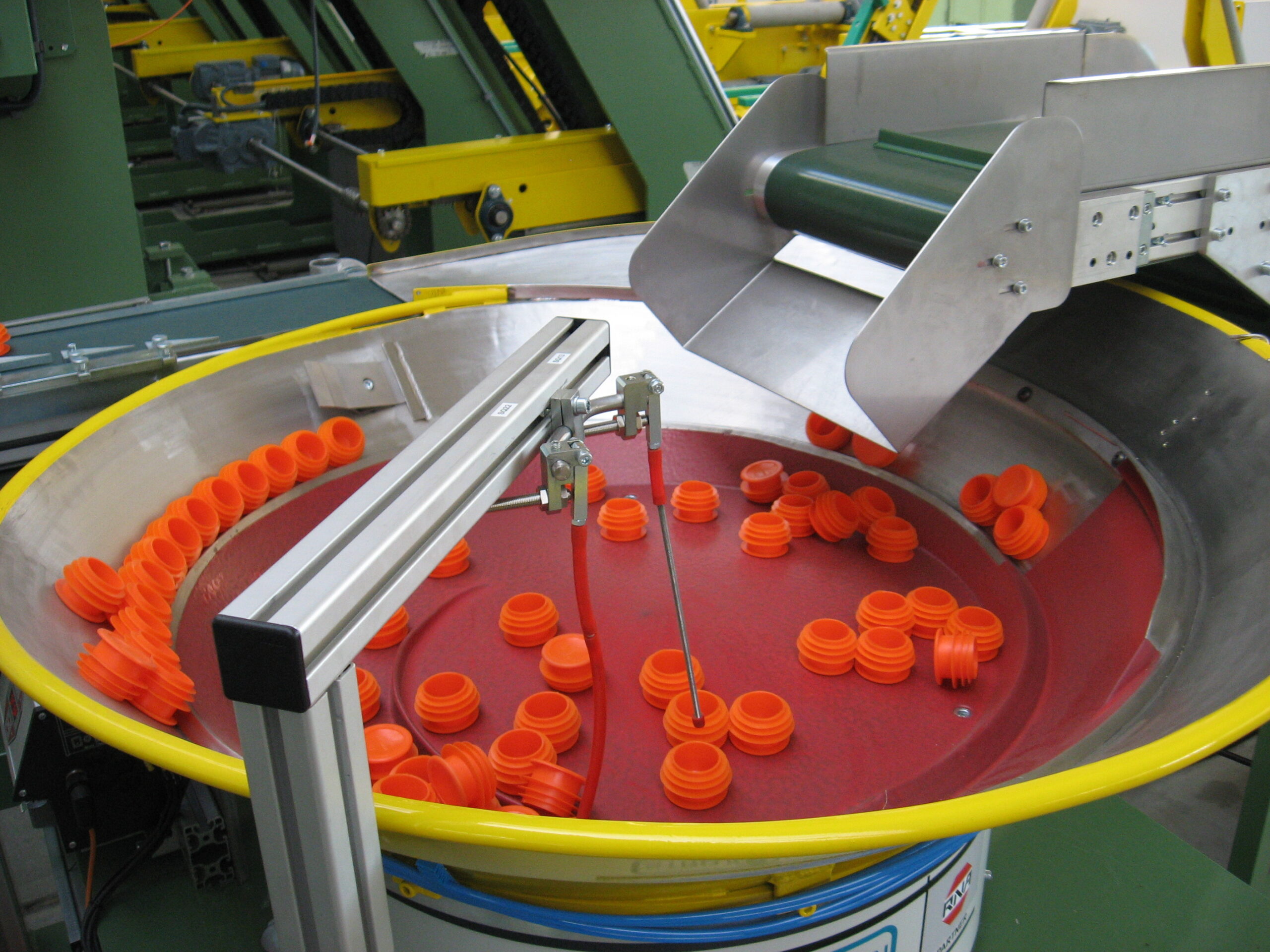

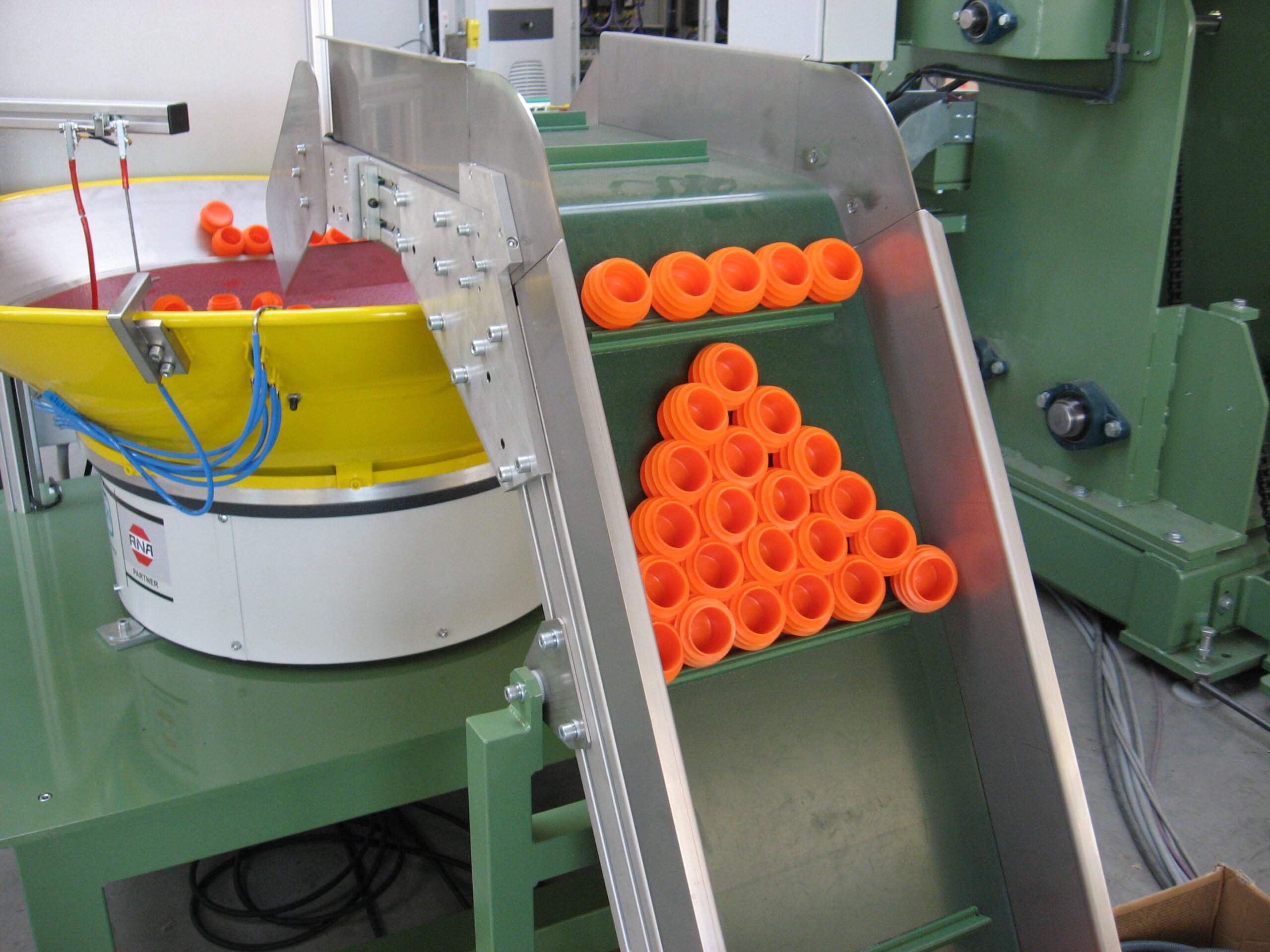

Sorting and plugging

Description of the device

Use in pipe separation and plugging

Designed for pipe thicknesses from 25 to 140 mm.

Technical parameters of the machine

- Customer-specific assembly

- Sorting pipes one piece at a time

- Automatic plugging cycle

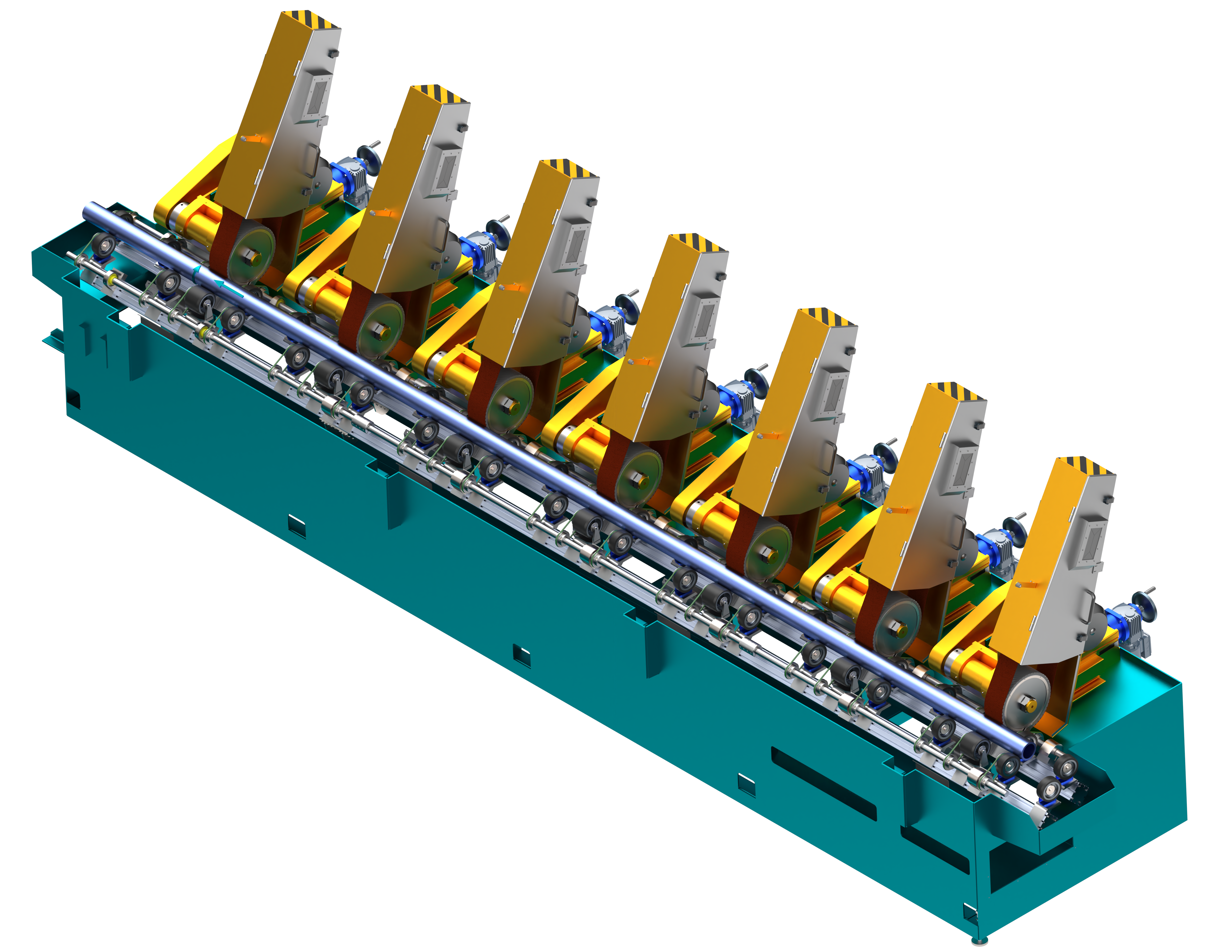

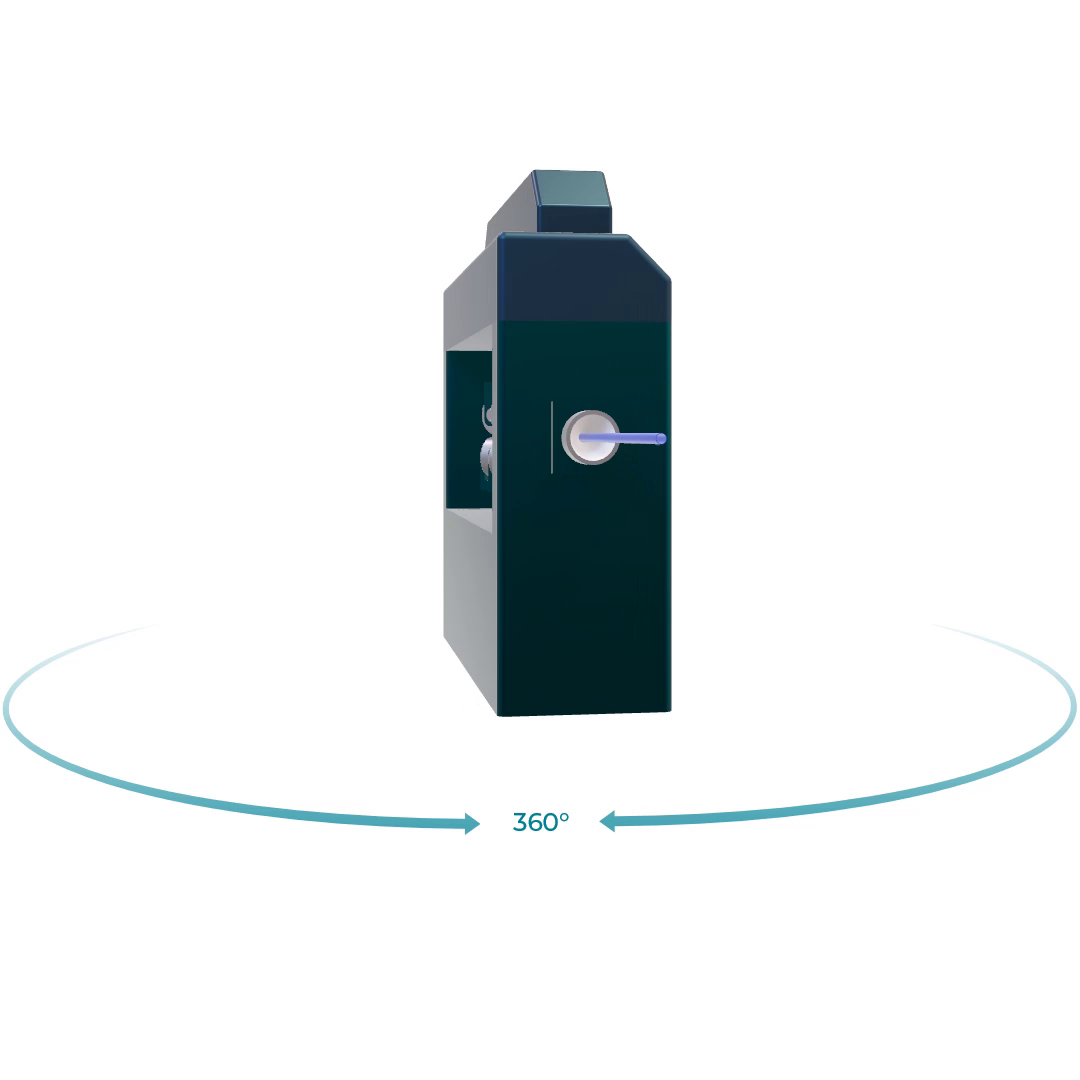

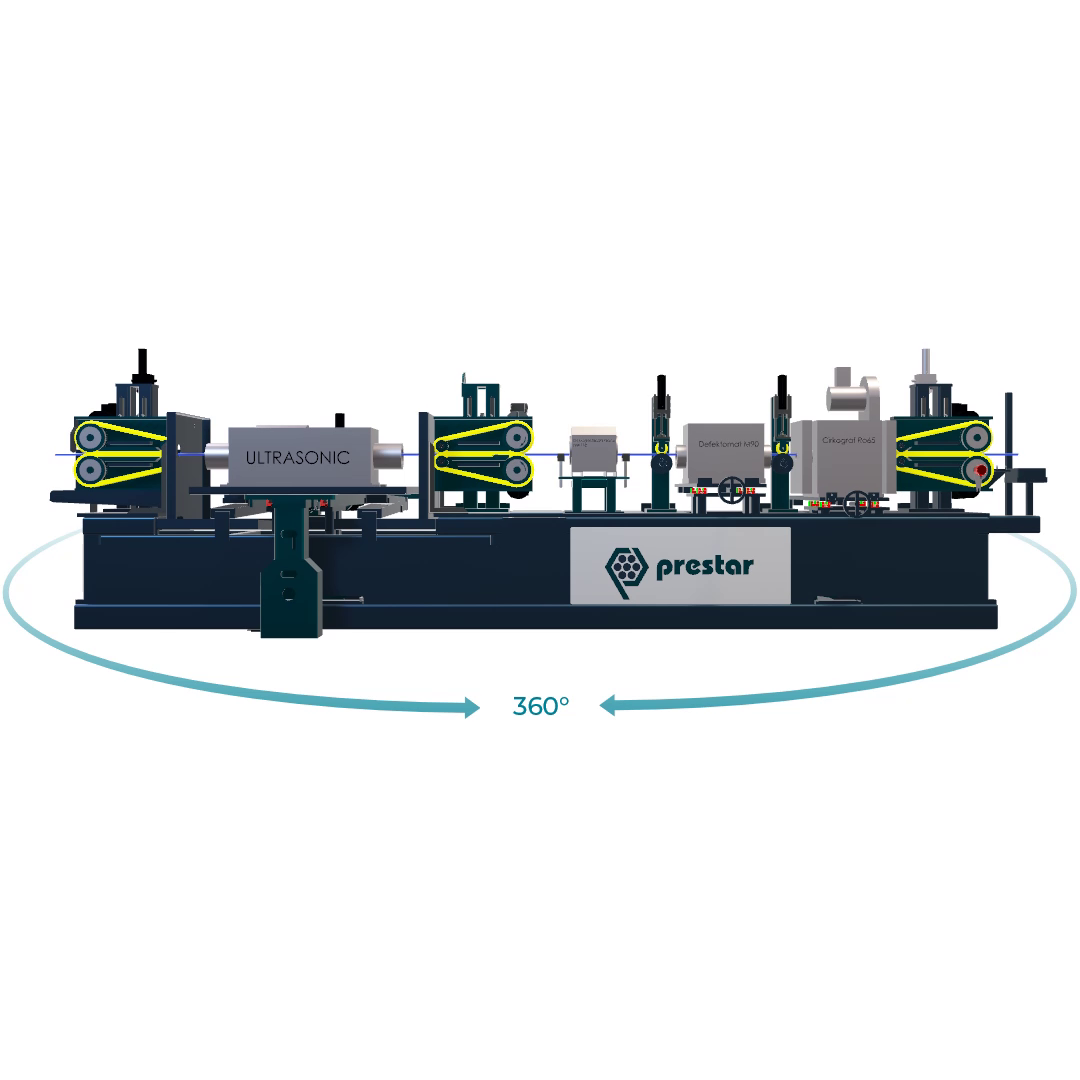

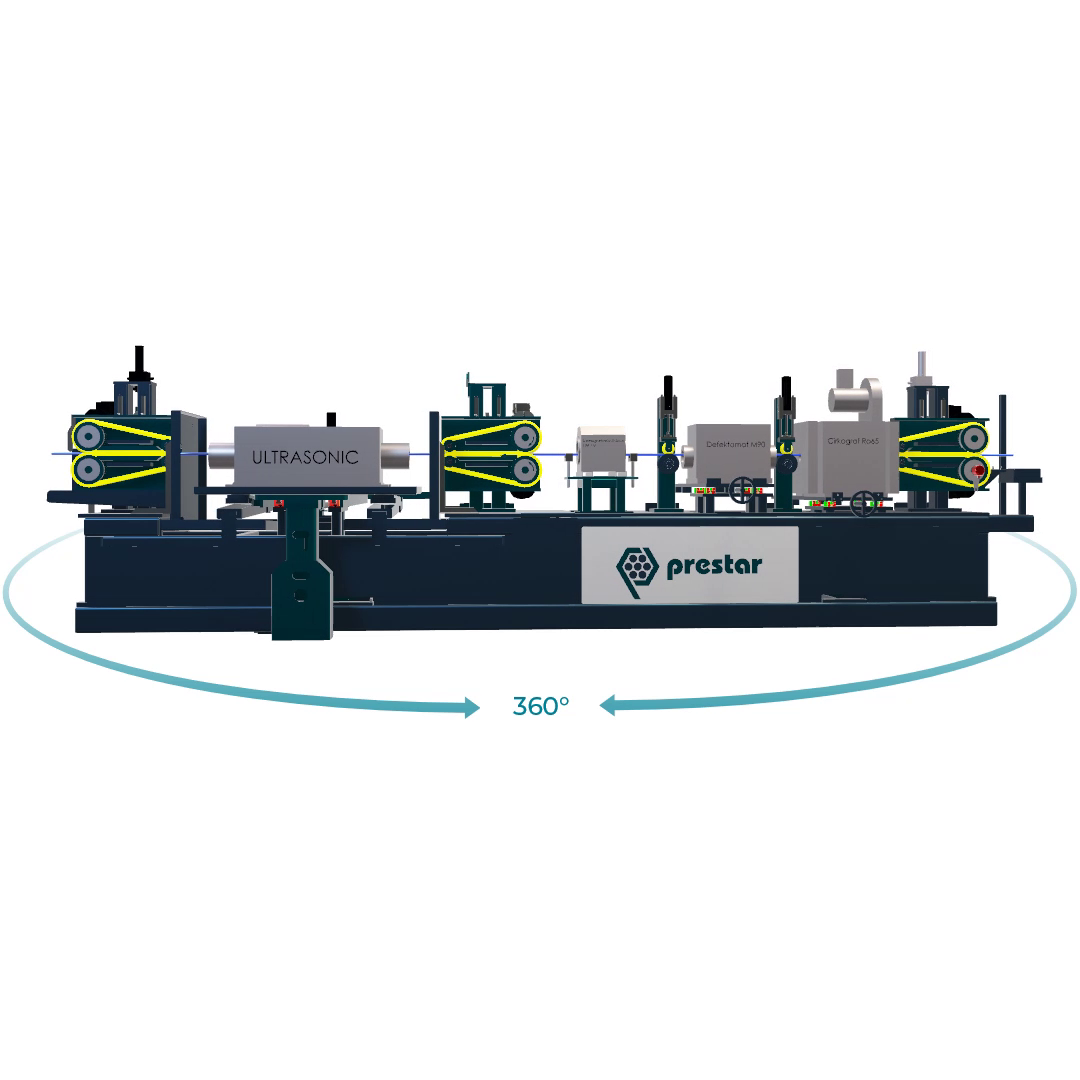

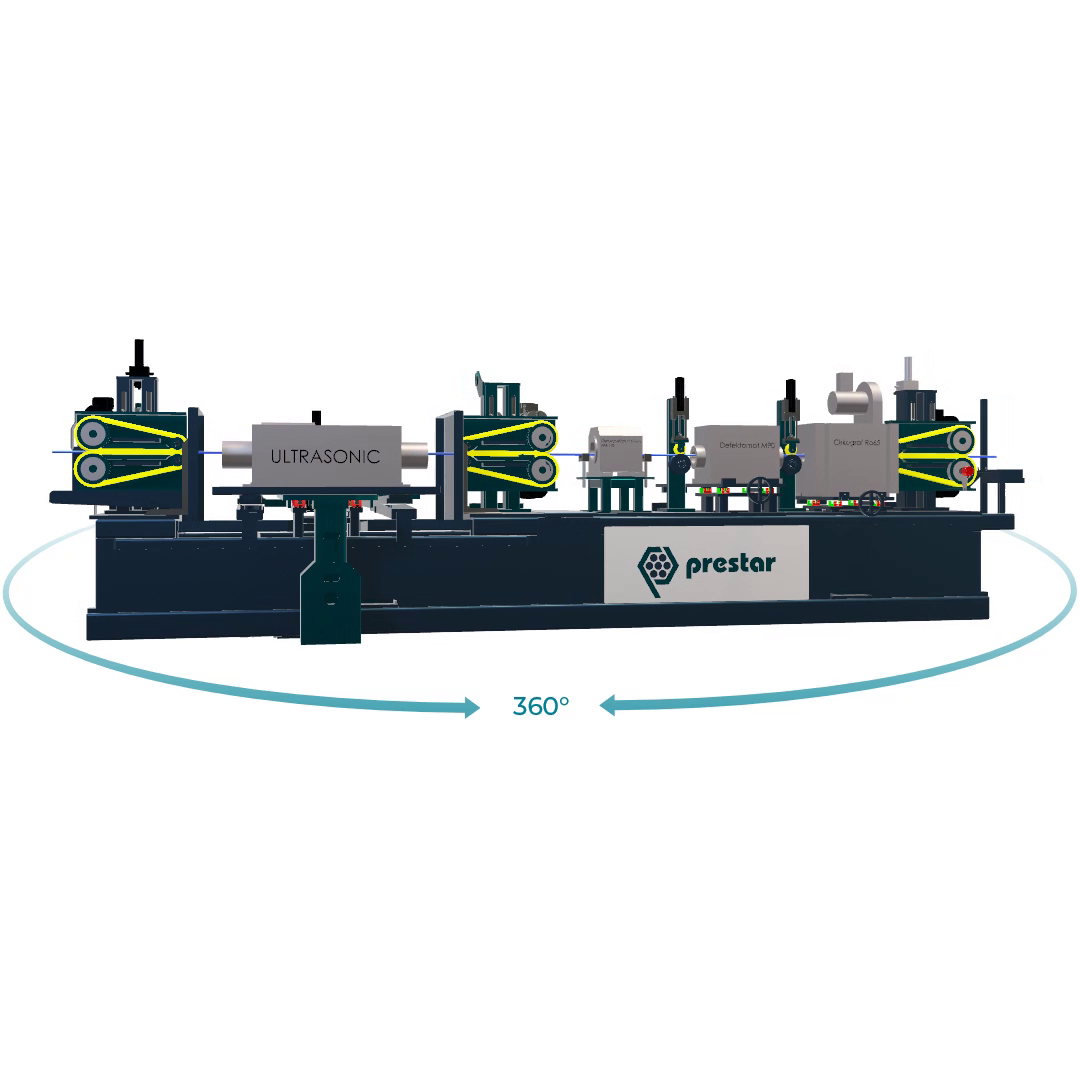

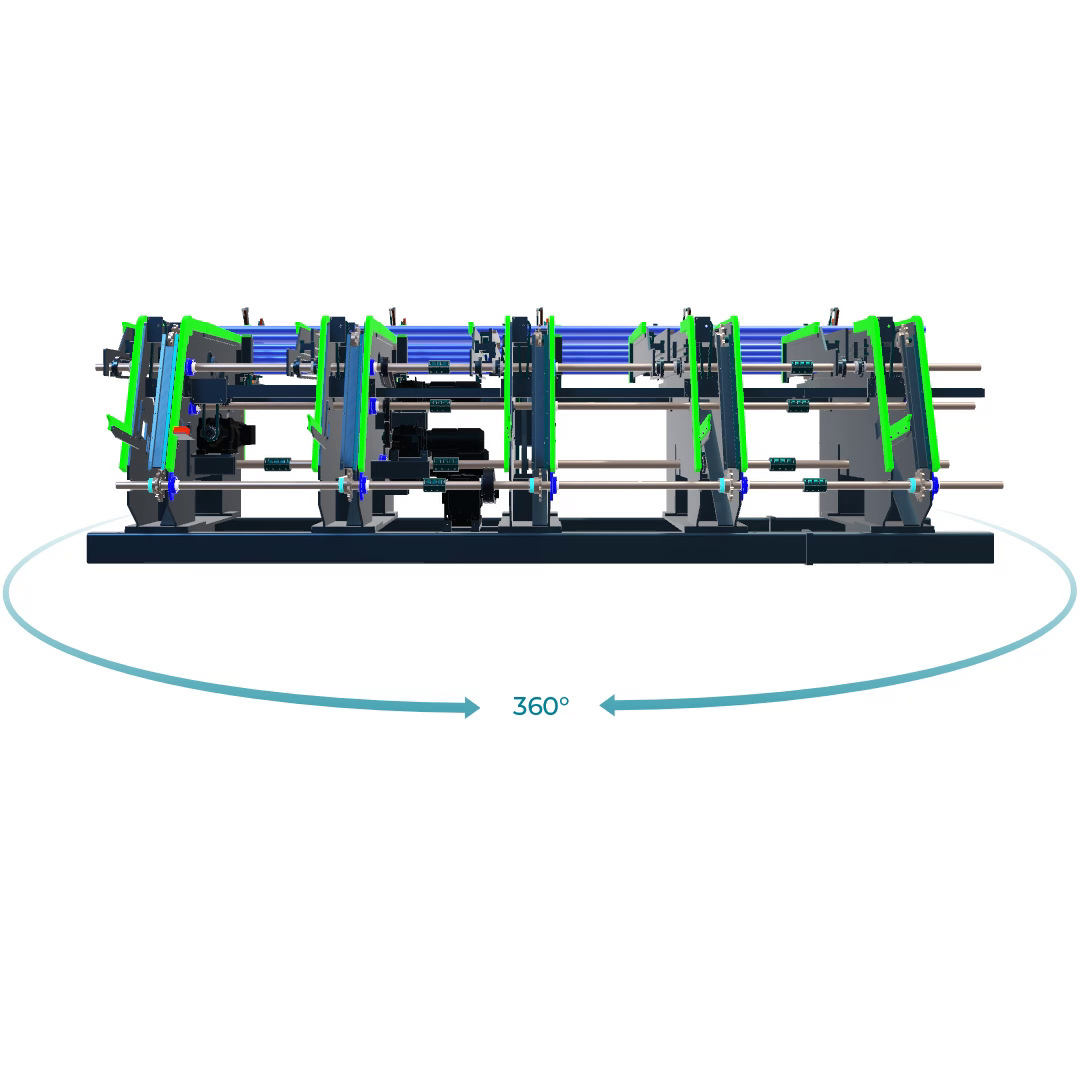

Control tables

Description of the device

Rigid inspection tables form the basis for quality testing instruments for long products. The inspection instruments identify transverse, longitudinal and point surface defects. They can detect internal defects, material substitutions, chemical composition, changes in heat treatment and mechanical properties of the product. Possible applications for bars, tubes of ferromagnetic and non-ferromagnetic metals. From normal temperatures to hot testing and throughout the processing.

Technical parameters of the machine

- Ensured passage of the product through the inspection instruments in a clearly defined axis and speed

- Product position information is collected throughout the process

- The marking device marks in colour the exact section of the defect occurrence It marks the type of defect with a specified colour

- Possibility to move the control device to the service position and create a by pass

- The control system transmits information about a conforming or non-conforming product to higher-level systems and transport systems

- Work in manual or automatic mode

- All parts of the table are controlled in manual mode by buttons on the HMI Human Machine Interface)

- The table is controlled by its own PLC

Other equipment of the machine

- The installation of the table is designed according to the spatial possibilities of the user

- Access to the device is via a security lock with a button to allow access

- Possibility to move the inspection table to the service position and create a by-pass

- All parts of the table are controlled in manual mode by buttons on the HMI (Human Machine Interface)

- The table is controlled by its own PLC

- A water supply and management system can be supplied for ultrasonic testing

- Delivery of transport system behind the non-destructive testing workplace - transport, sorting of conforming and non-conforming products

- Possibility of technological machines for optimal preparation of surfaces and product faces or for self-testing - brushing, degreasing, ionization nozzle, etc.

- For ultrasonic testing, we offer a system for transporting closed profiles „in touch“ and thus minimizing liquid ingress into the profile

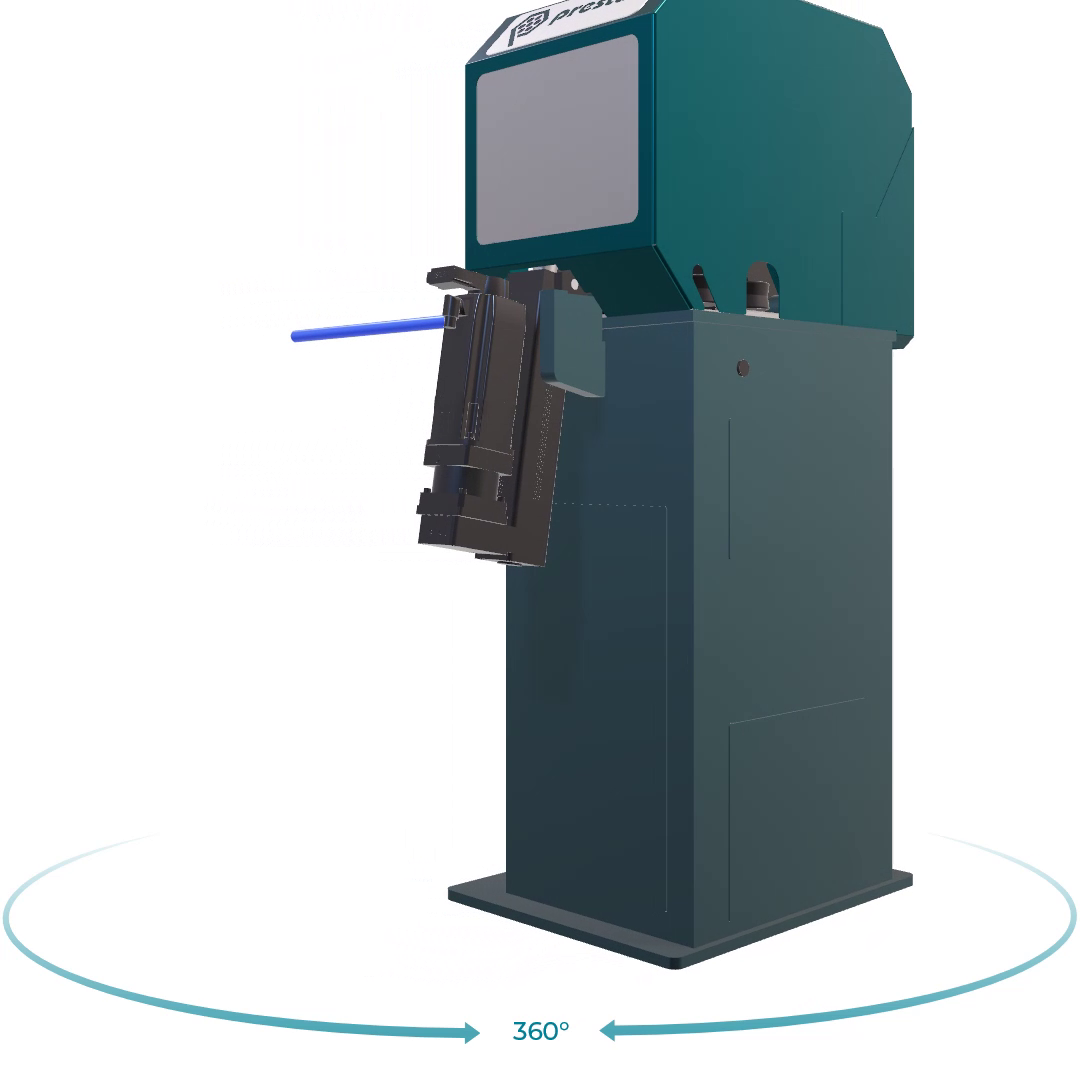

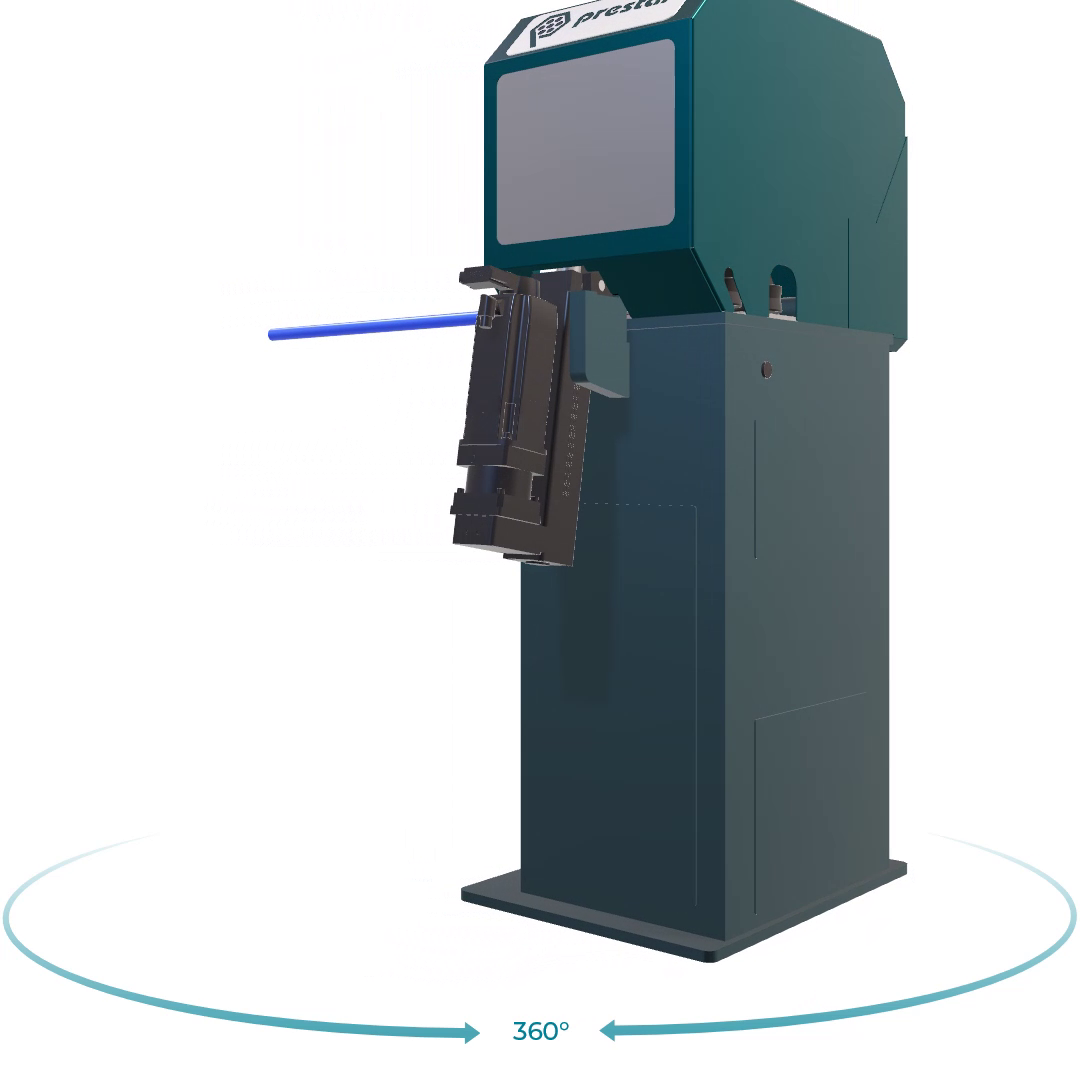

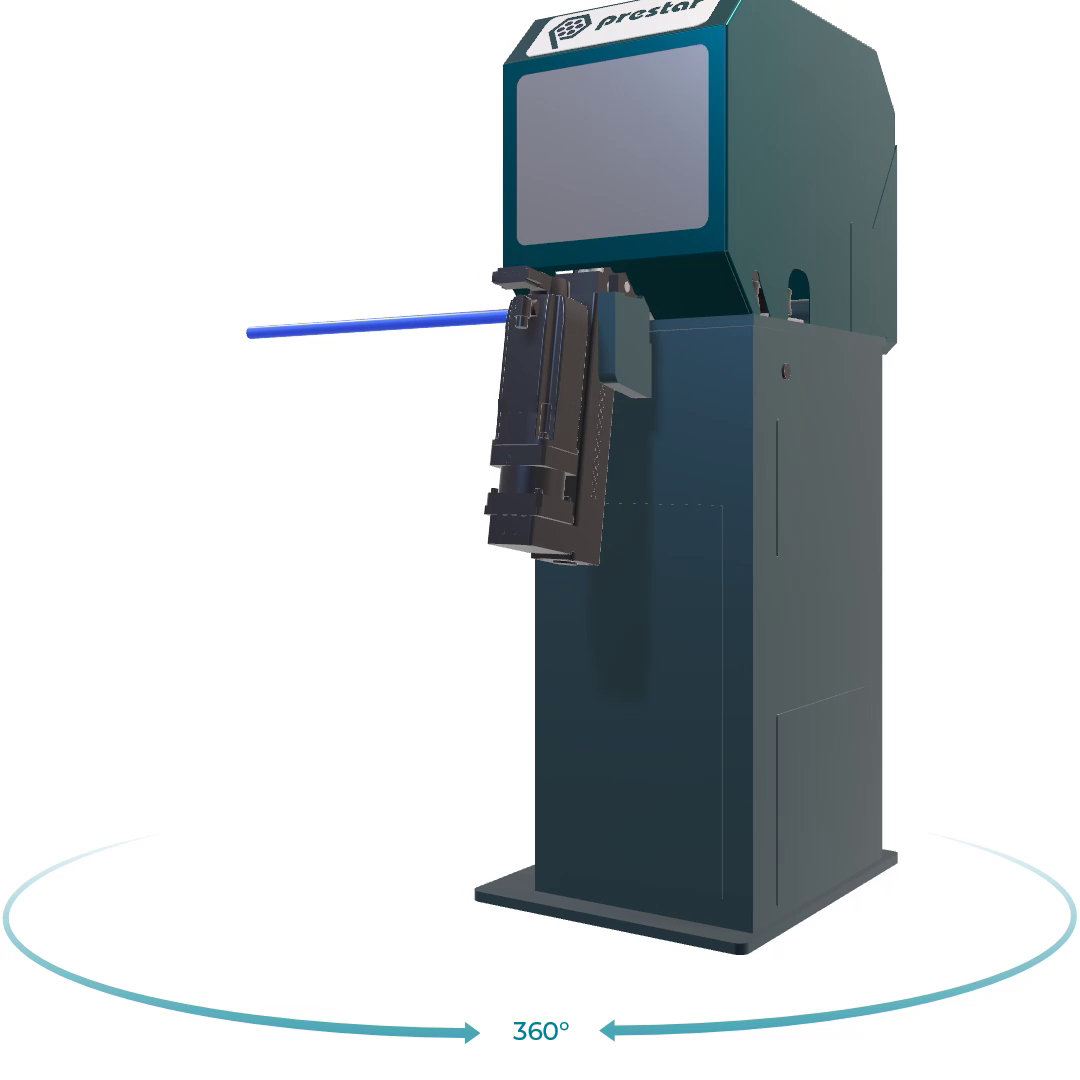

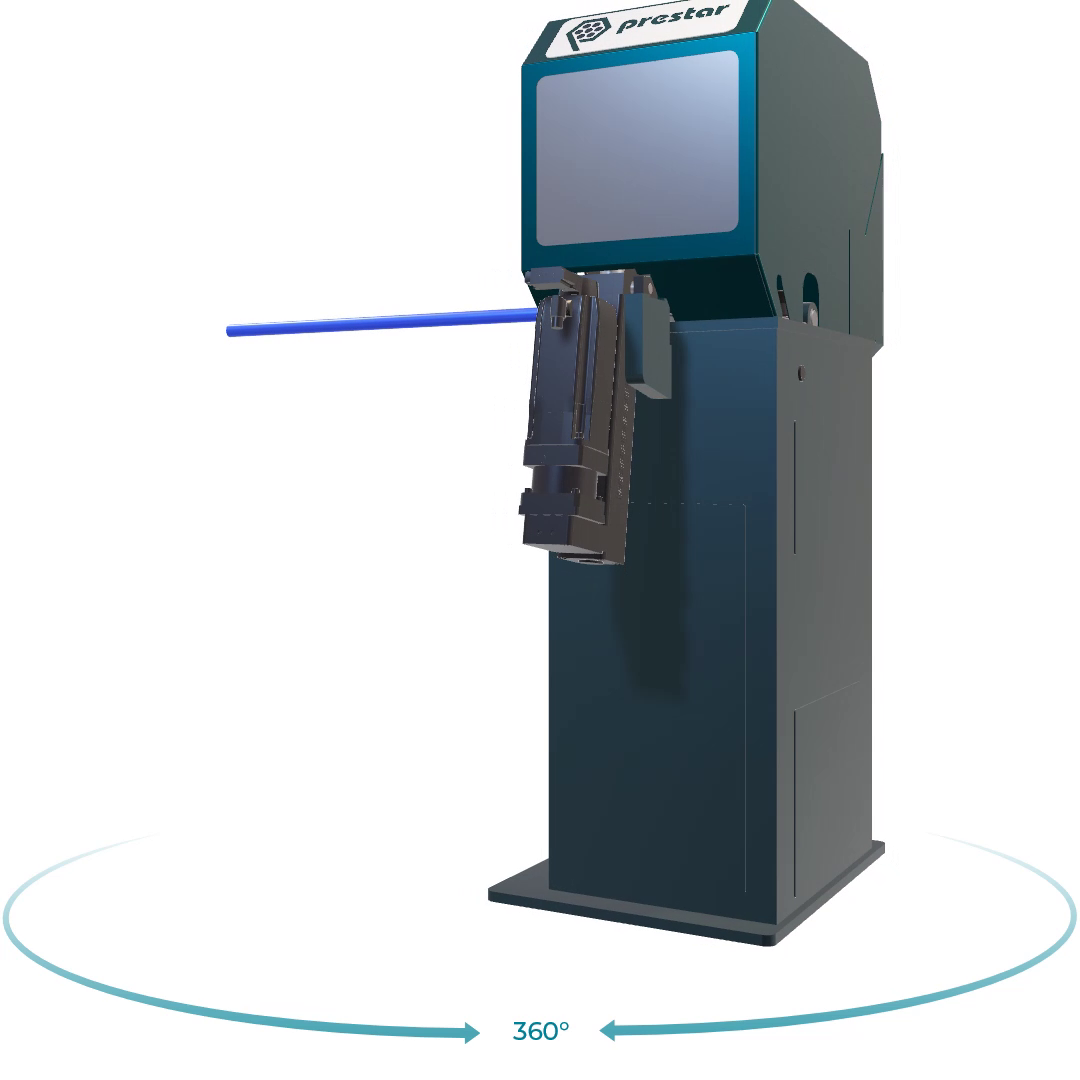

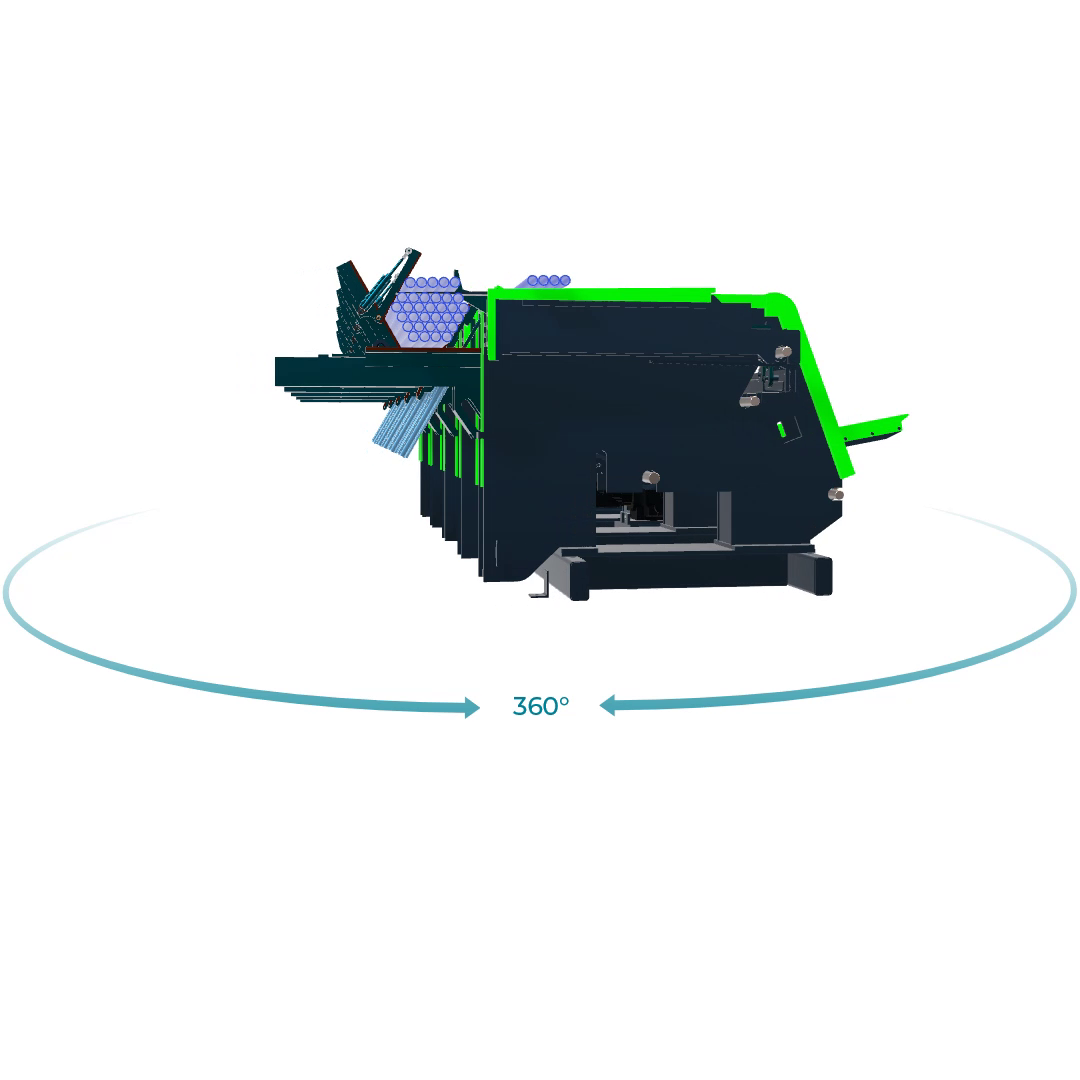

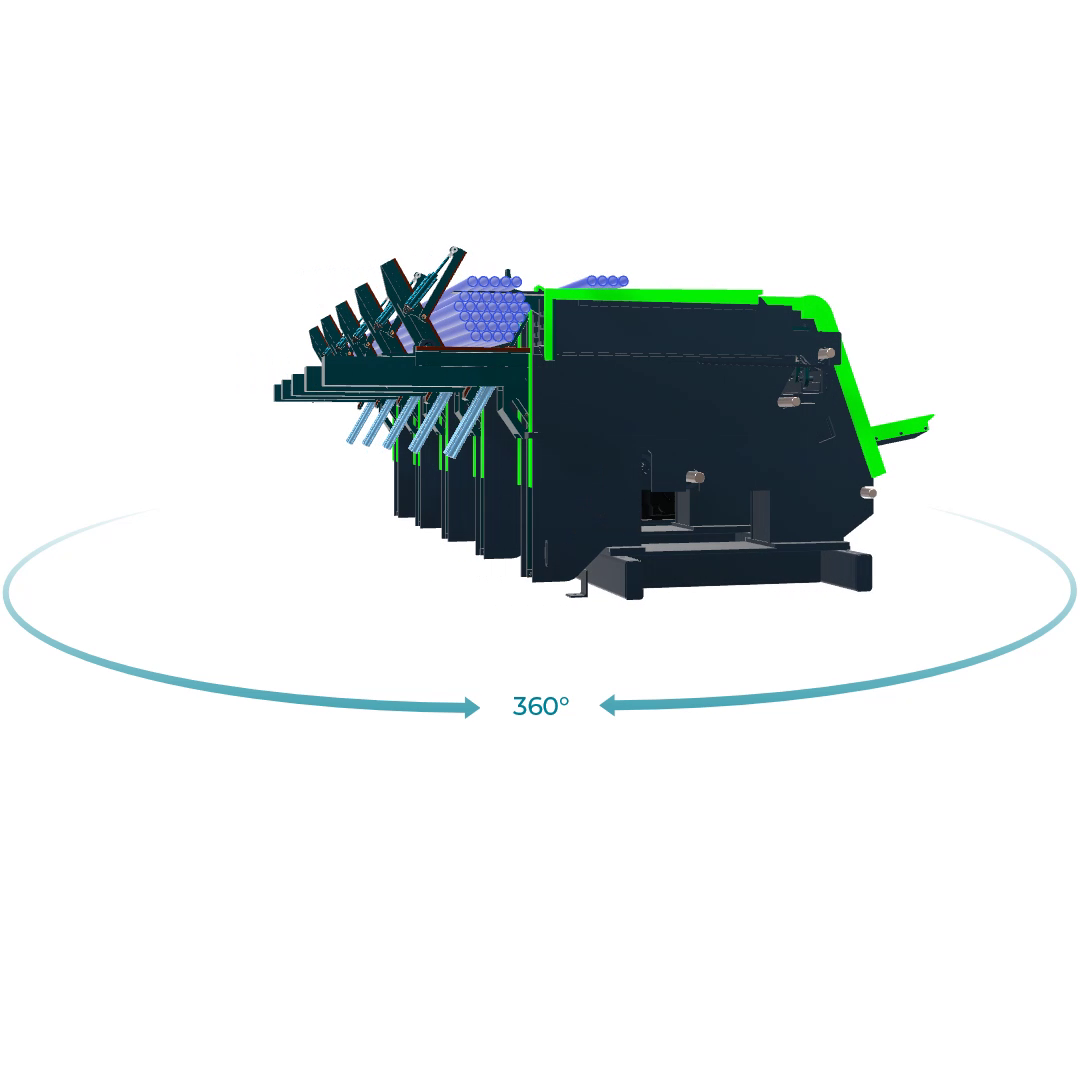

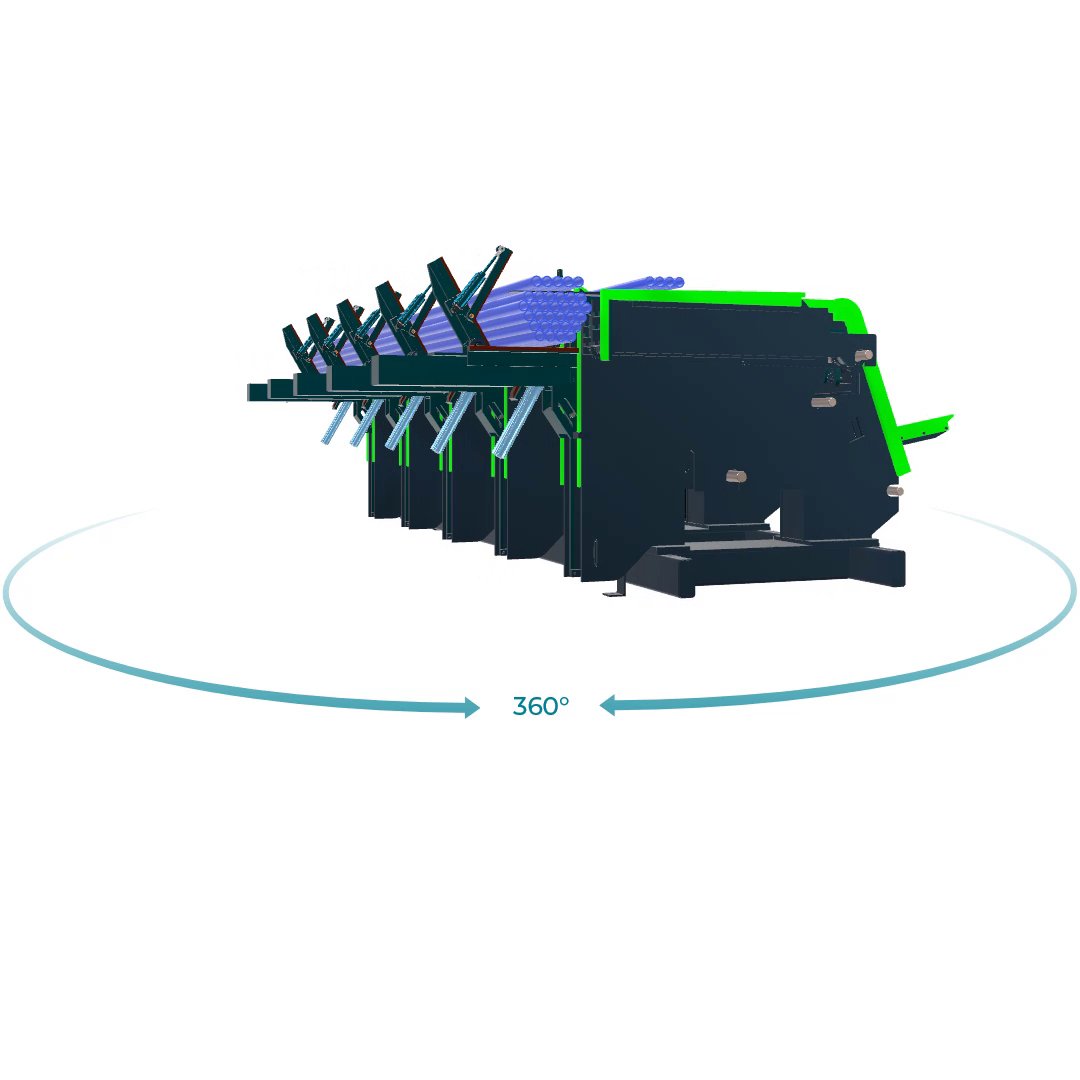

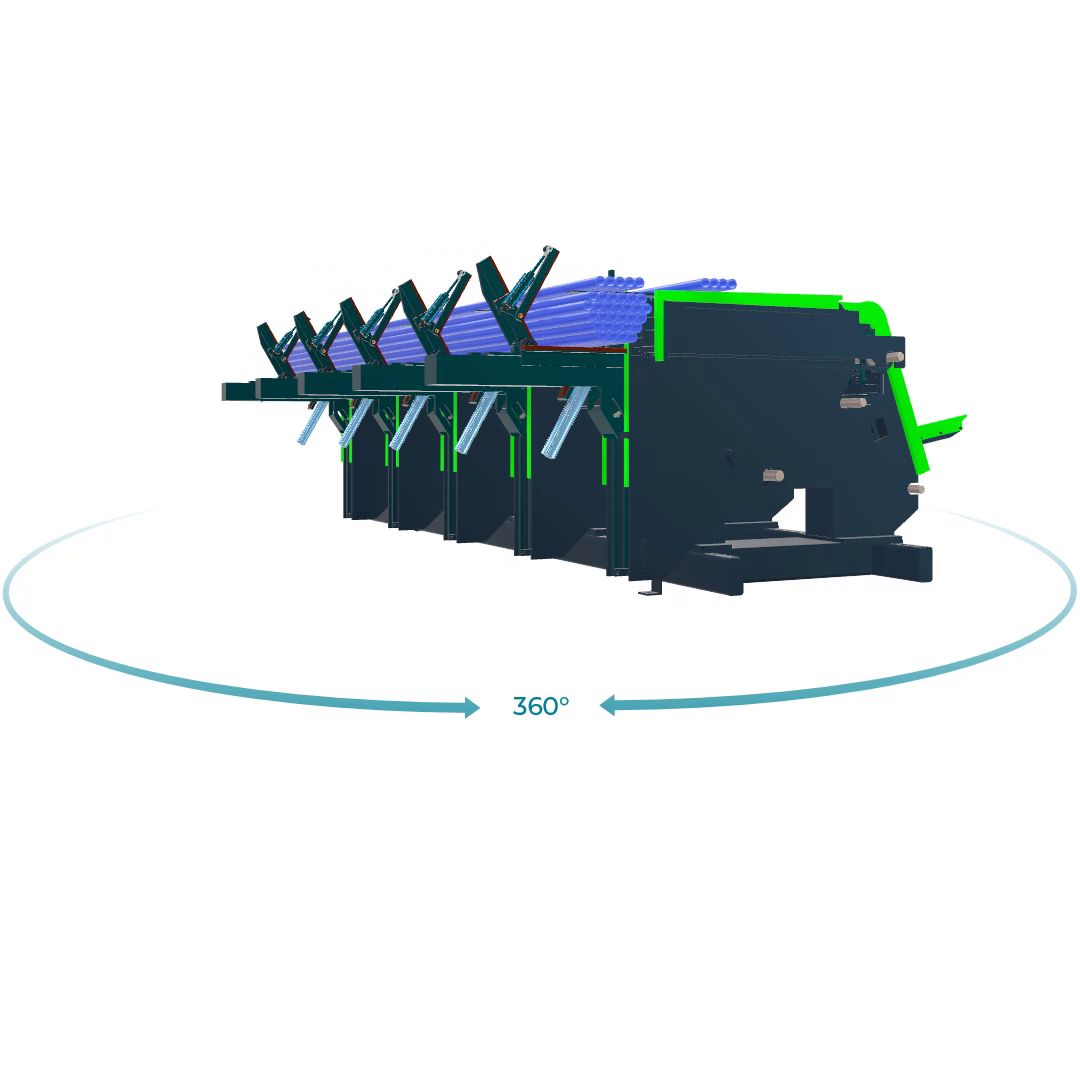

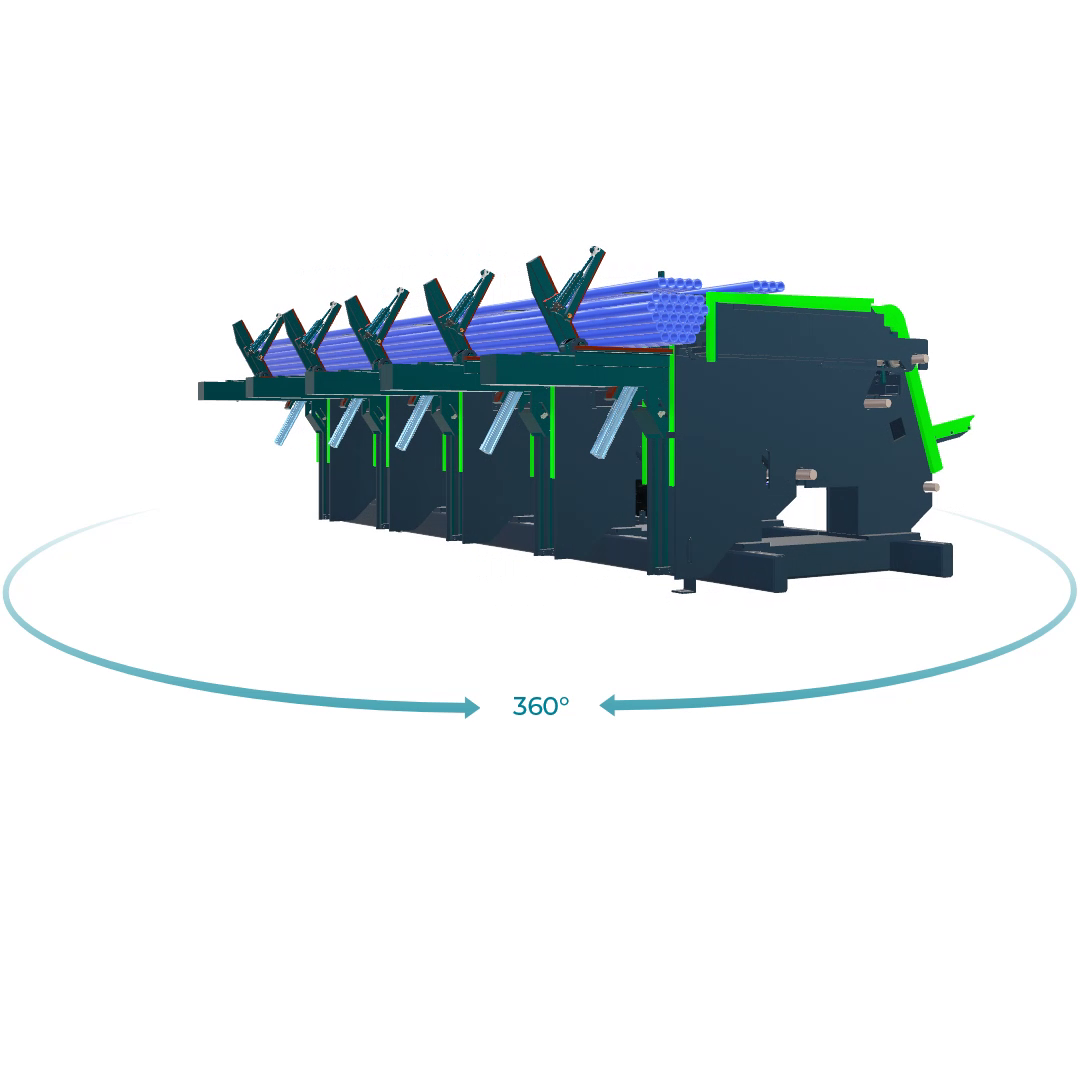

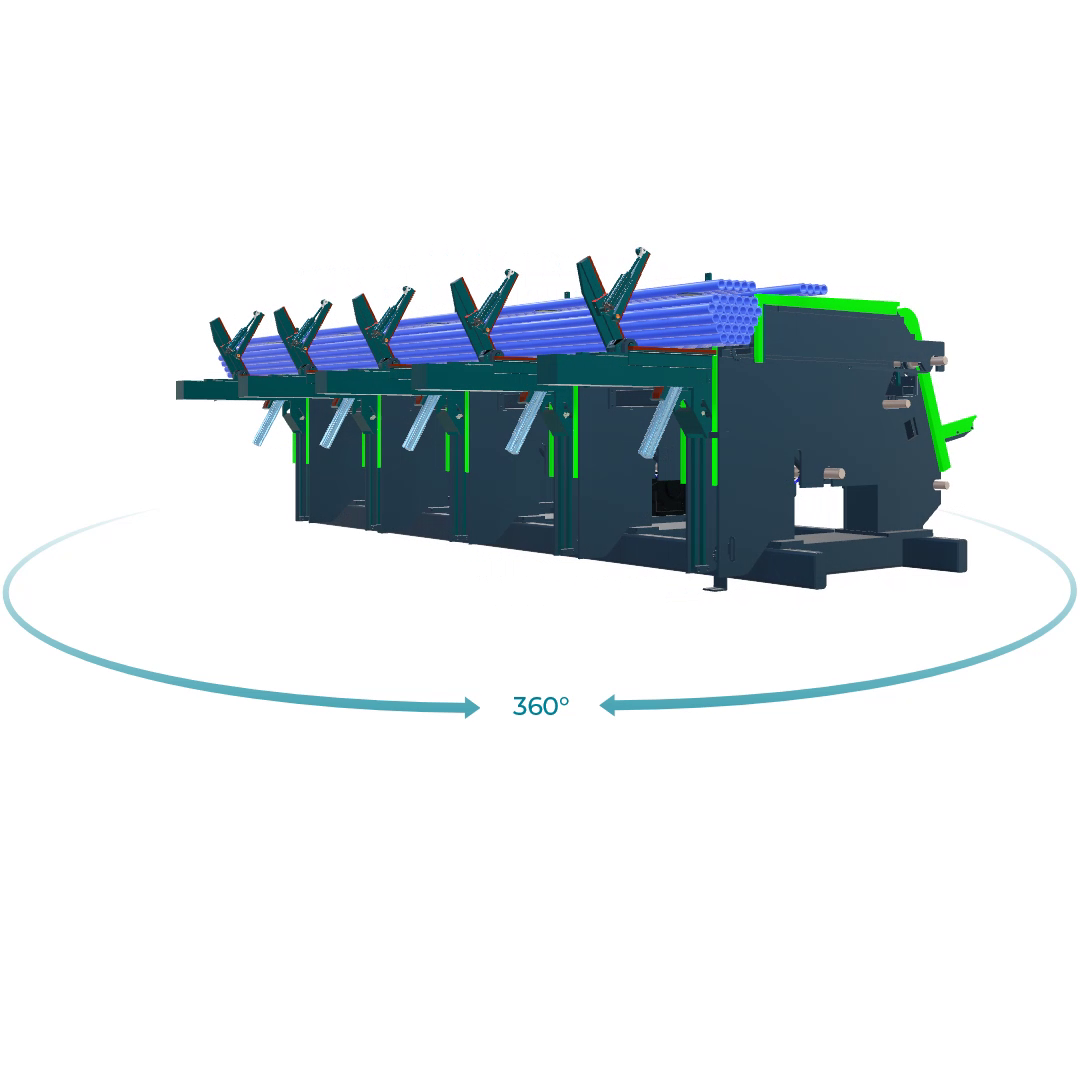

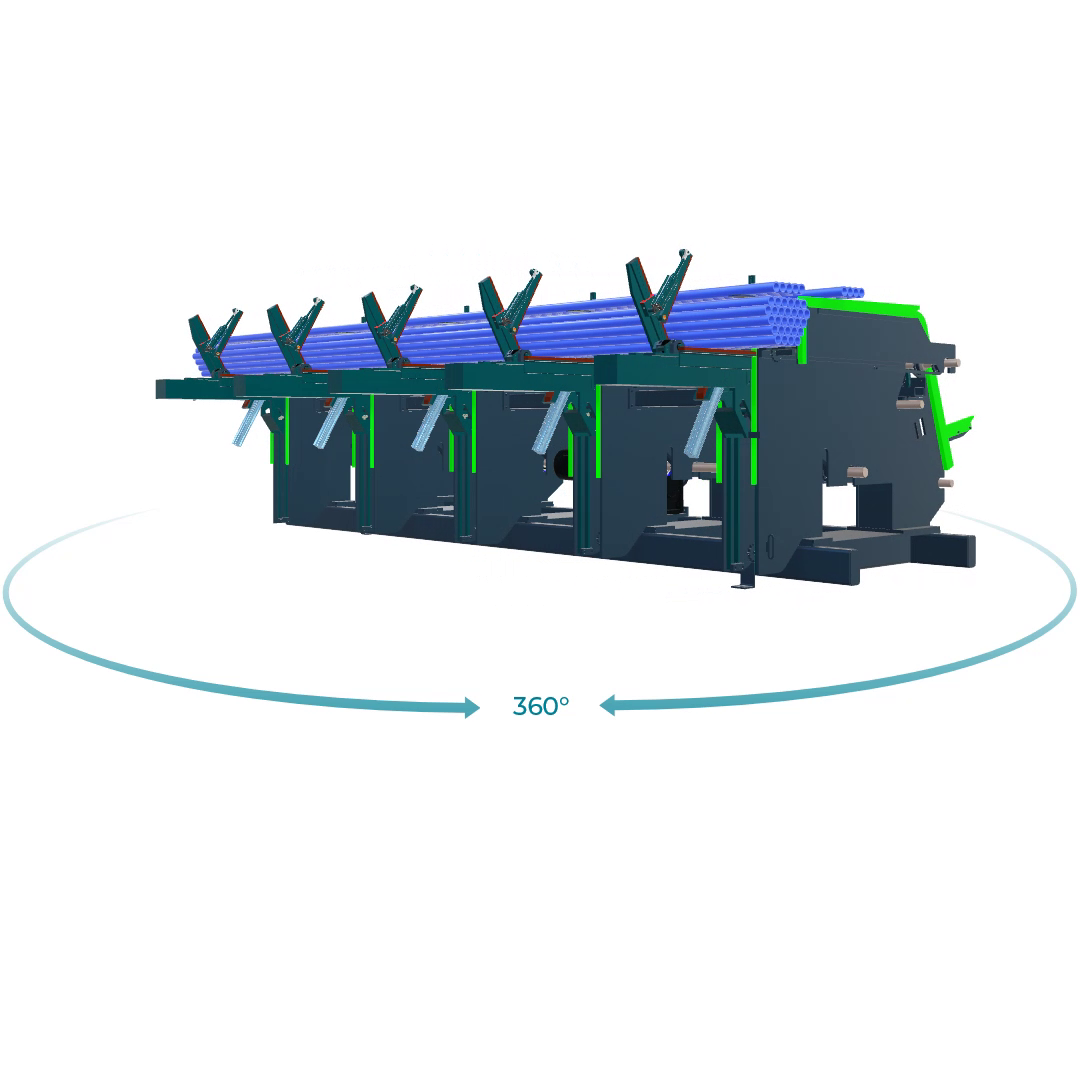

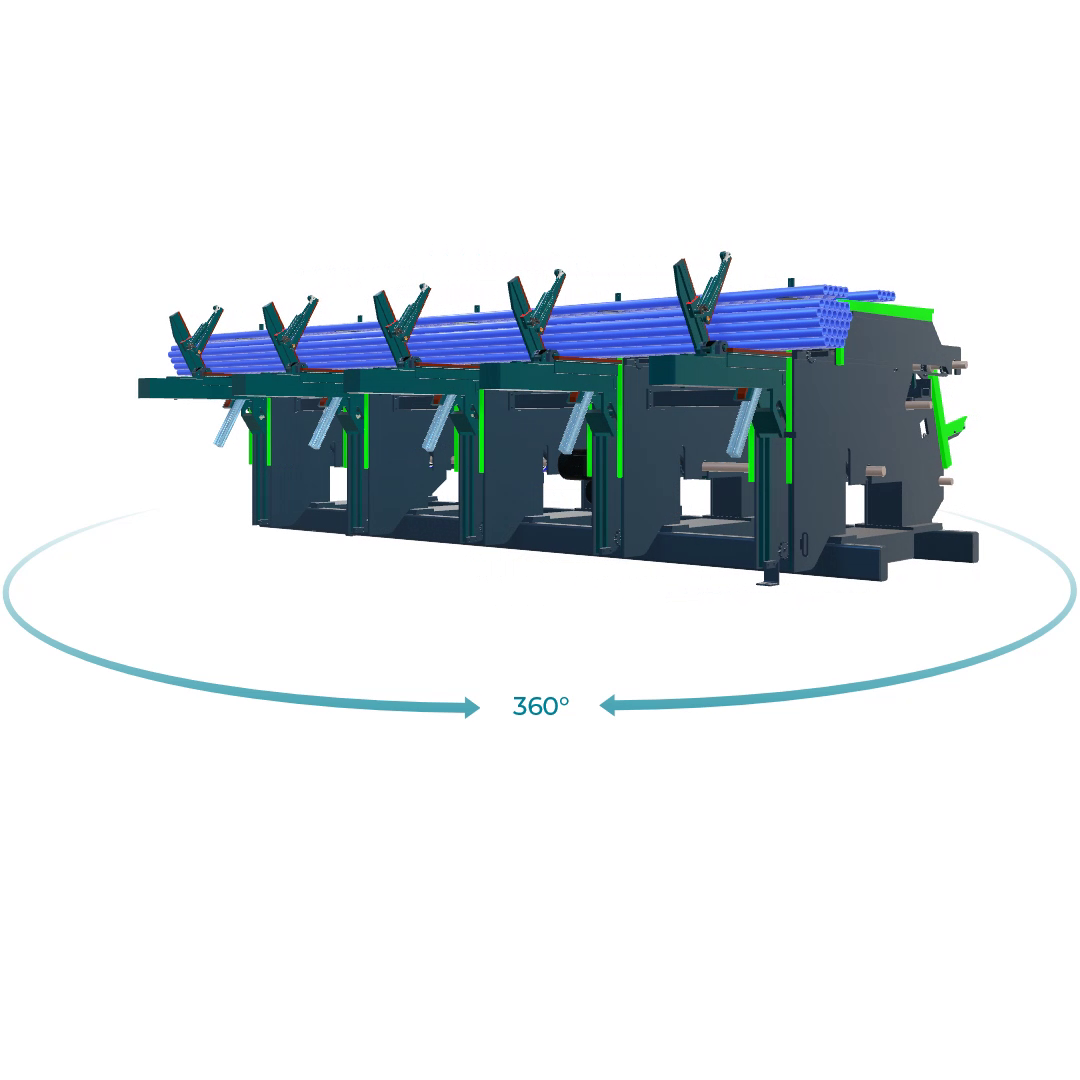

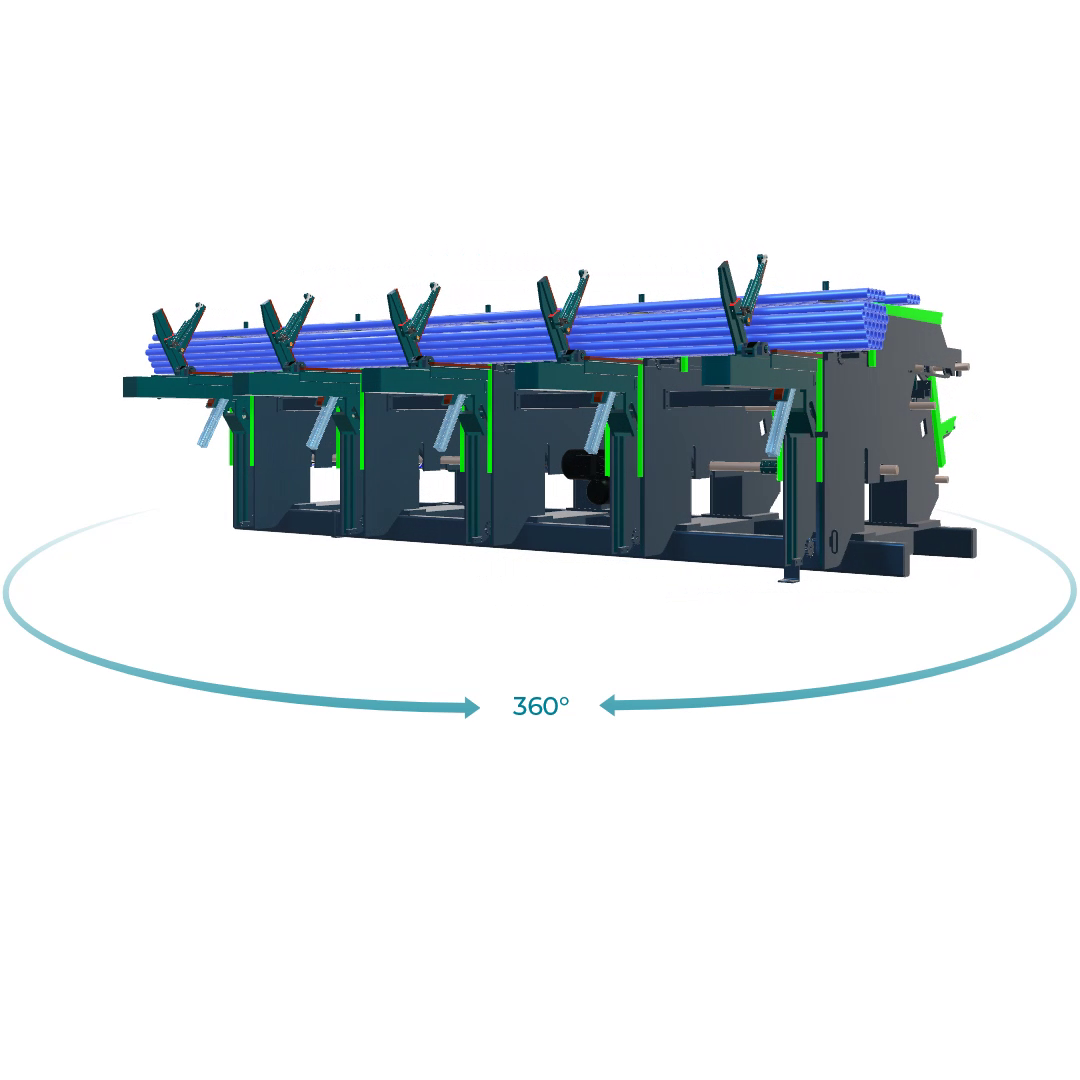

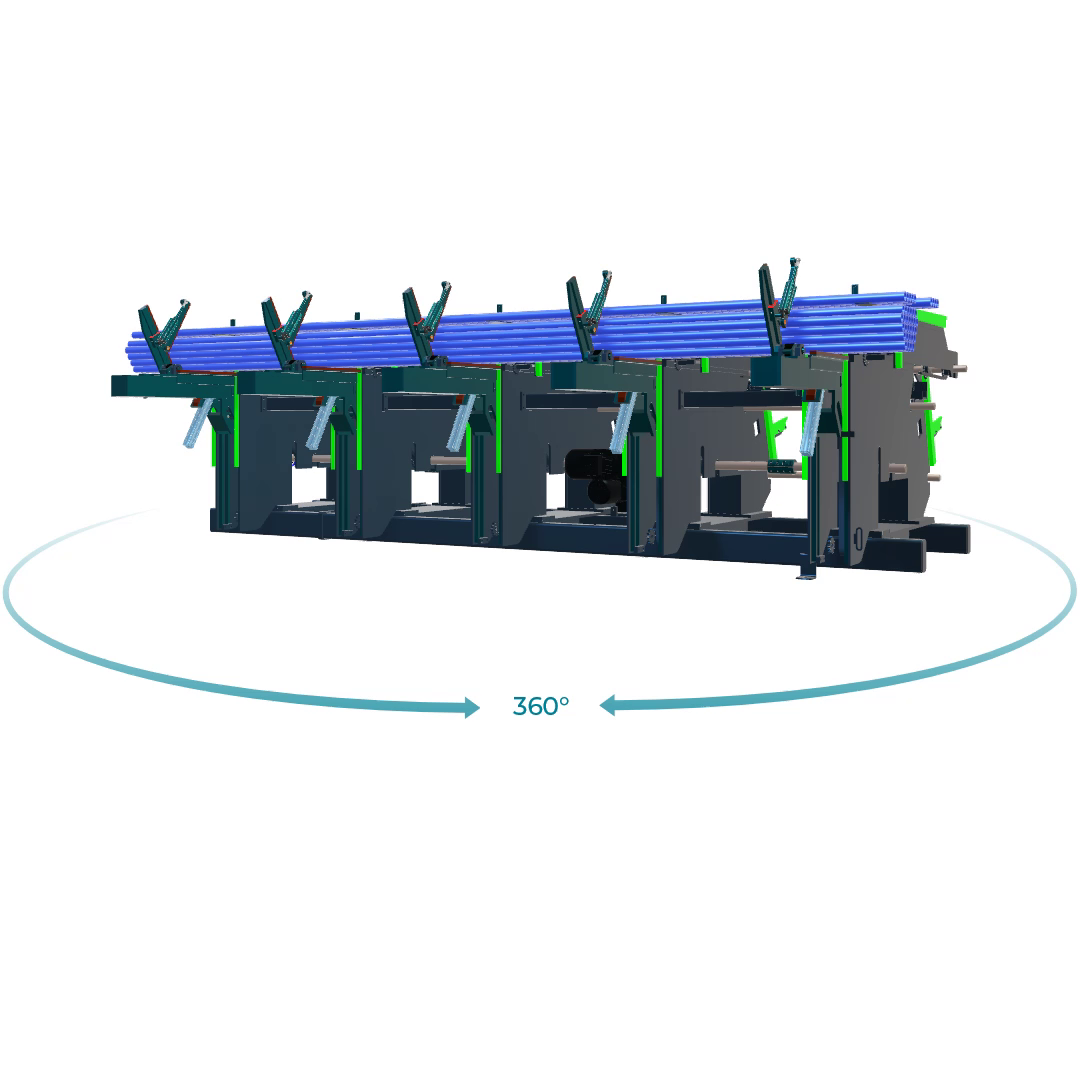

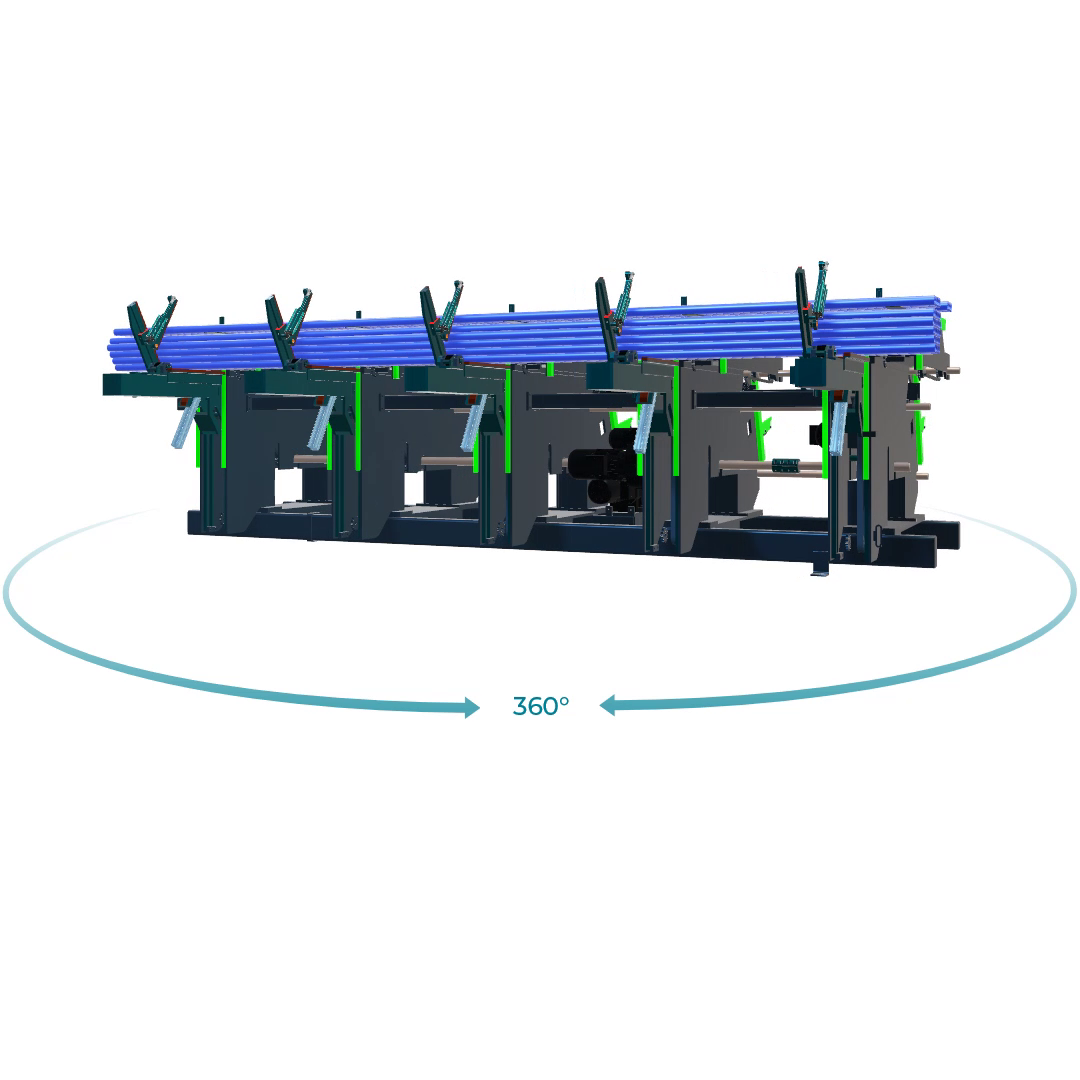

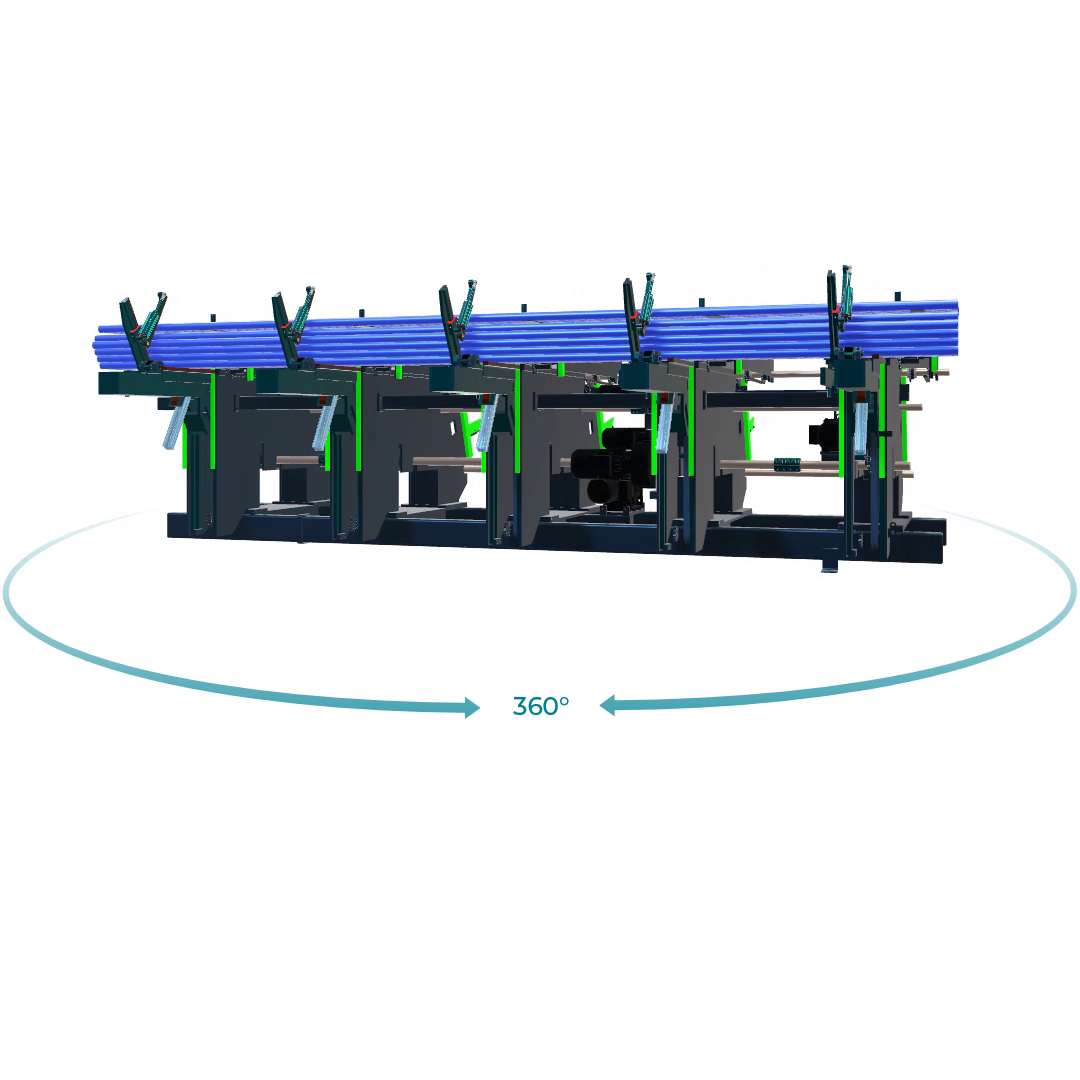

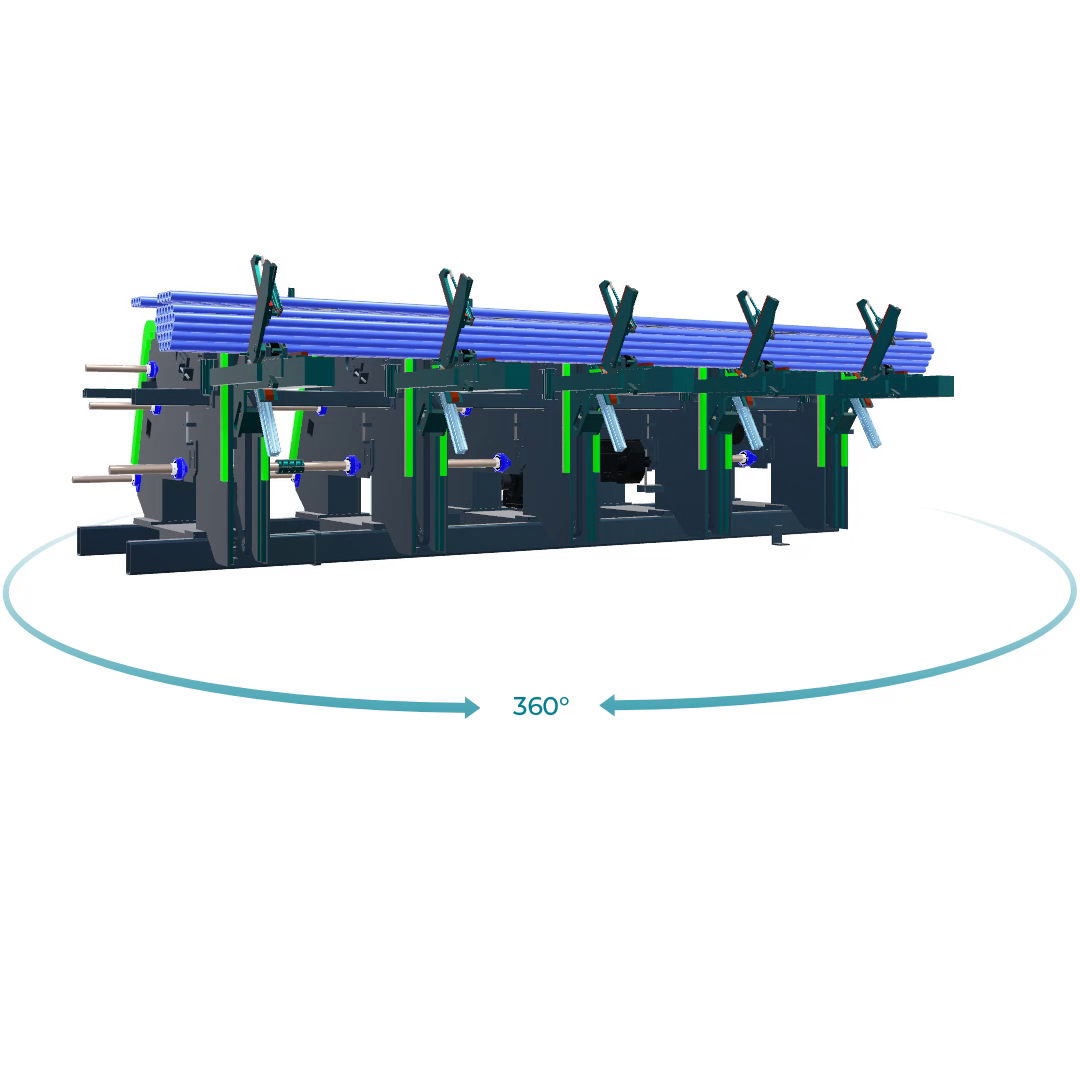

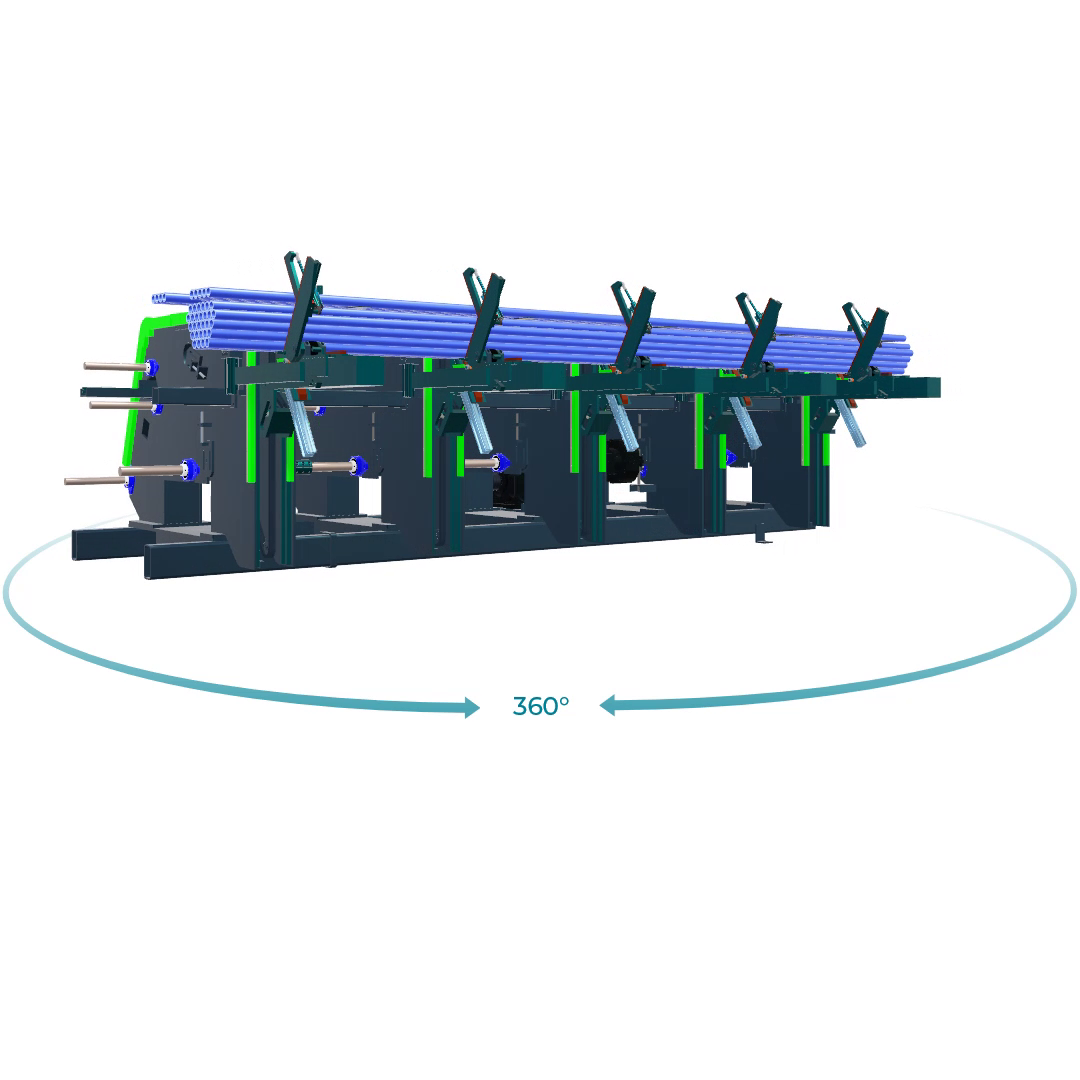

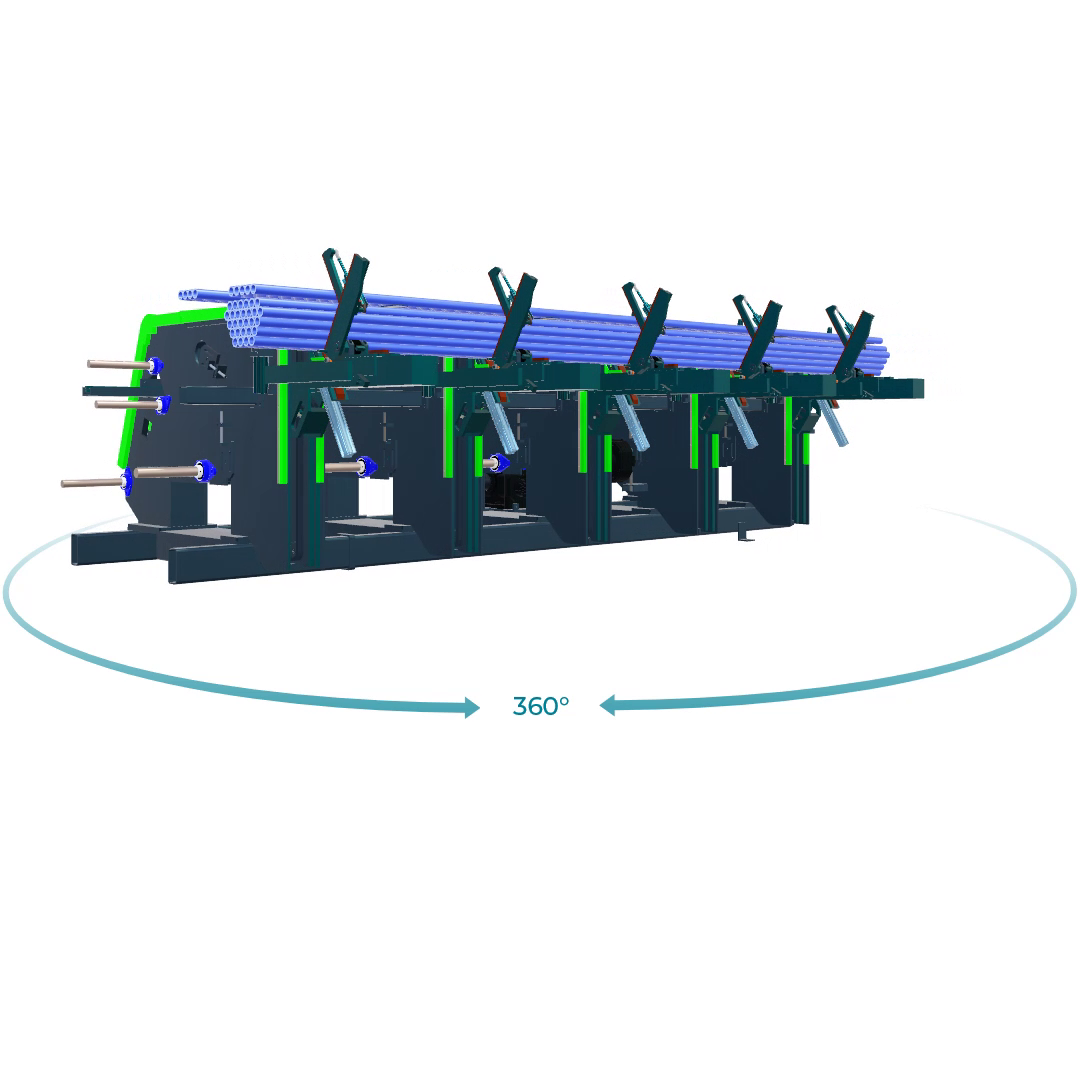

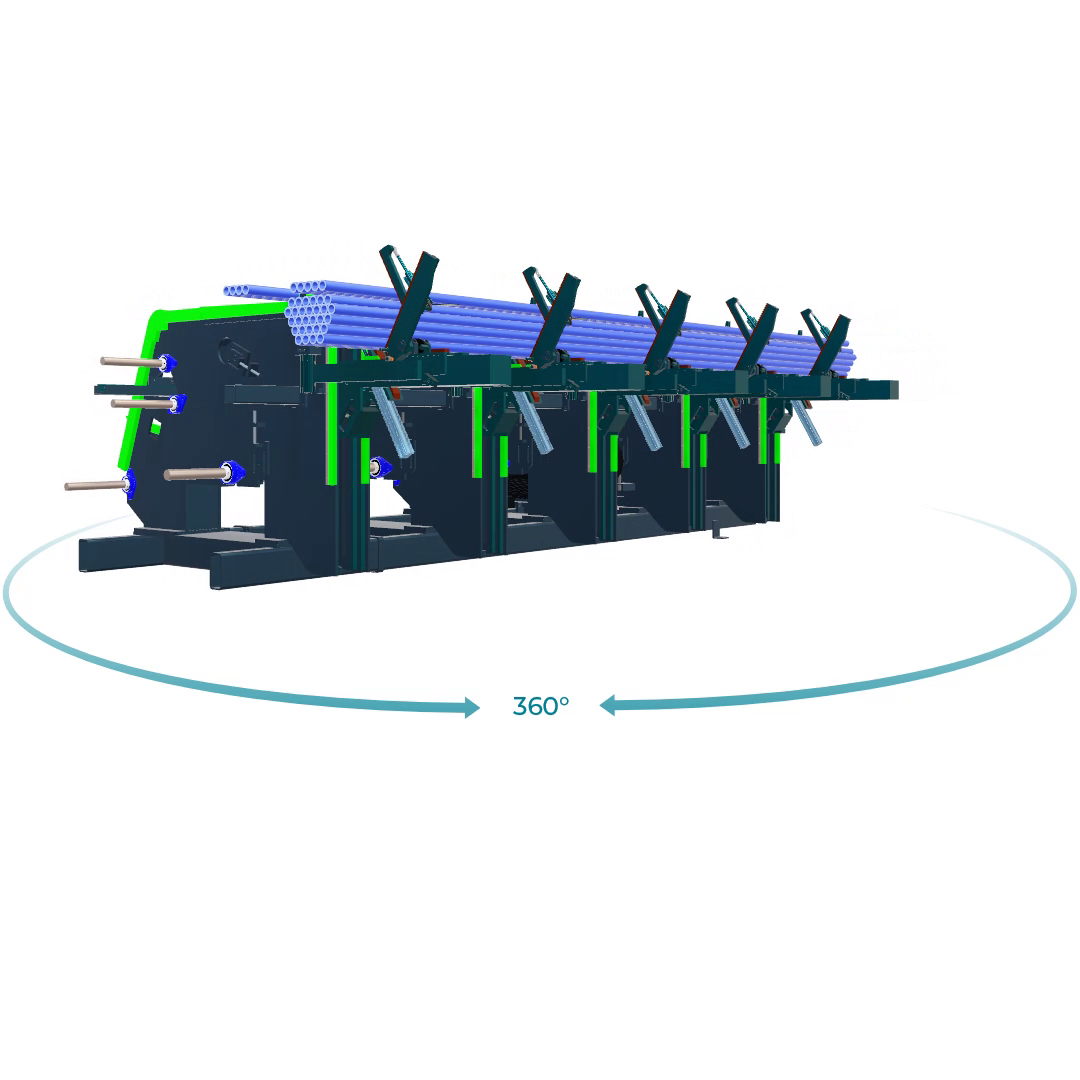

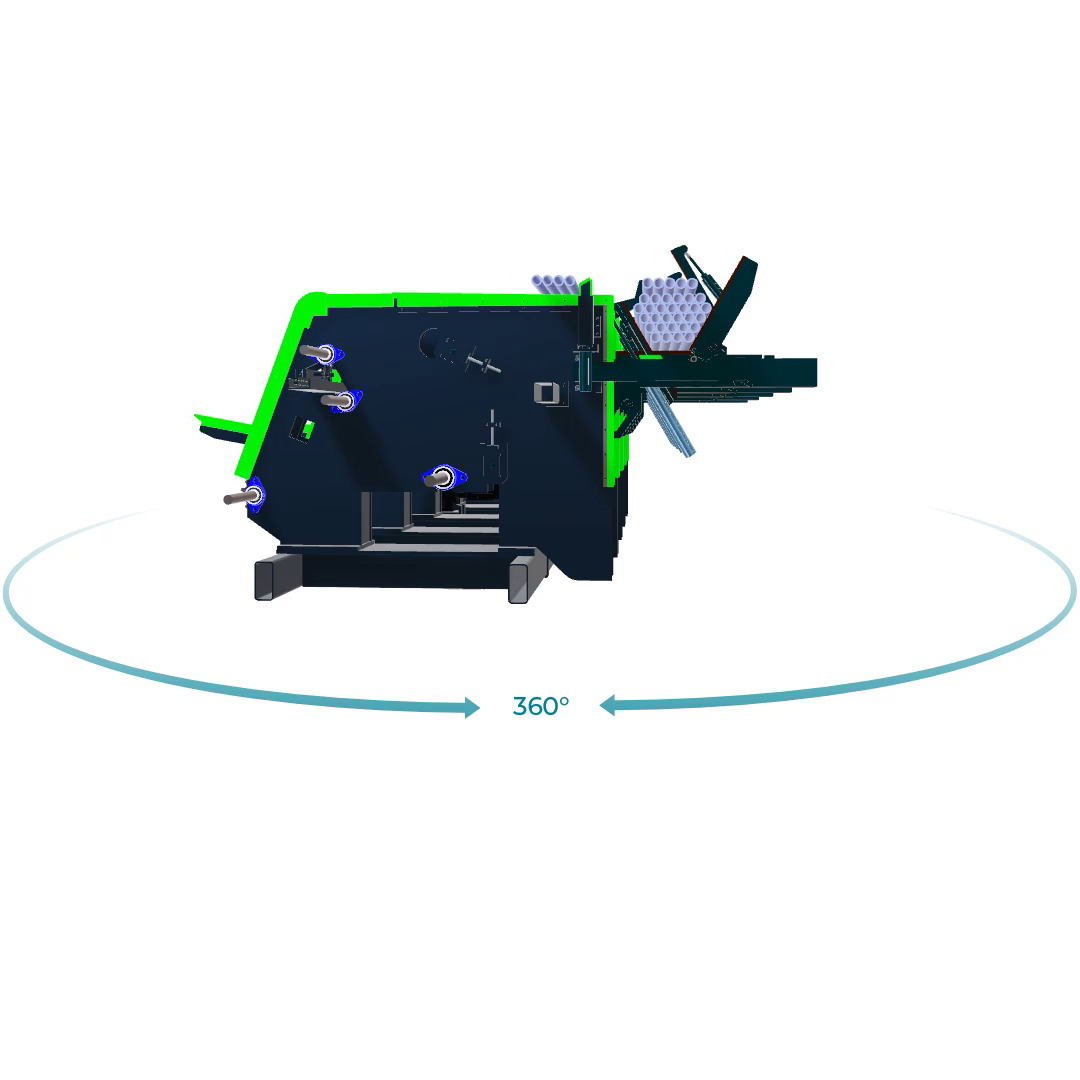

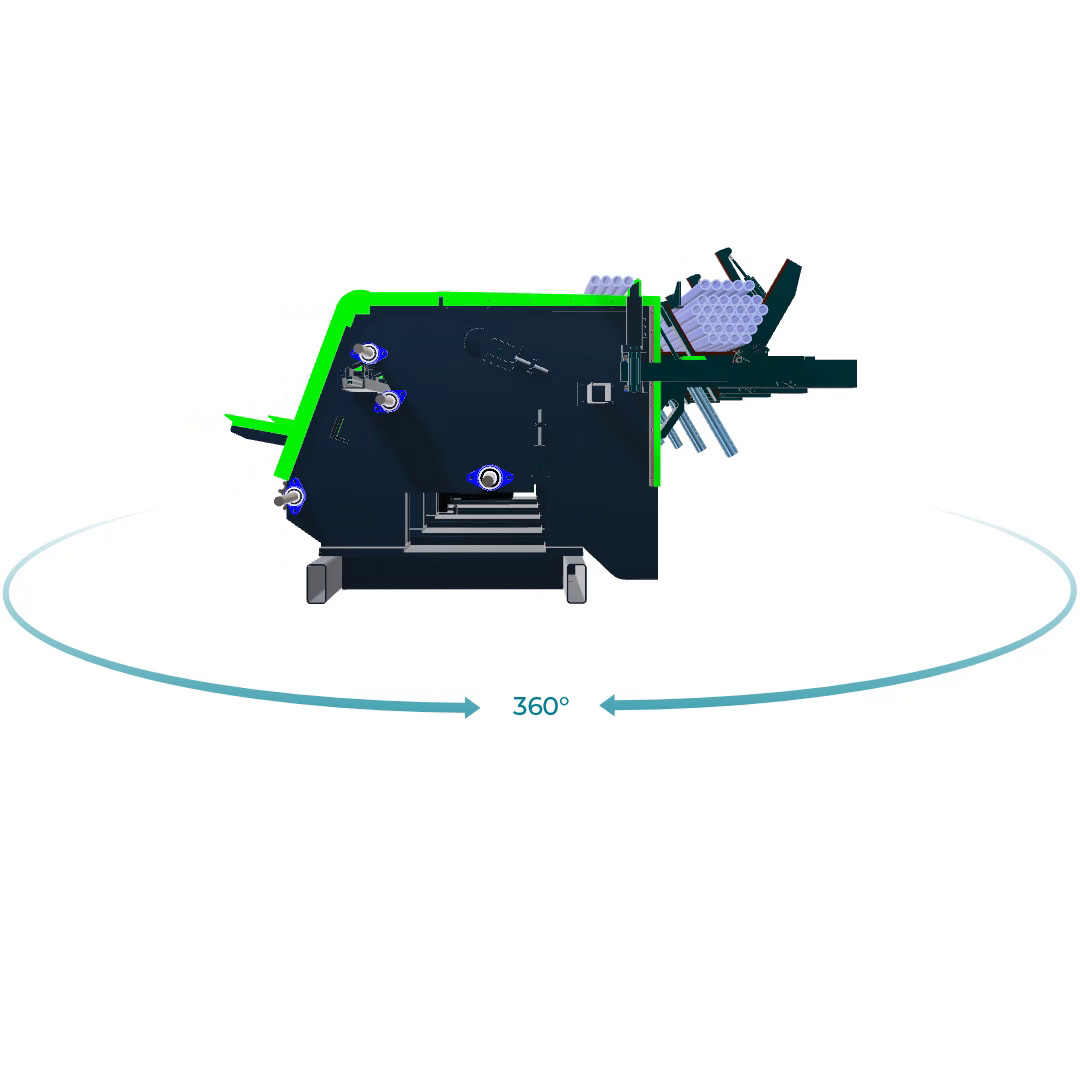

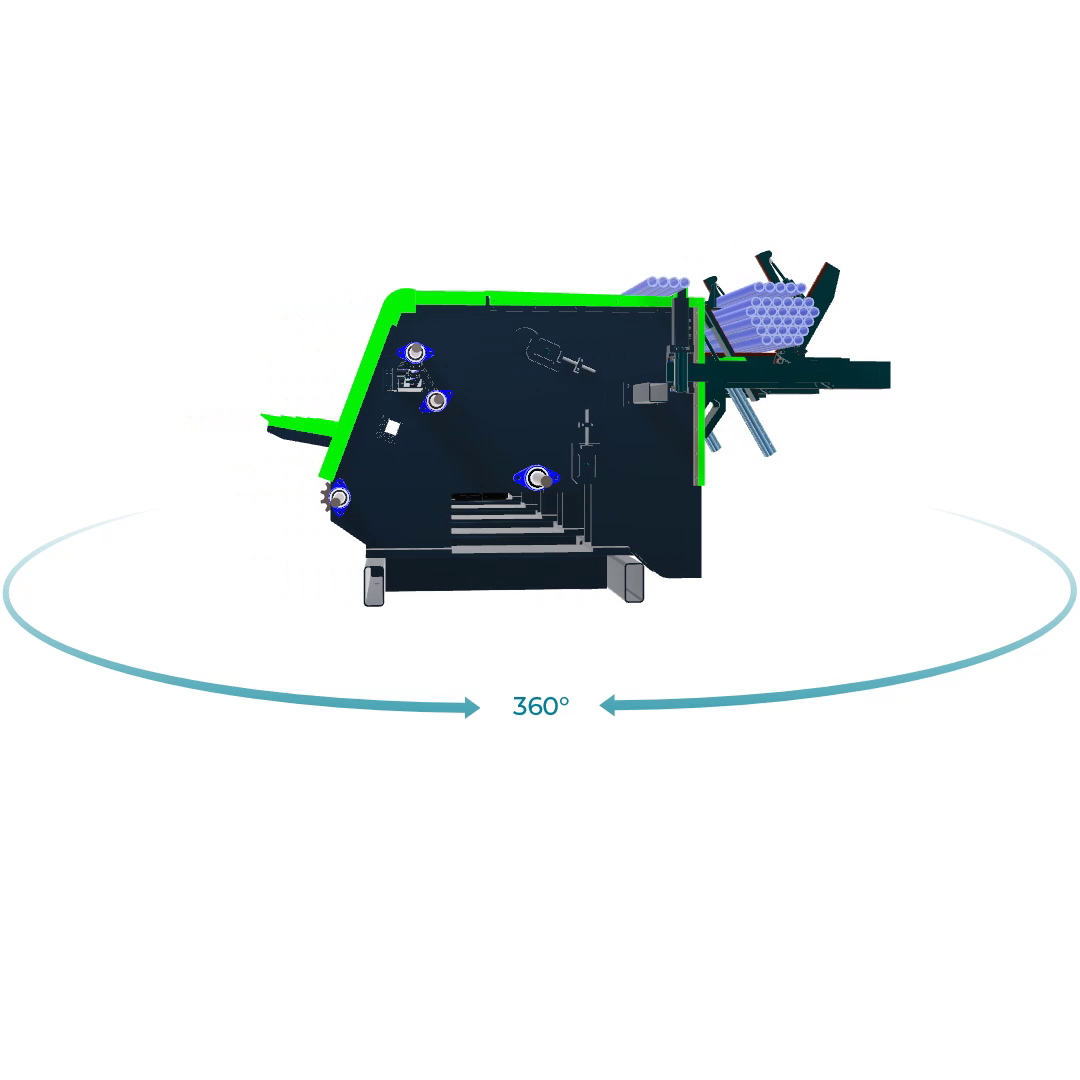

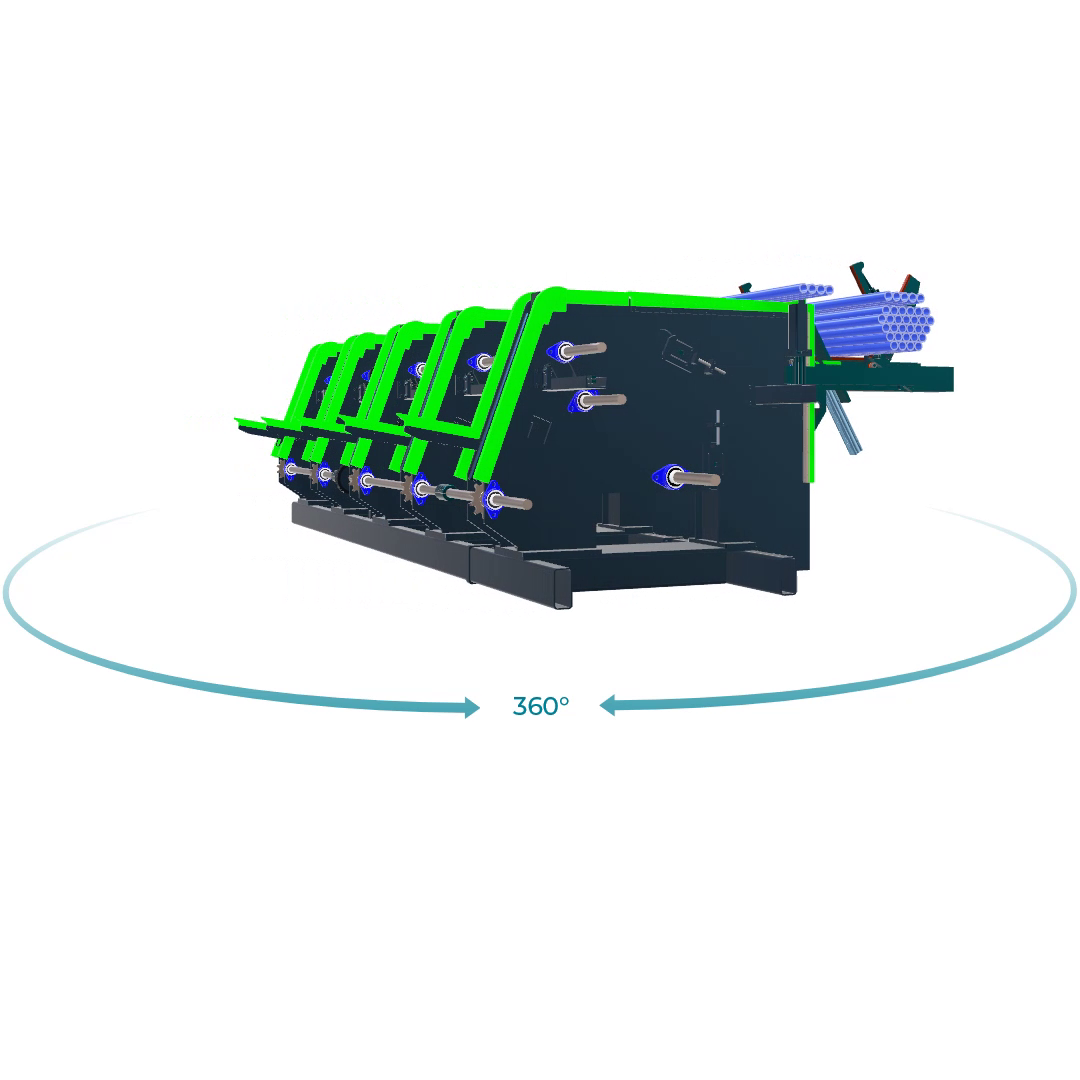

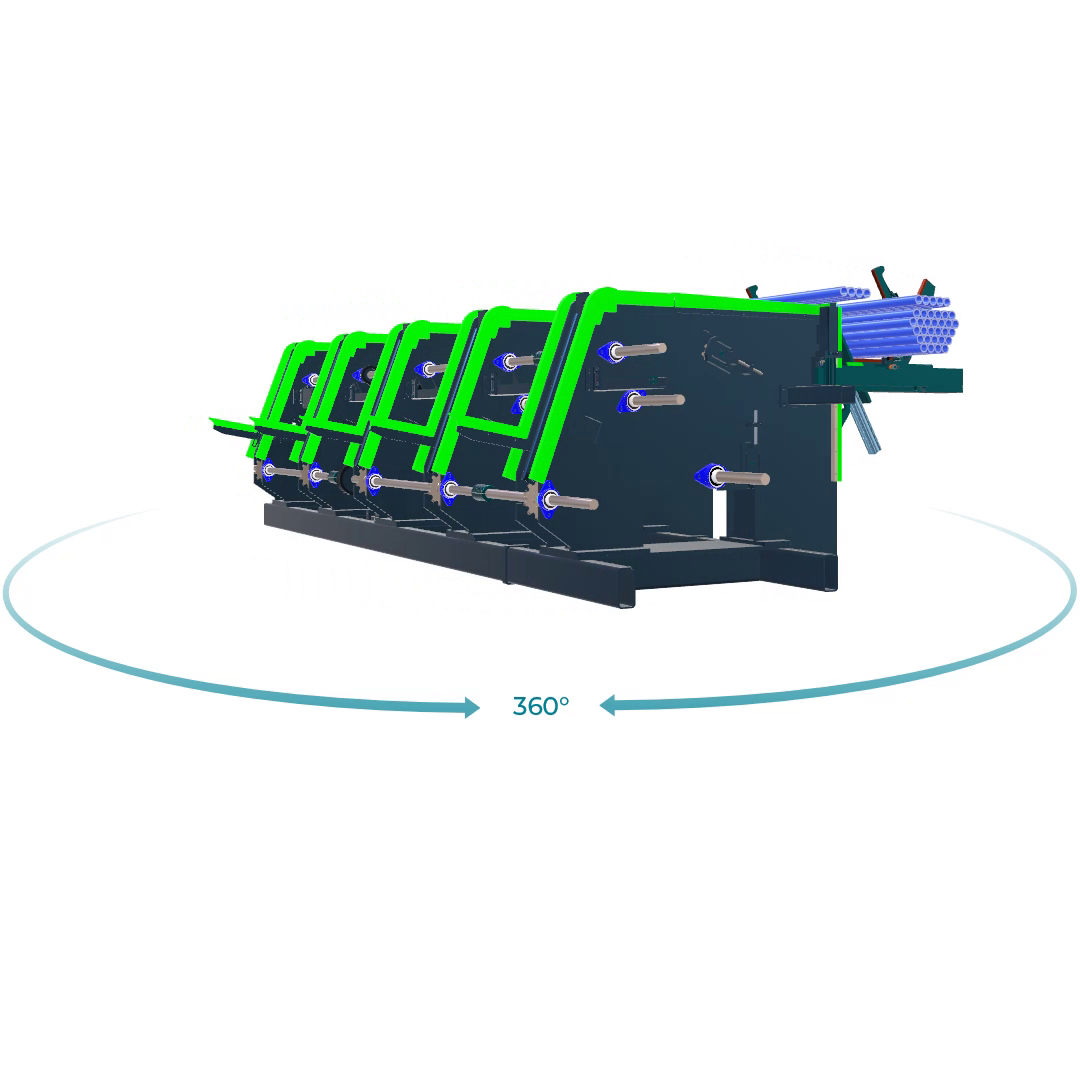

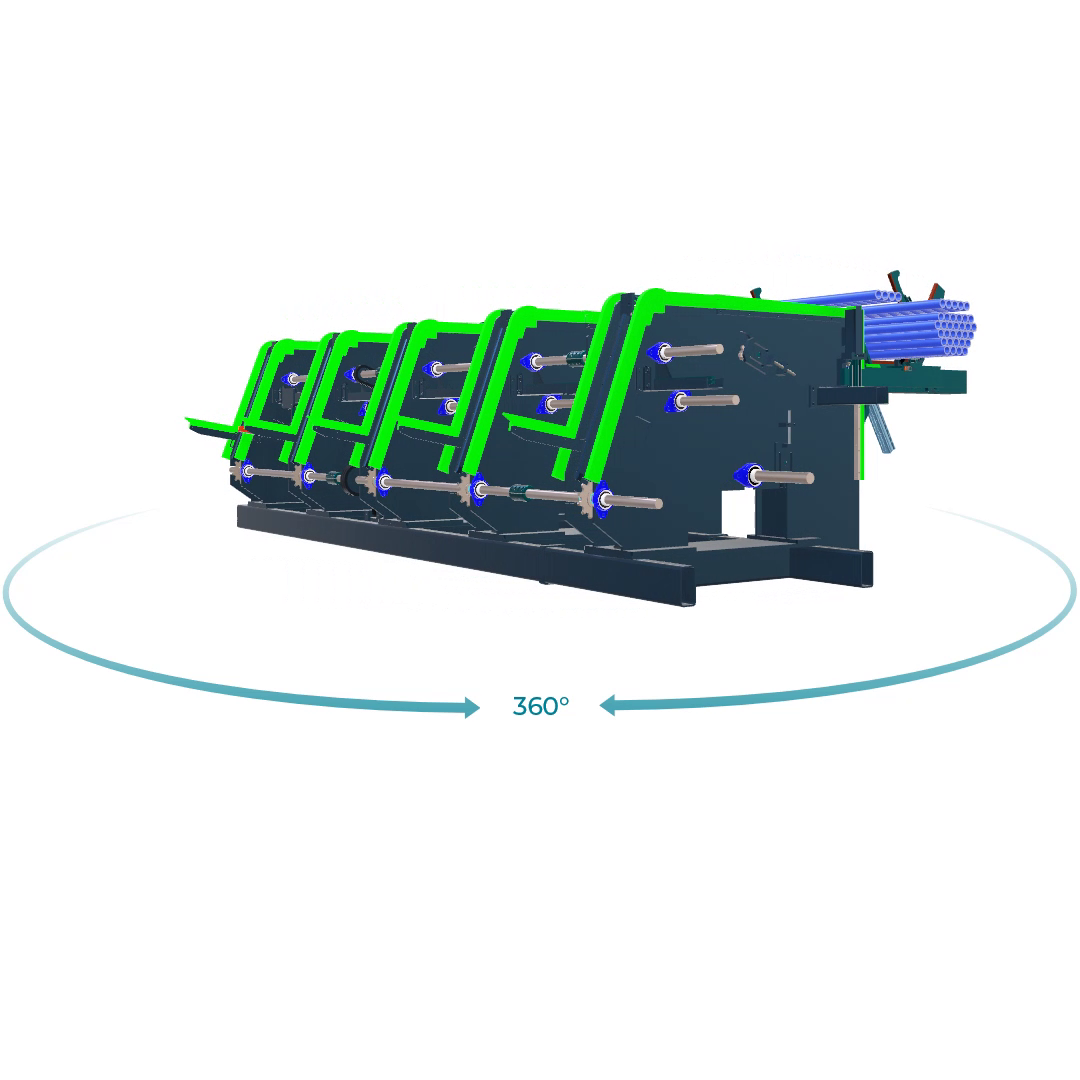

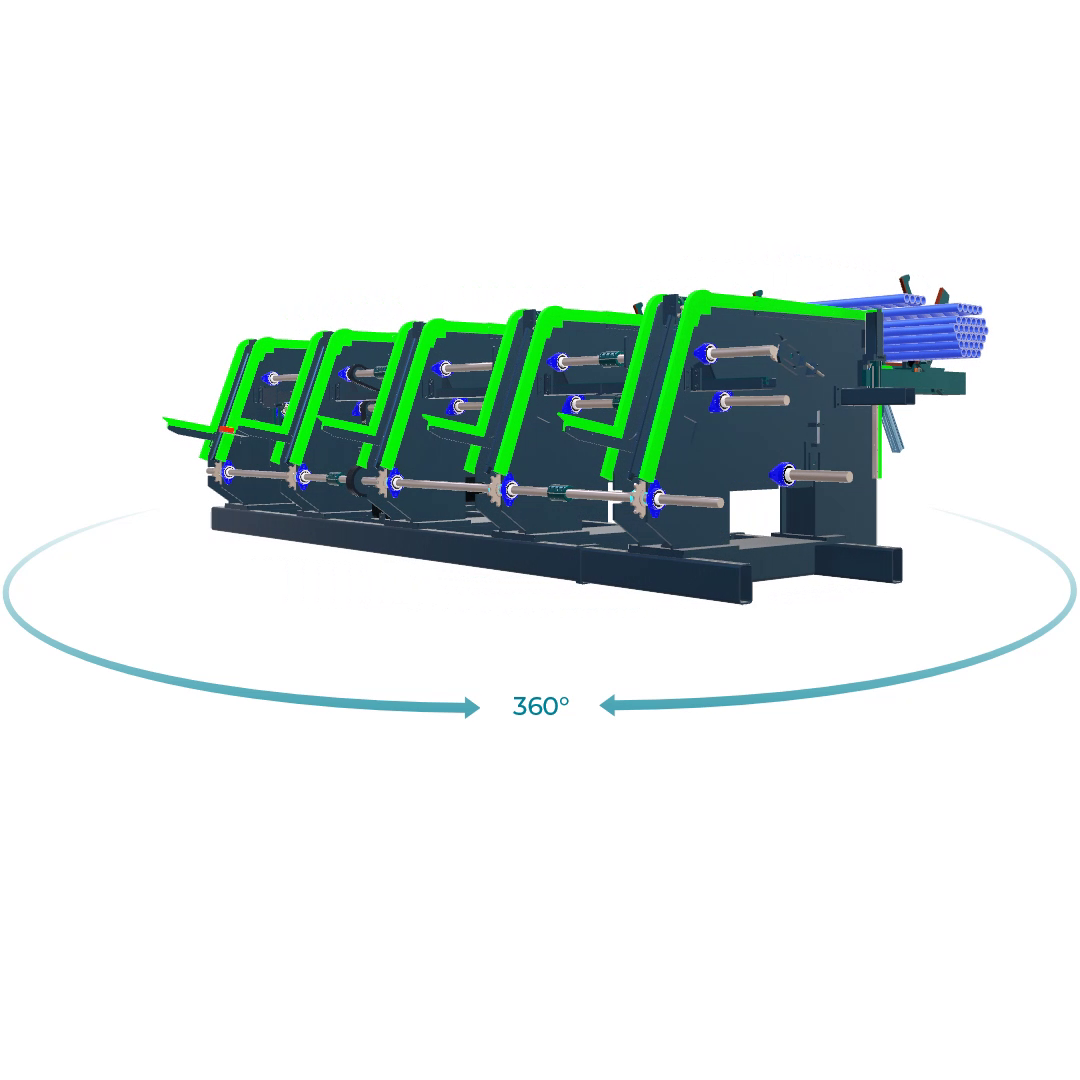

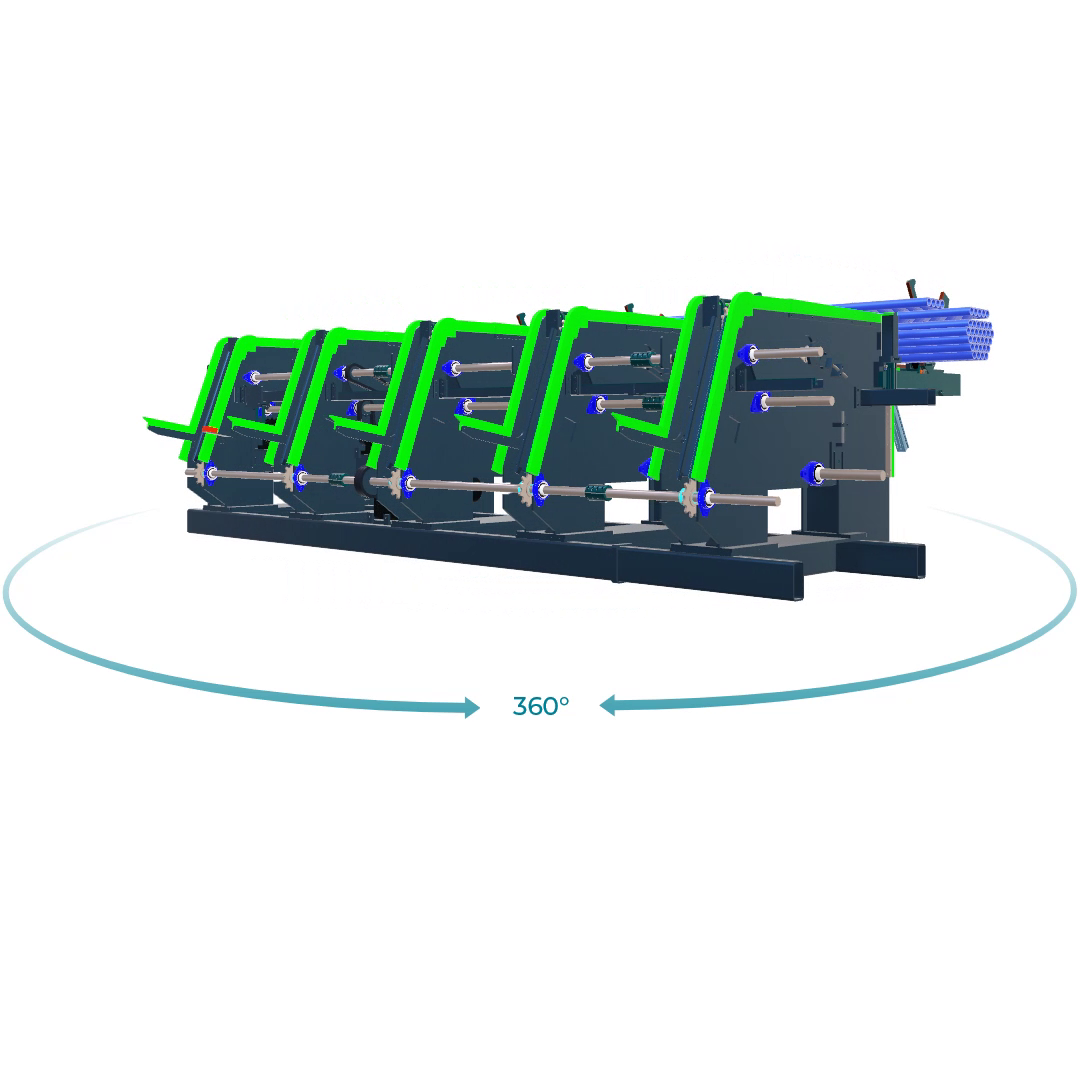

Packaging machines

Description of the device

The tubes and rods are automatically packed to the square or hexagonal shape. A bundle is automatically created based on the diameter of the tubes and required bundle size.

Technical parameters of the machine

|

Profiles to bundle: |

Round, hexagonal, square, rectangular, profile steel |

|

Pipe diameters: |

6 – 120 mm |

|

Lengths of tubes, rods: |

3 – 18 m |

|

Bundle size hexagon, square: |

up to 600 mm |

|

Bundle weight: |

to 6 000 kg |

|

Control system: |

Simatic S7 |

|

Inlet pipe cycle: |

from 5 sec/ pc |

|

Output cycle: |

Depending on the number of pieces in a bundle |

|

Strapping cycle: |

Approx. 60 sec per tape |

|

Desk equipment: |

Process display, production statistics, error messages, data transfer to company management |

|

Automatic, semi automatic and manual mode |

|

Other equipment of the machine

- Separating the free bundle and feeding the tubes into the packaging machine of 1 pc each

- Equipping the machine with zip ties to create a circular bundle during manual strapping

- Weighing a bundle on certified scales and printing a weighing ticket

- Automatic stoppering of pipes and closed profiles with transport plugs

- Marking of individual pipes and whole bundles based on customer requirements

- Backing of steel tape with paper tapes

- Wrapping the entire bundle or ends of the bundle into stretch foil

- Blowing through pipes to remove liquid, chips and dirt from the inner diameter

- Extended visualization of machines with an emphasis on intuitive and detailed display of the operating states of the packaging machine

- Extended diagnostics of the machine with an emphasis on displaying the place of occurrence of the fault on the layout scheme of the machine

- Extended service with the possibility of displaying manuals, service manuals and other necessary documentation on machines in order to minimize service times

- Collection of agreed production parameters with automatic saving, display and data export.

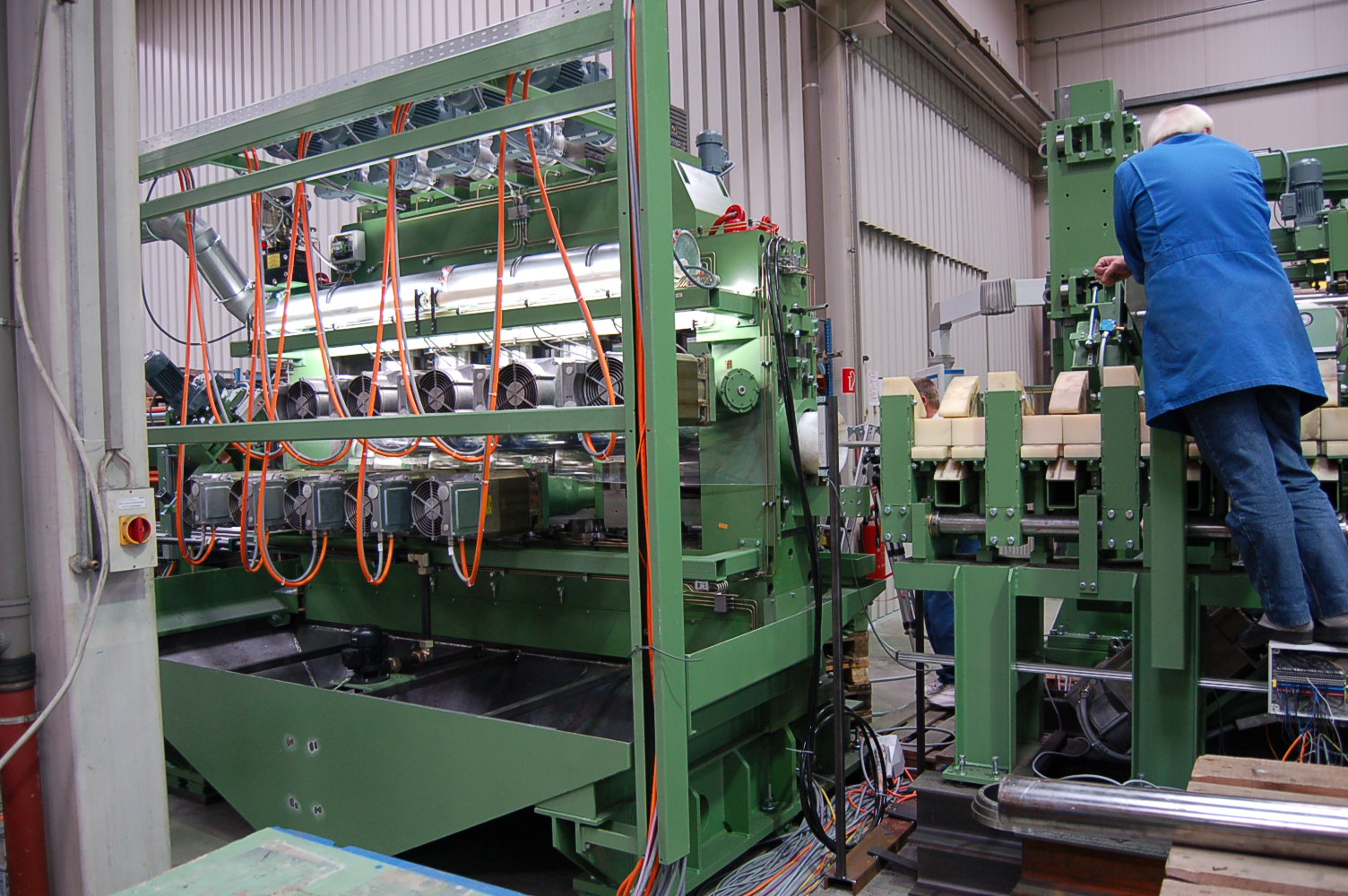

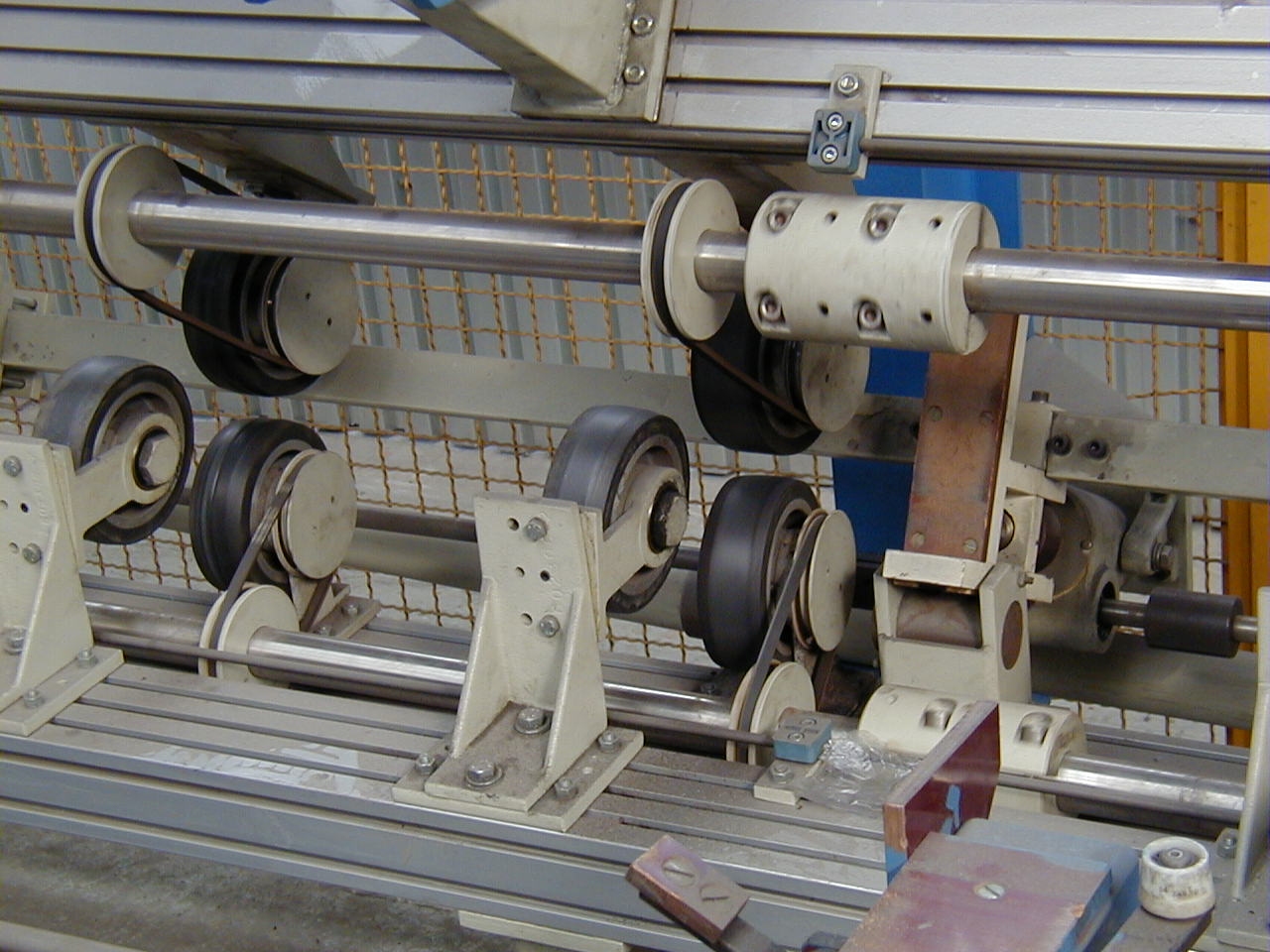

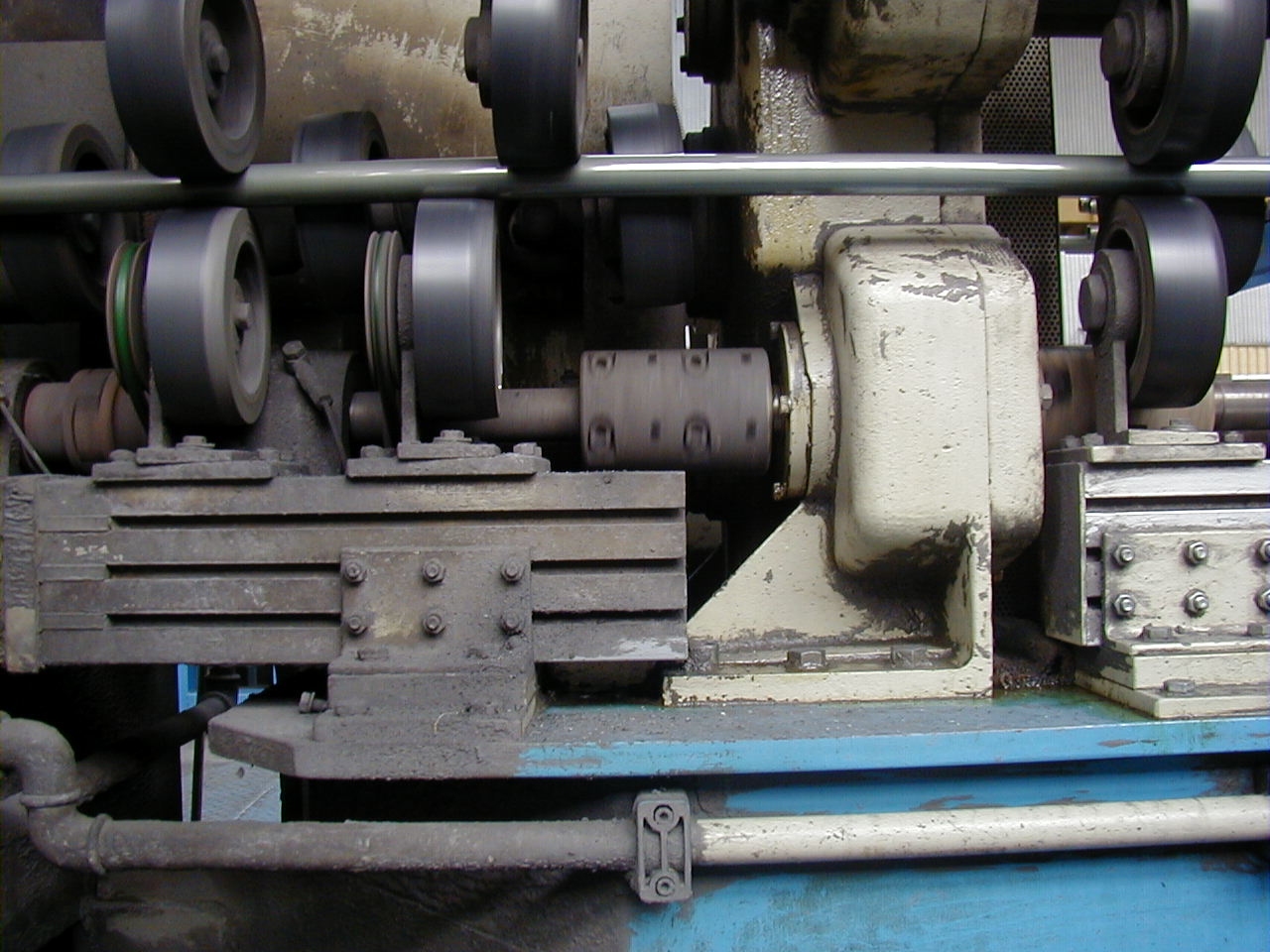

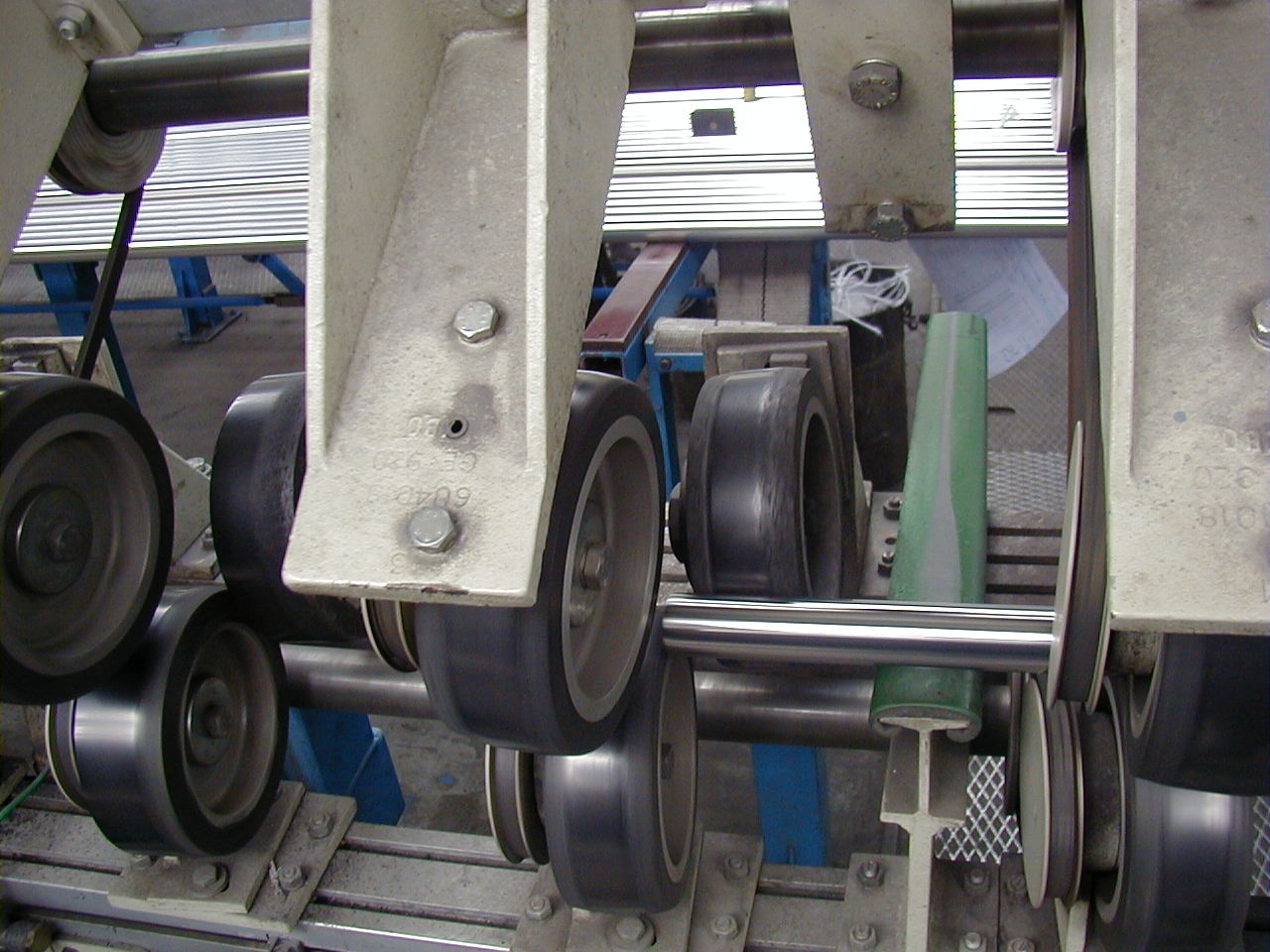

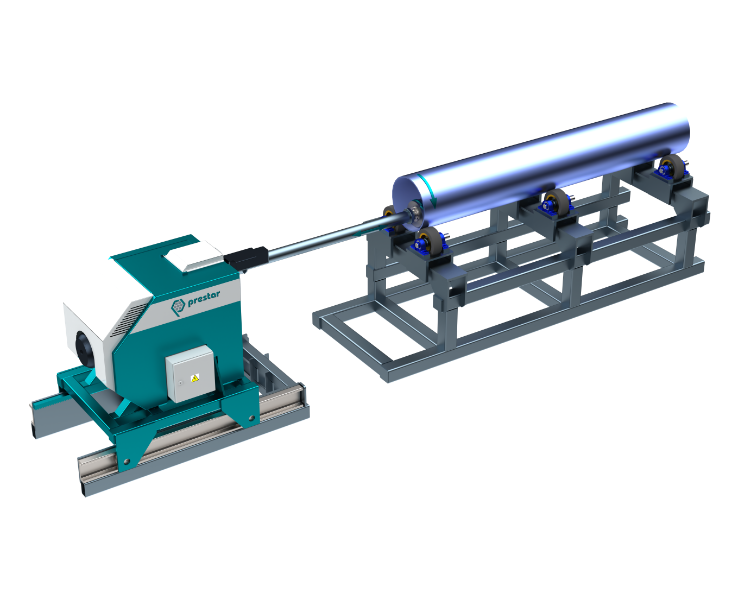

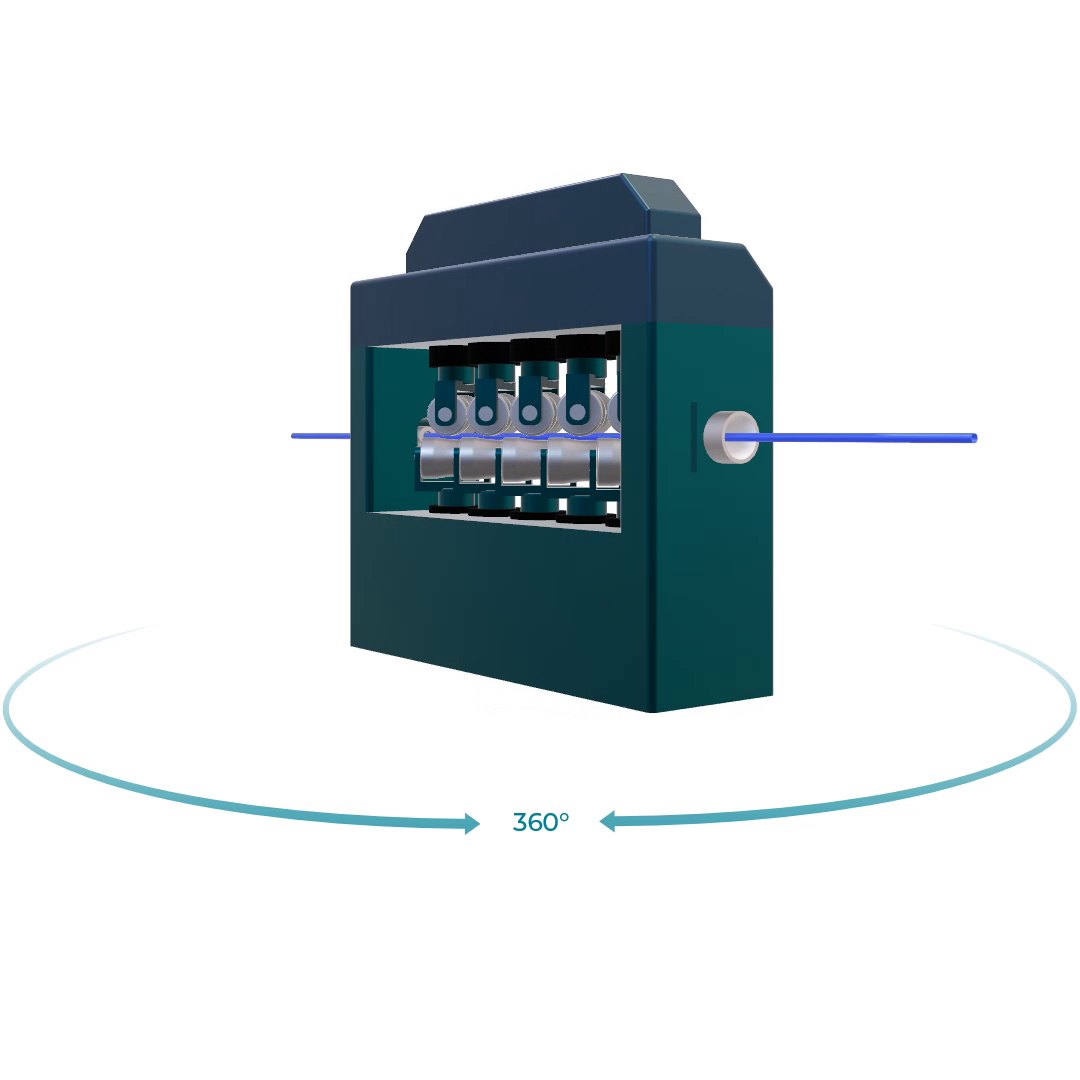

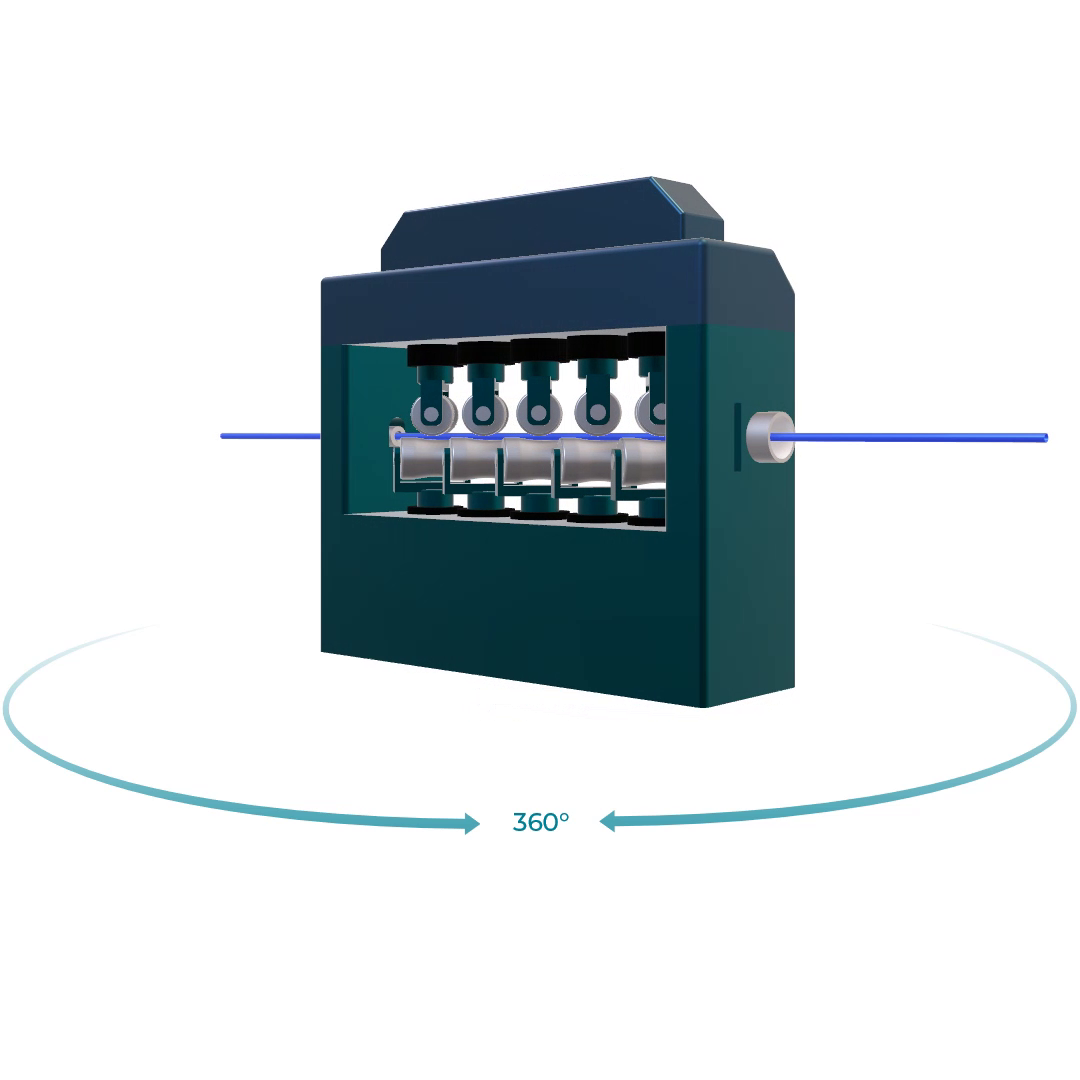

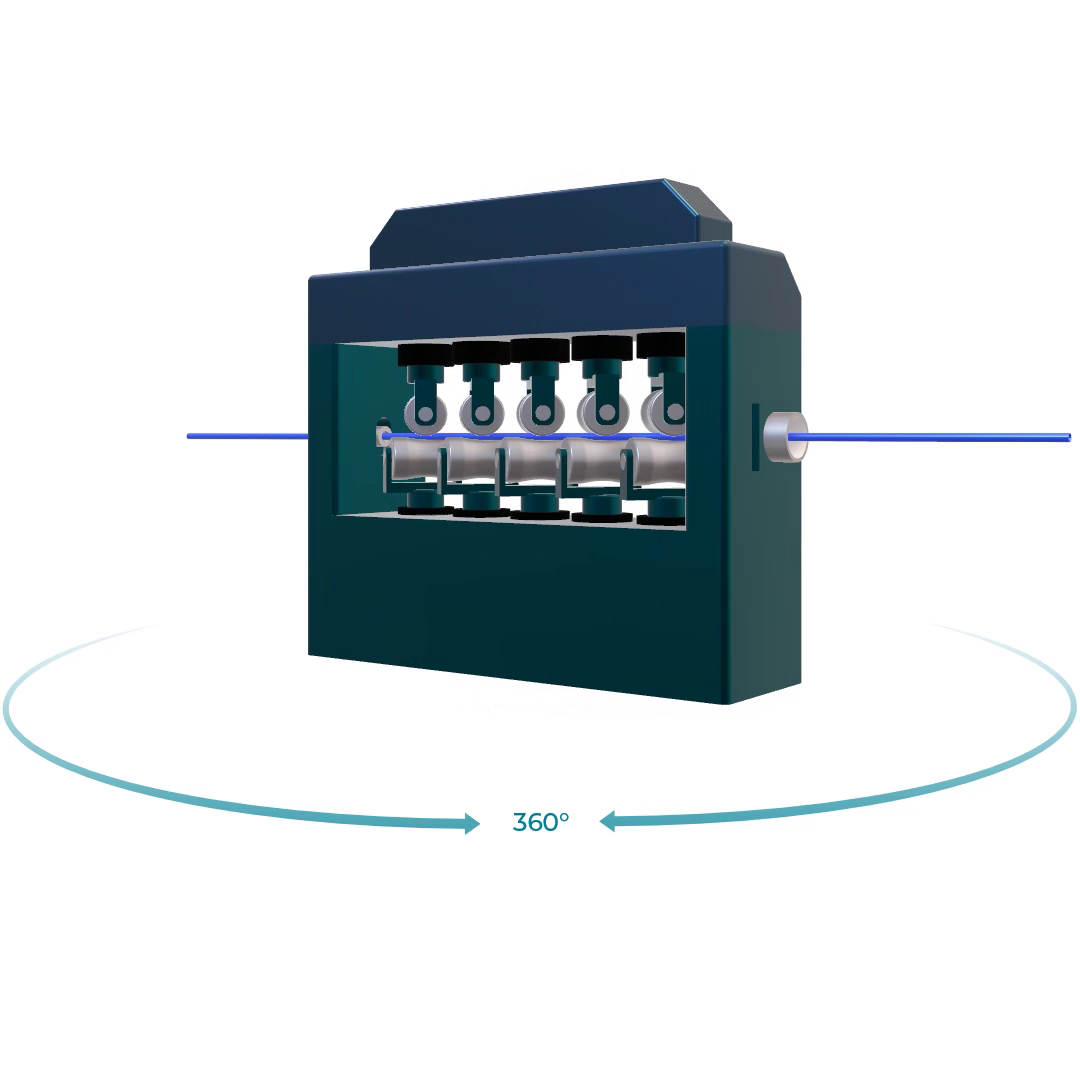

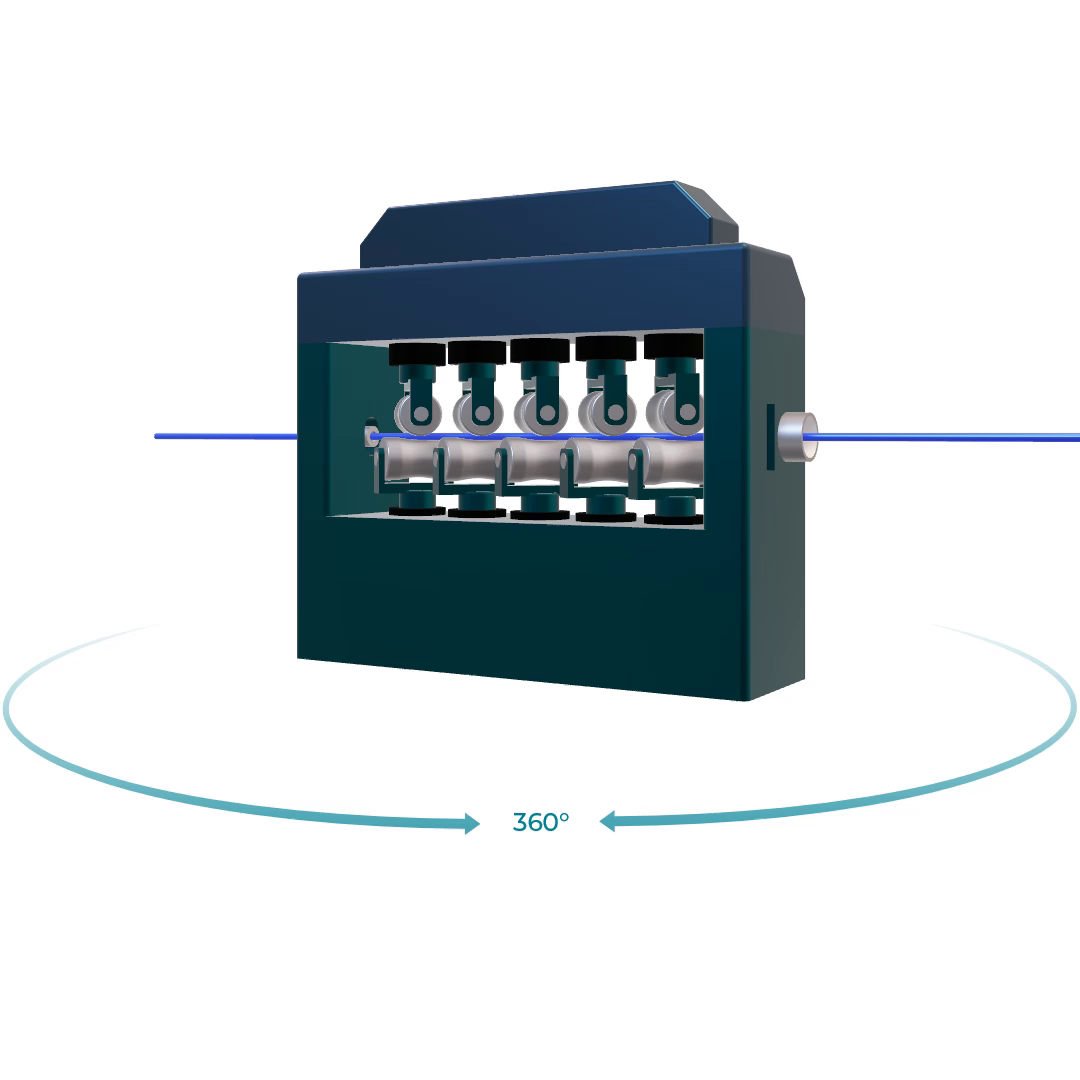

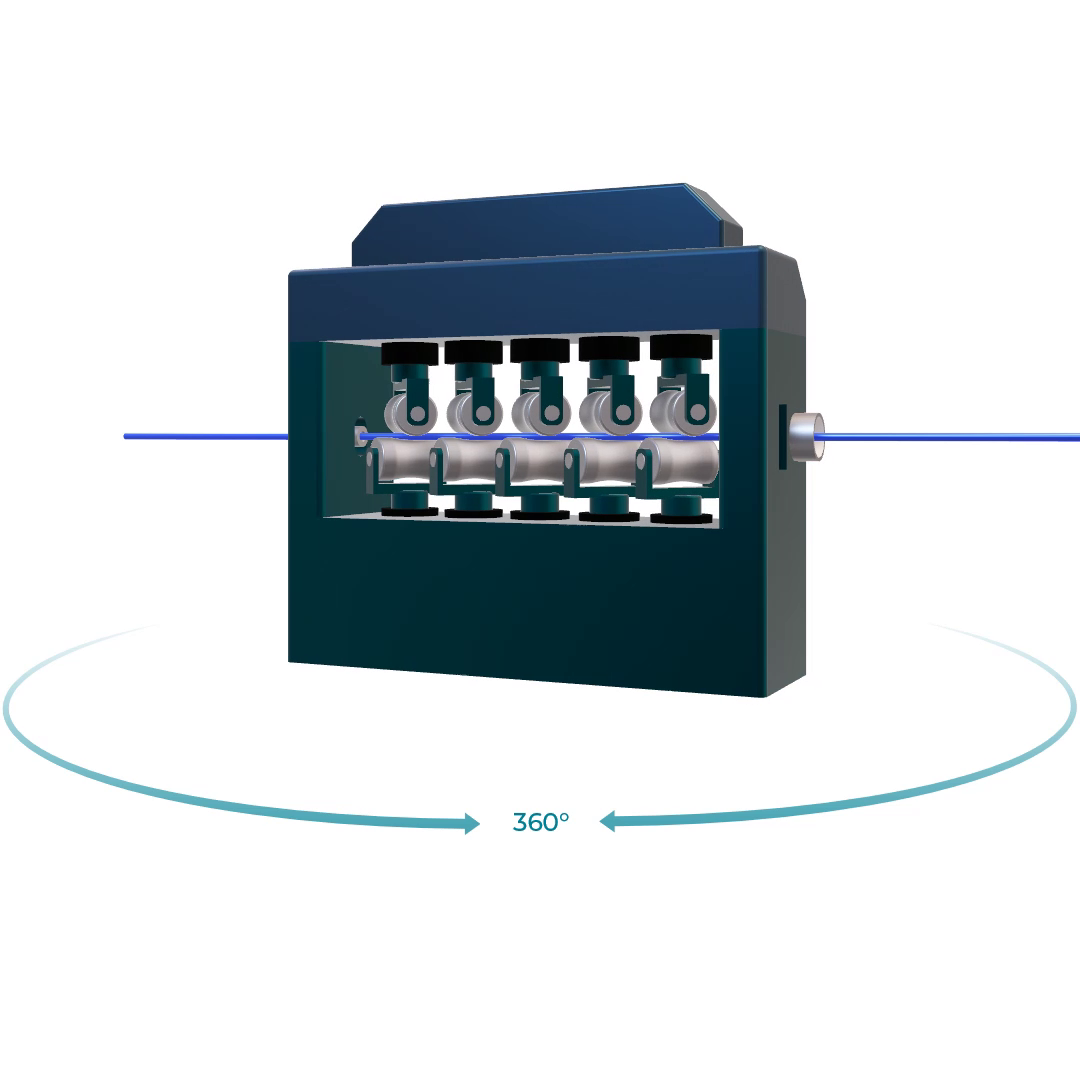

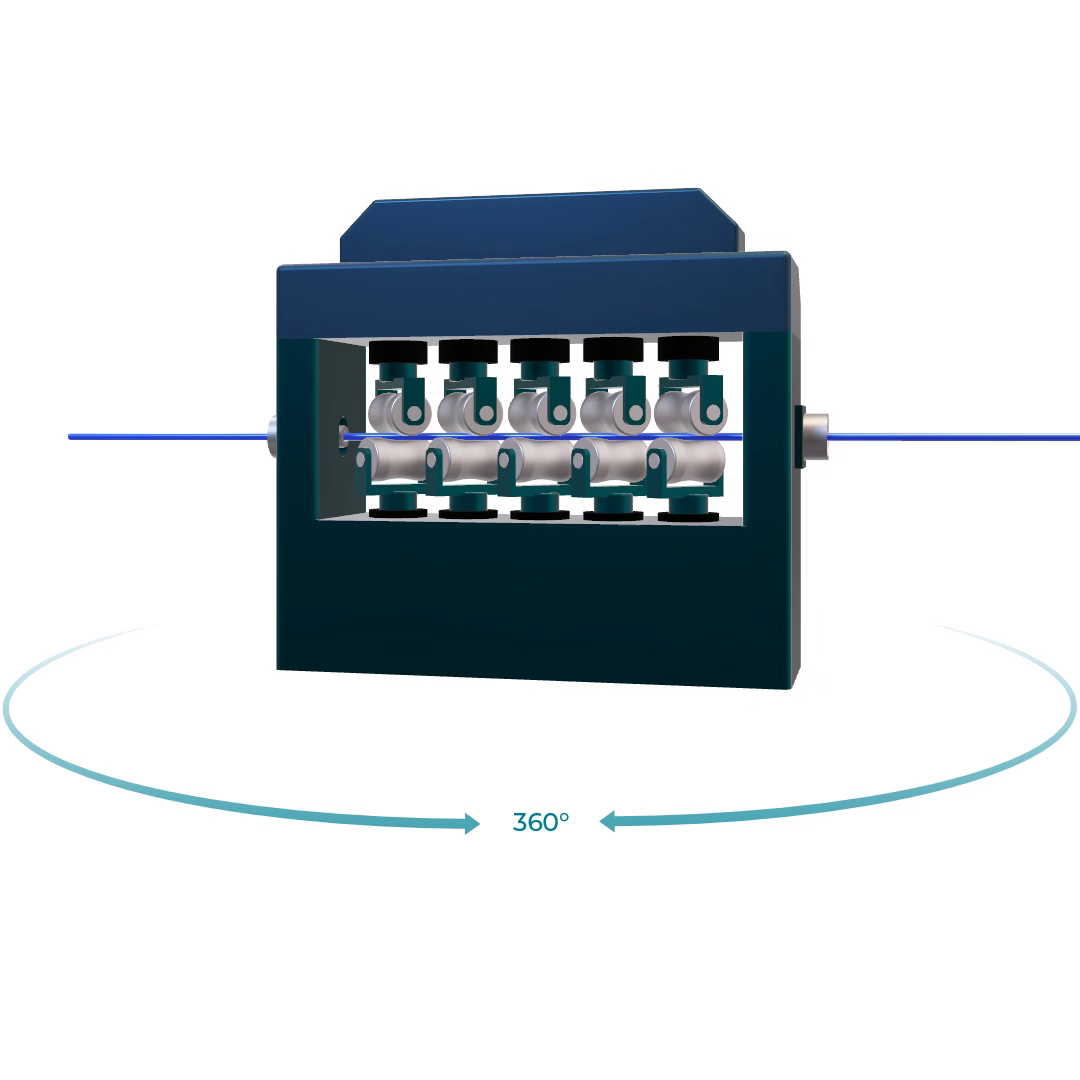

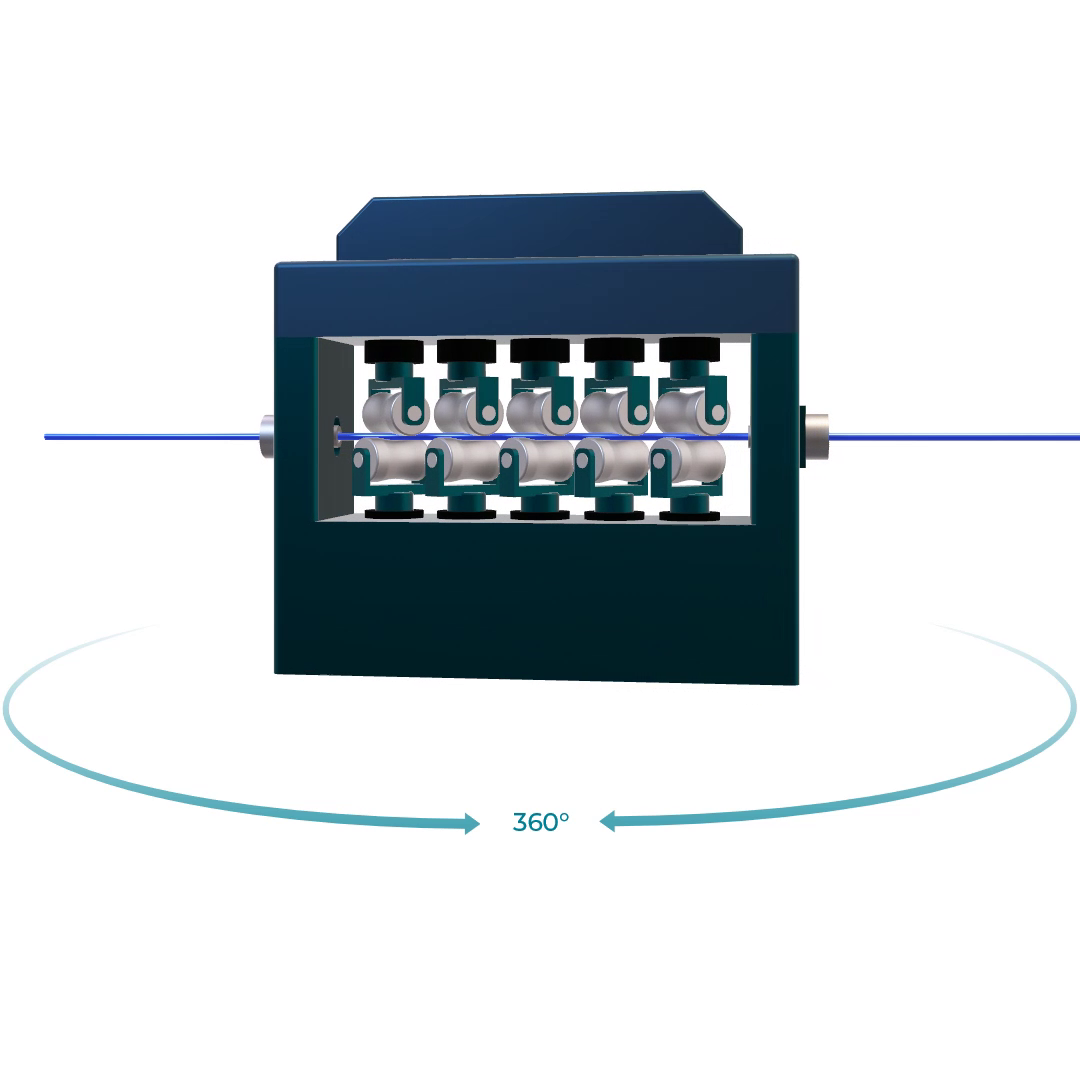

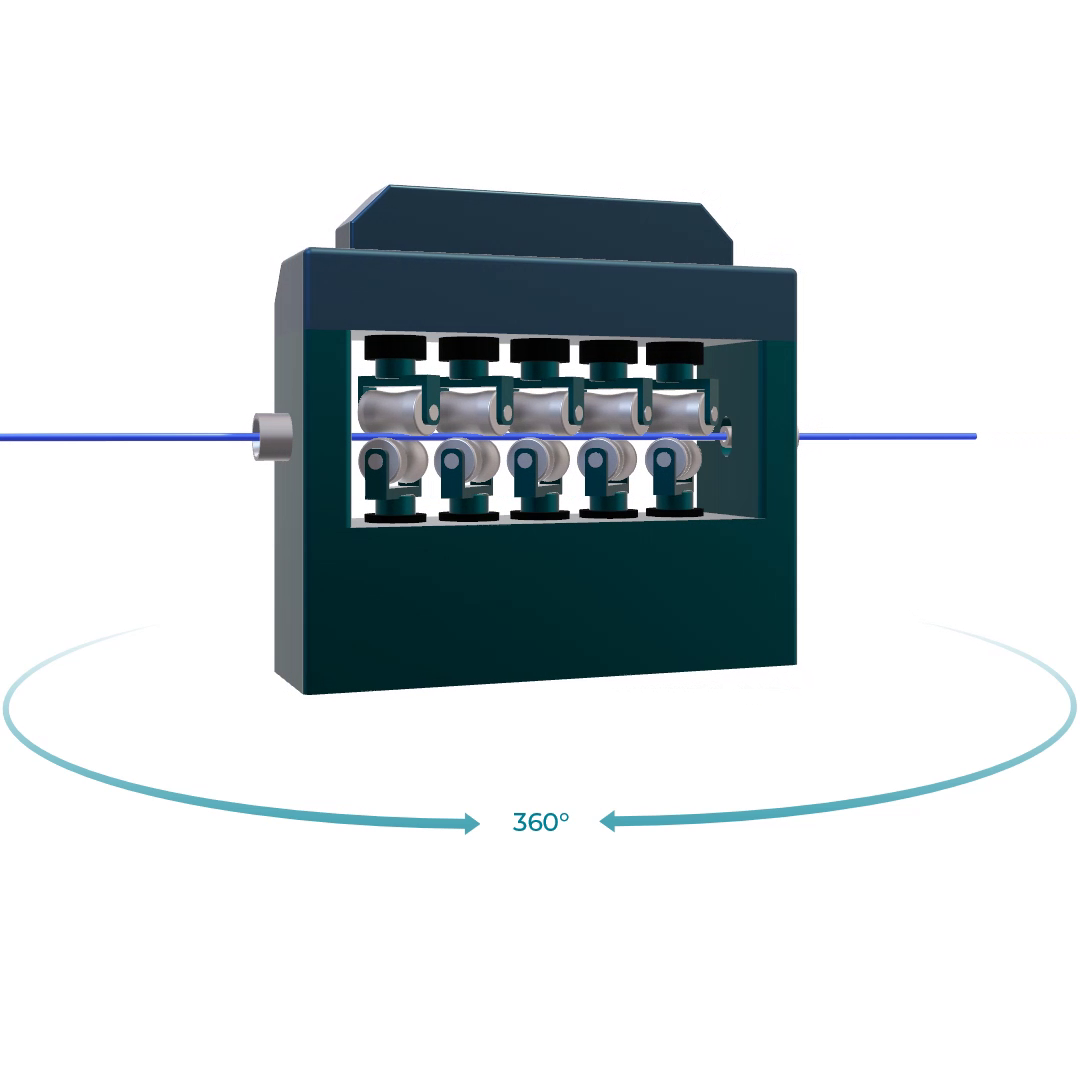

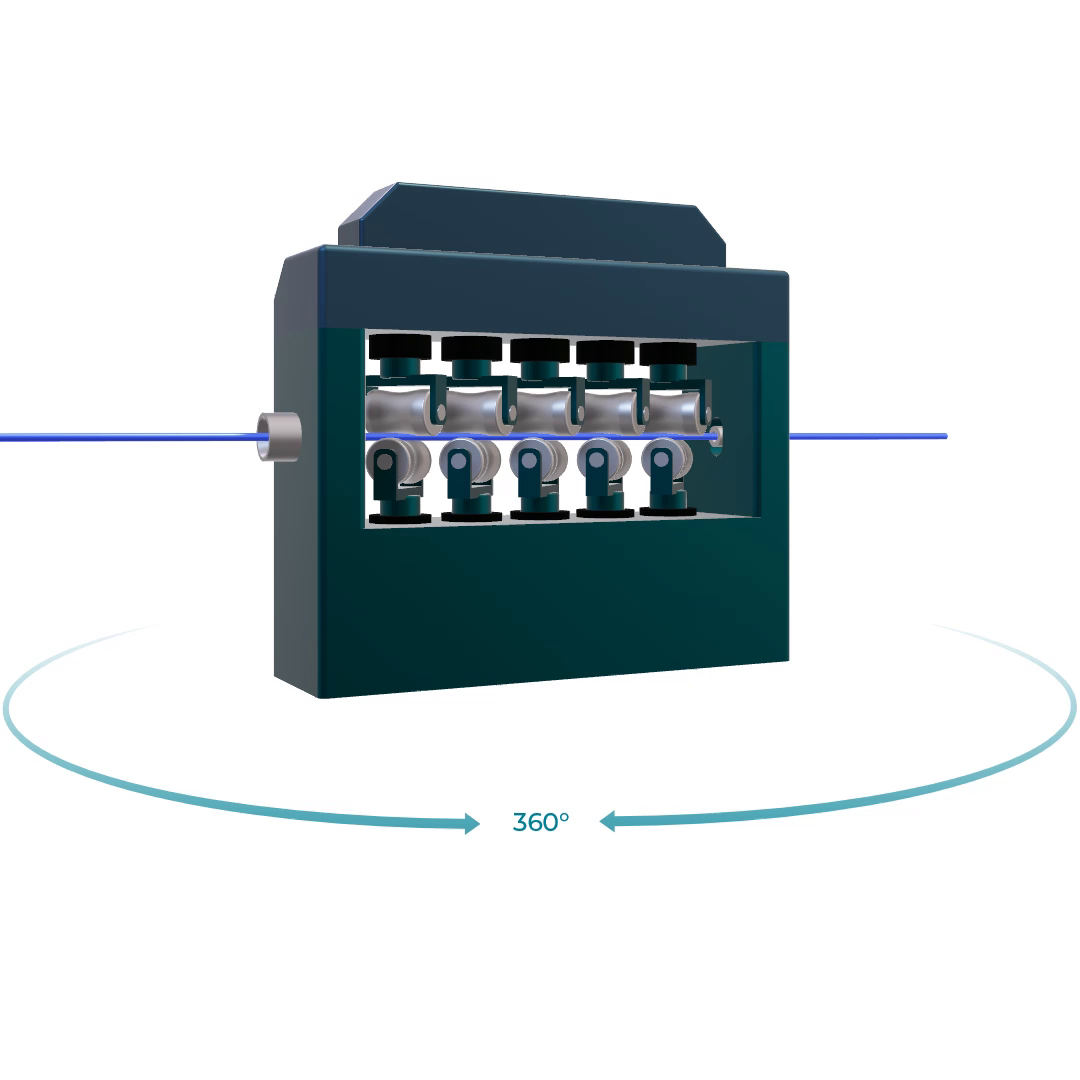

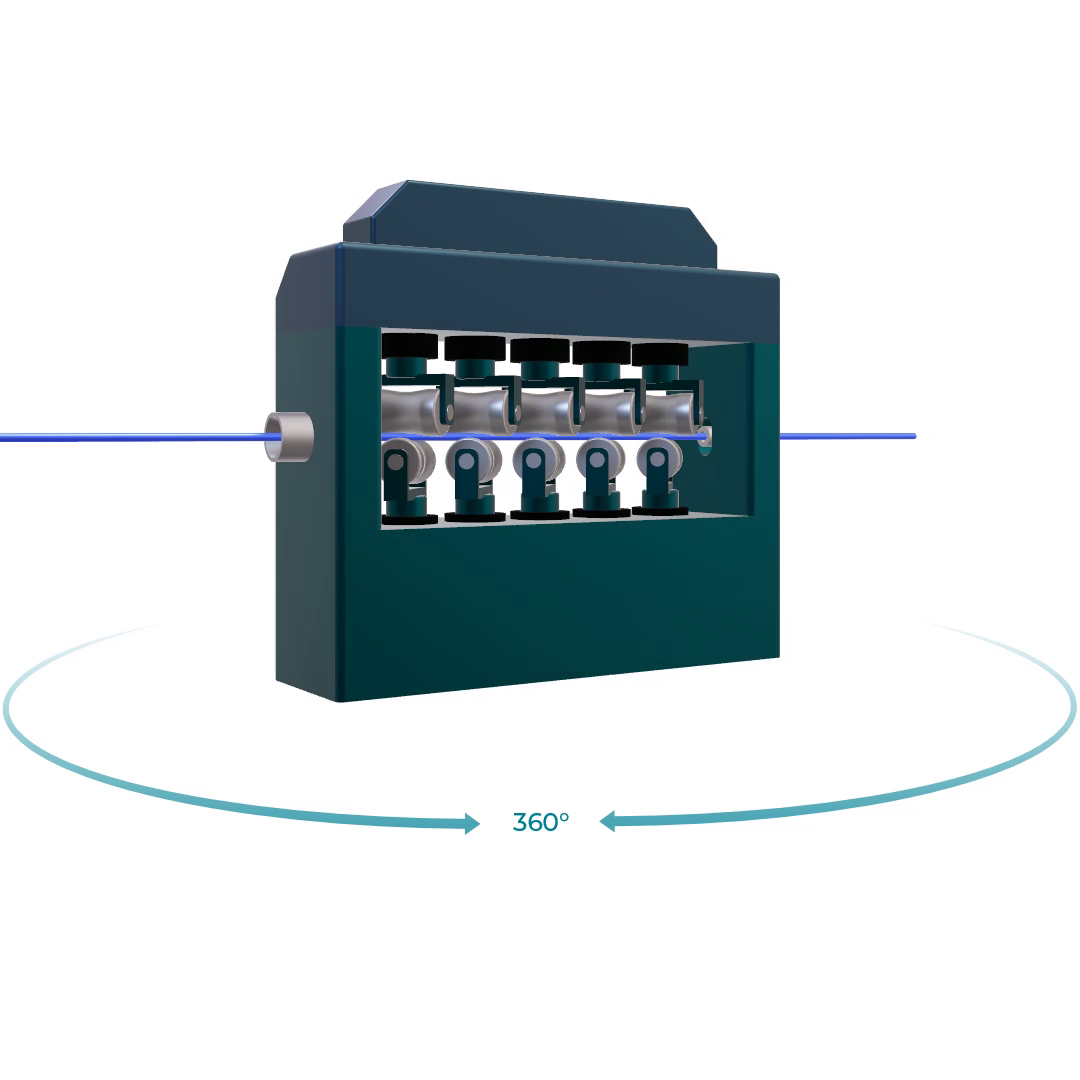

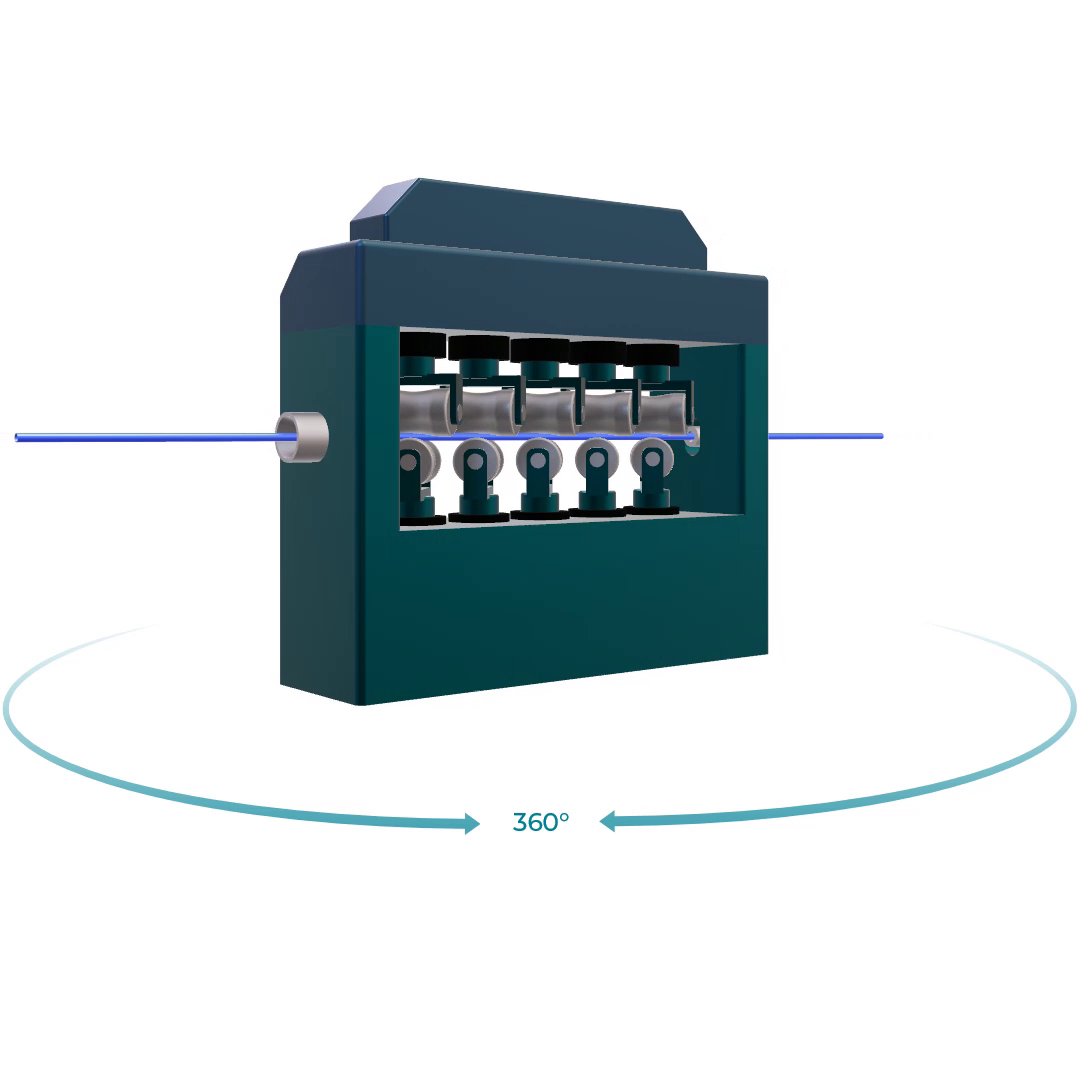

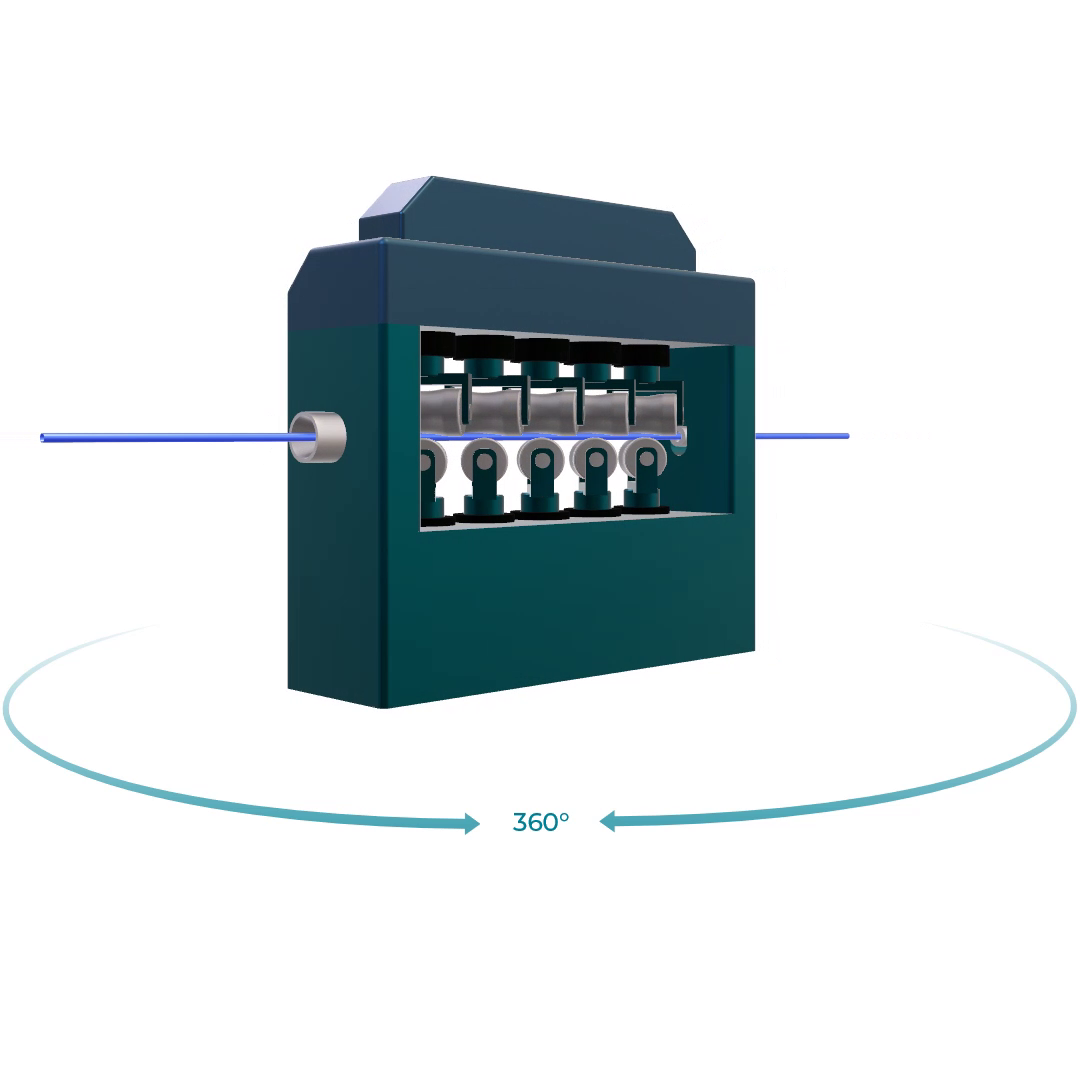

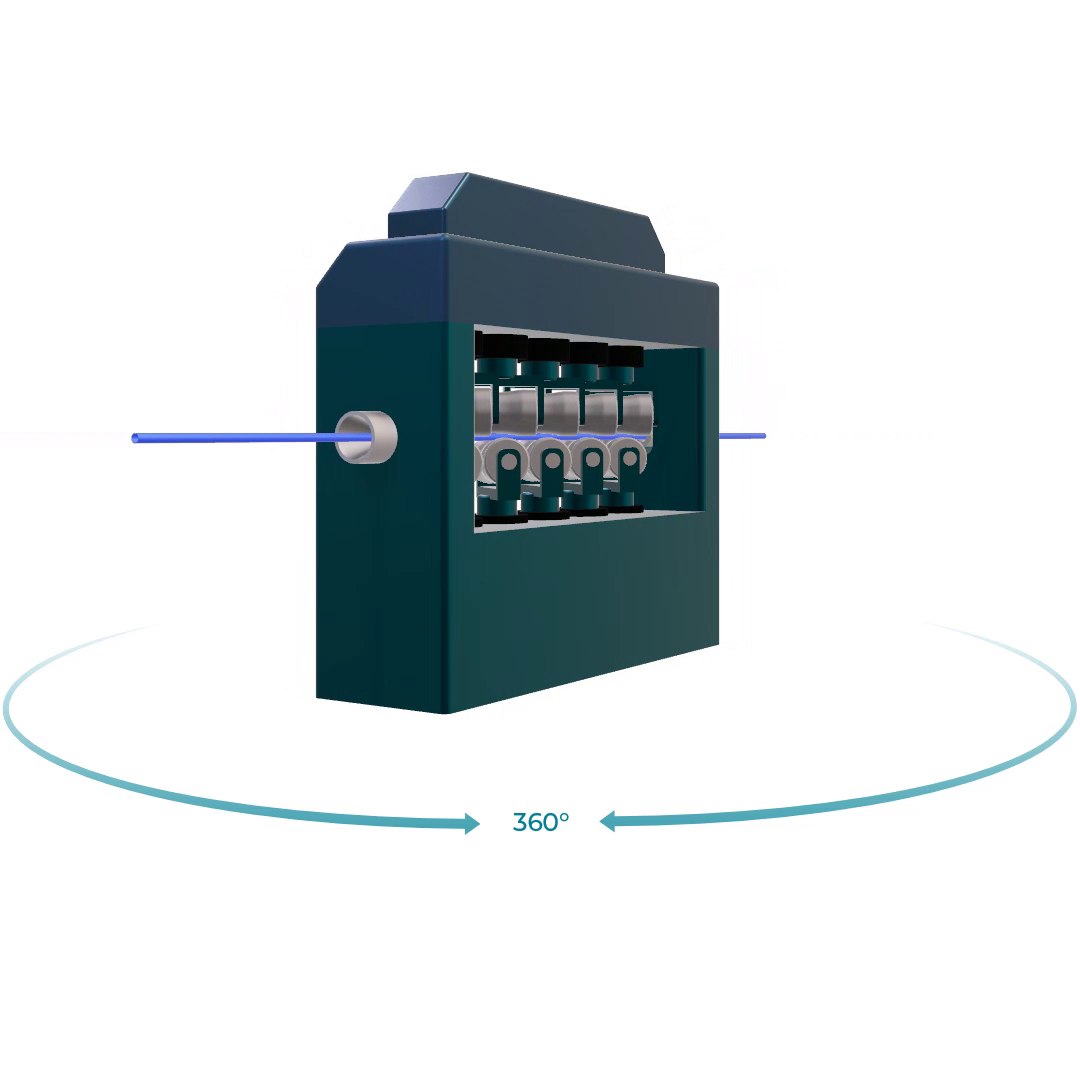

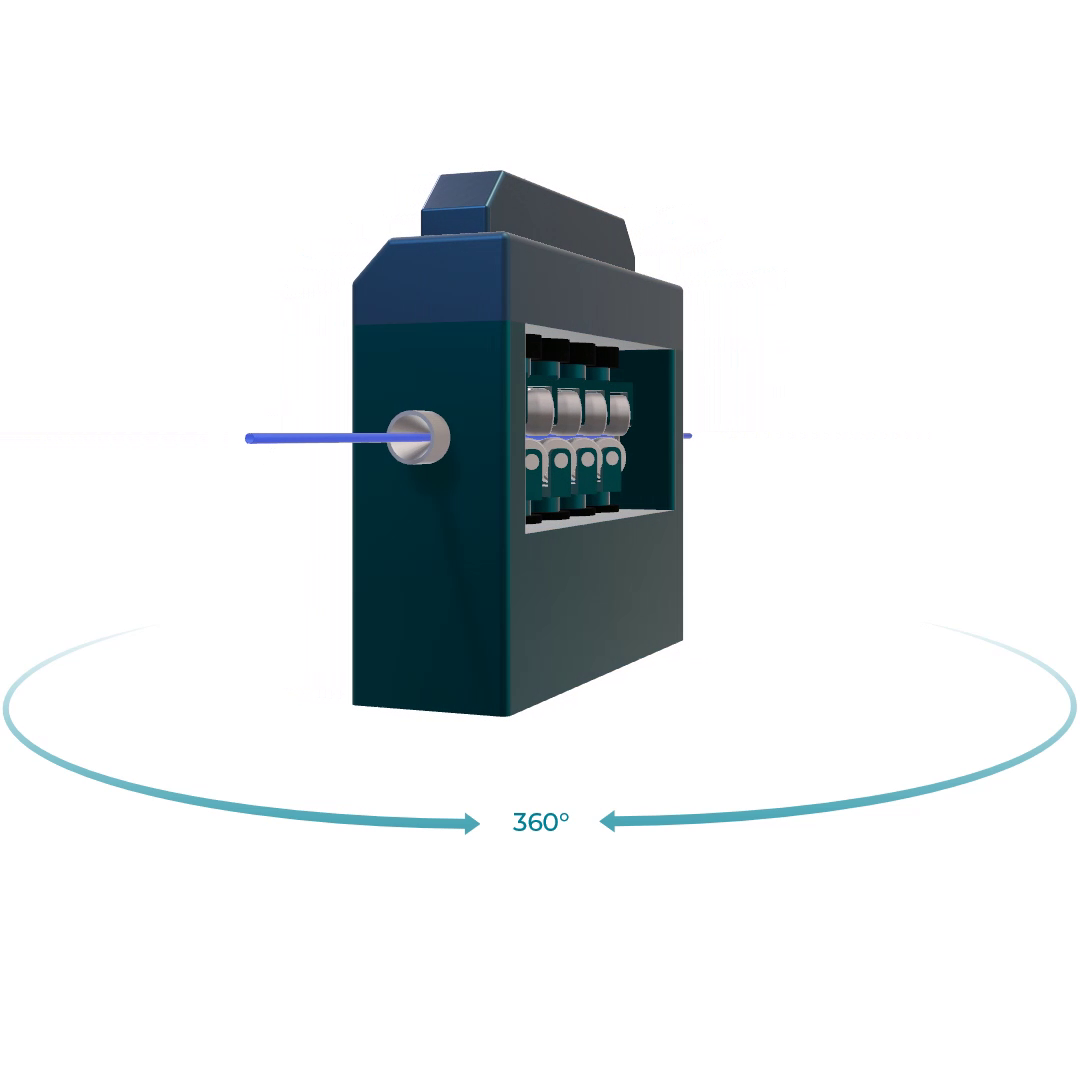

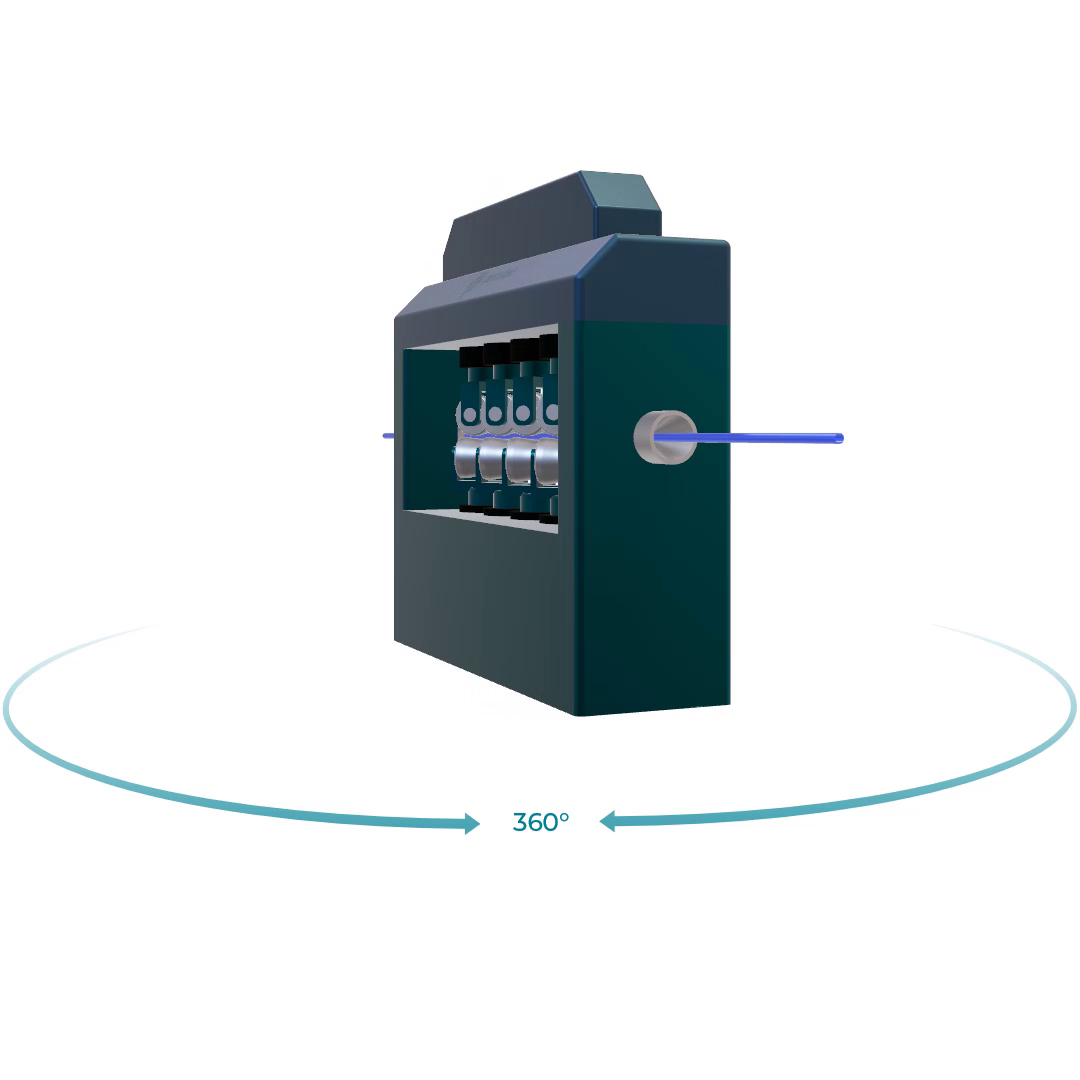

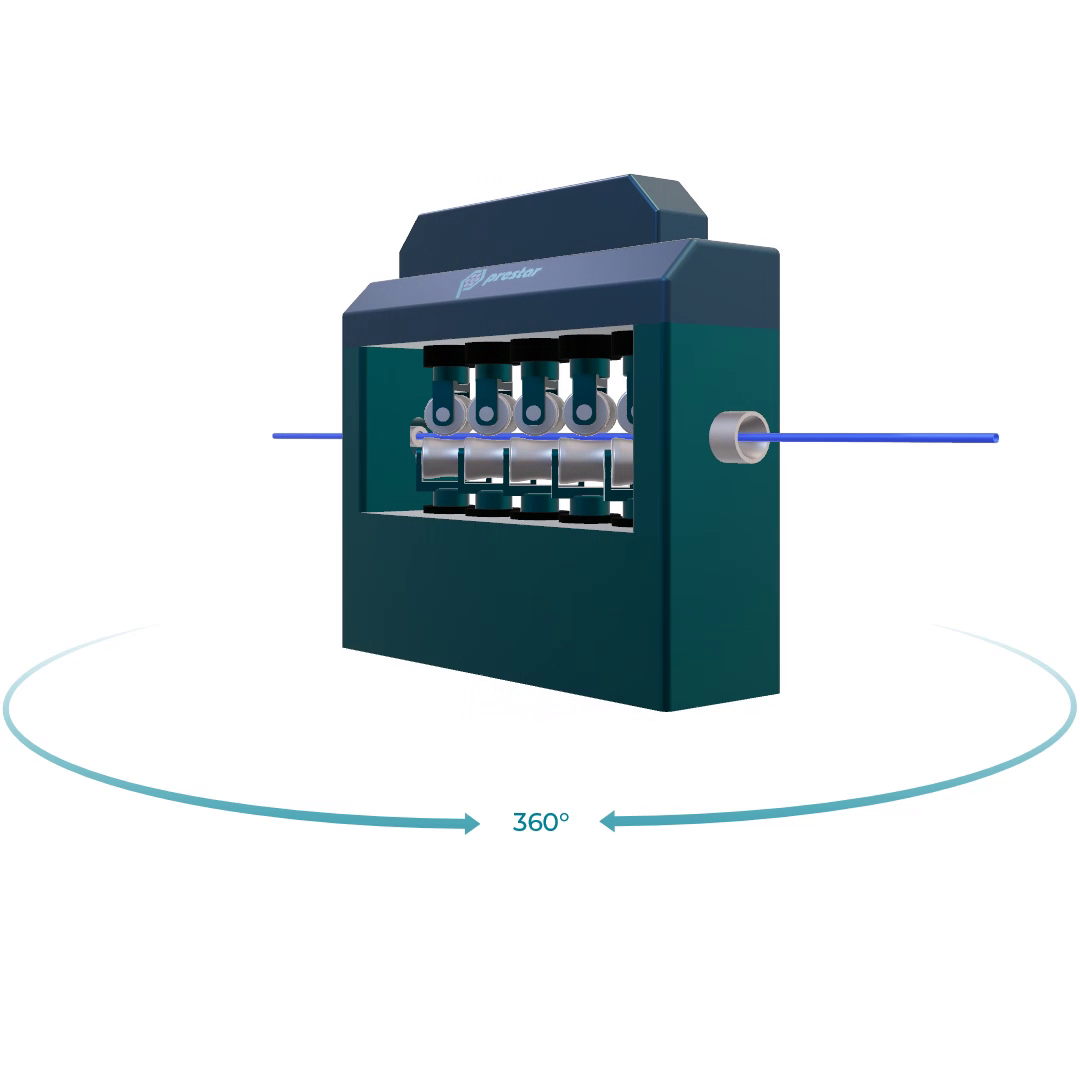

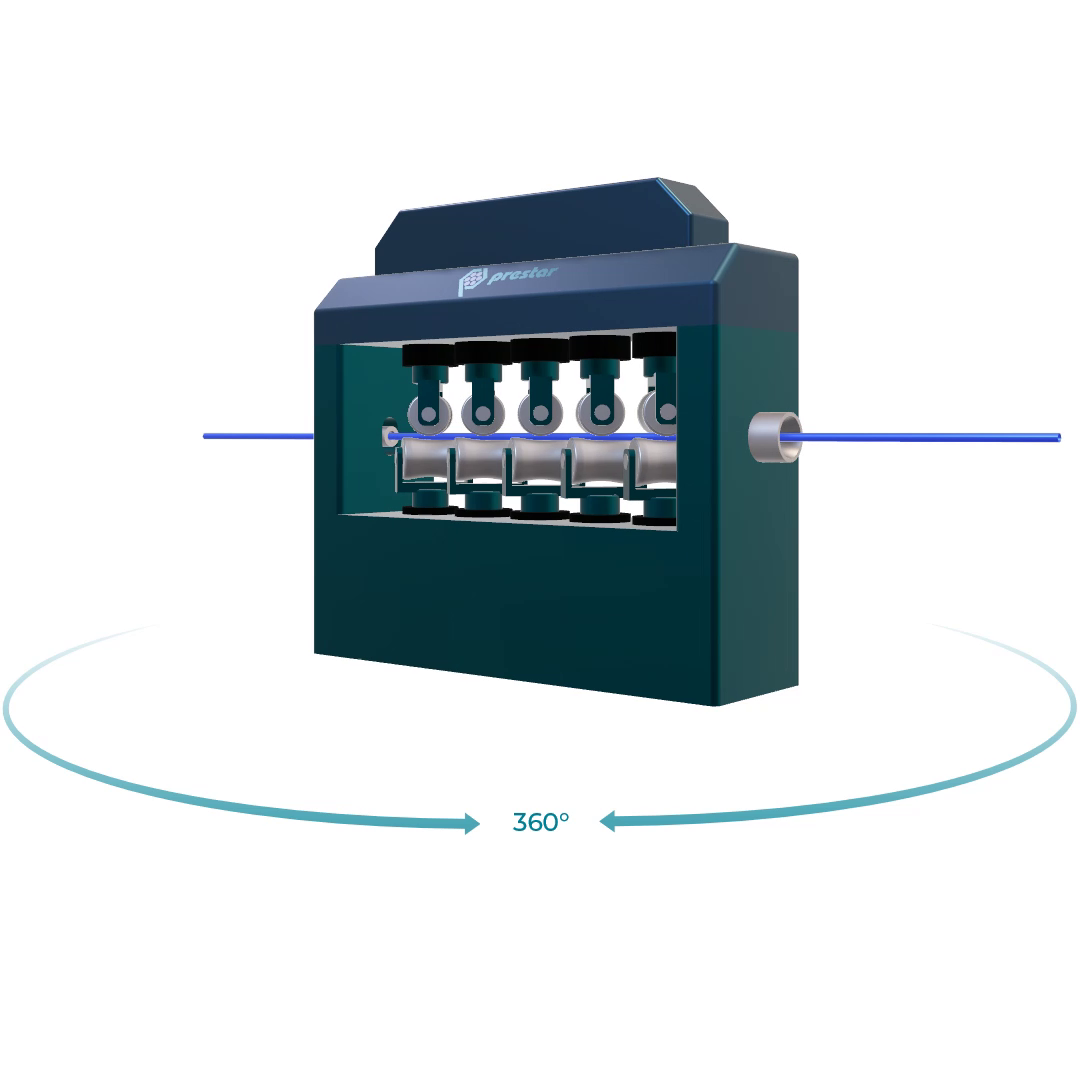

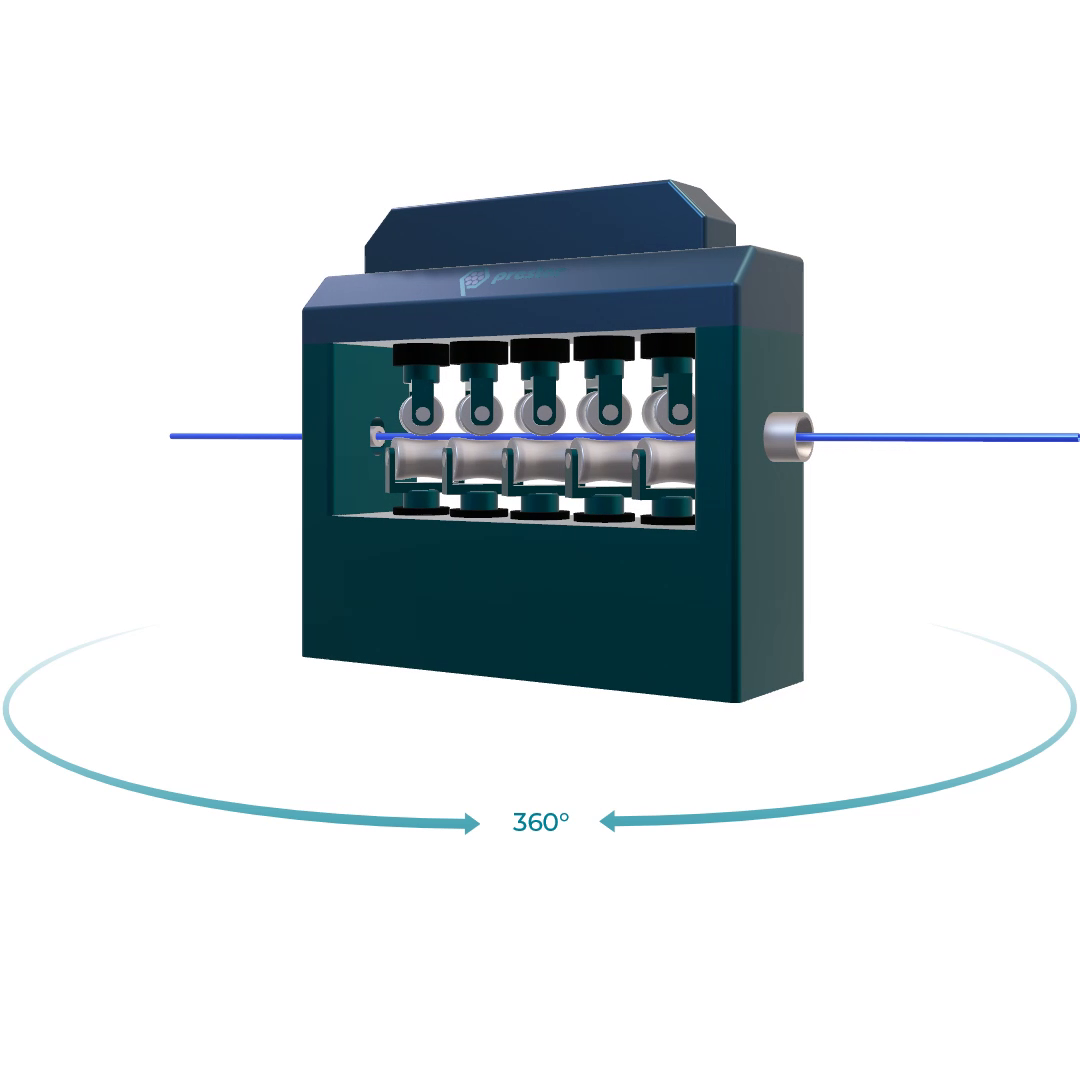

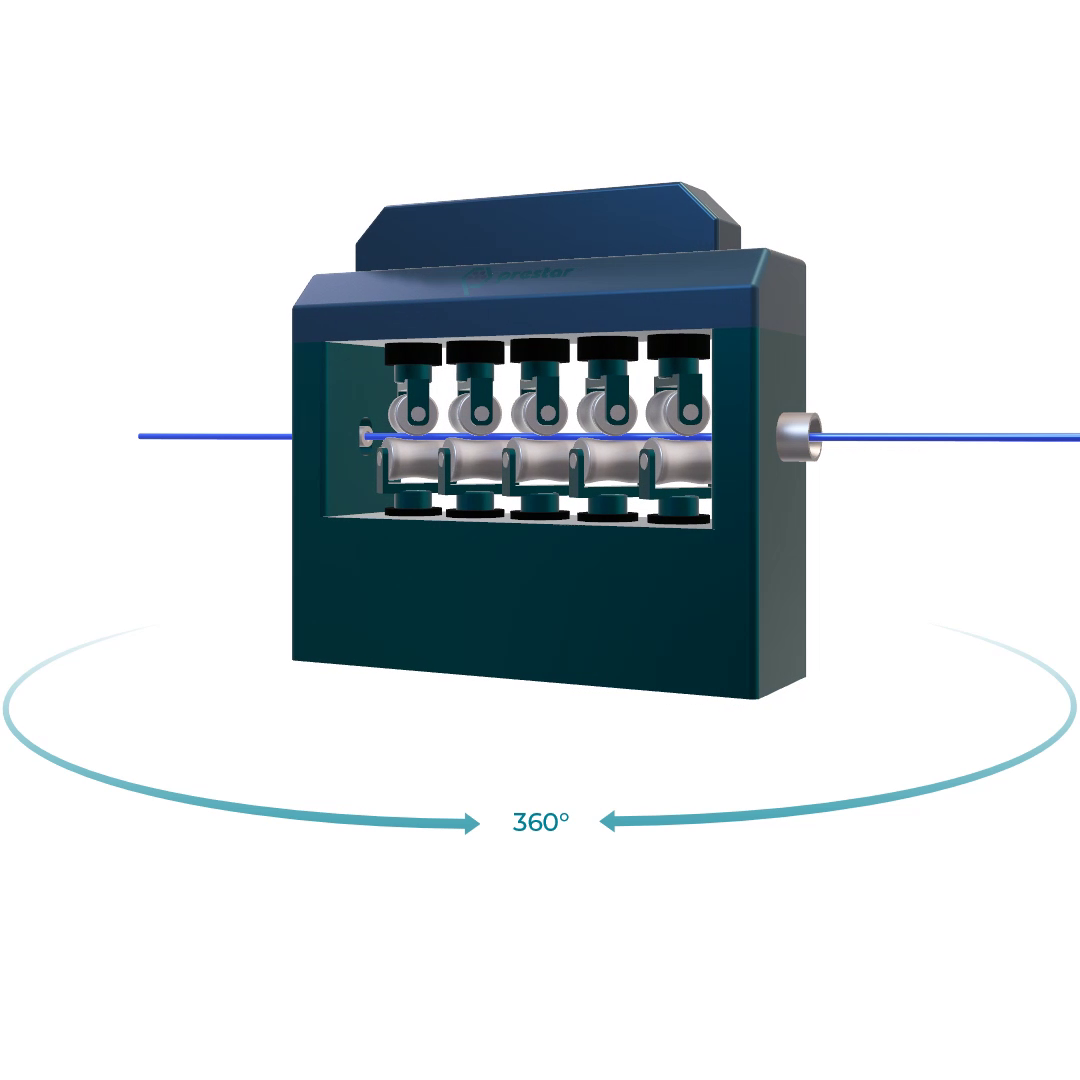

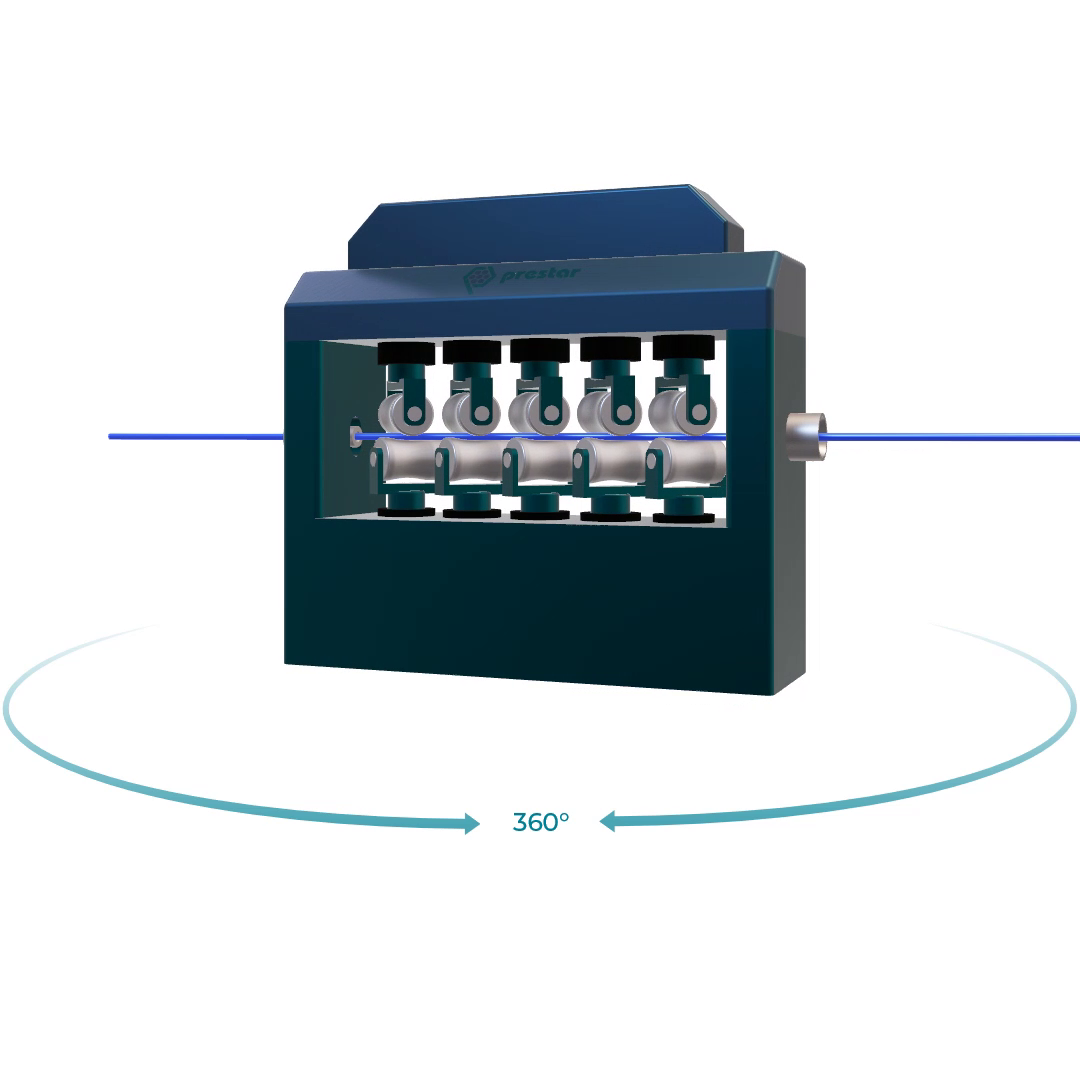

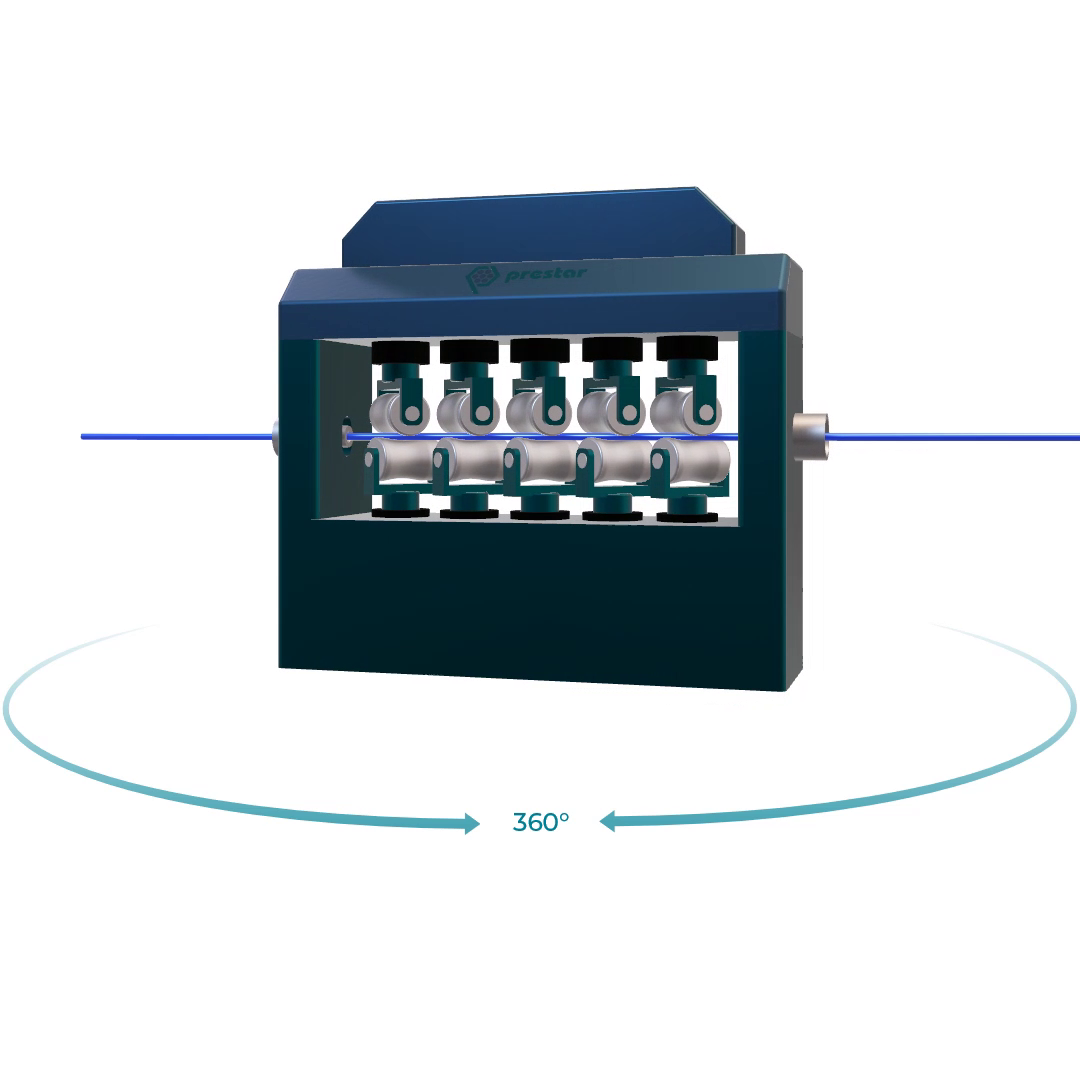

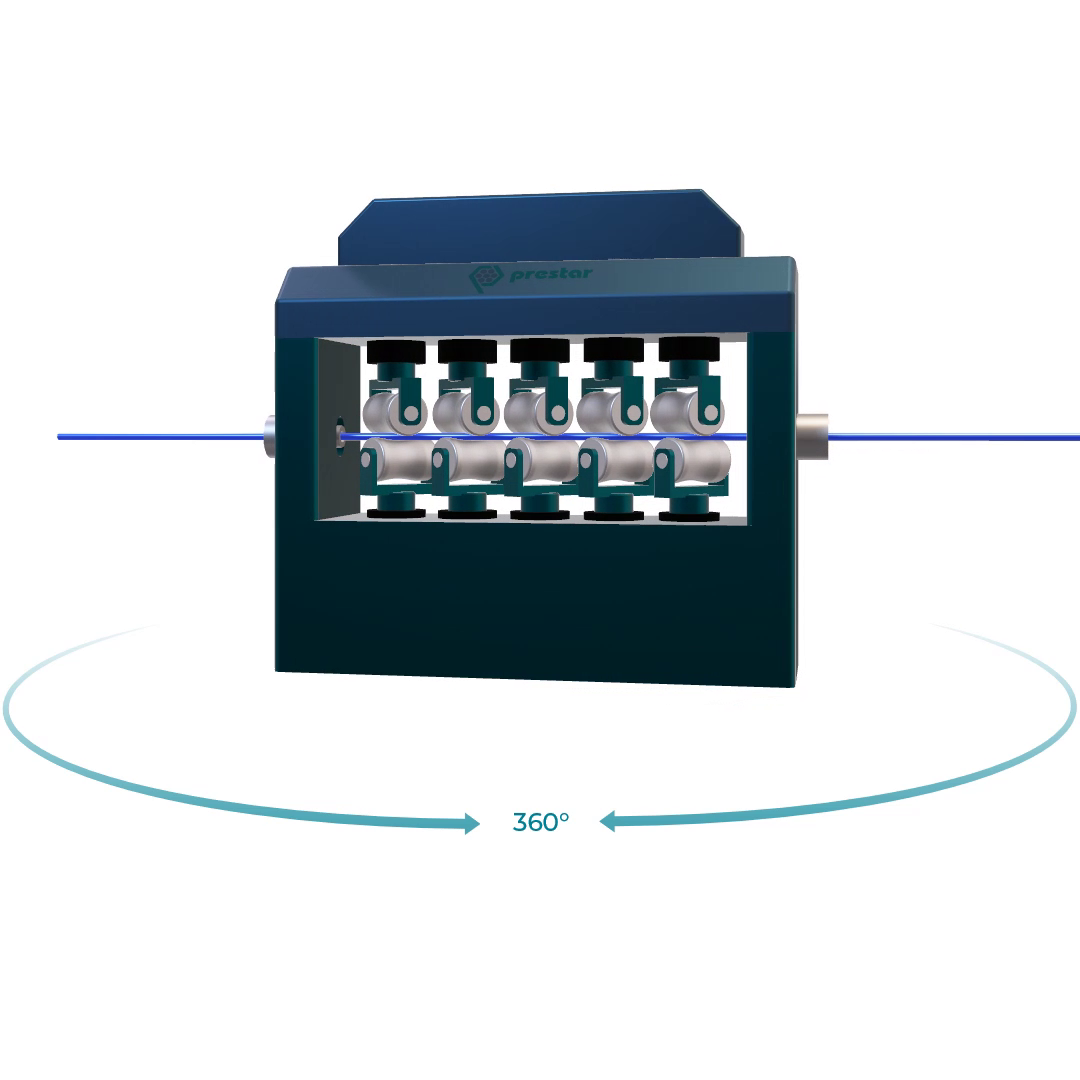

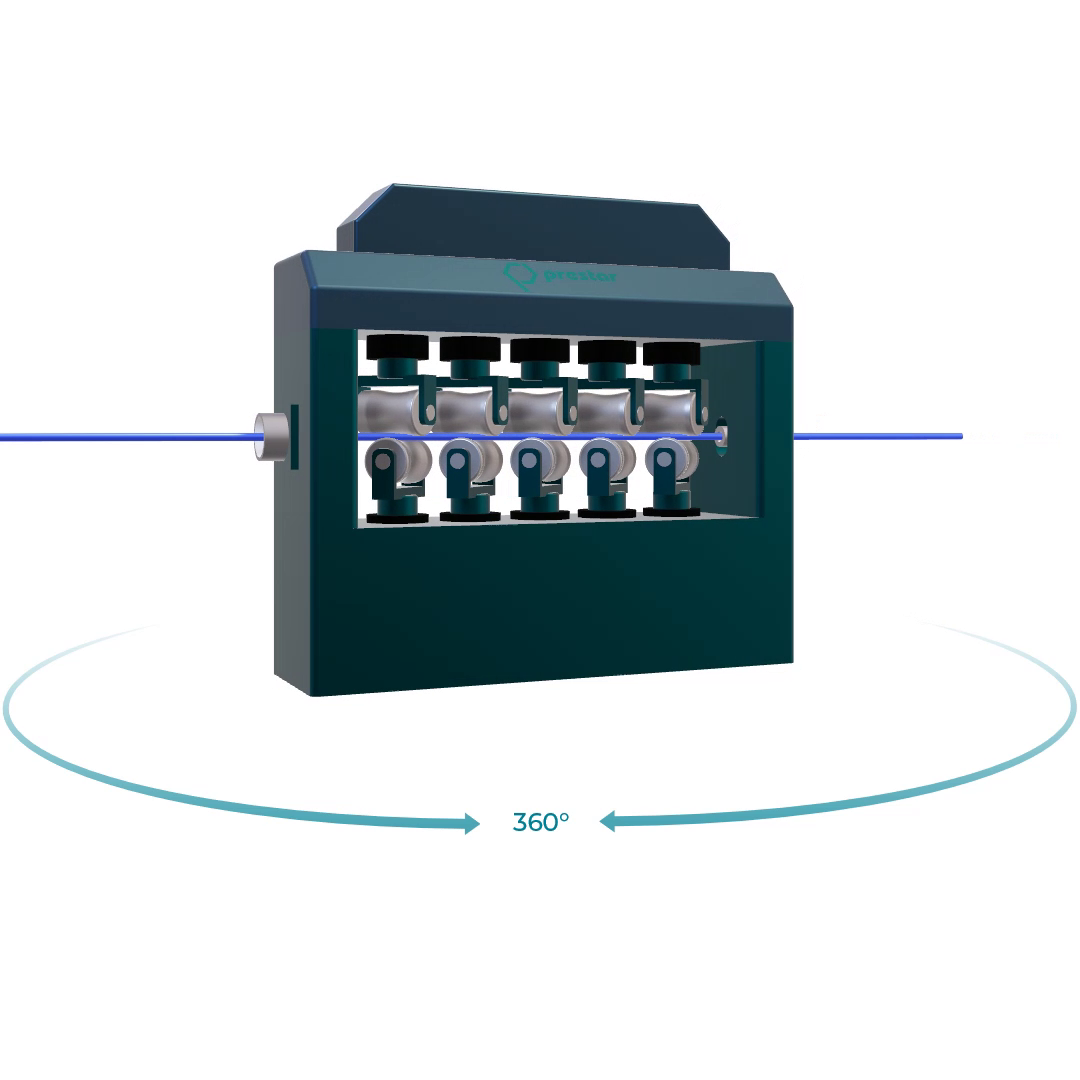

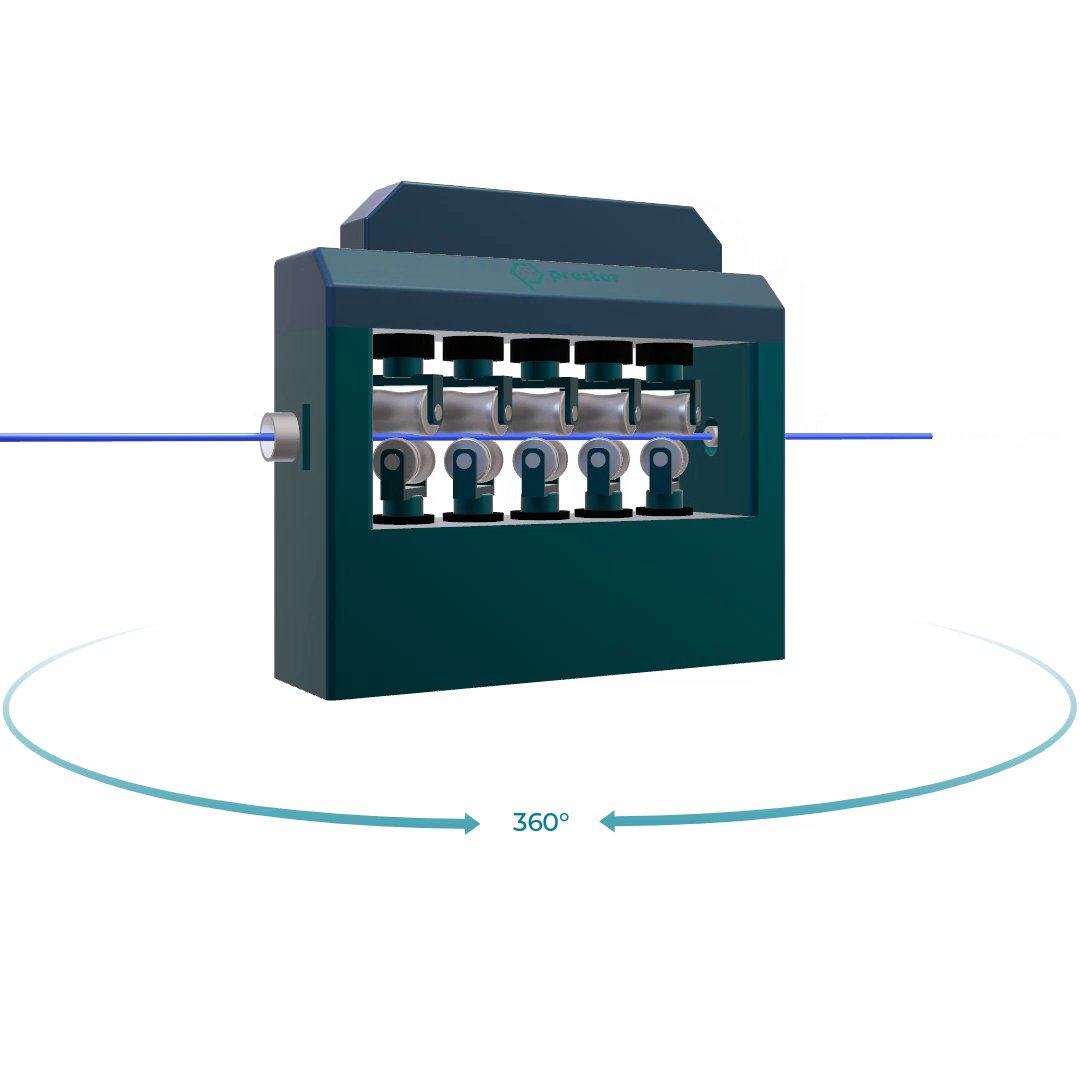

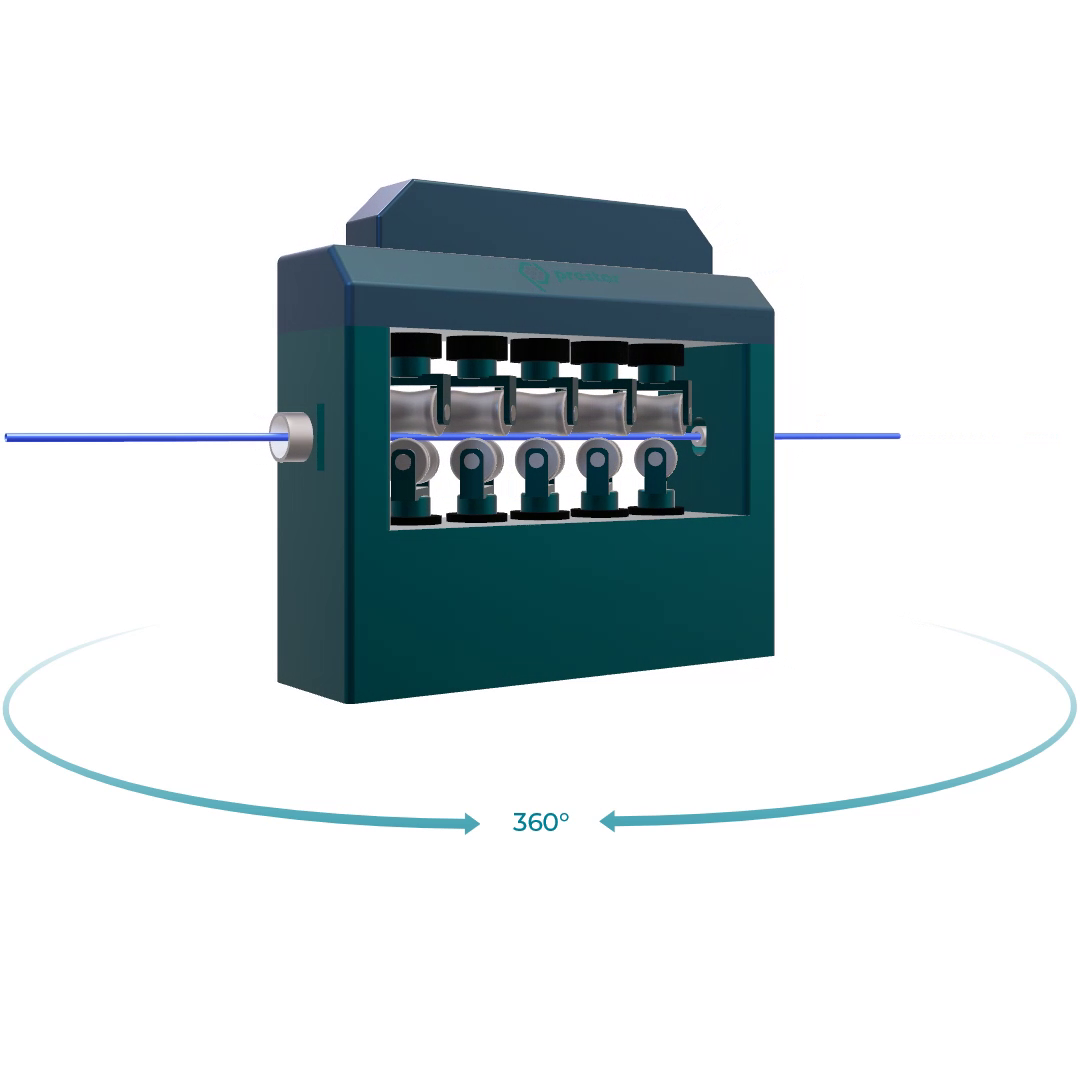

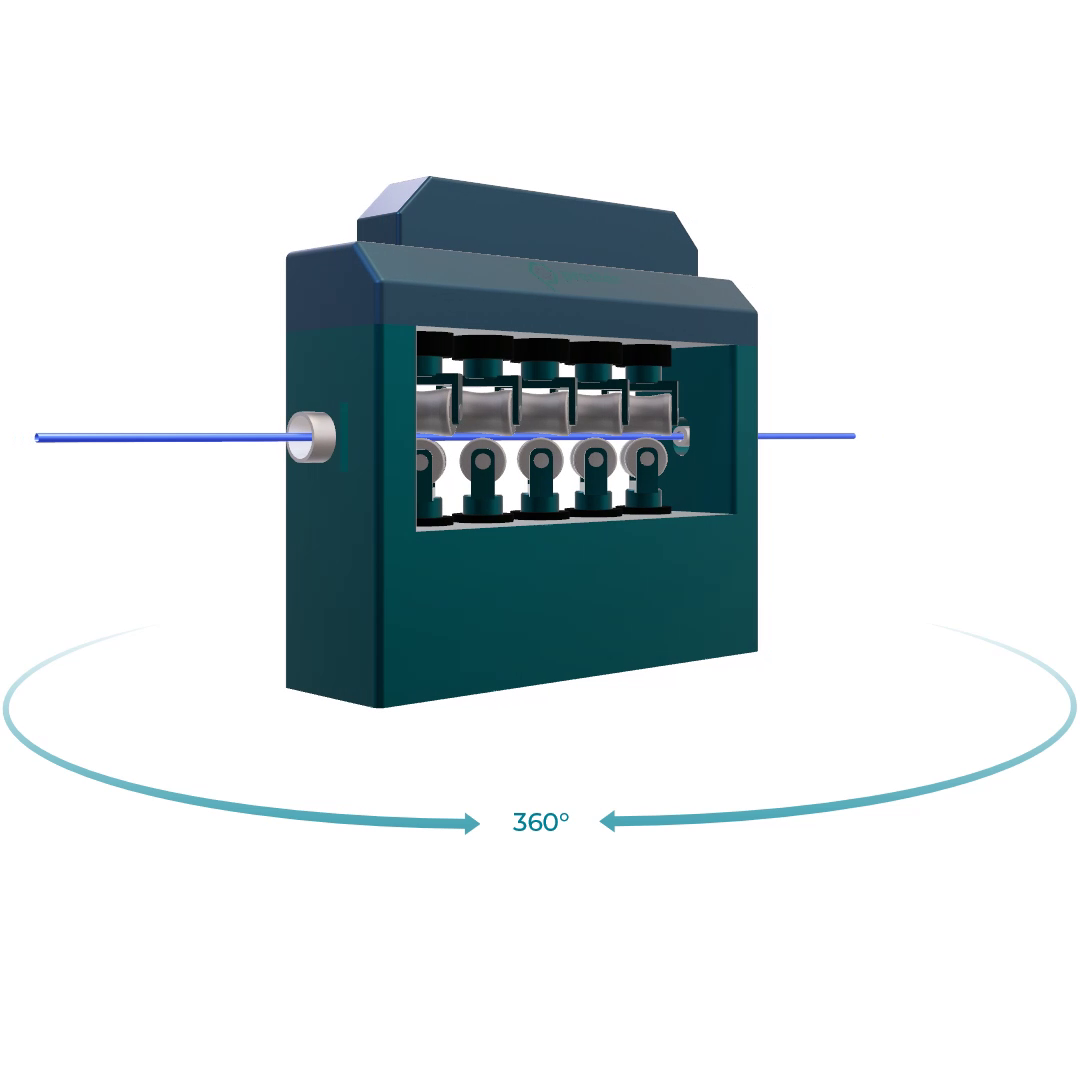

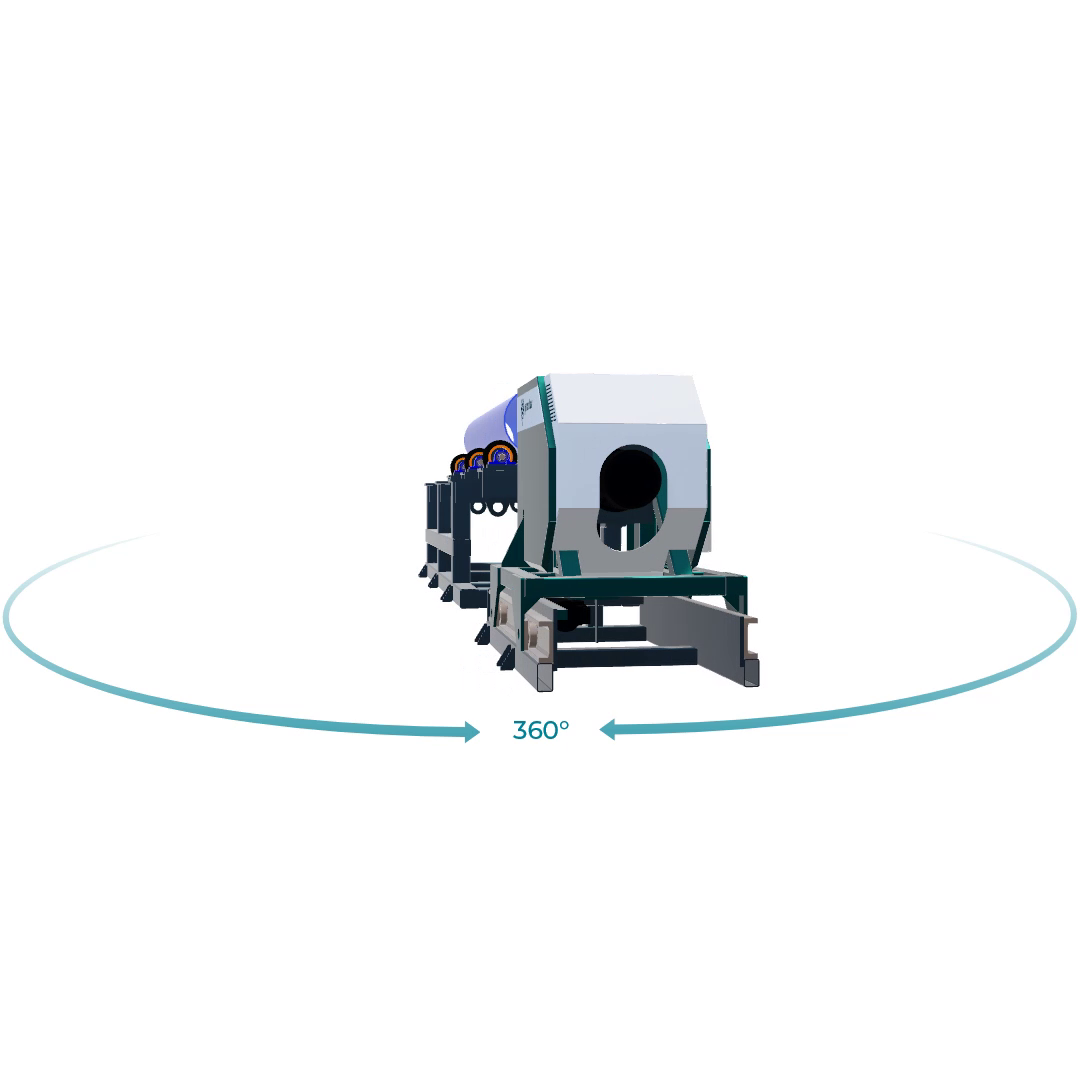

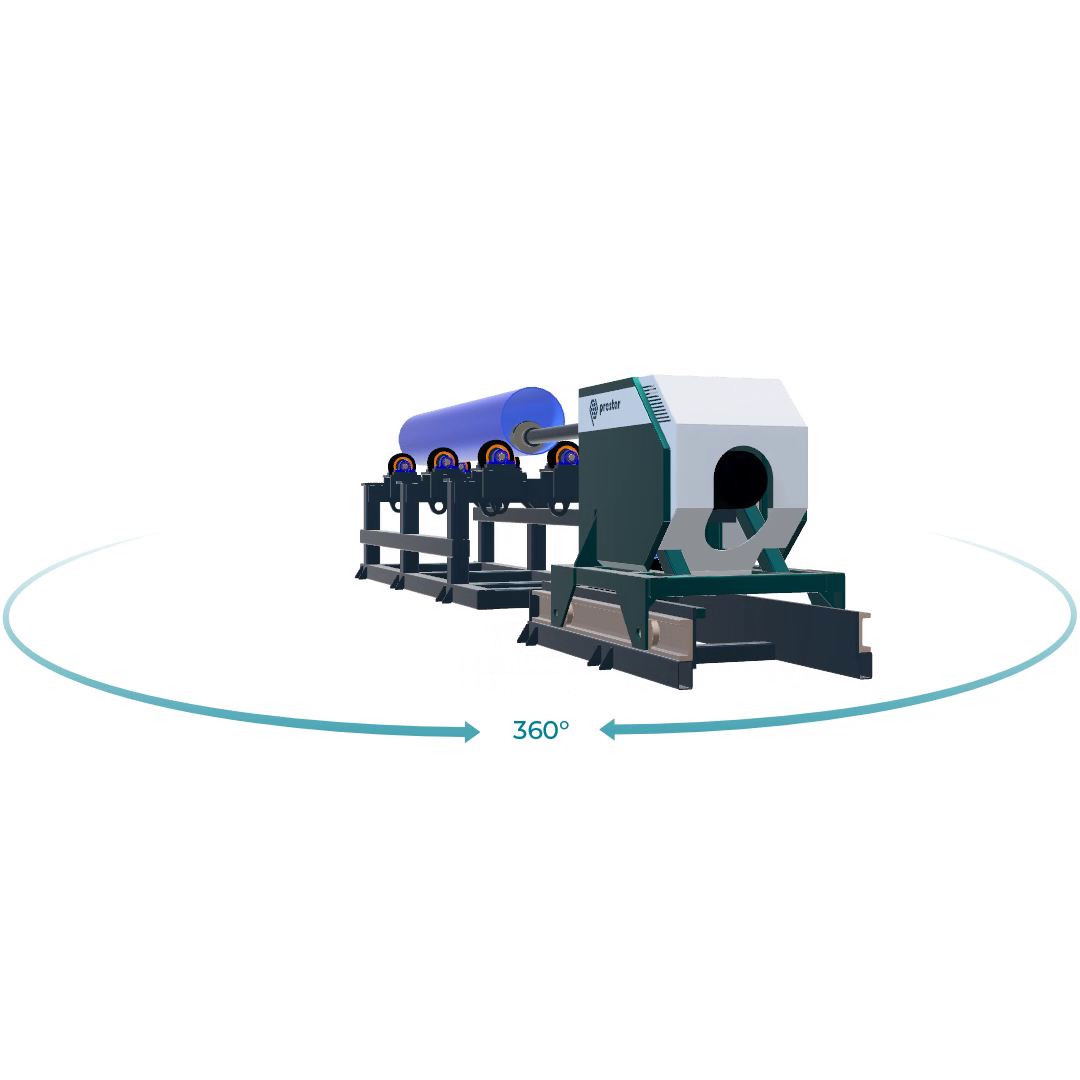

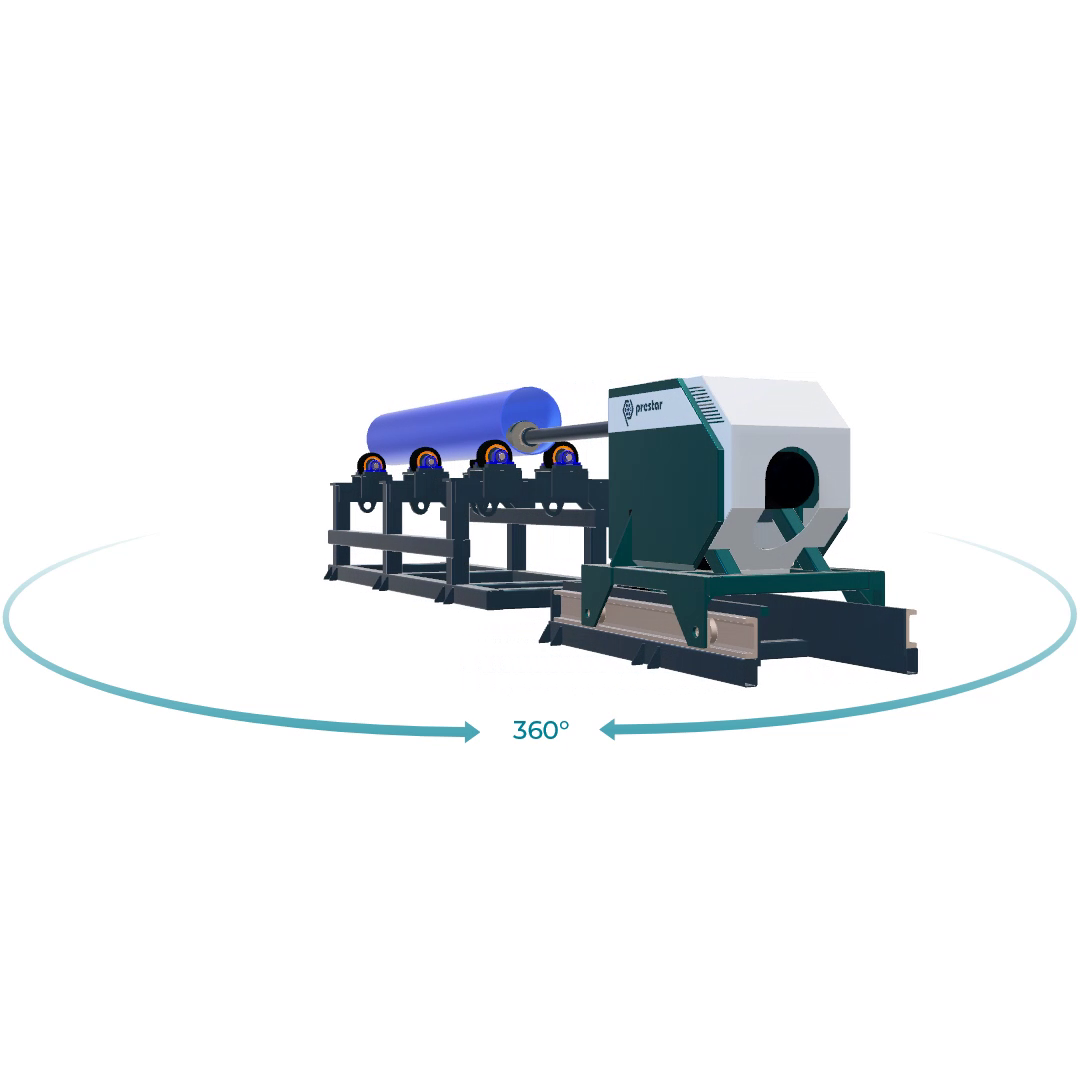

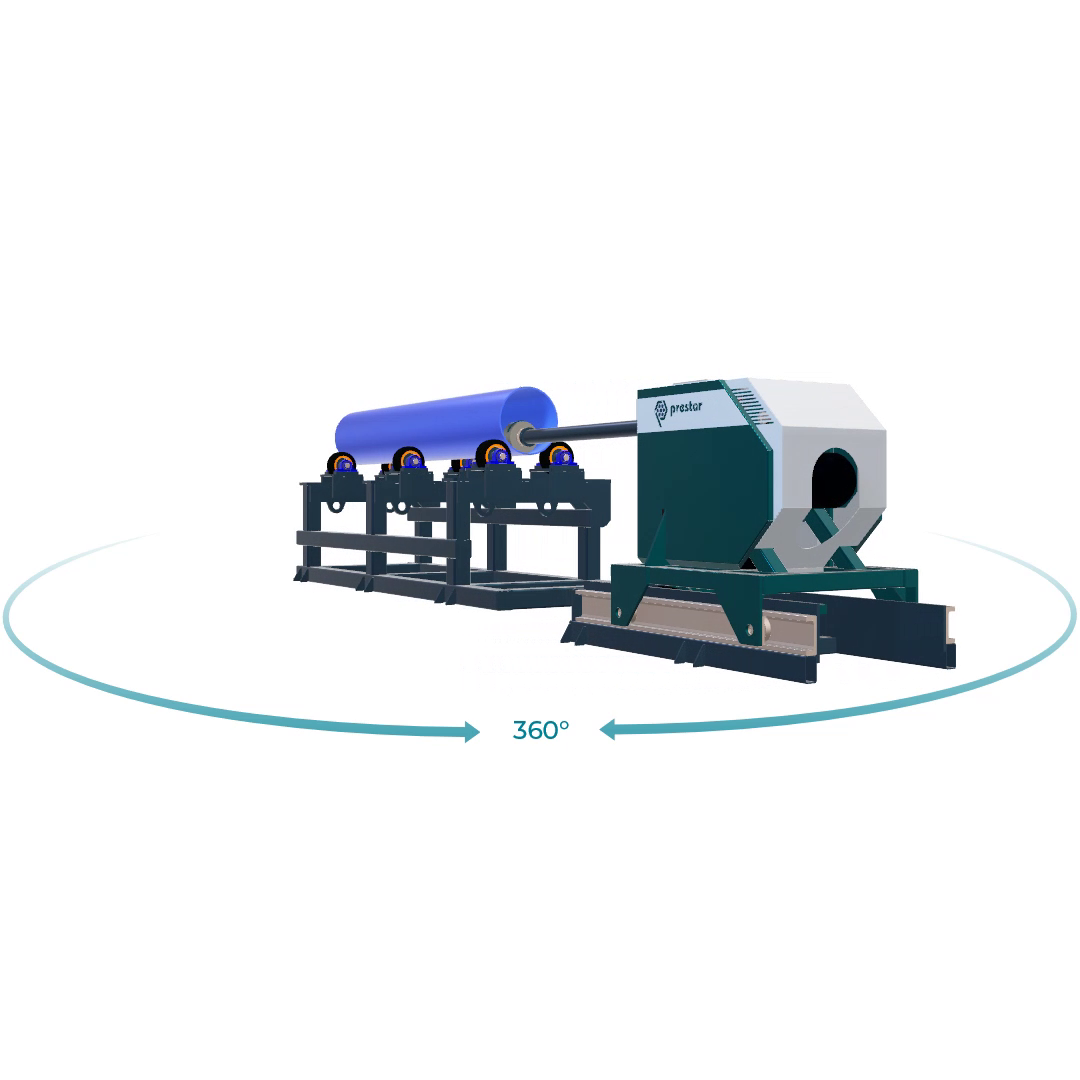

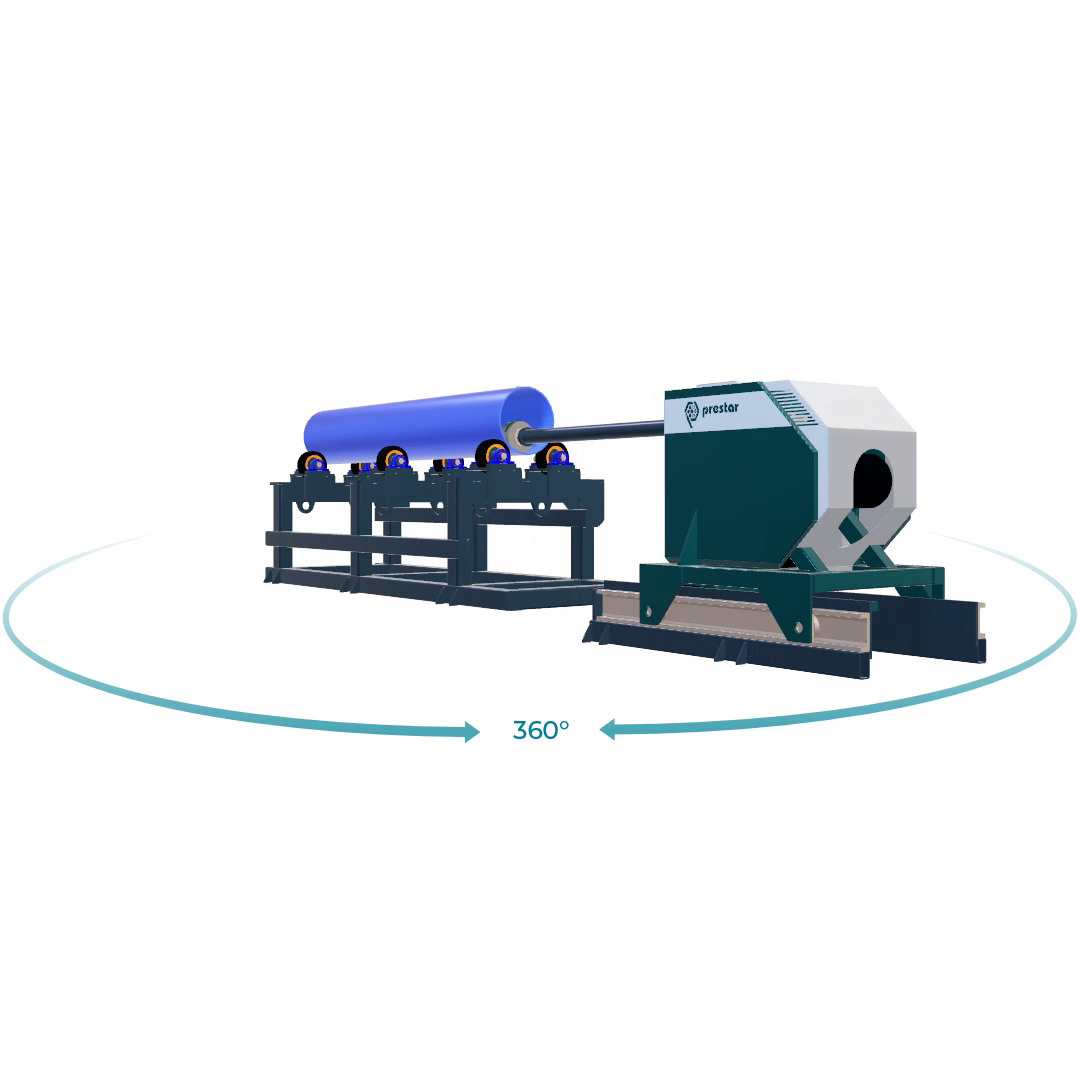

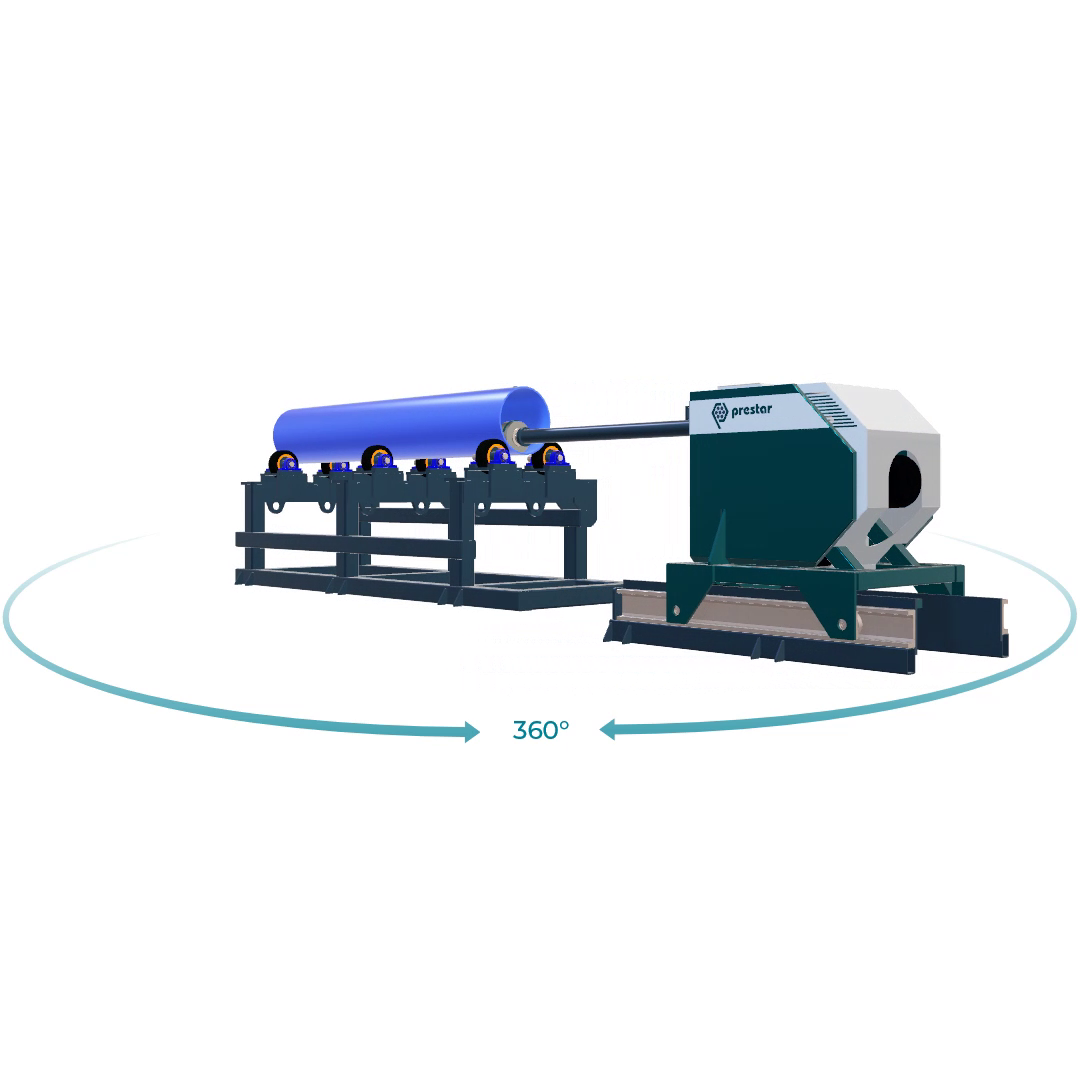

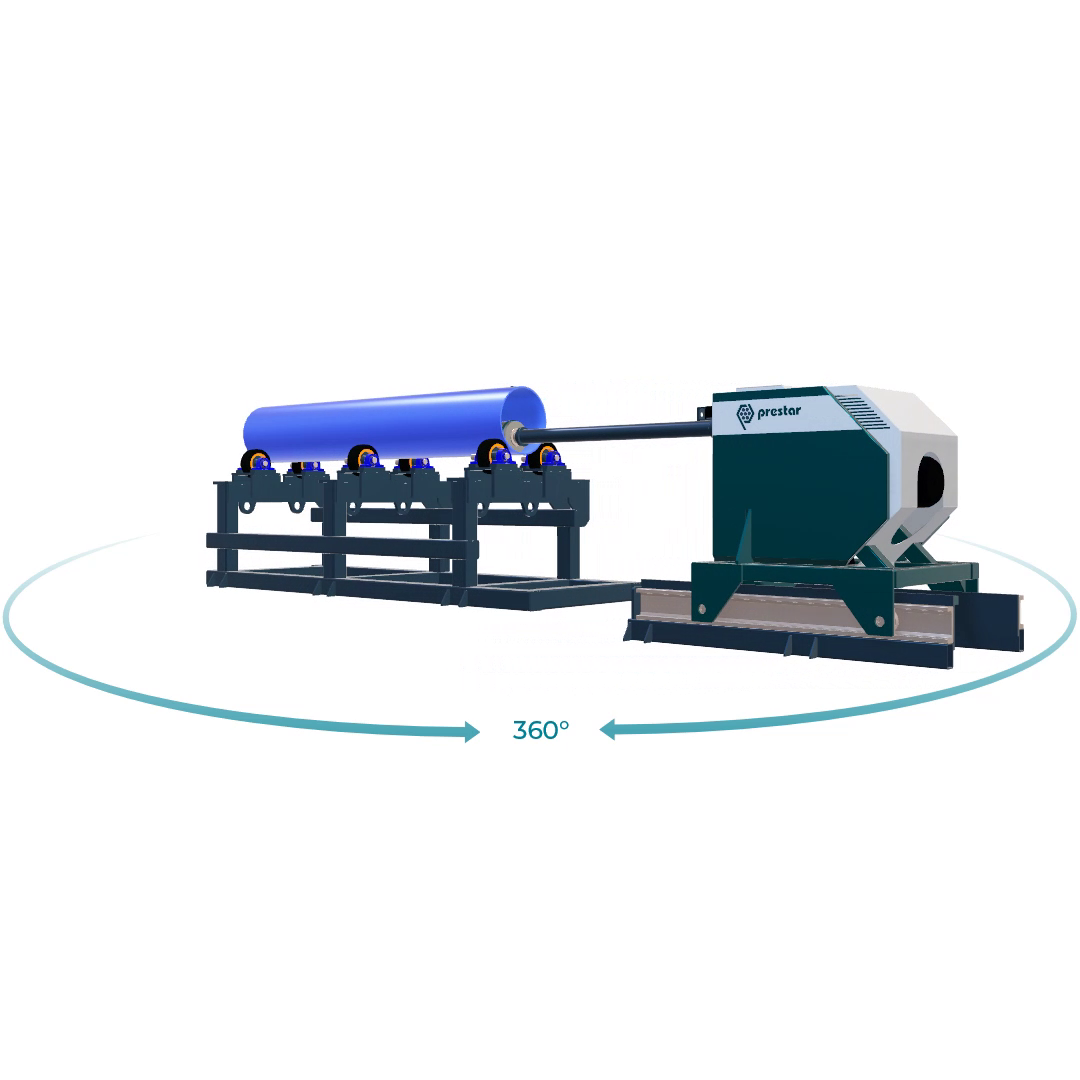

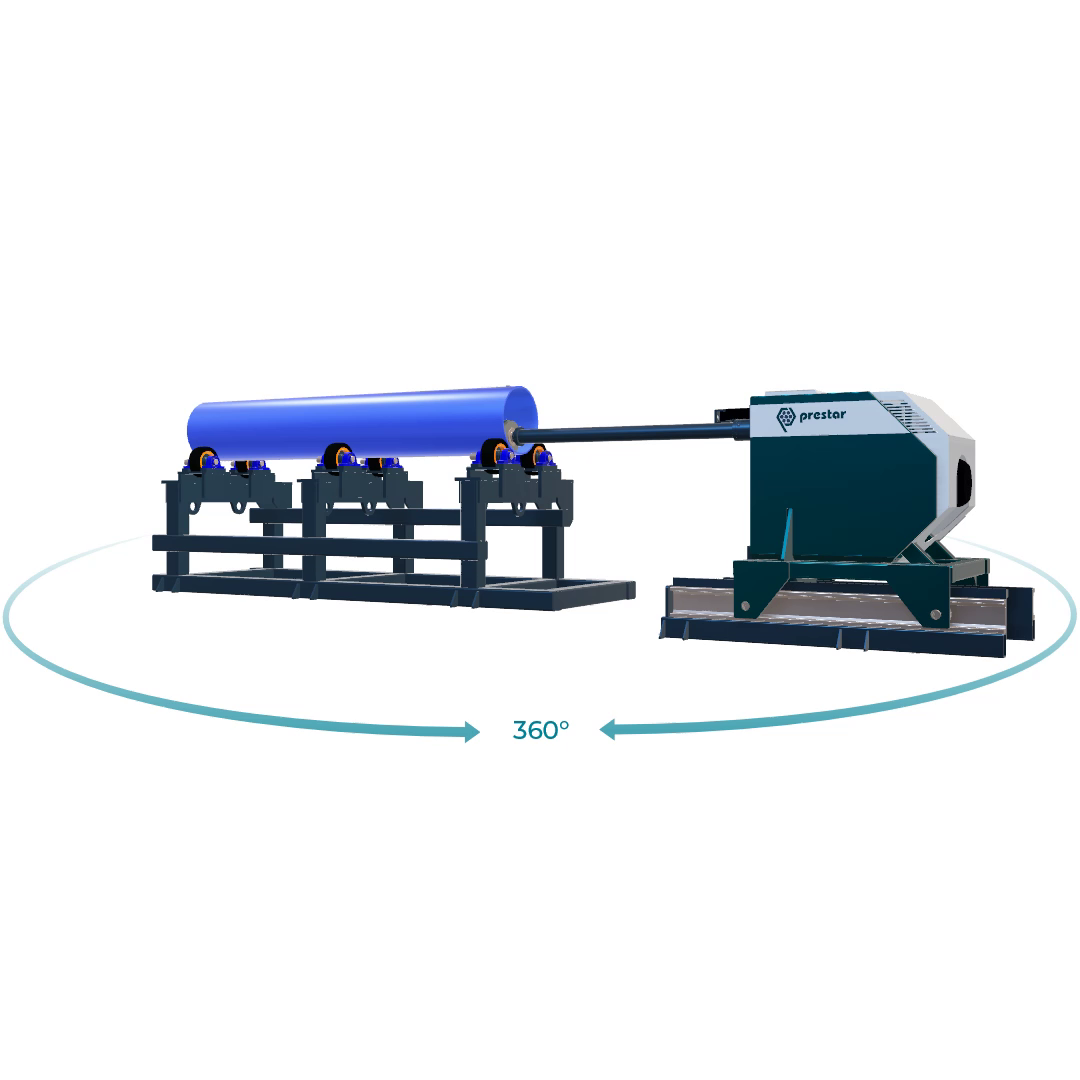

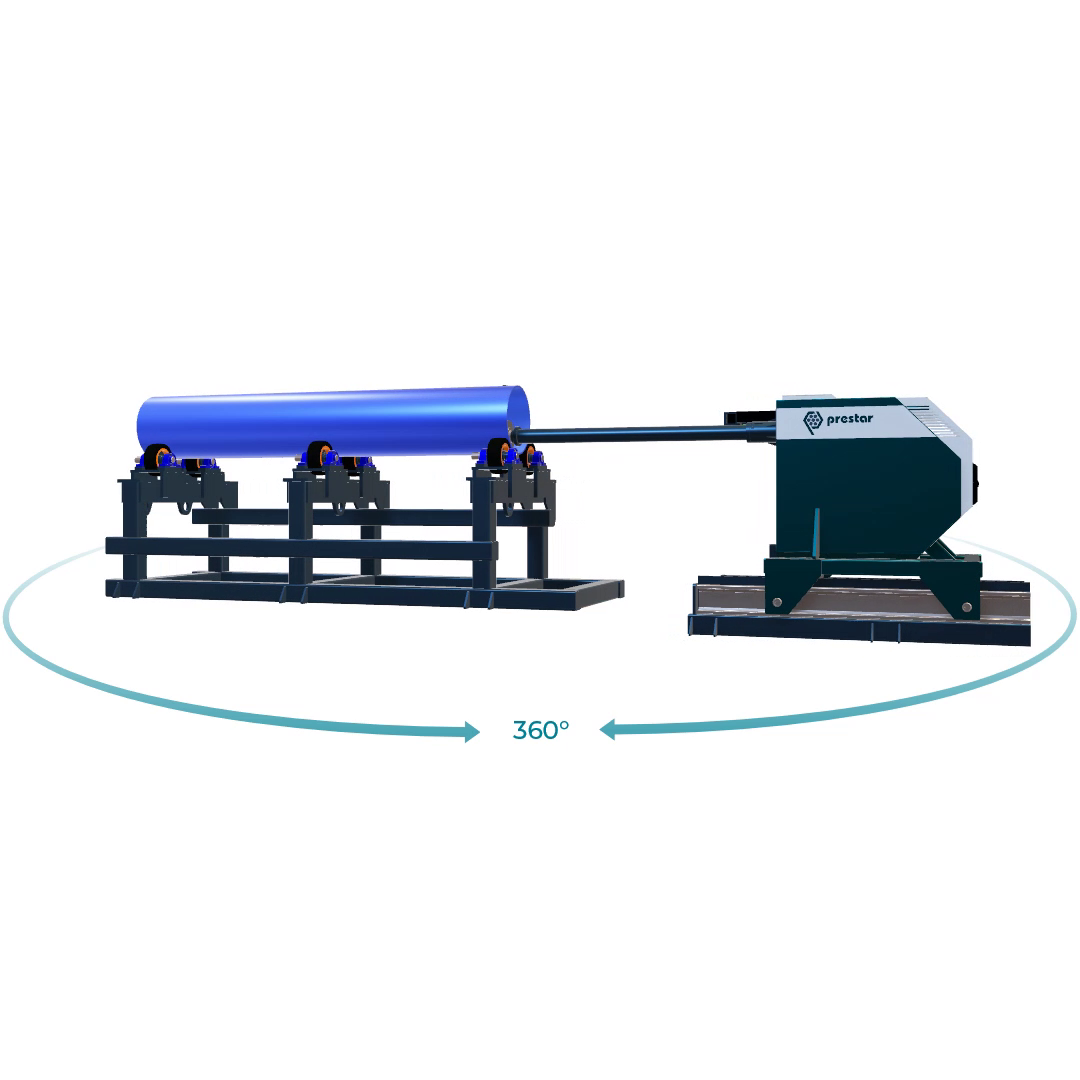

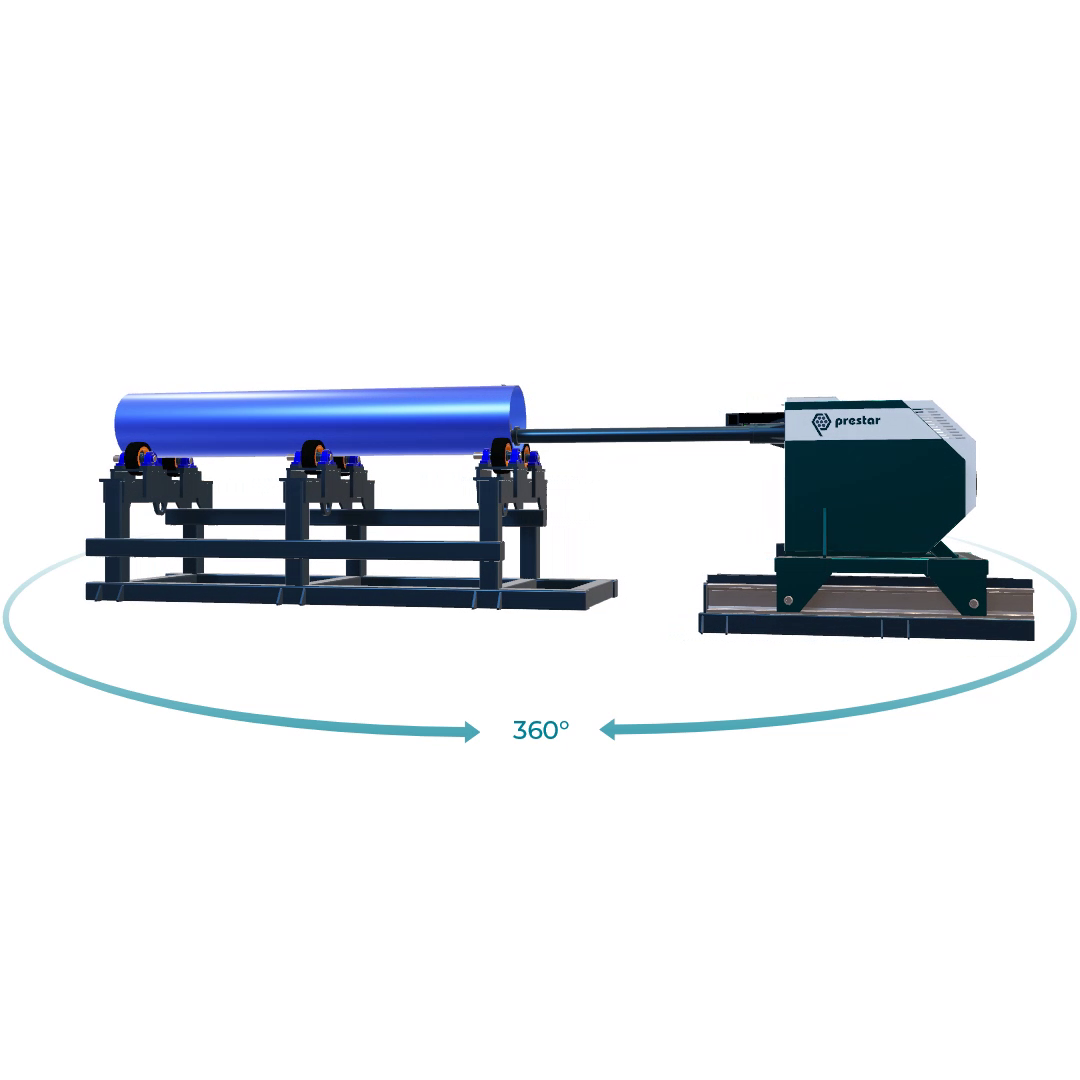

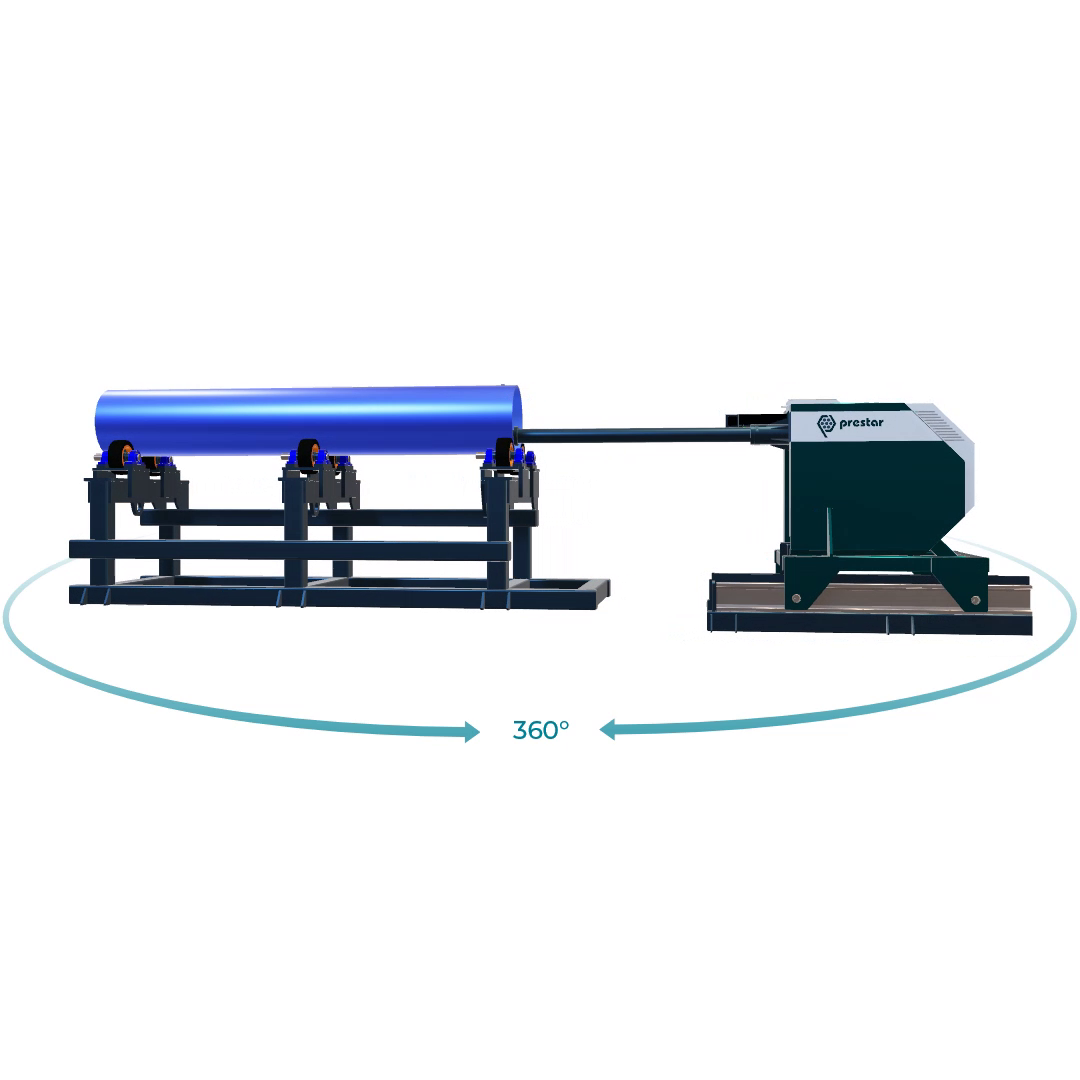

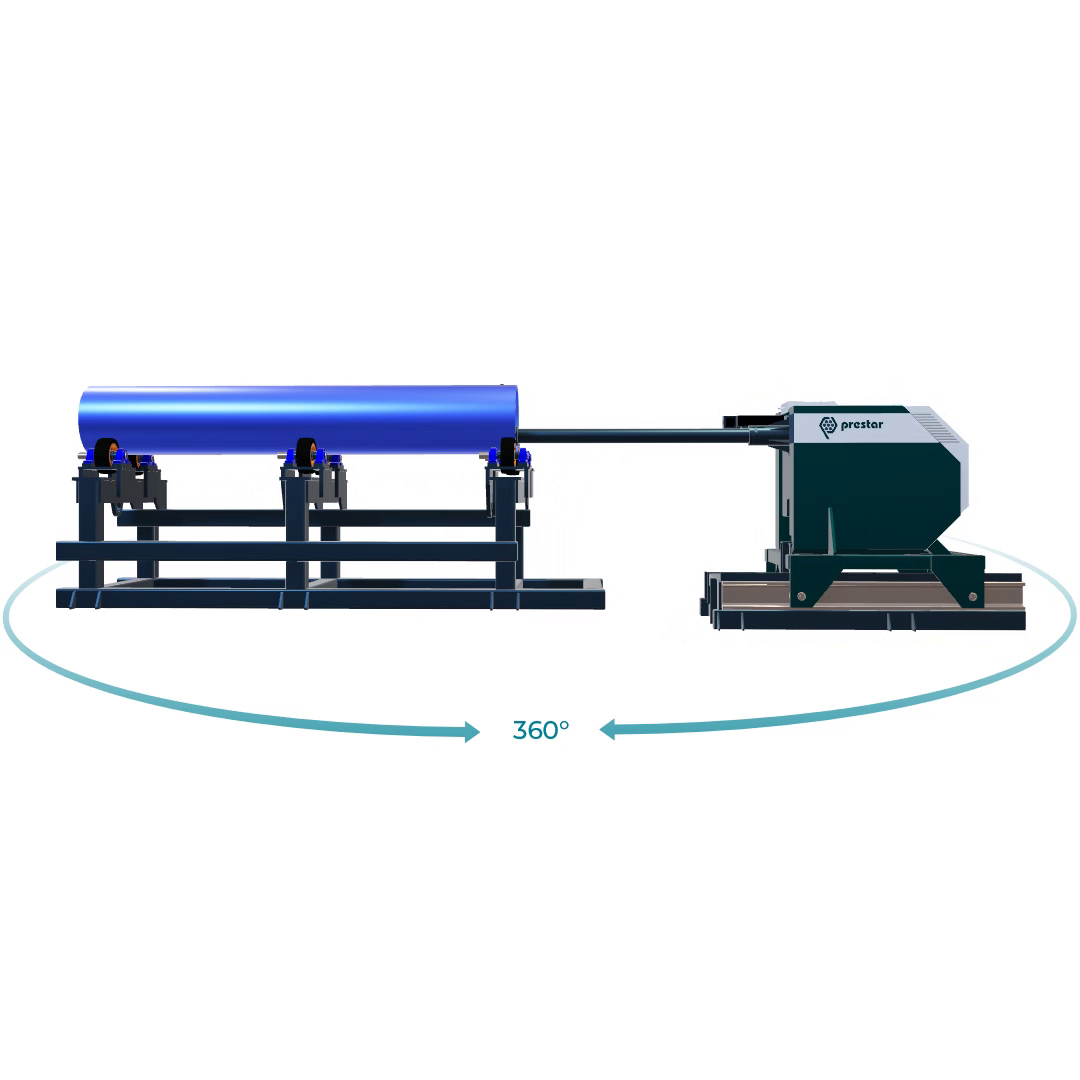

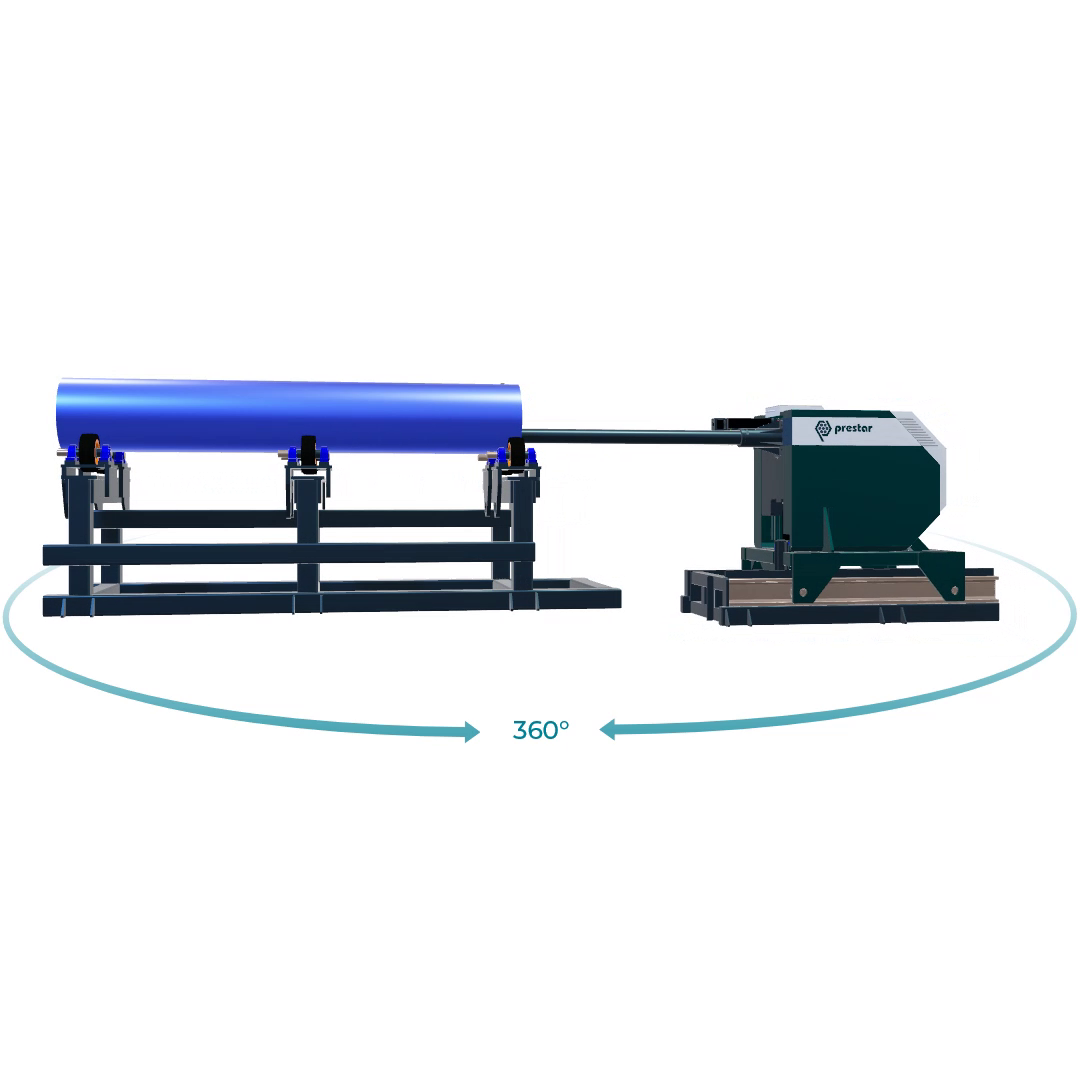

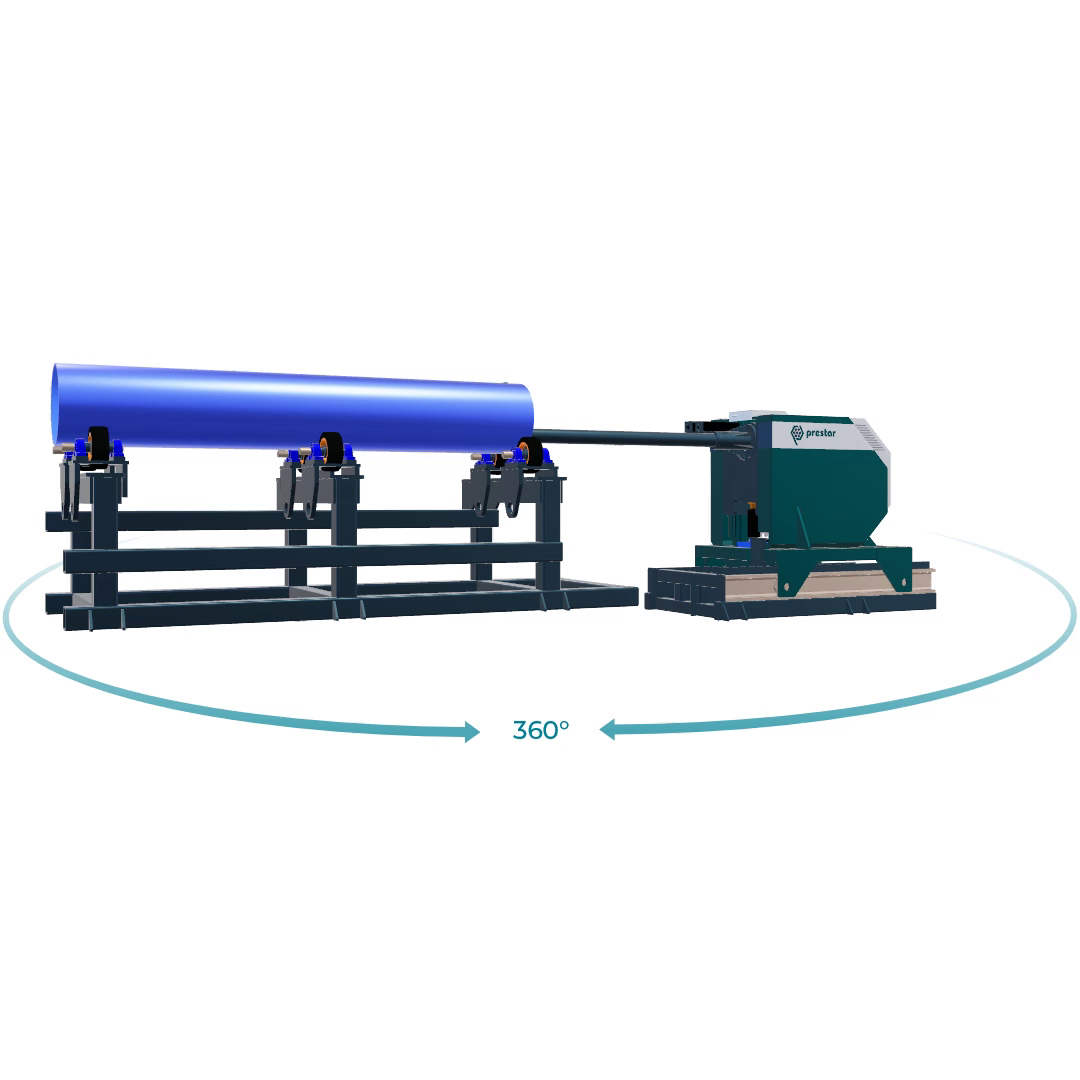

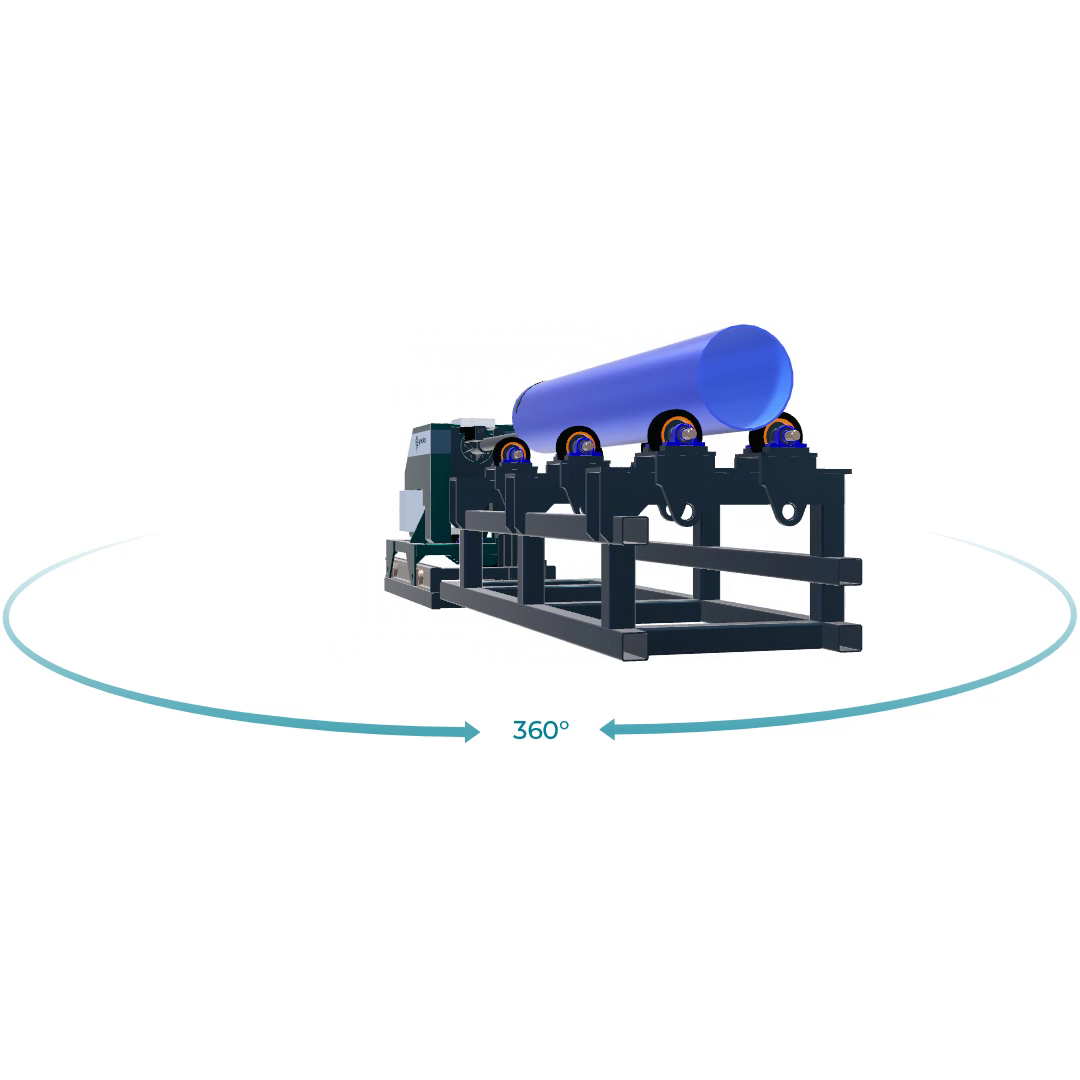

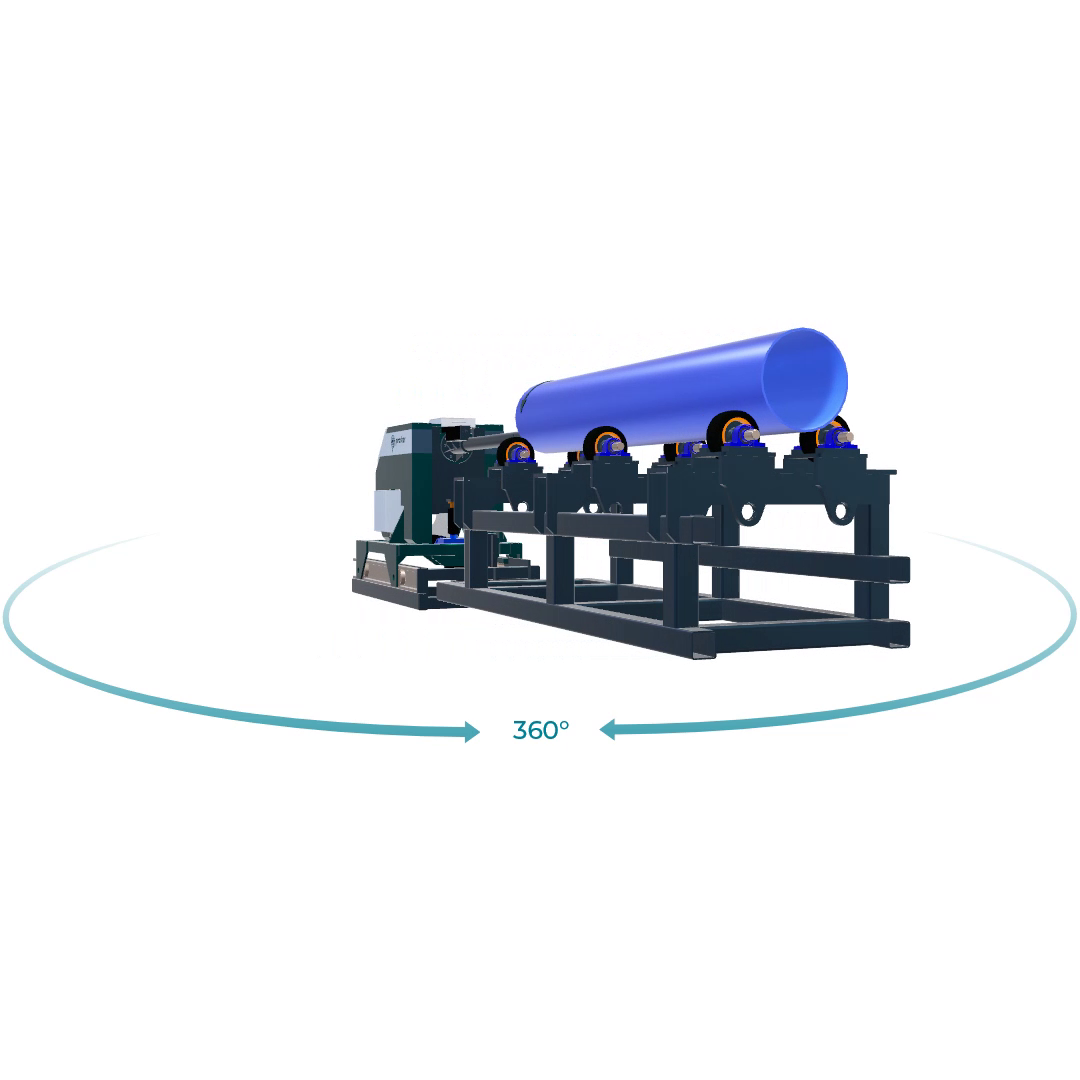

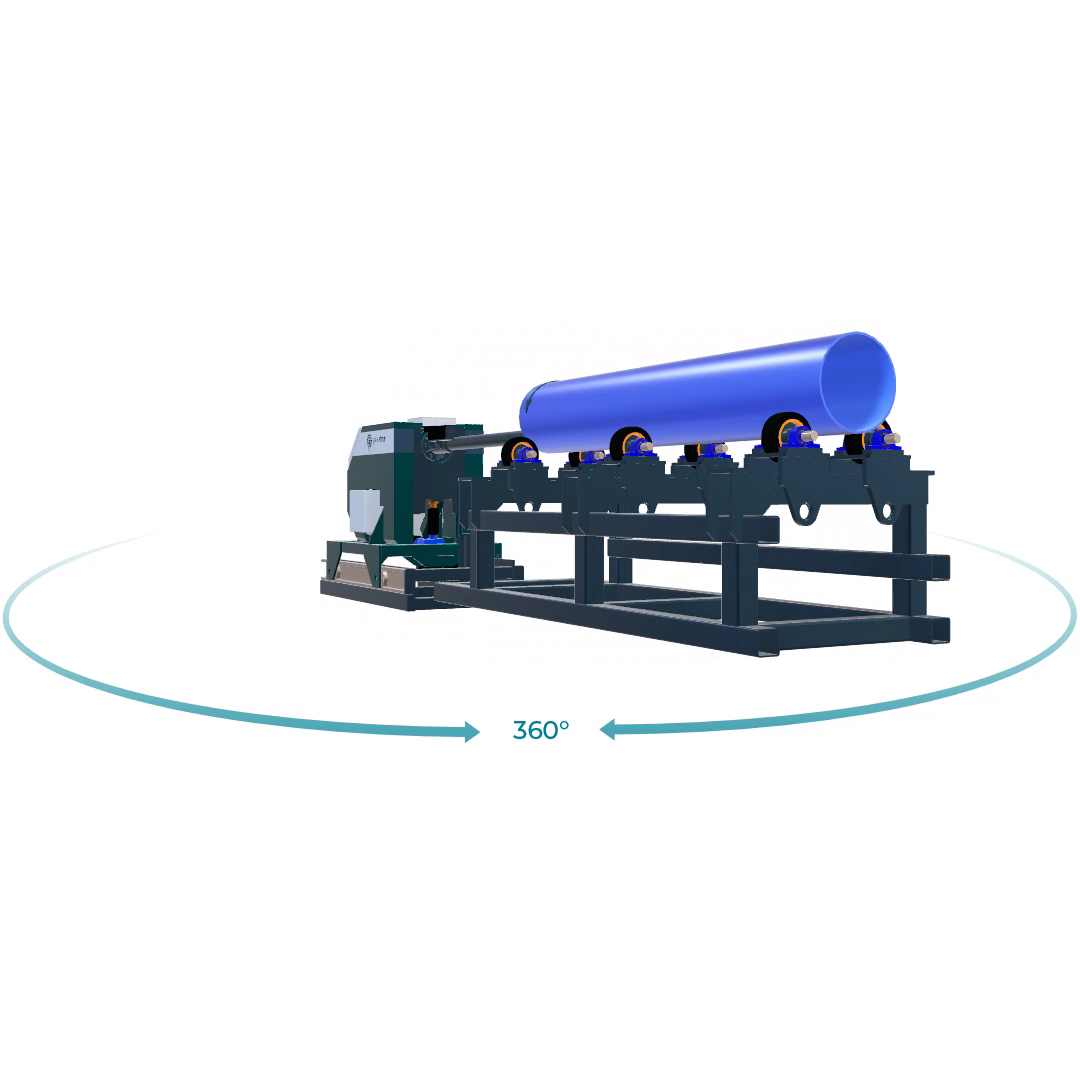

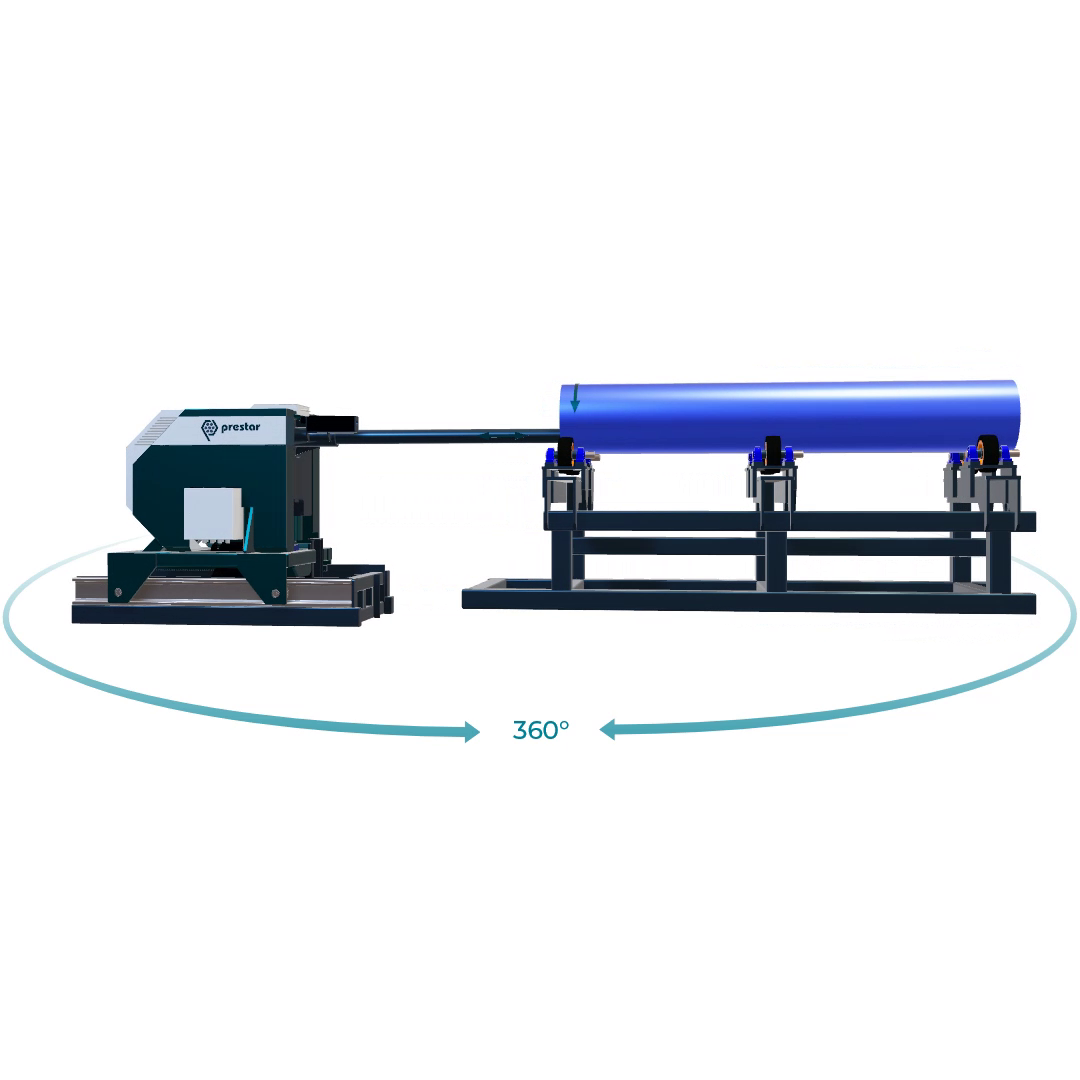

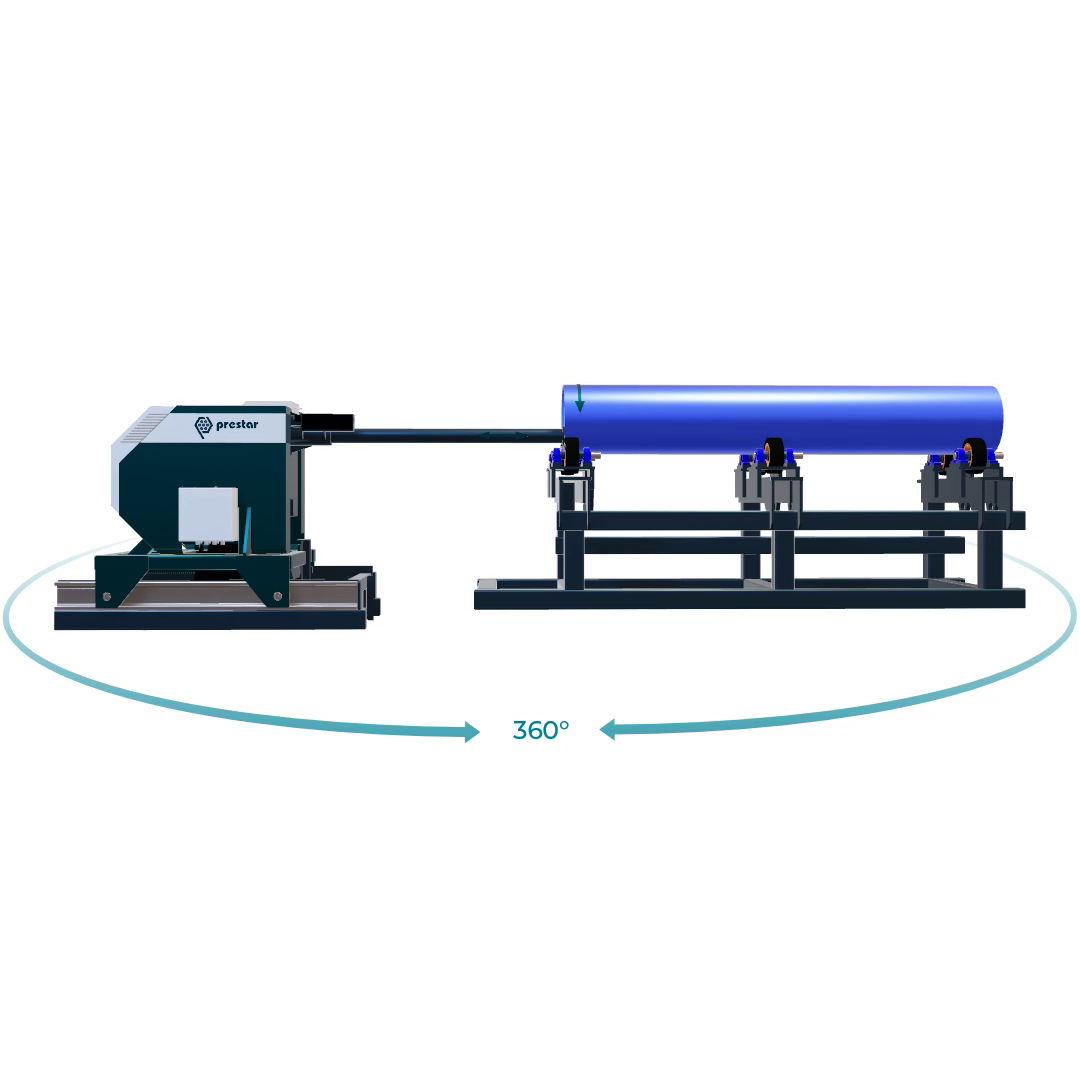

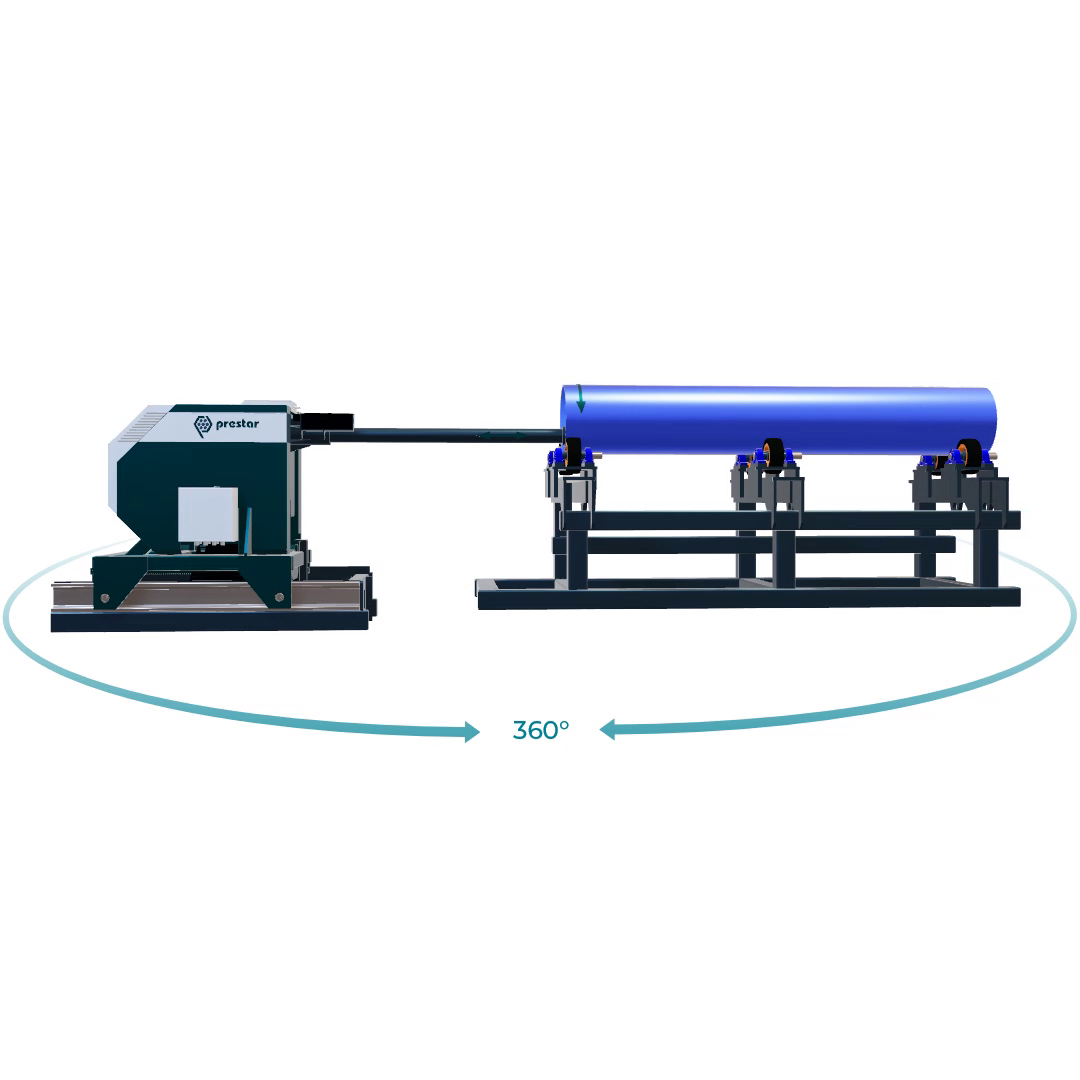

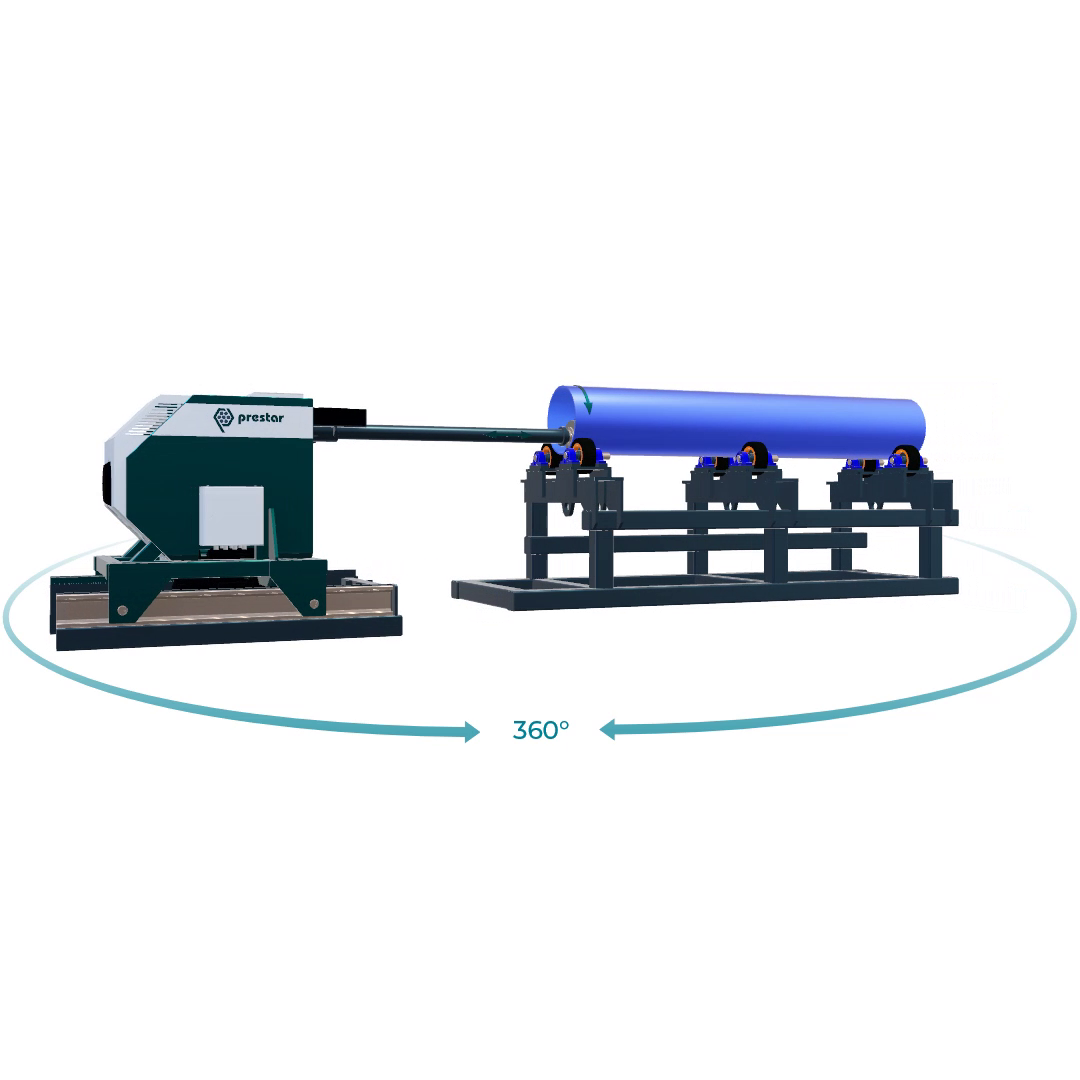

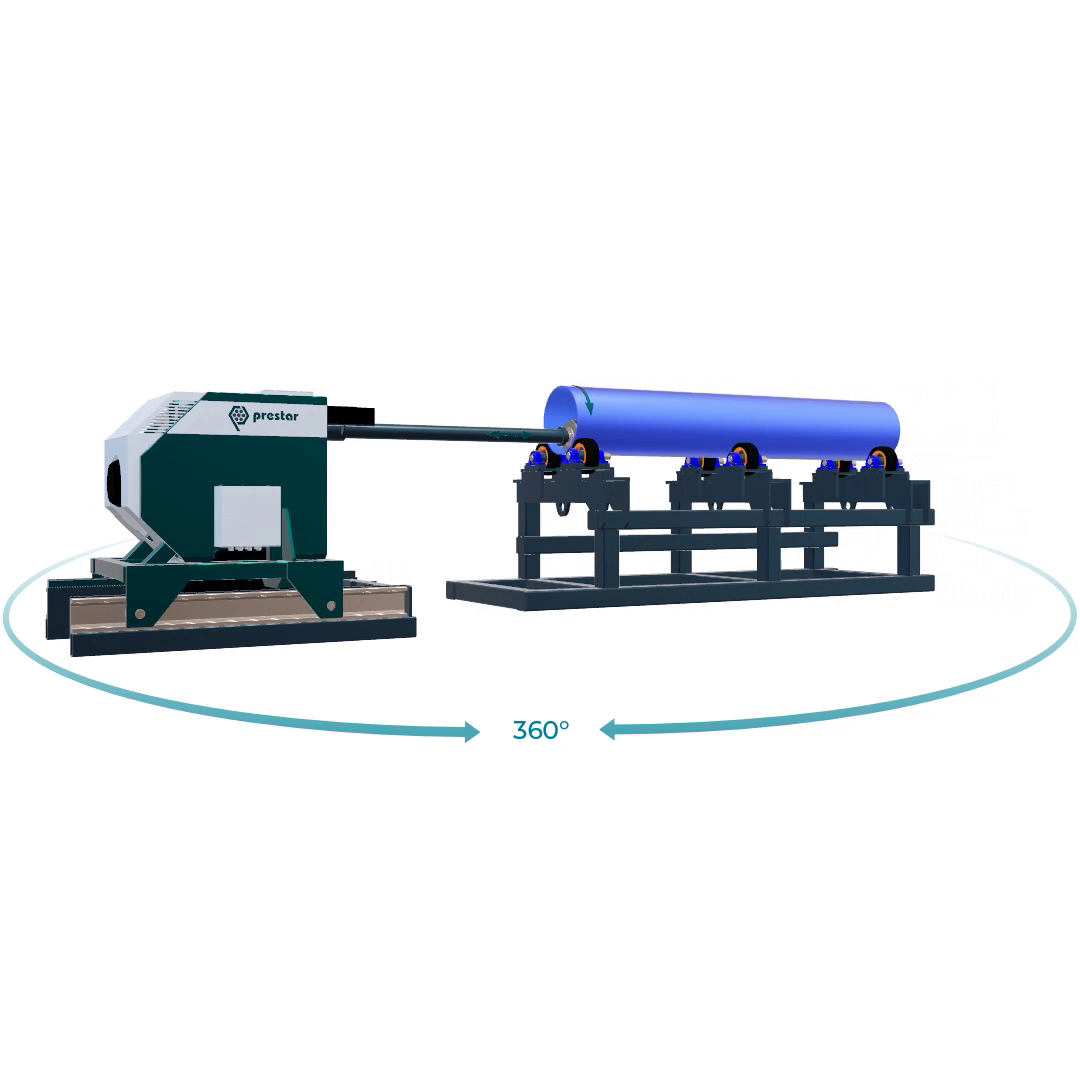

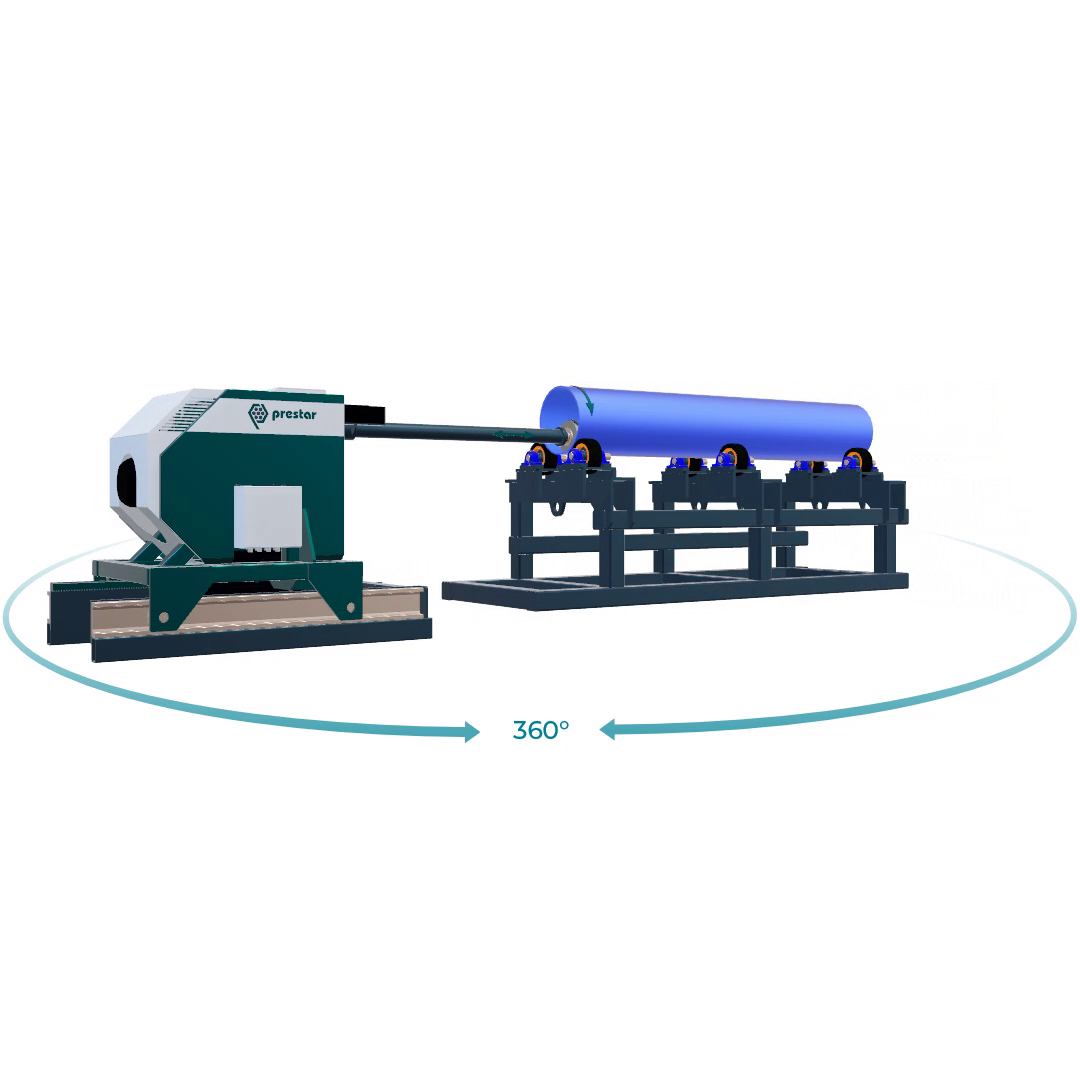

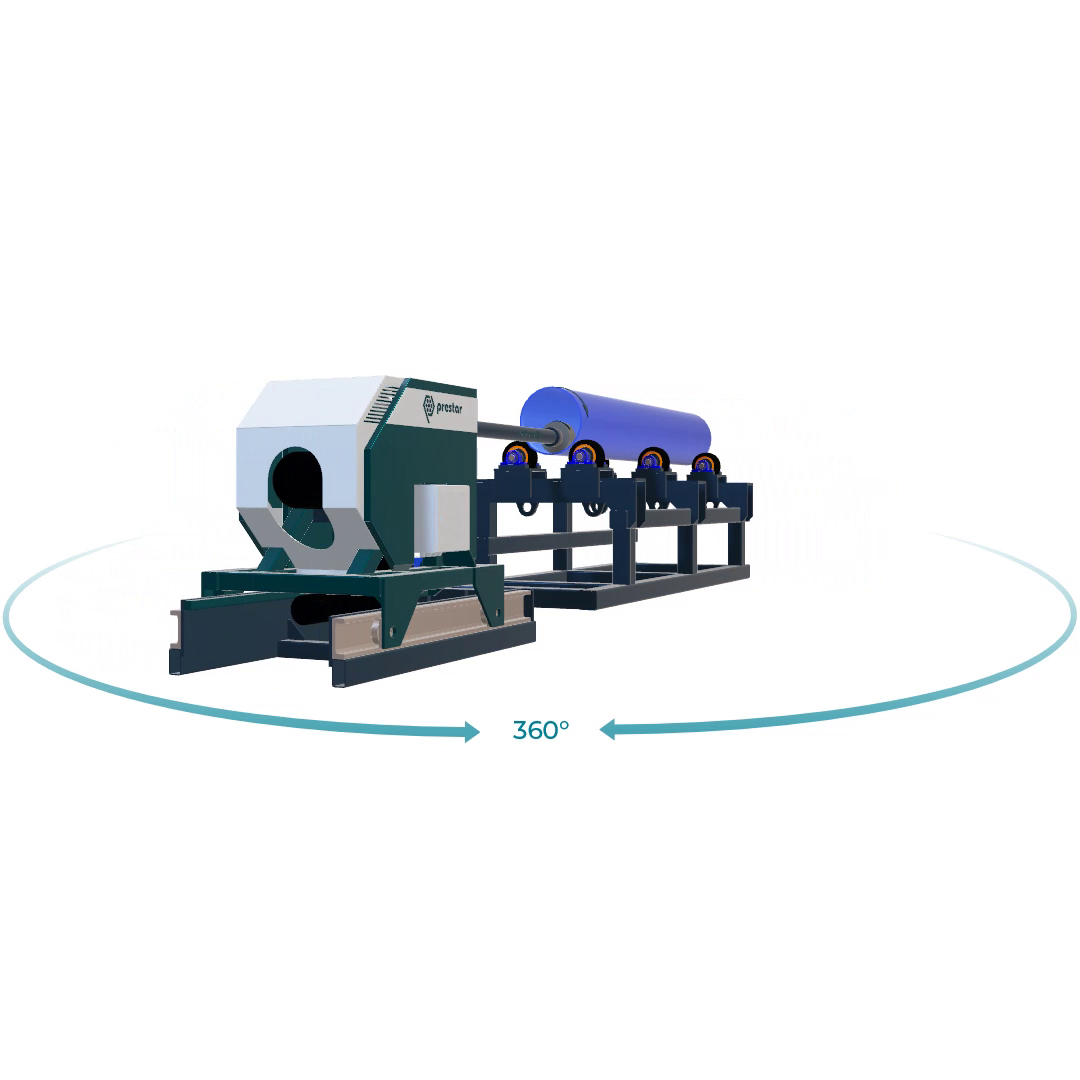

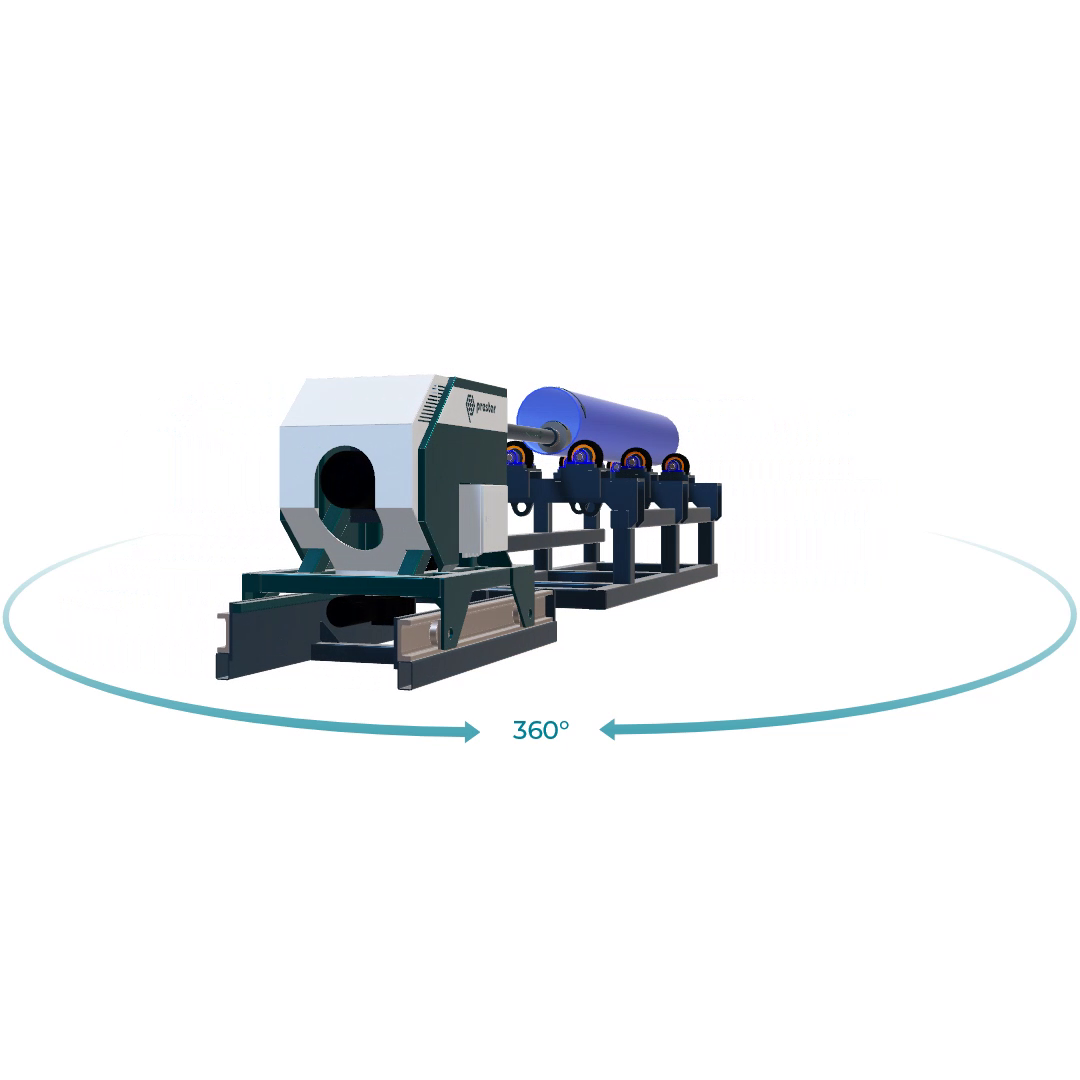

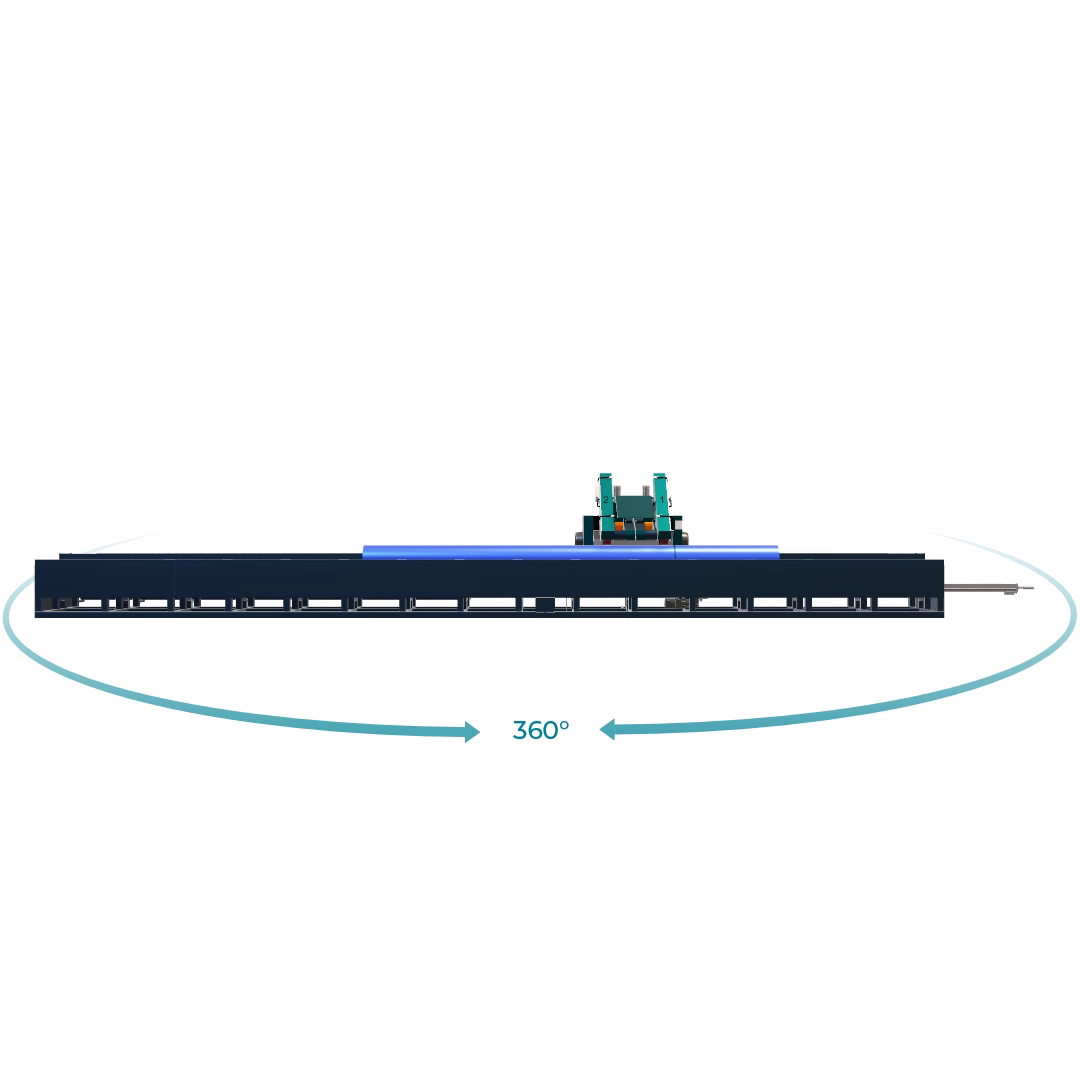

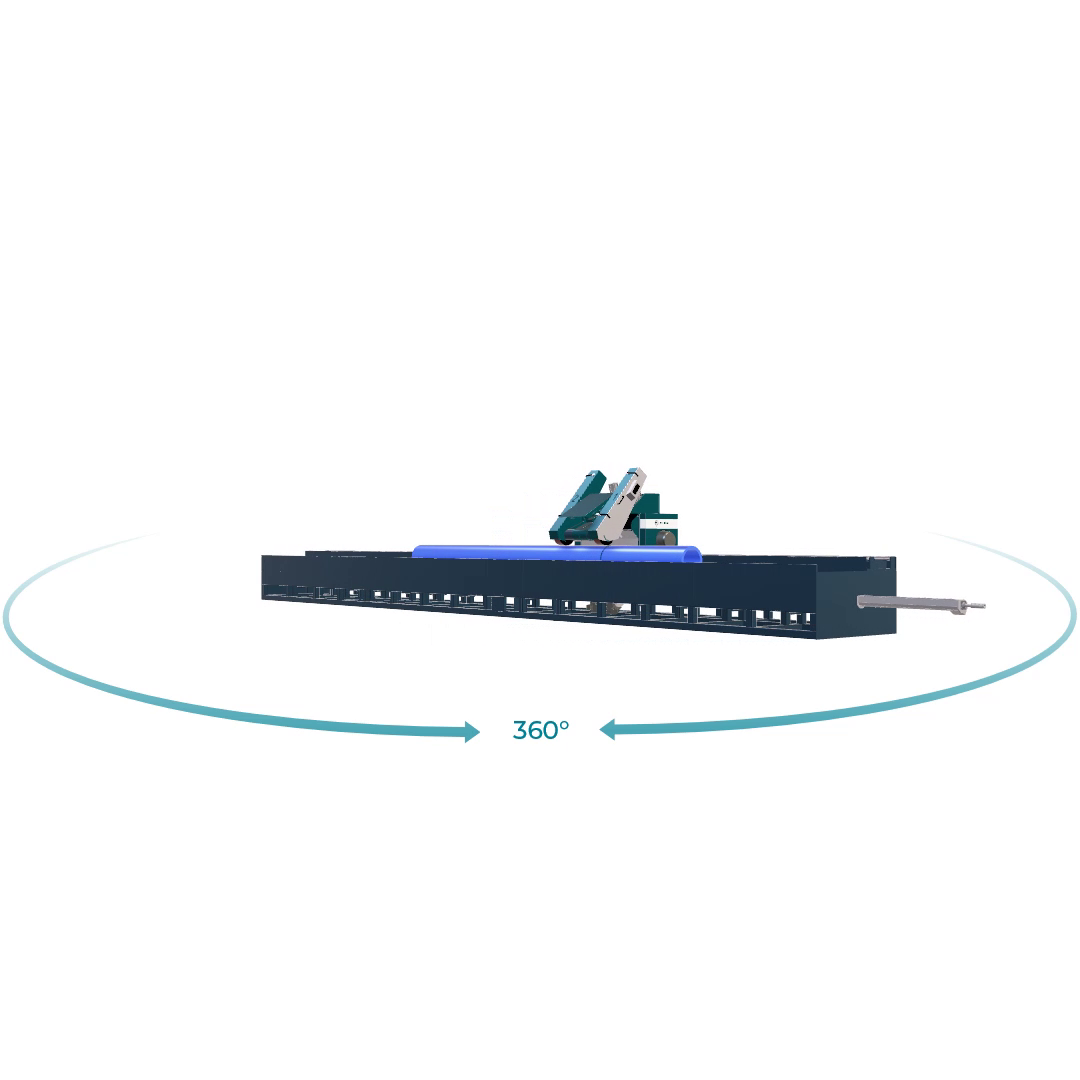

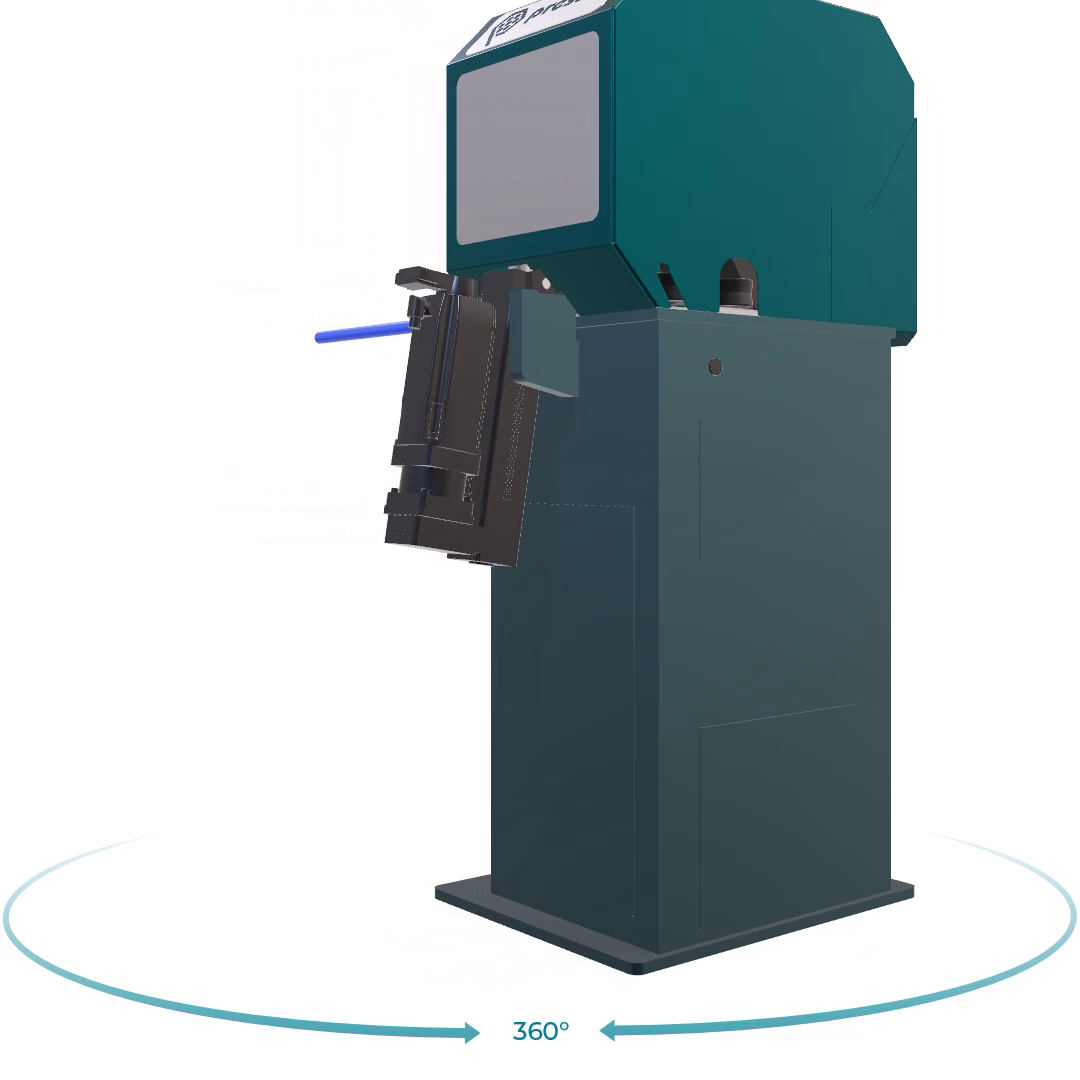

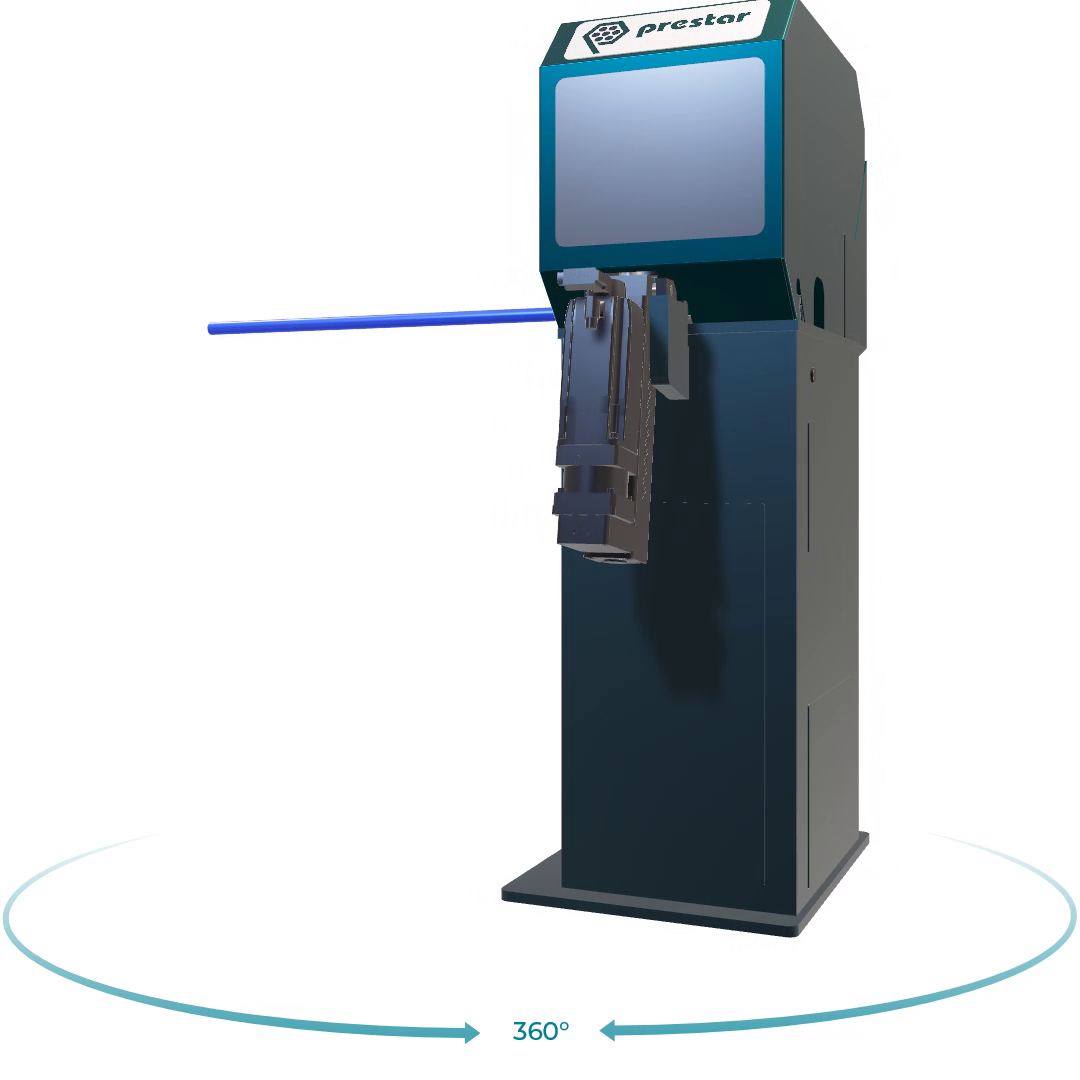

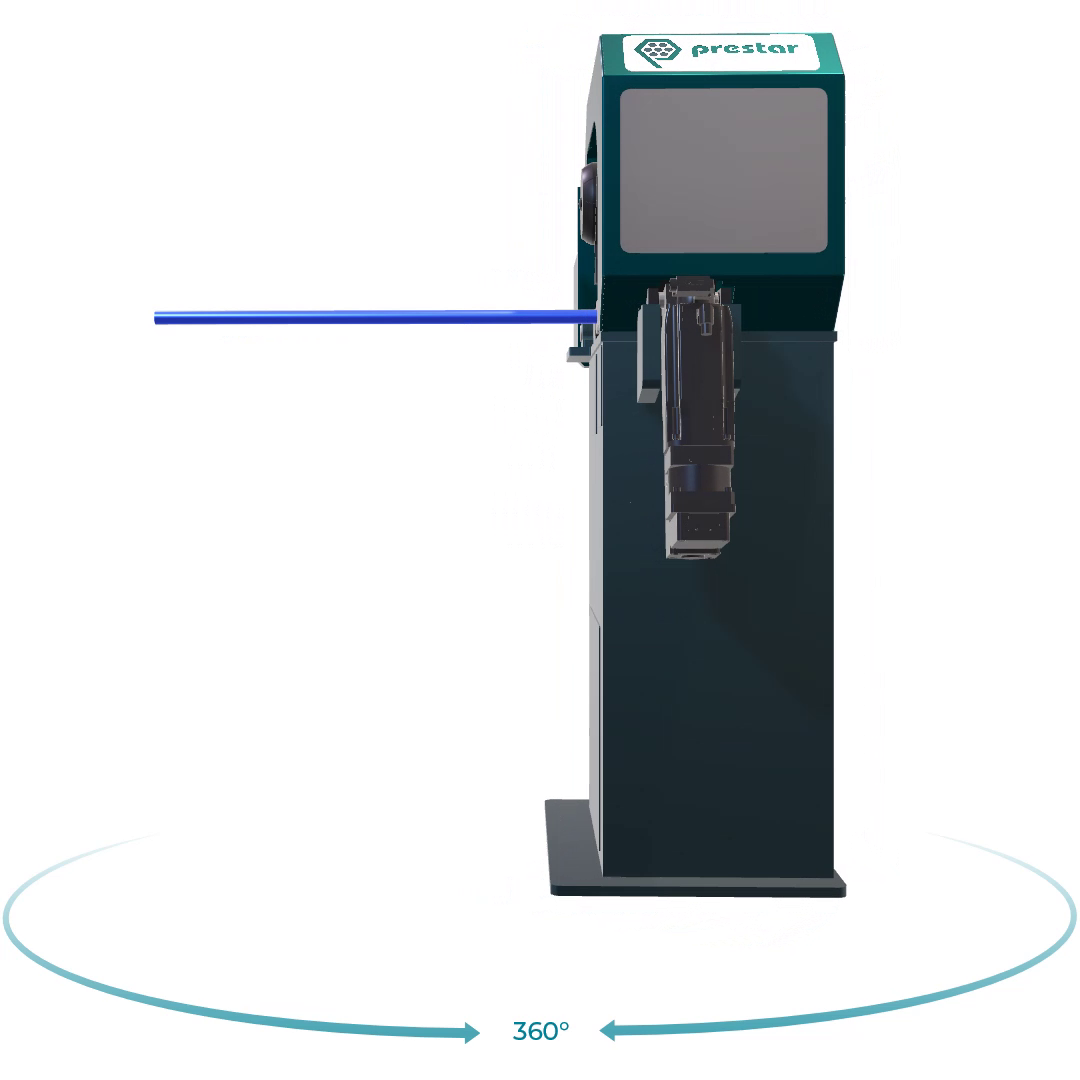

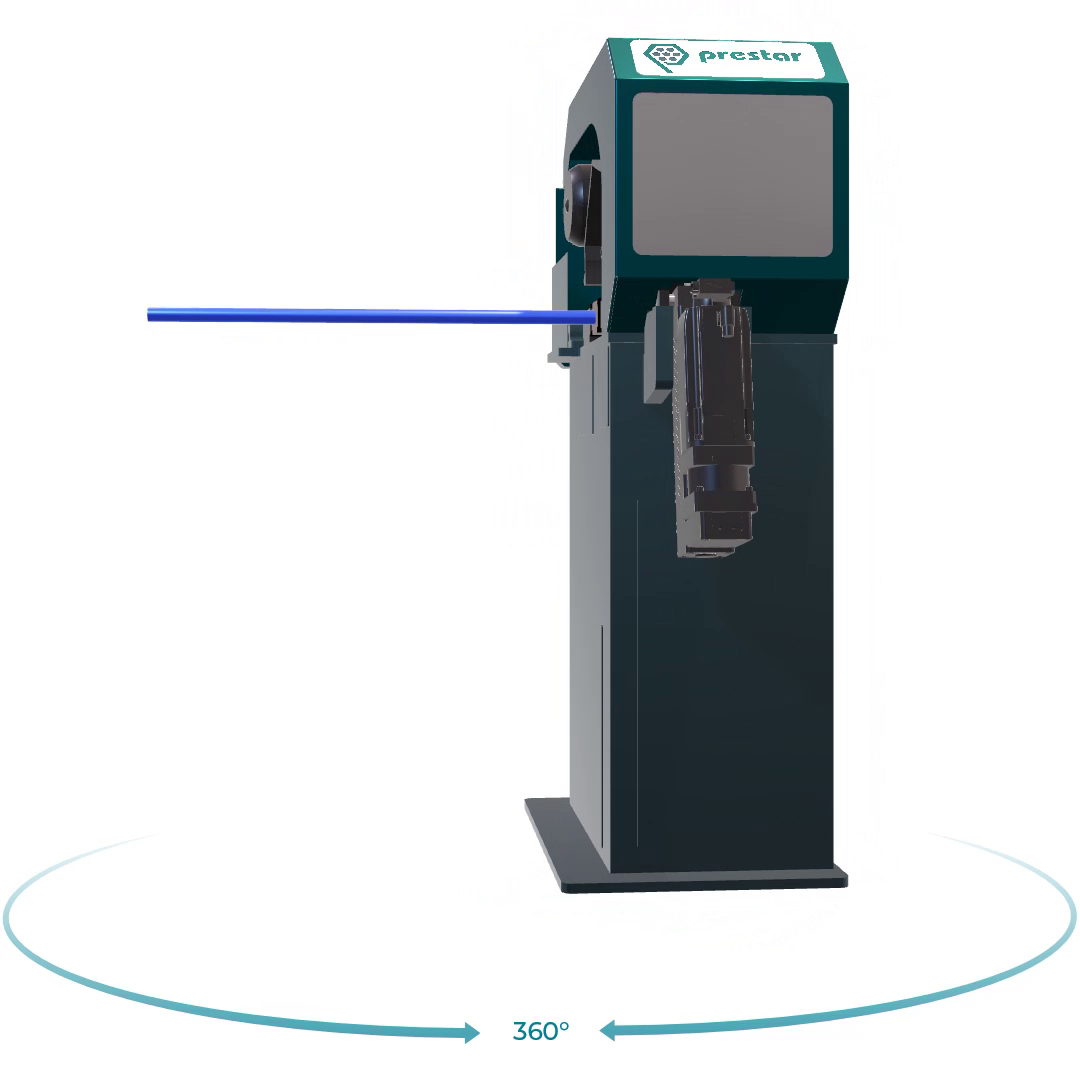

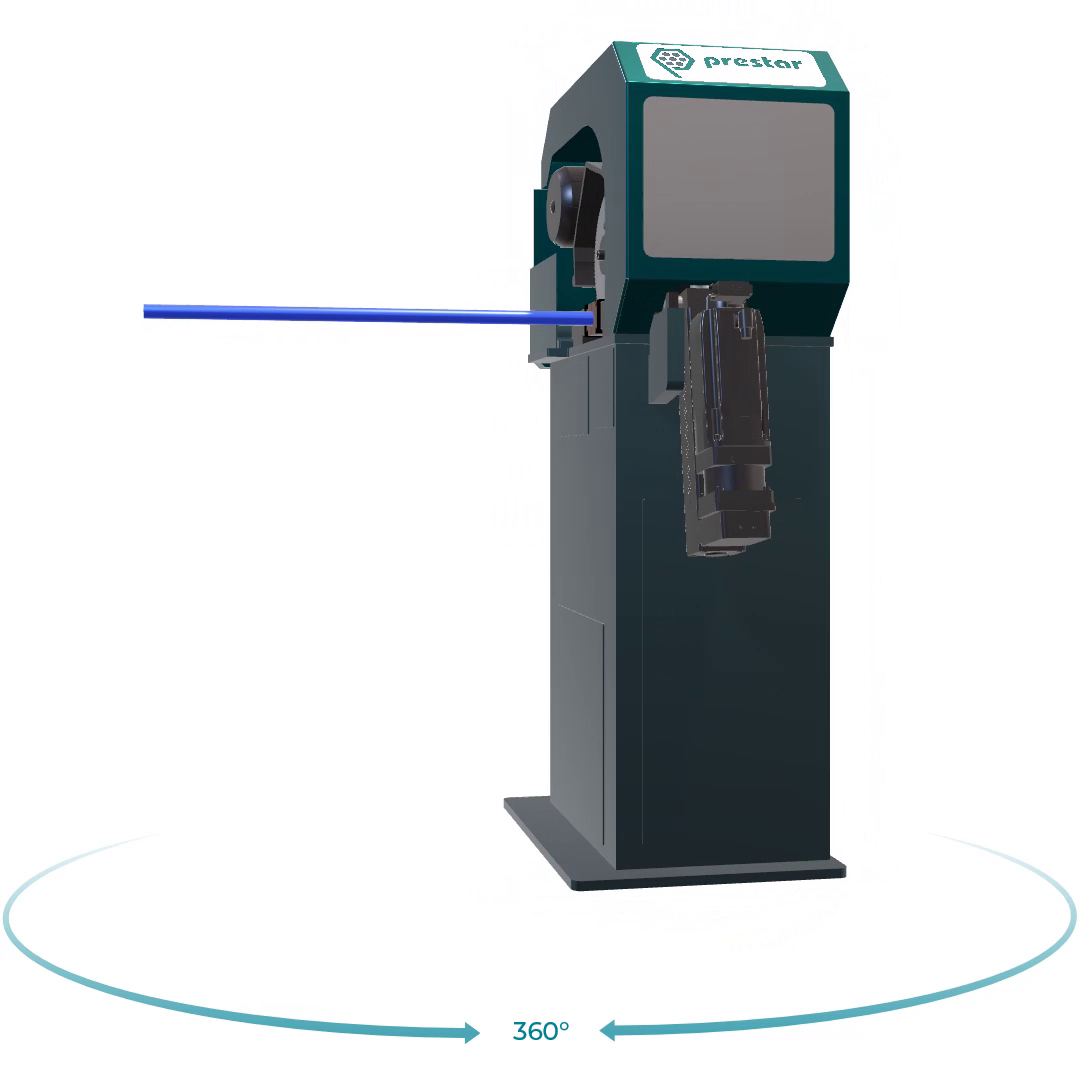

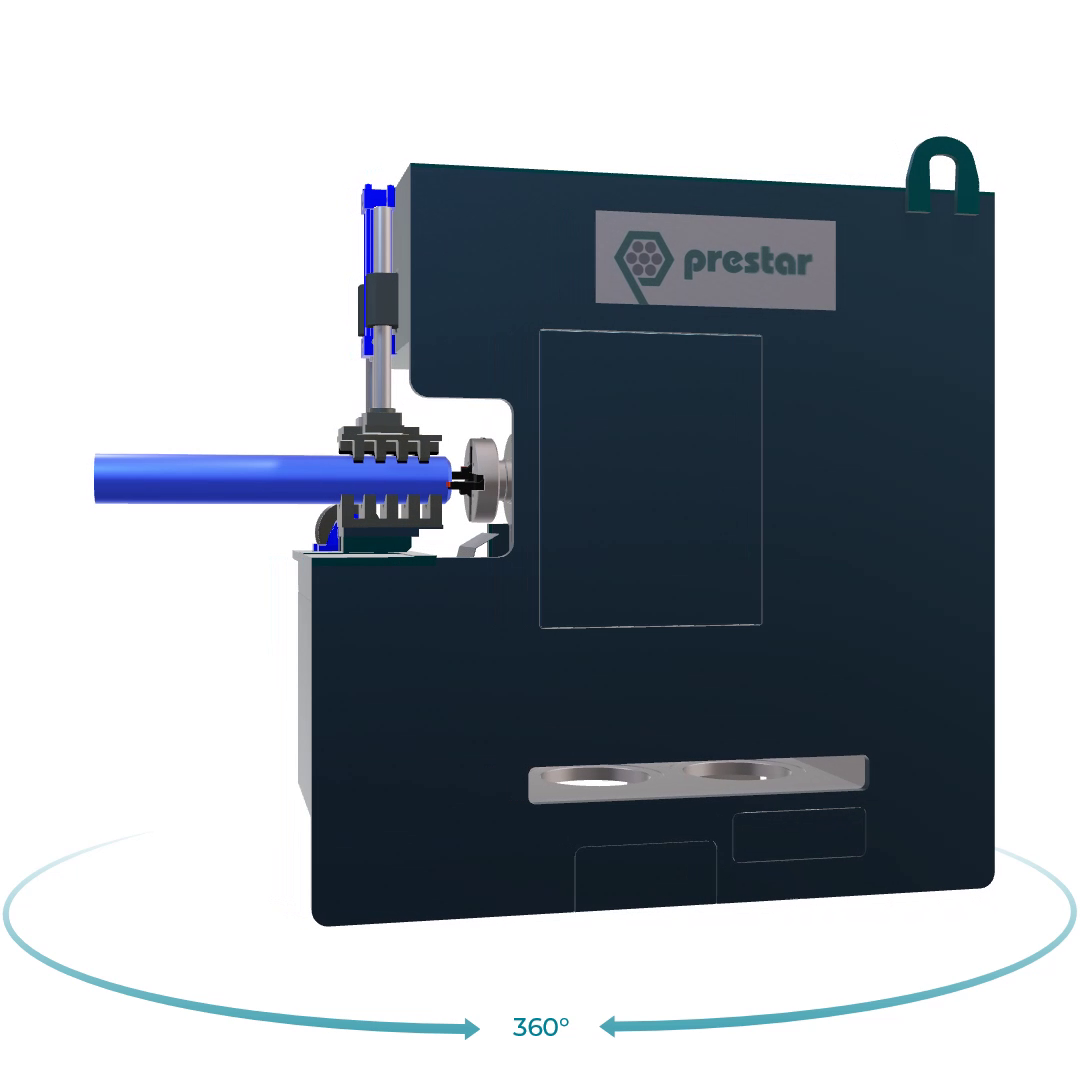

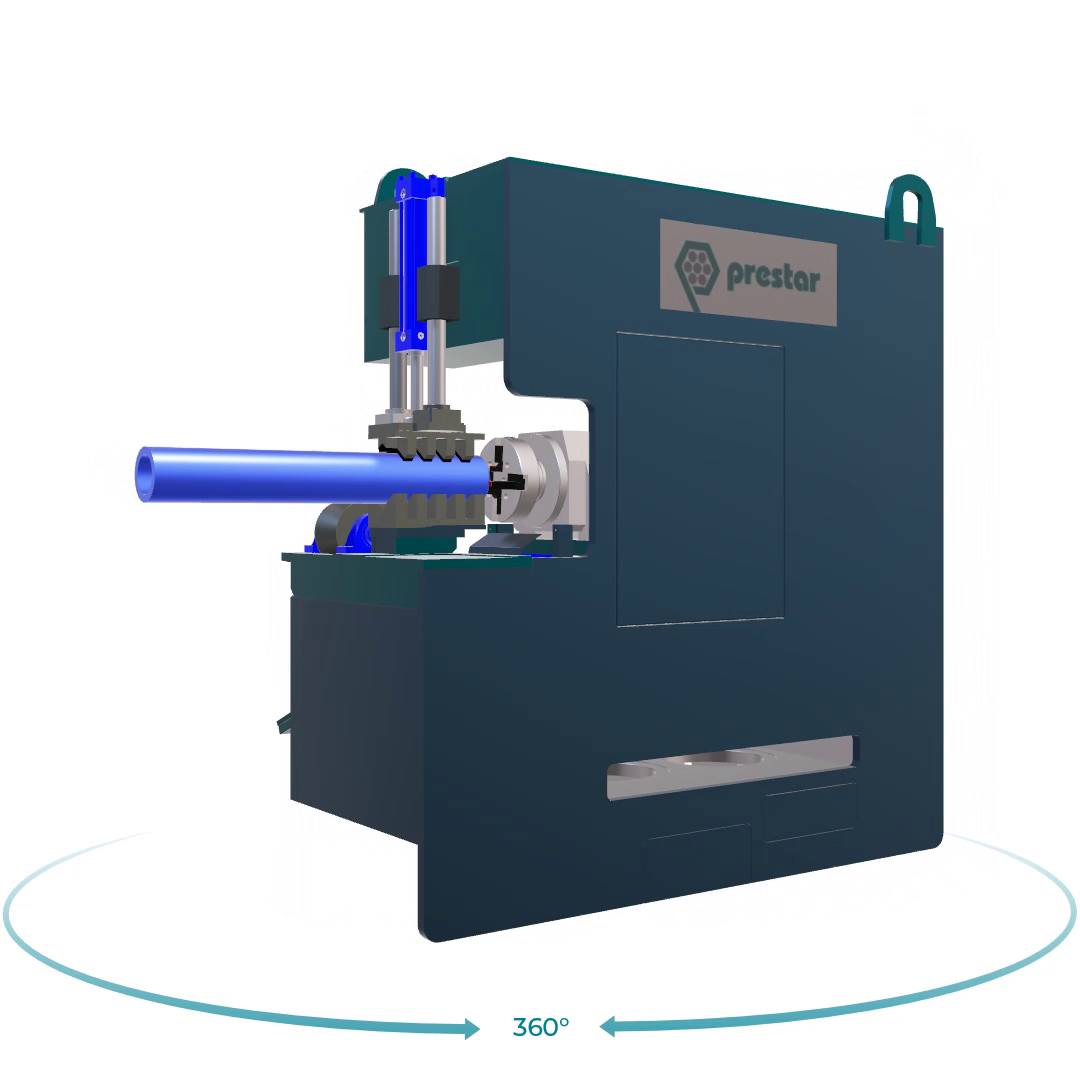

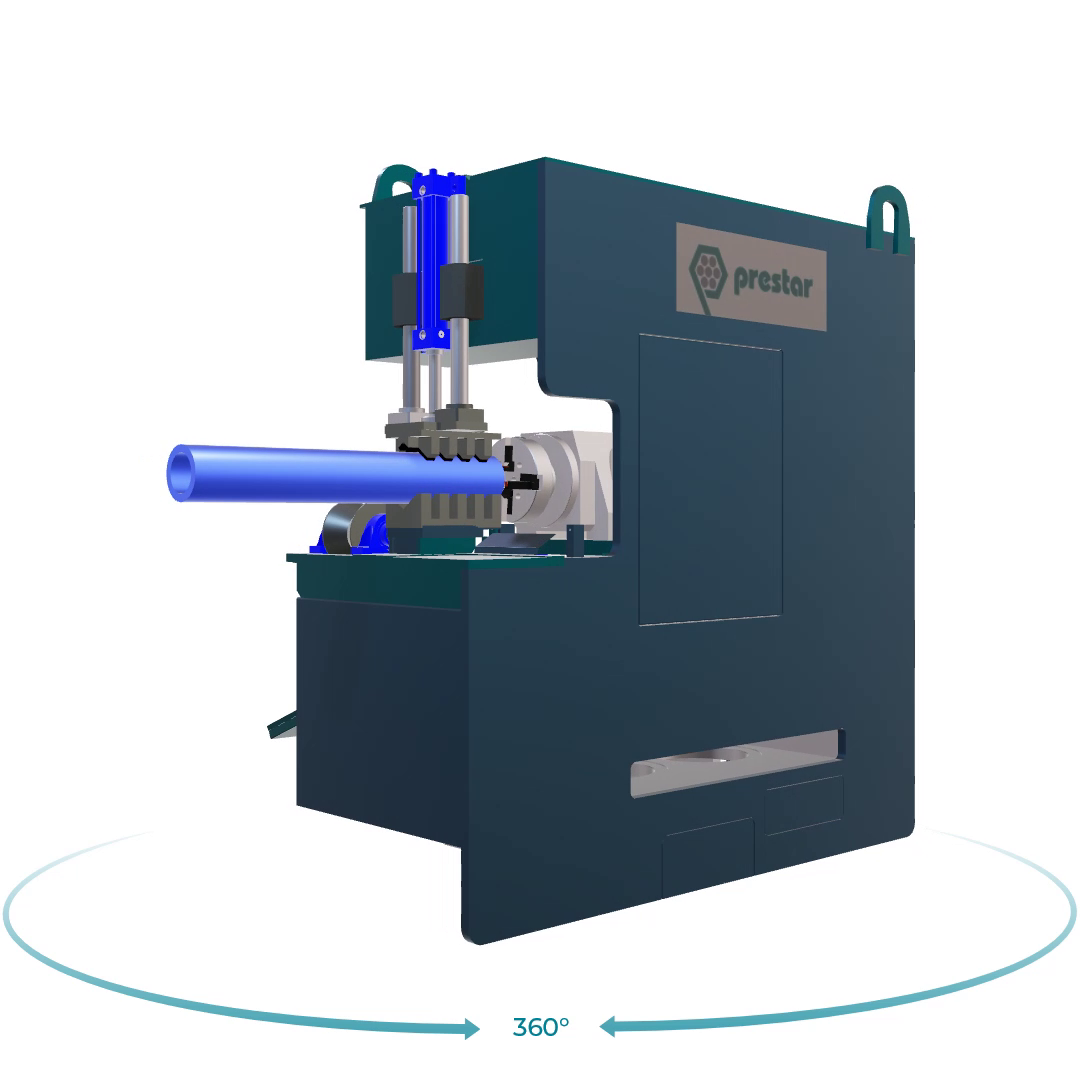

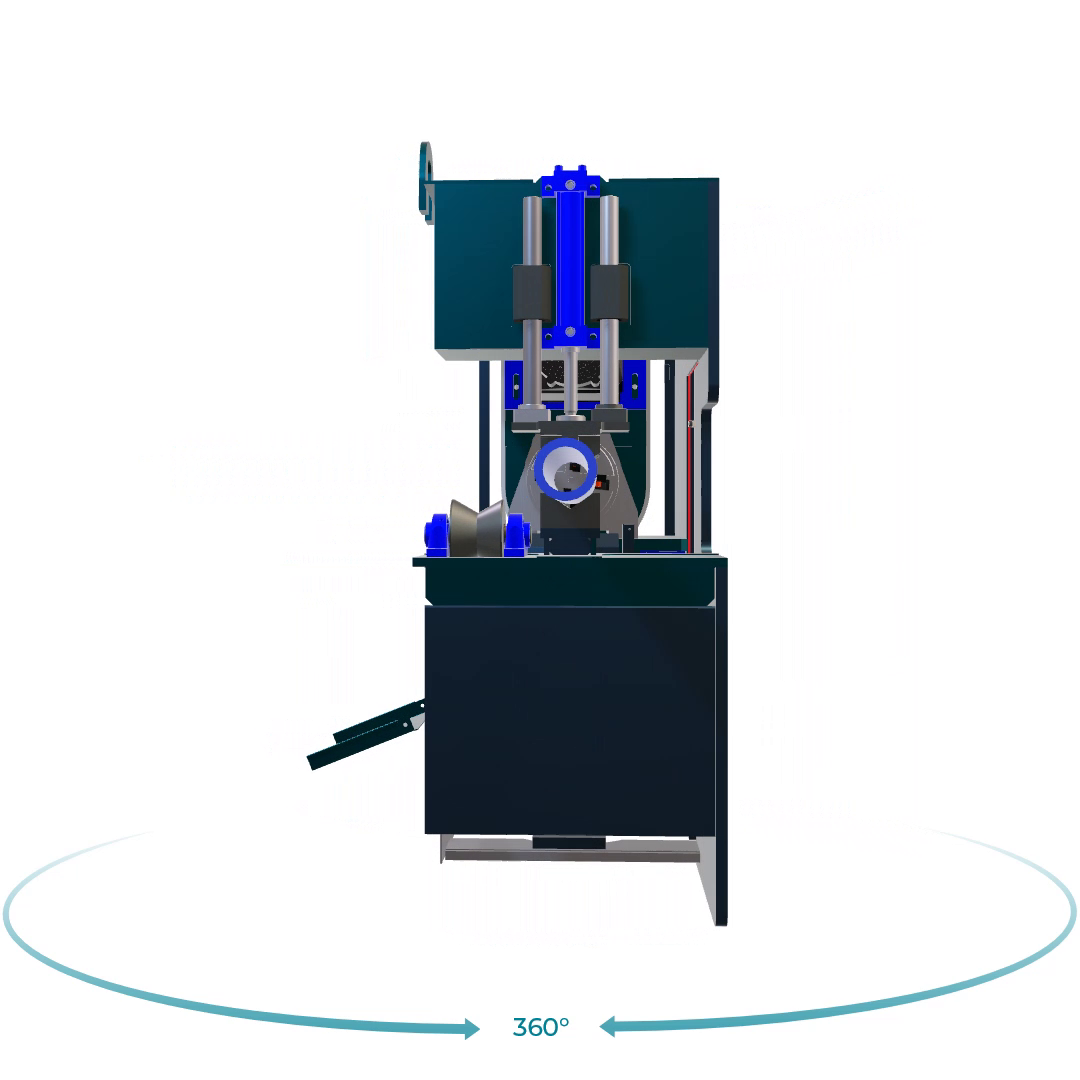

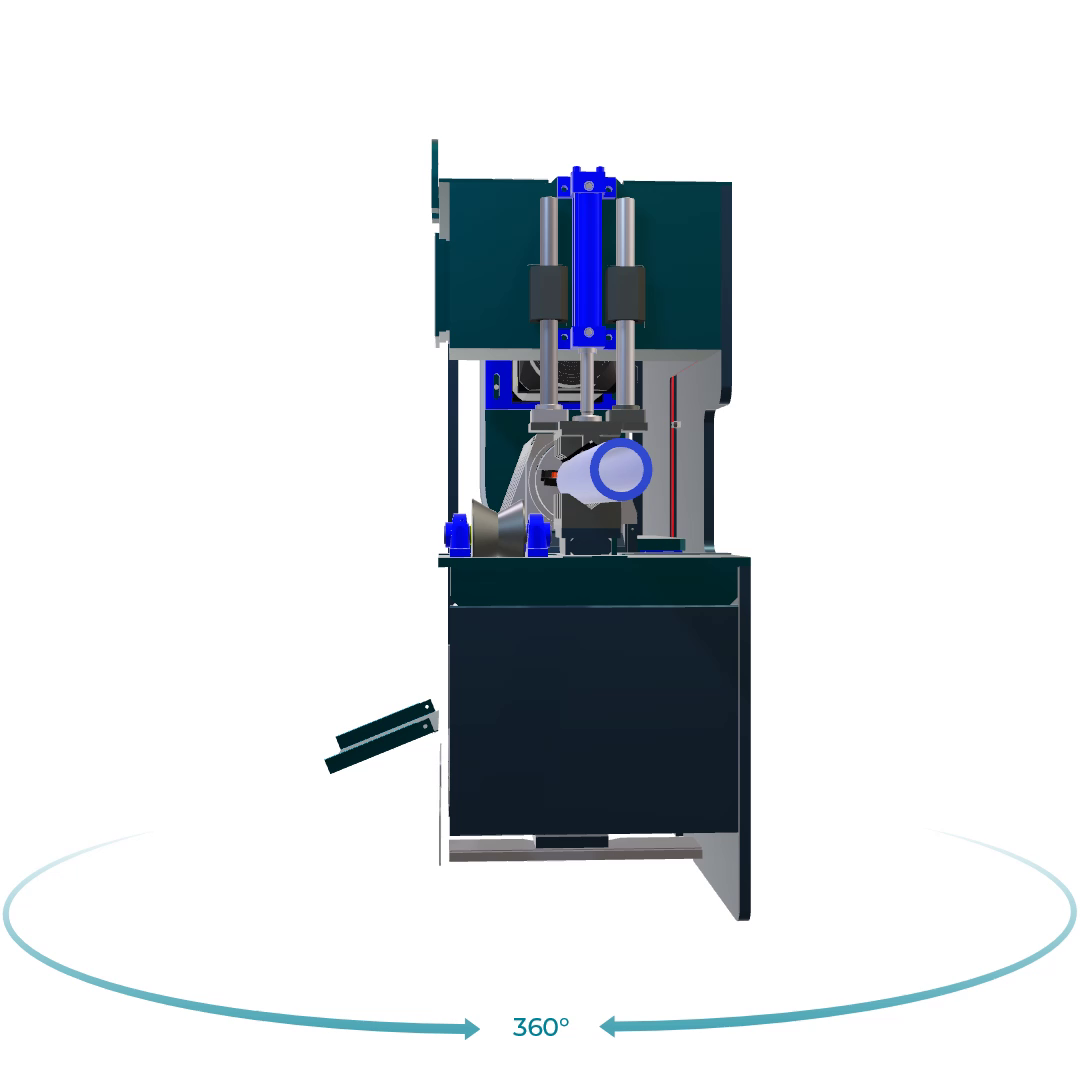

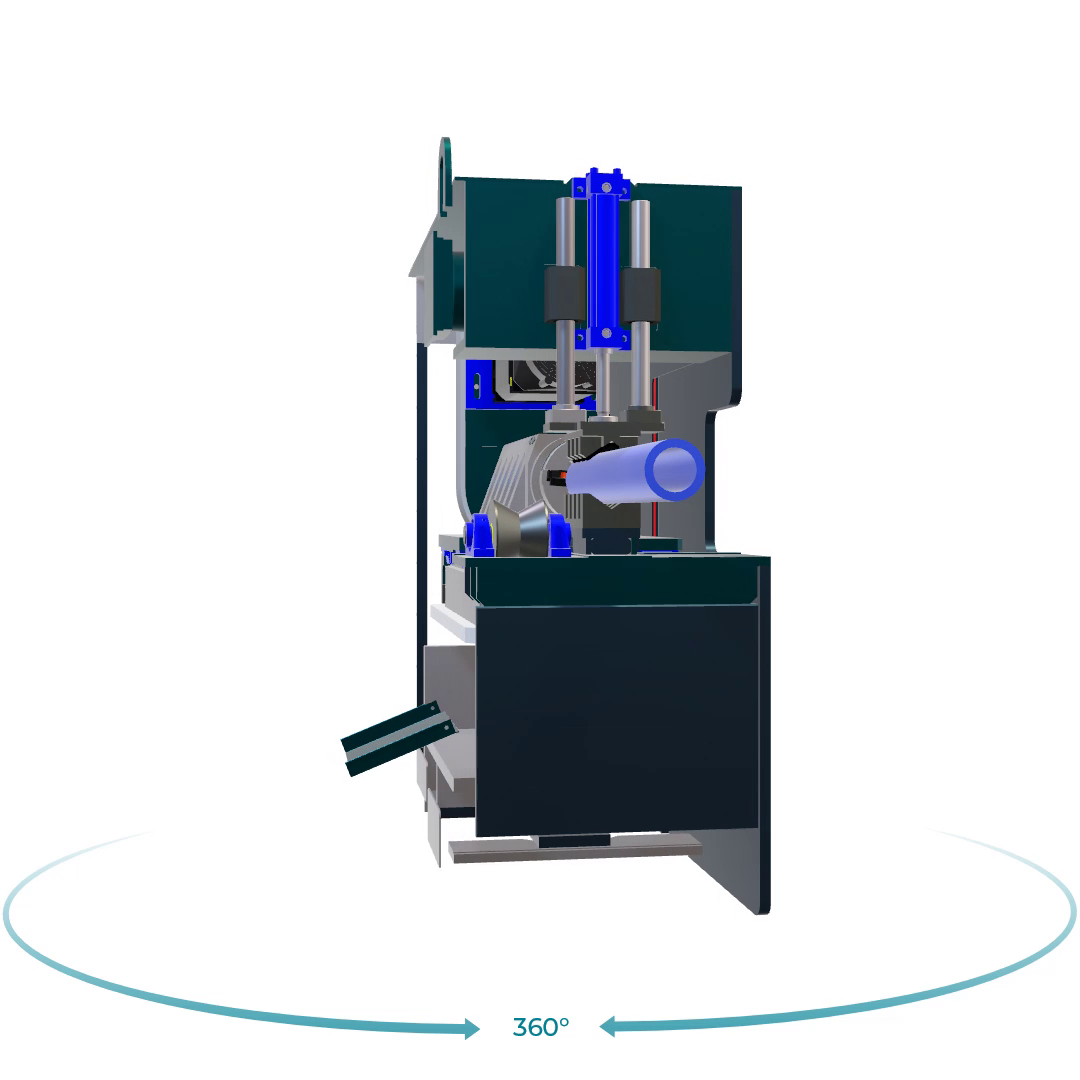

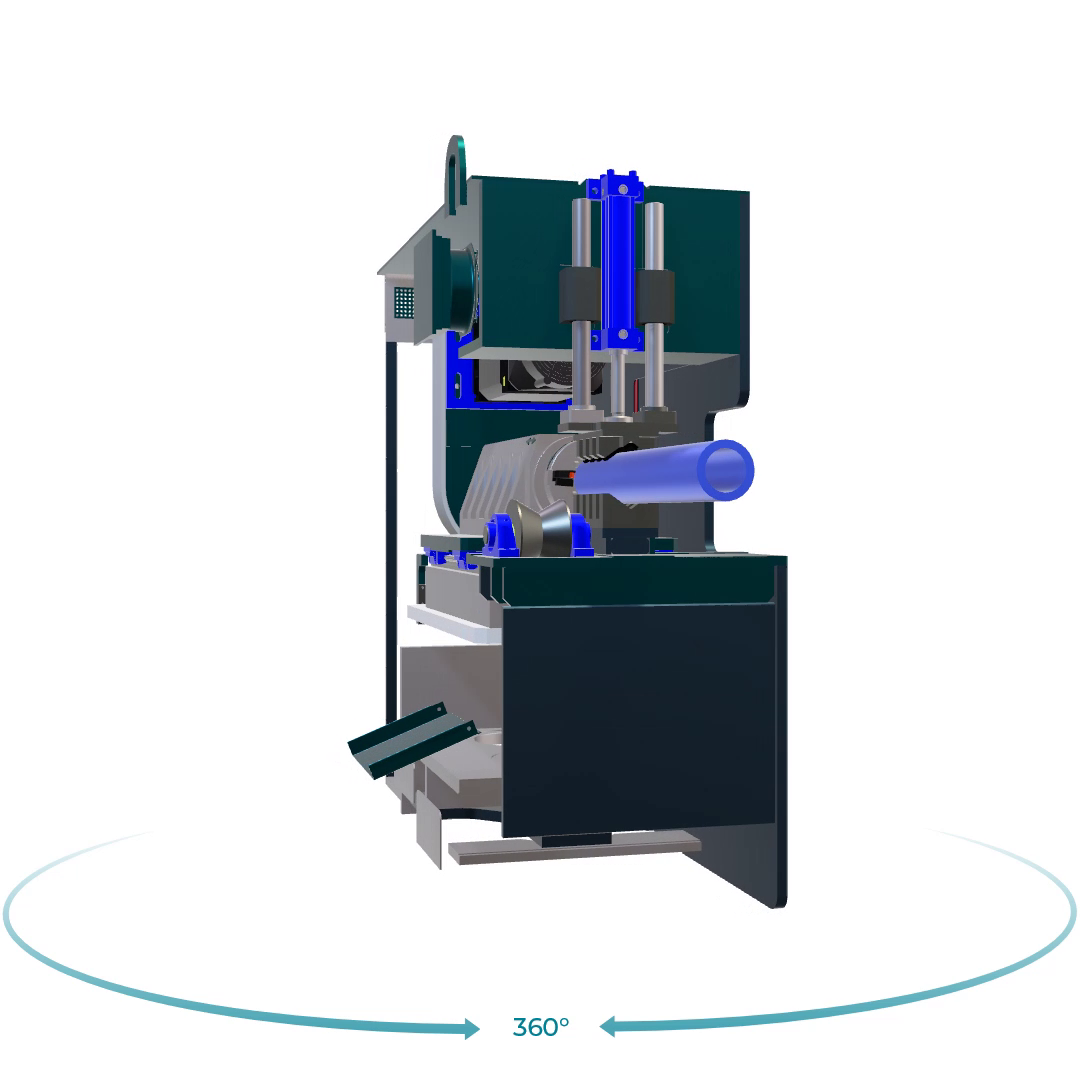

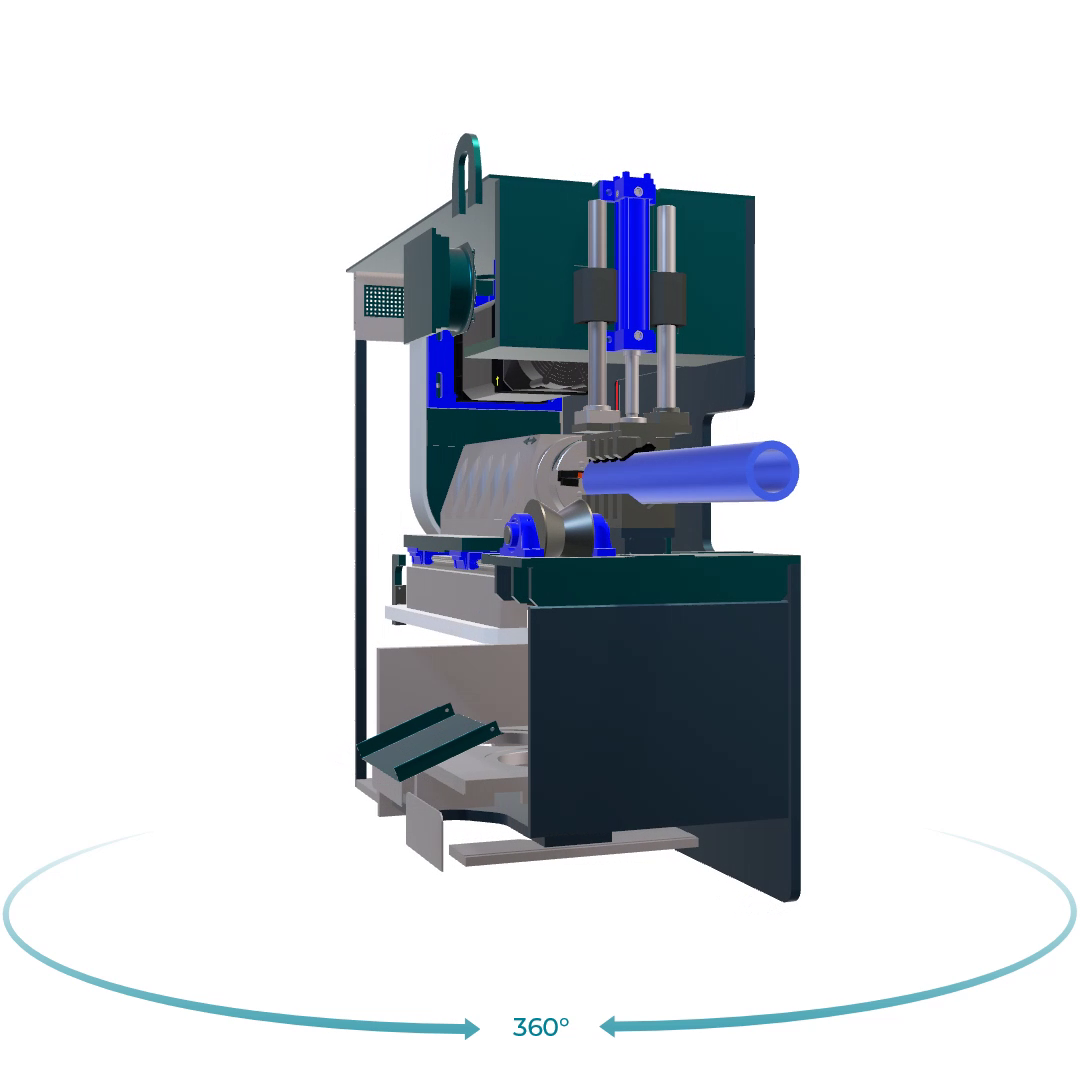

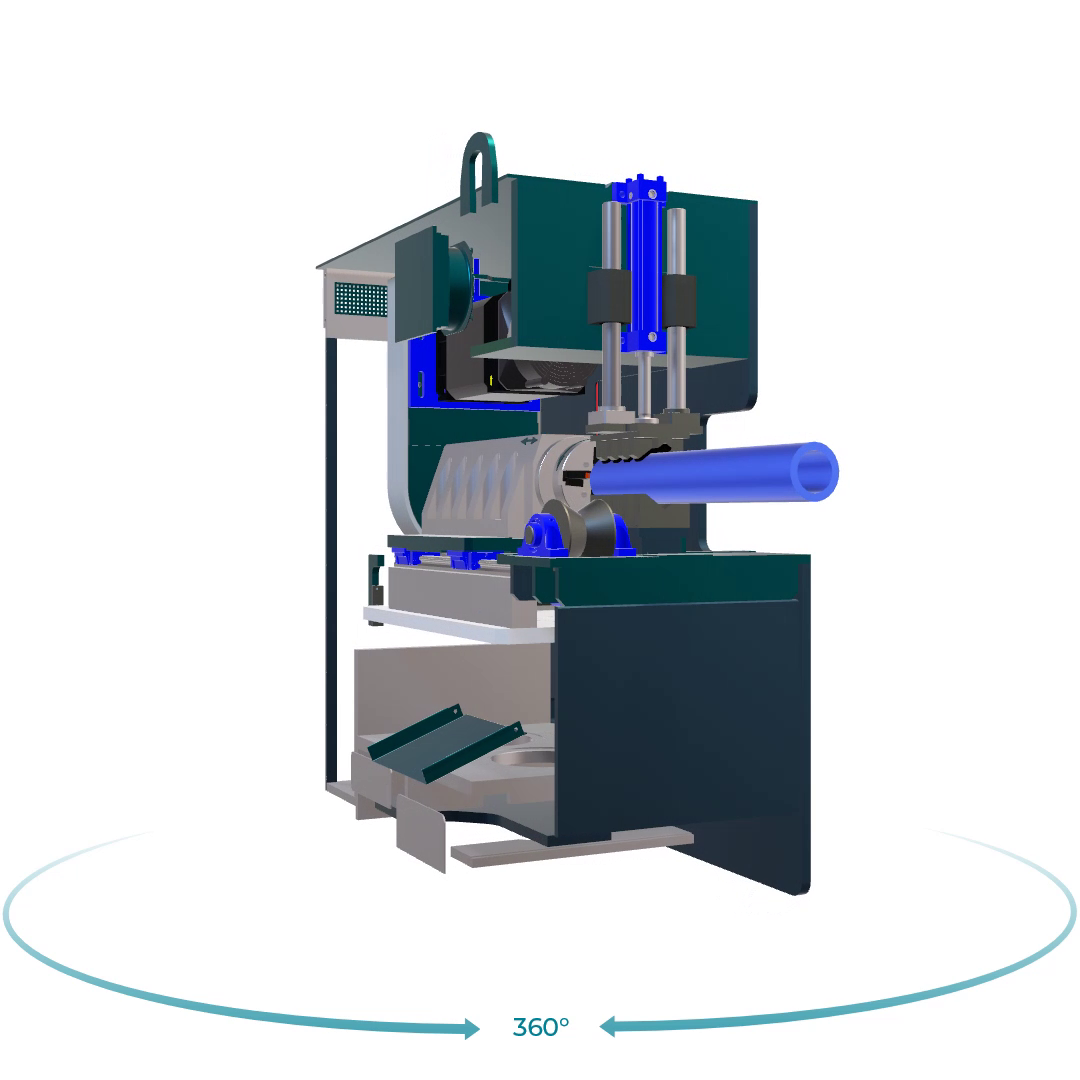

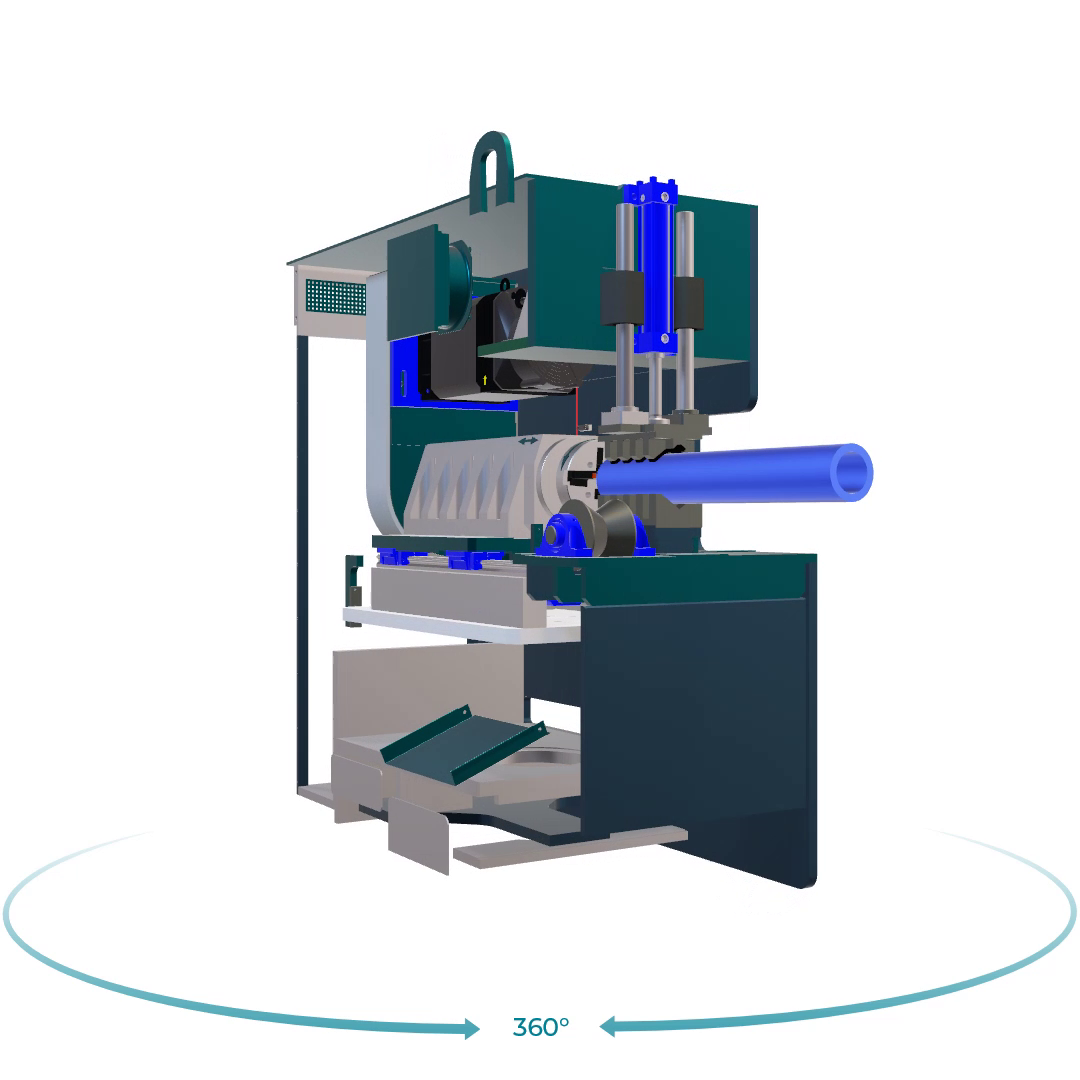

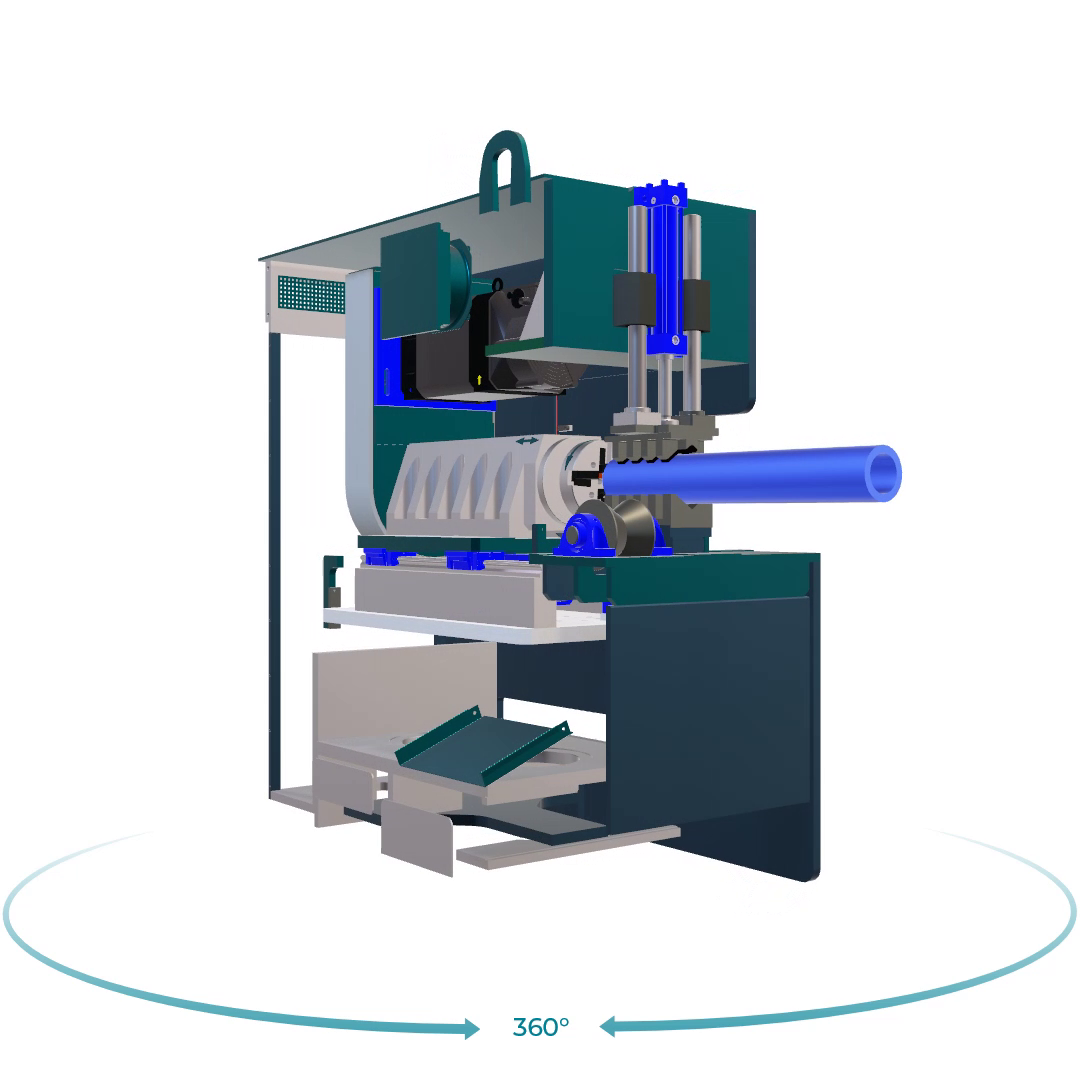

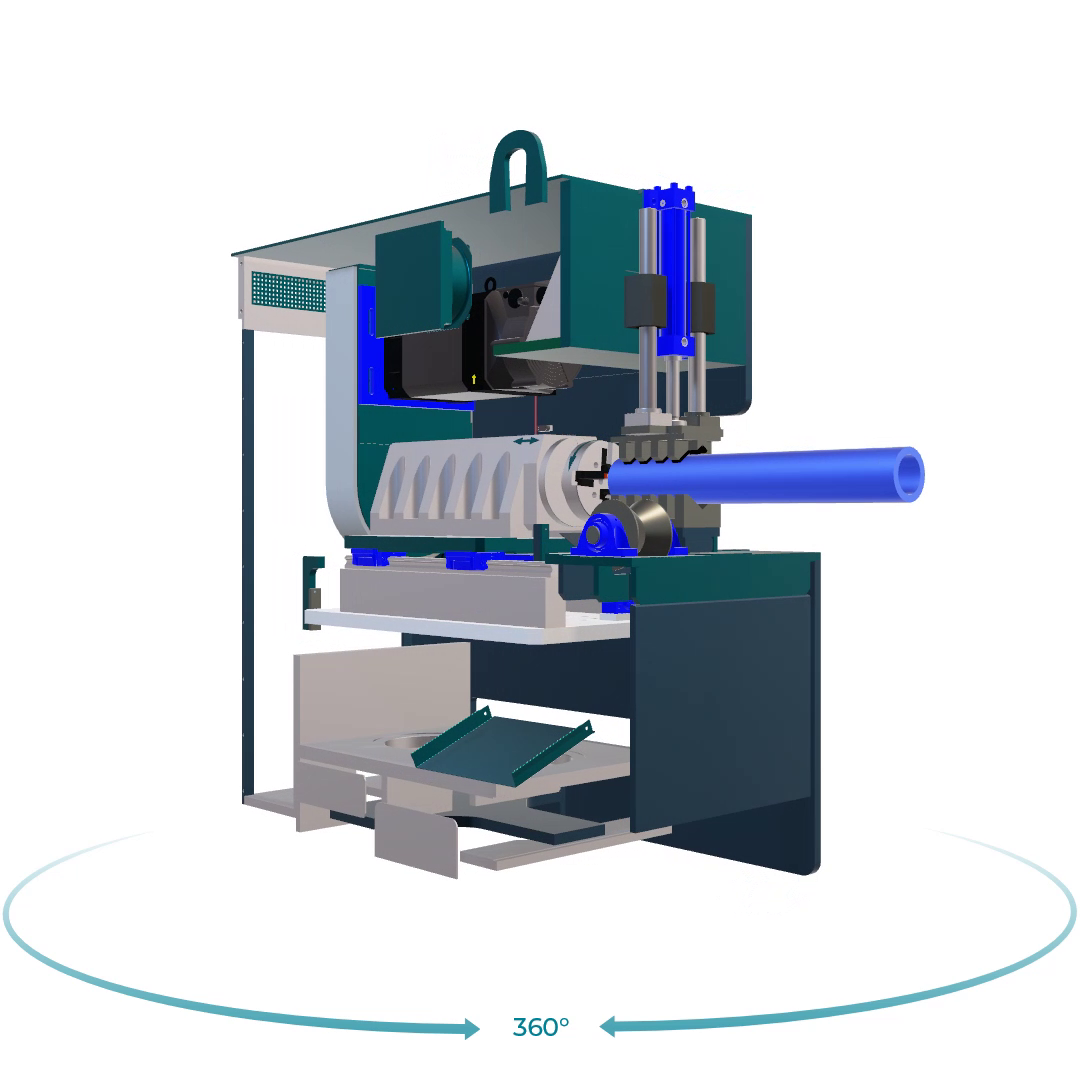

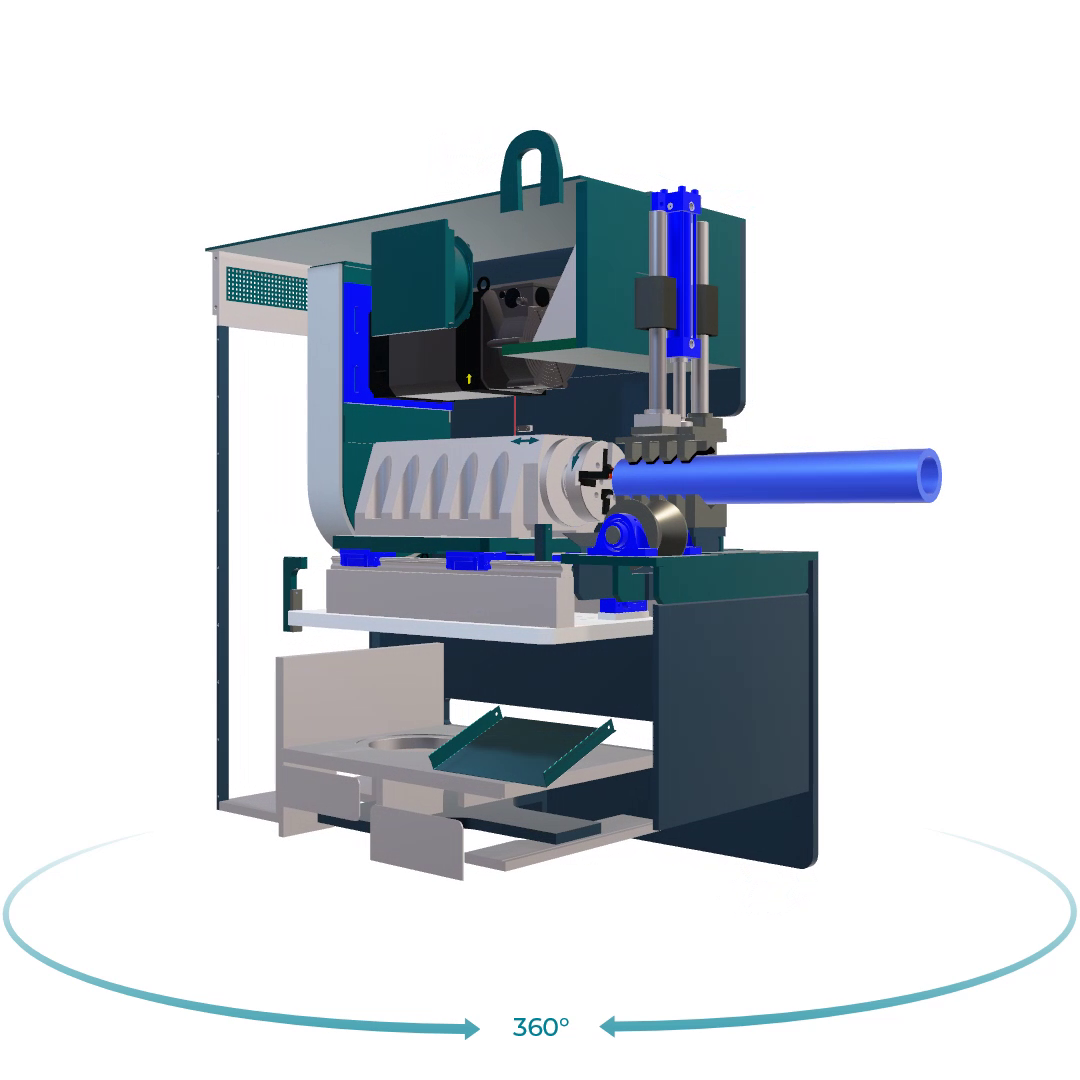

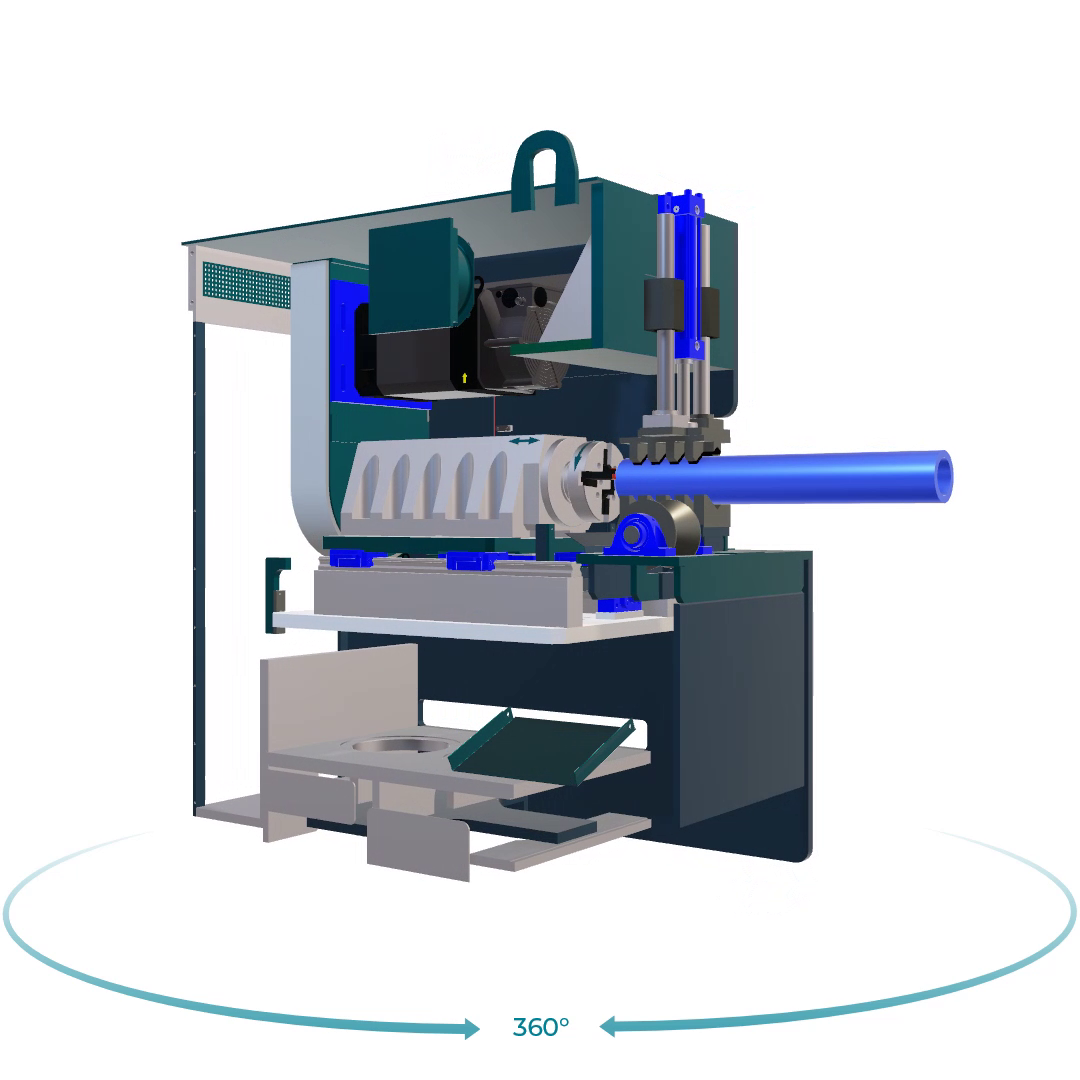

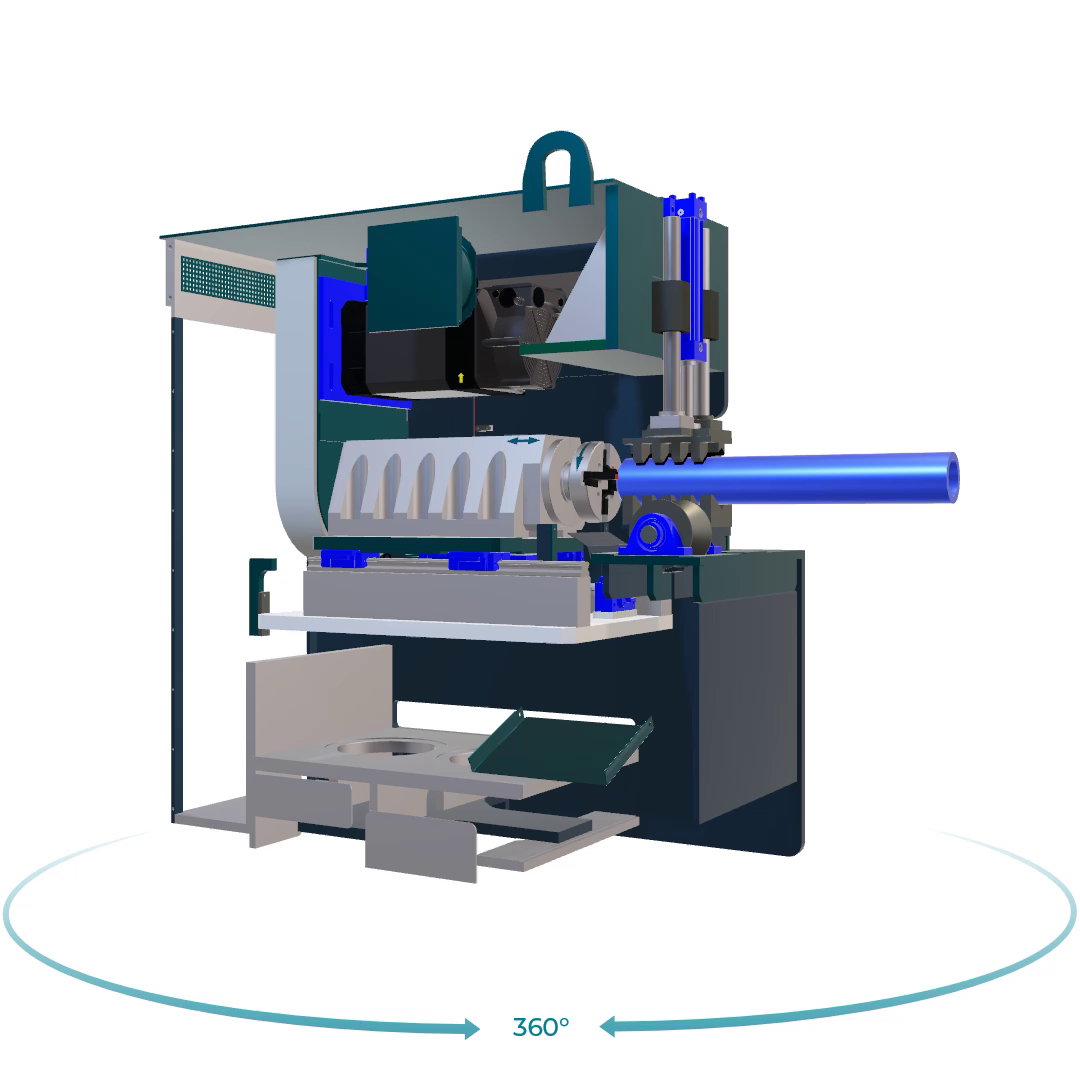

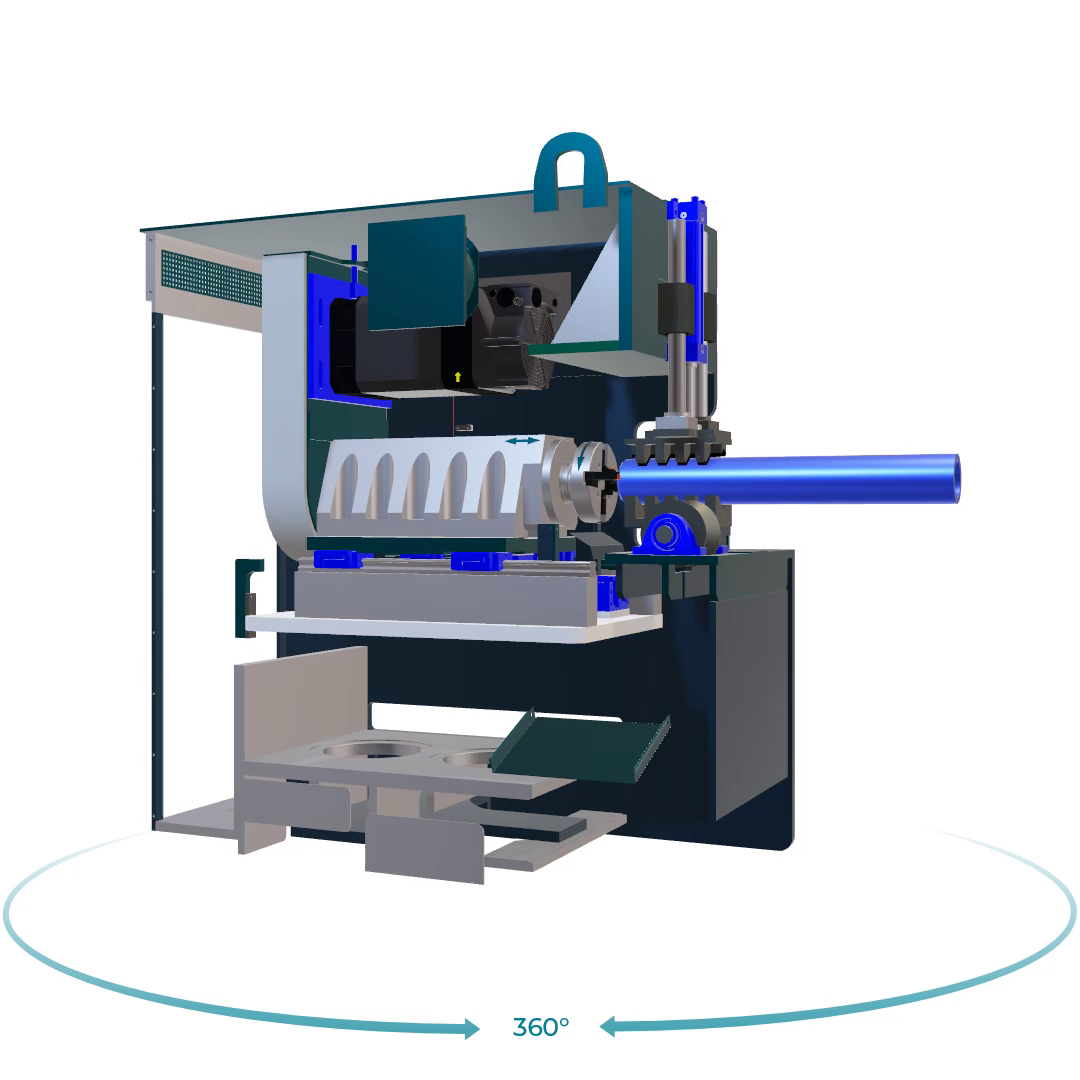

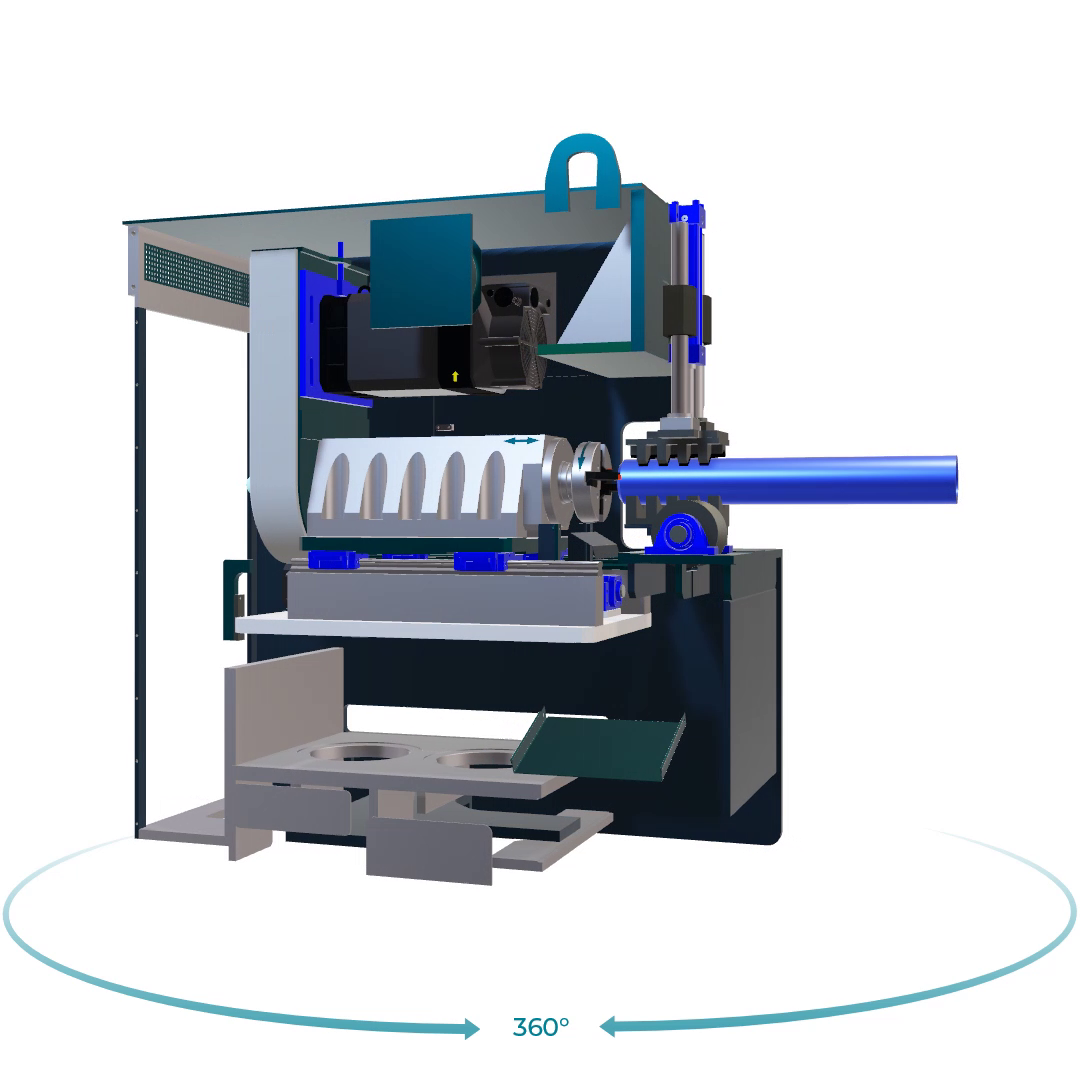

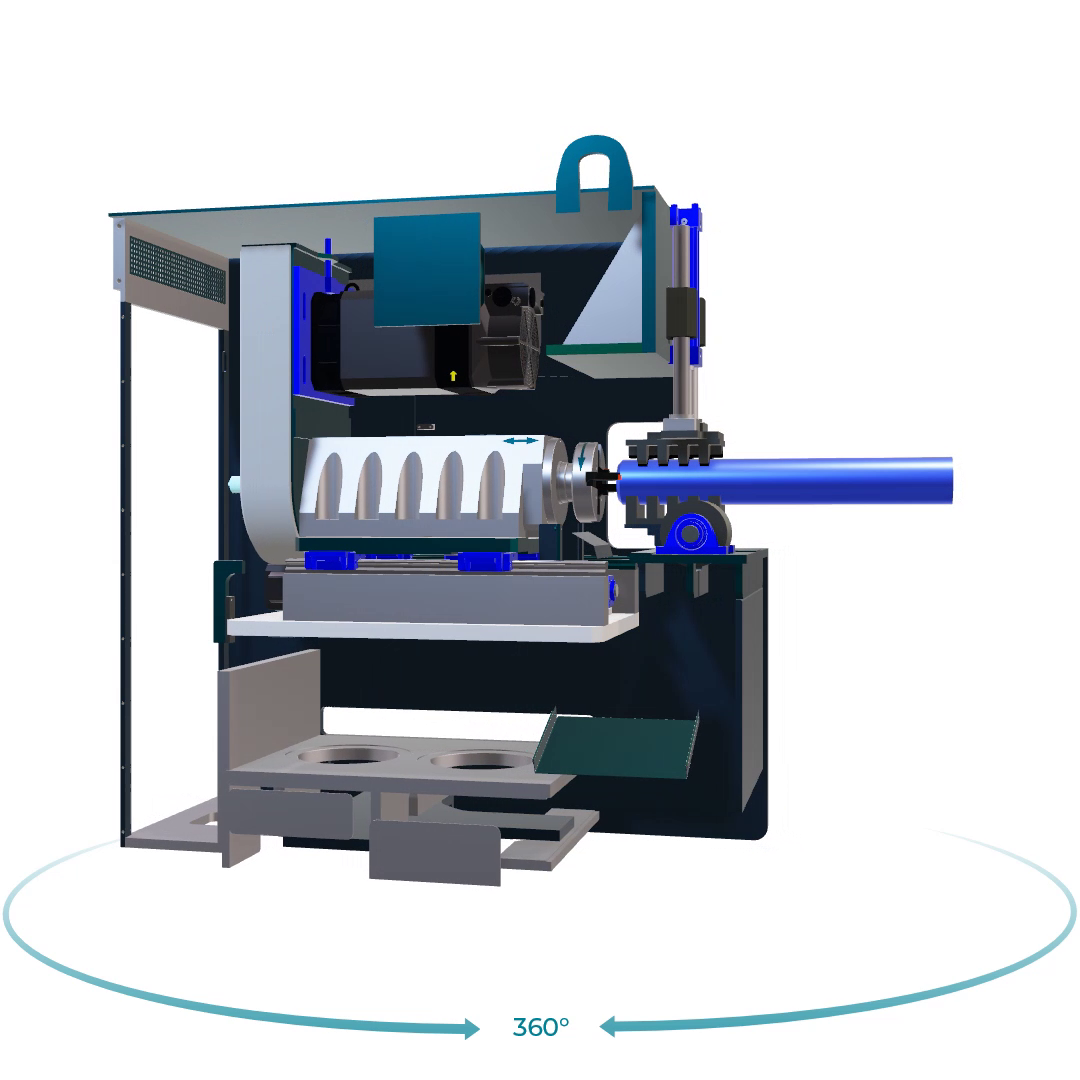

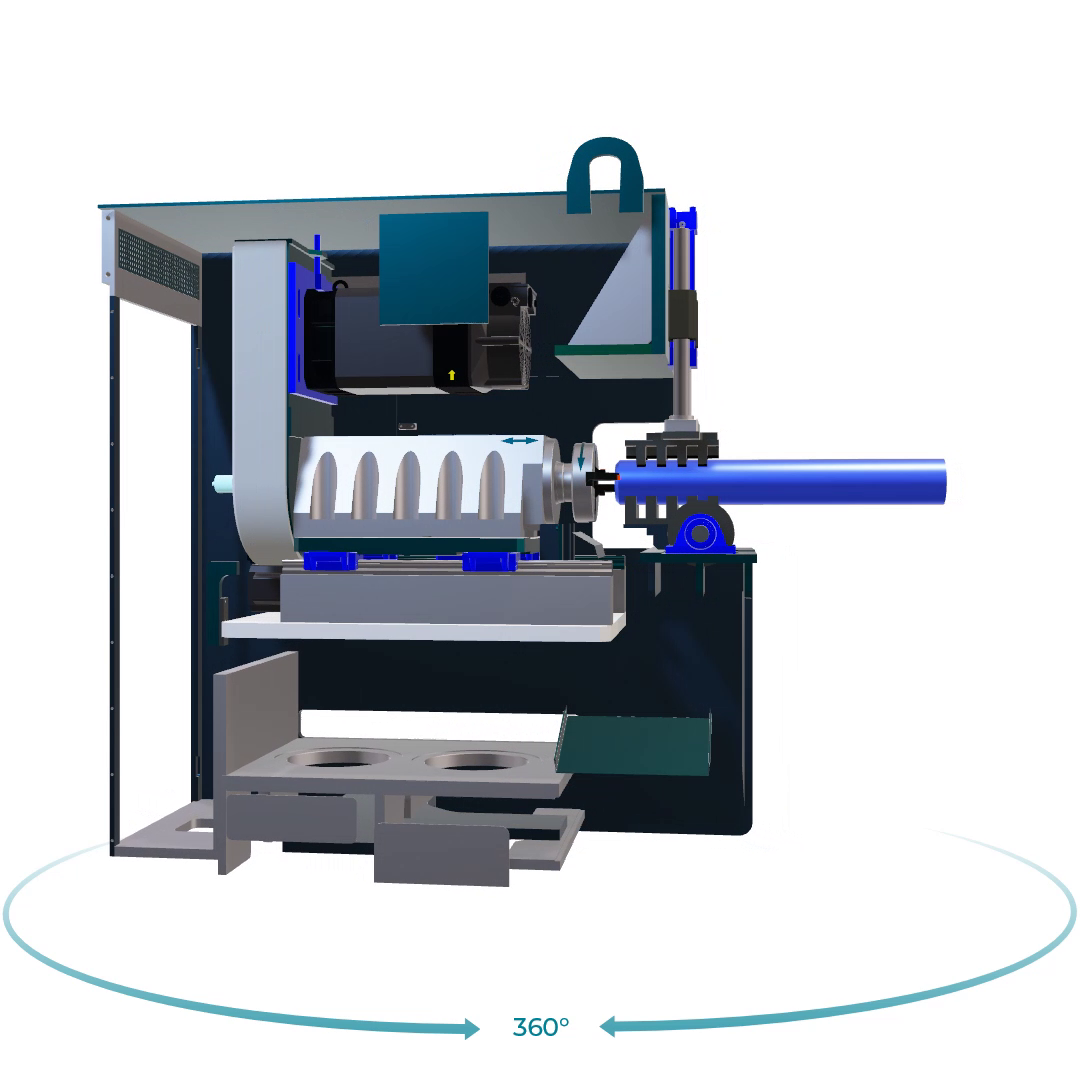

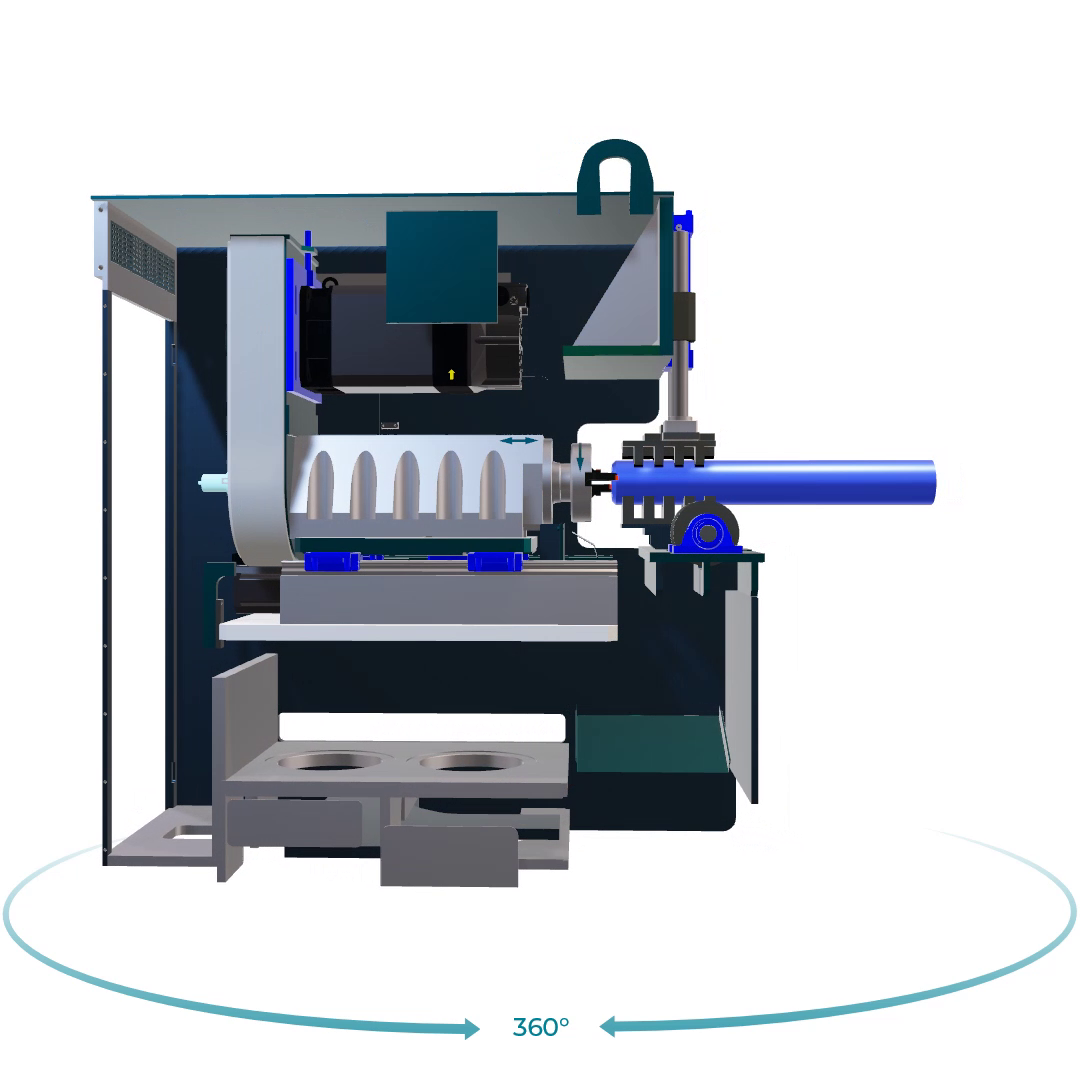

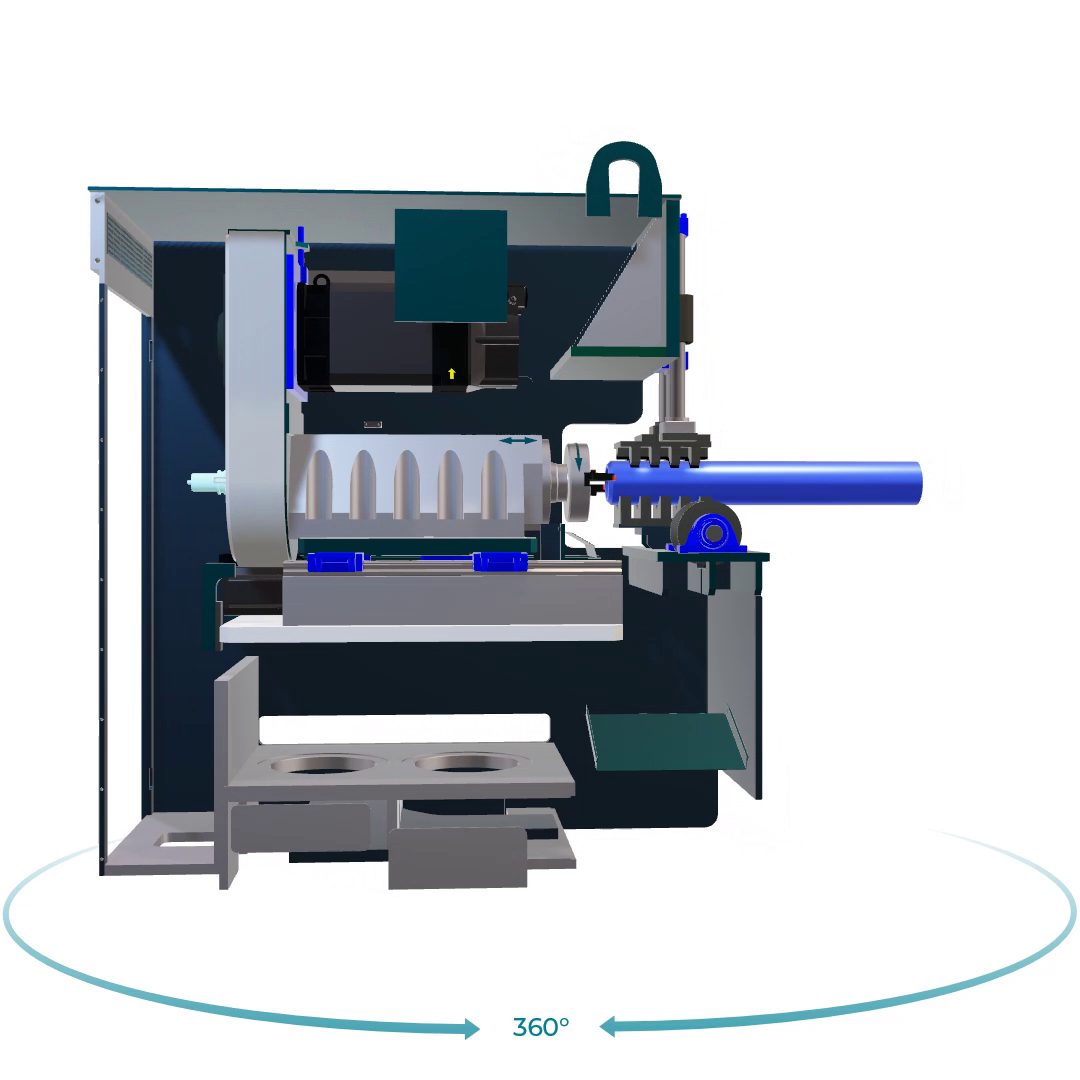

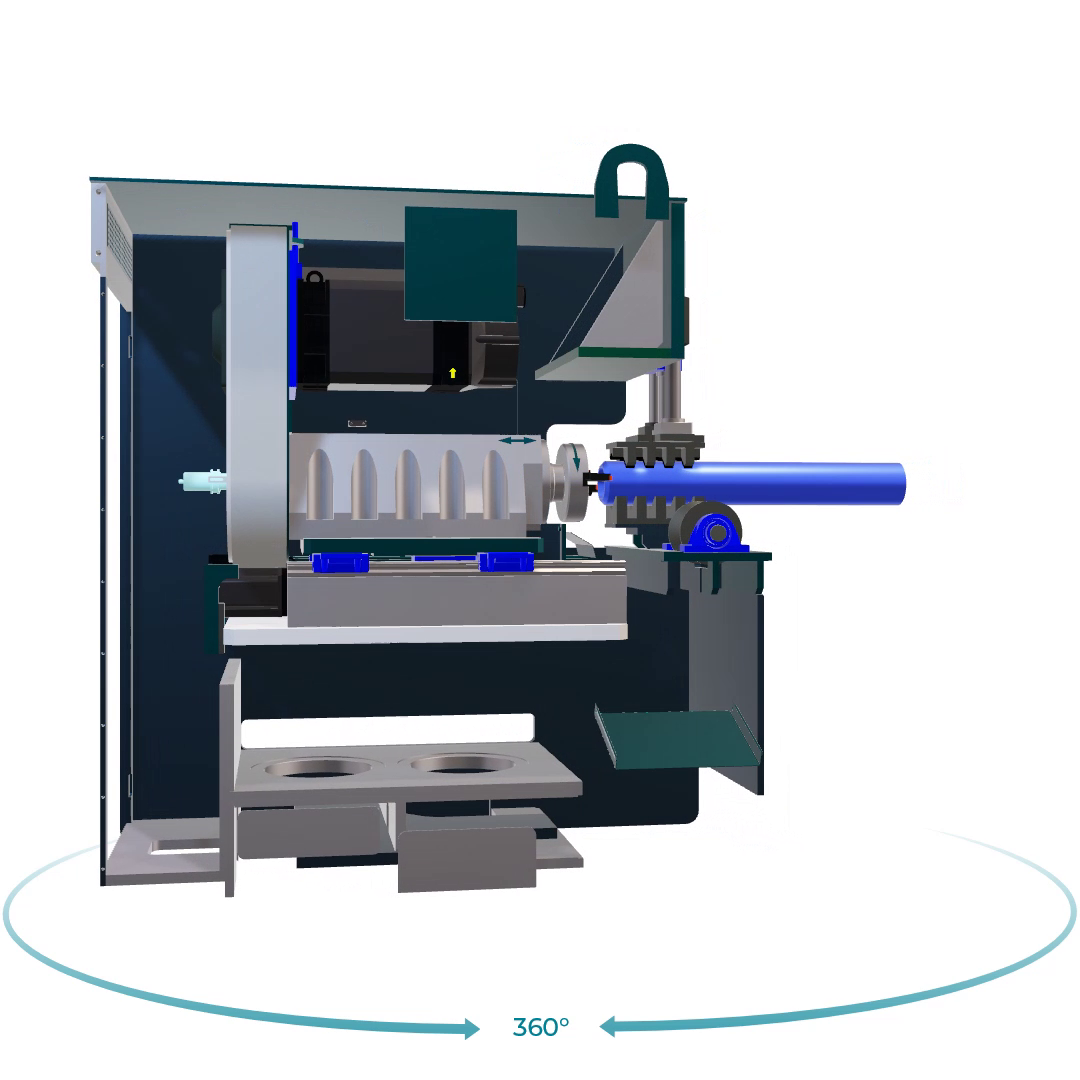

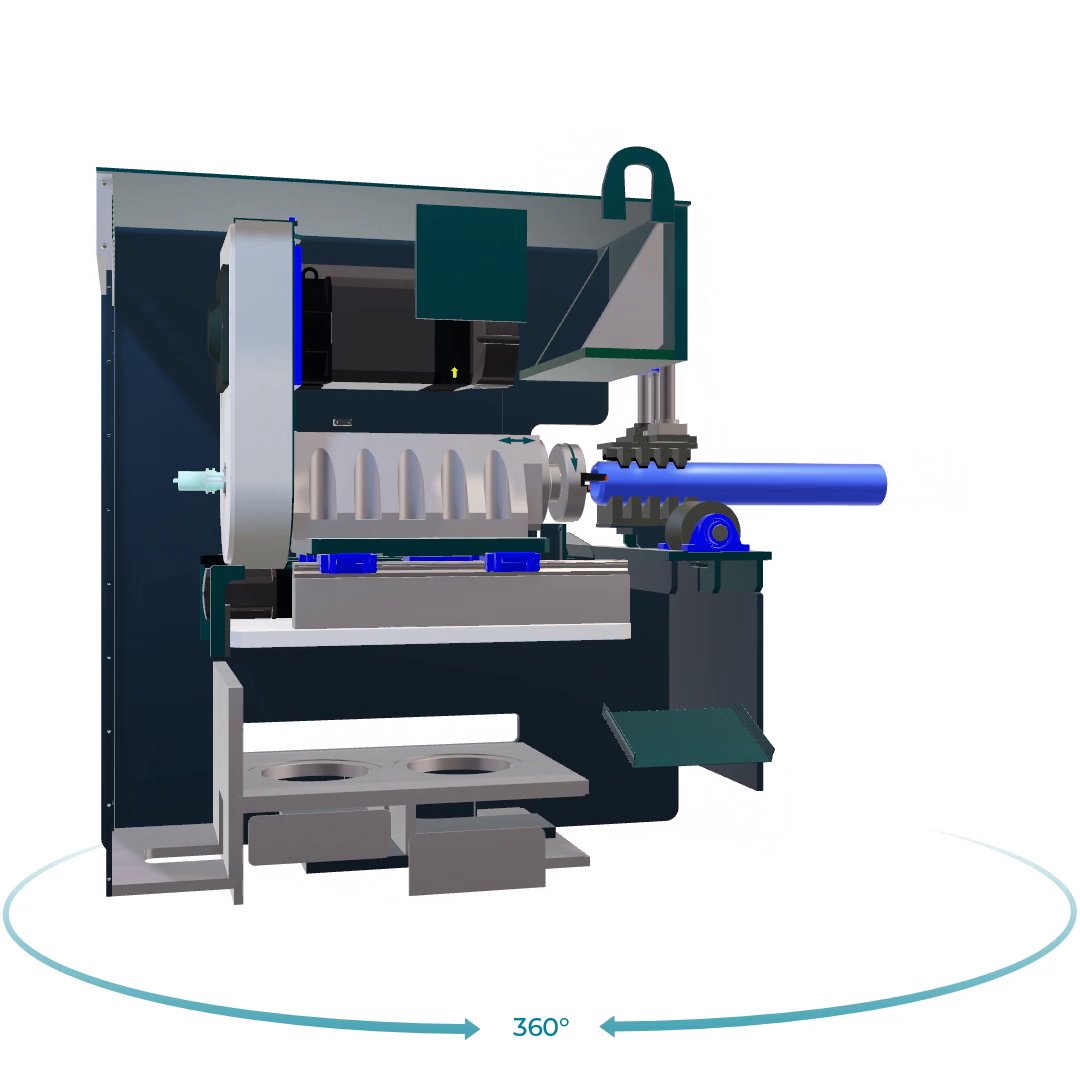

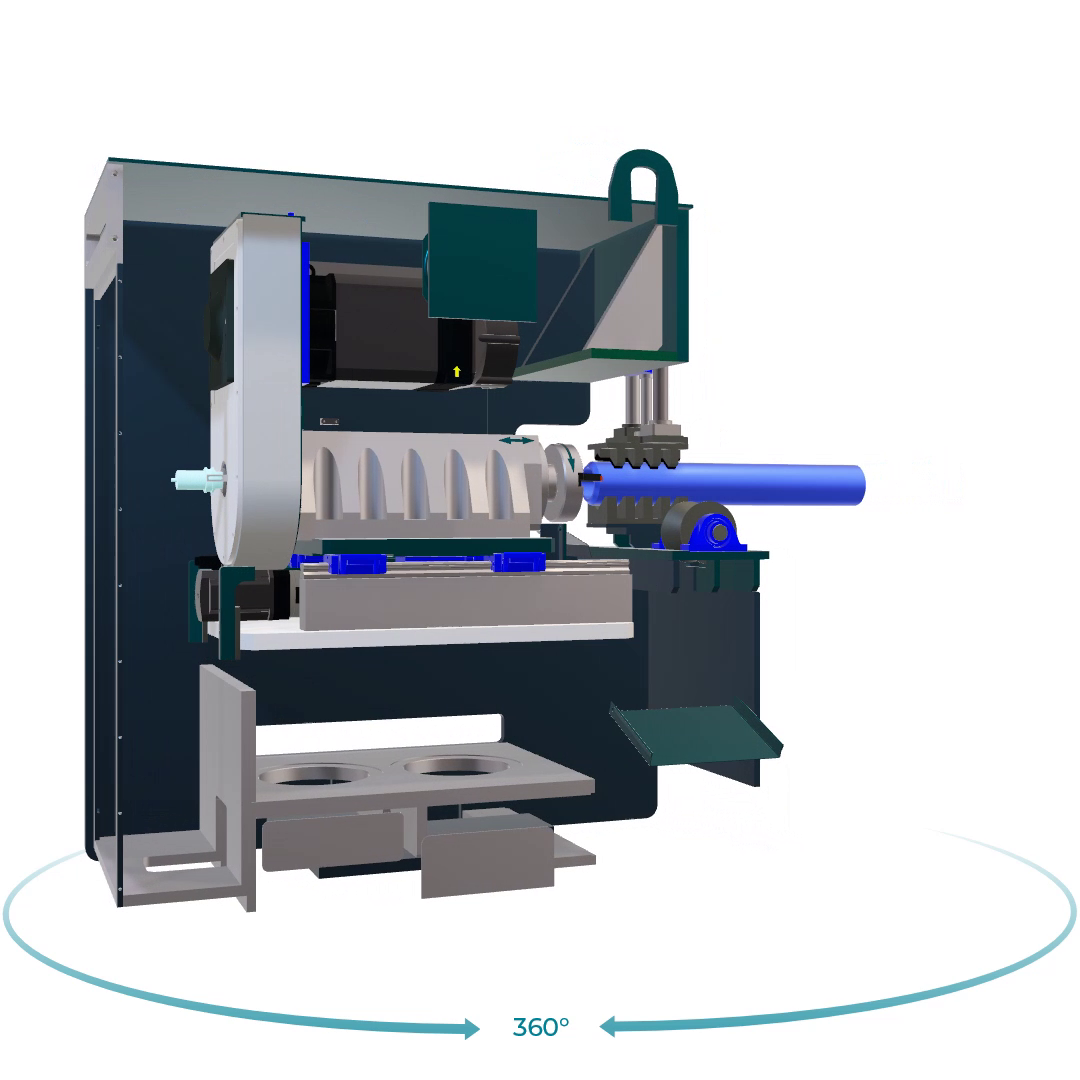

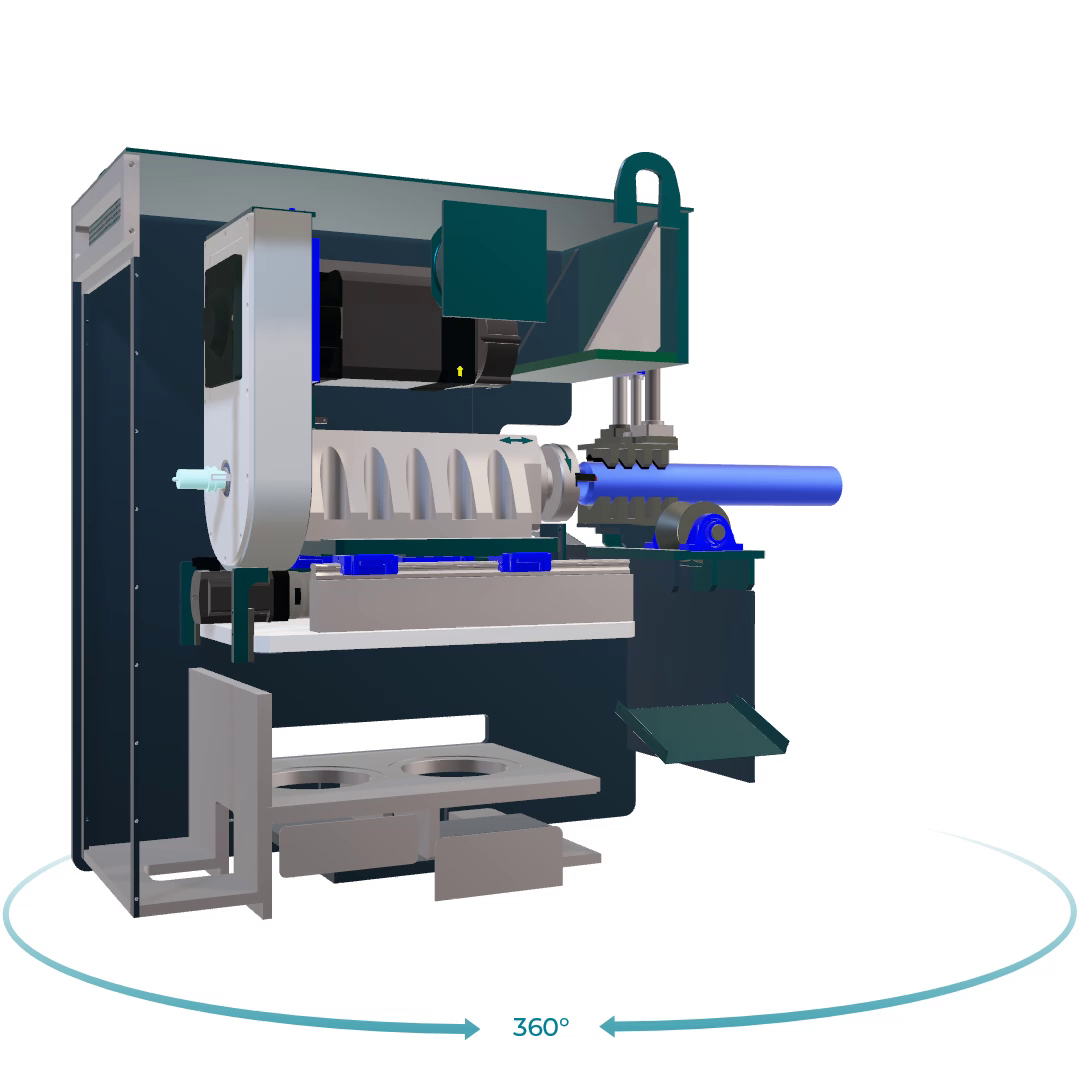

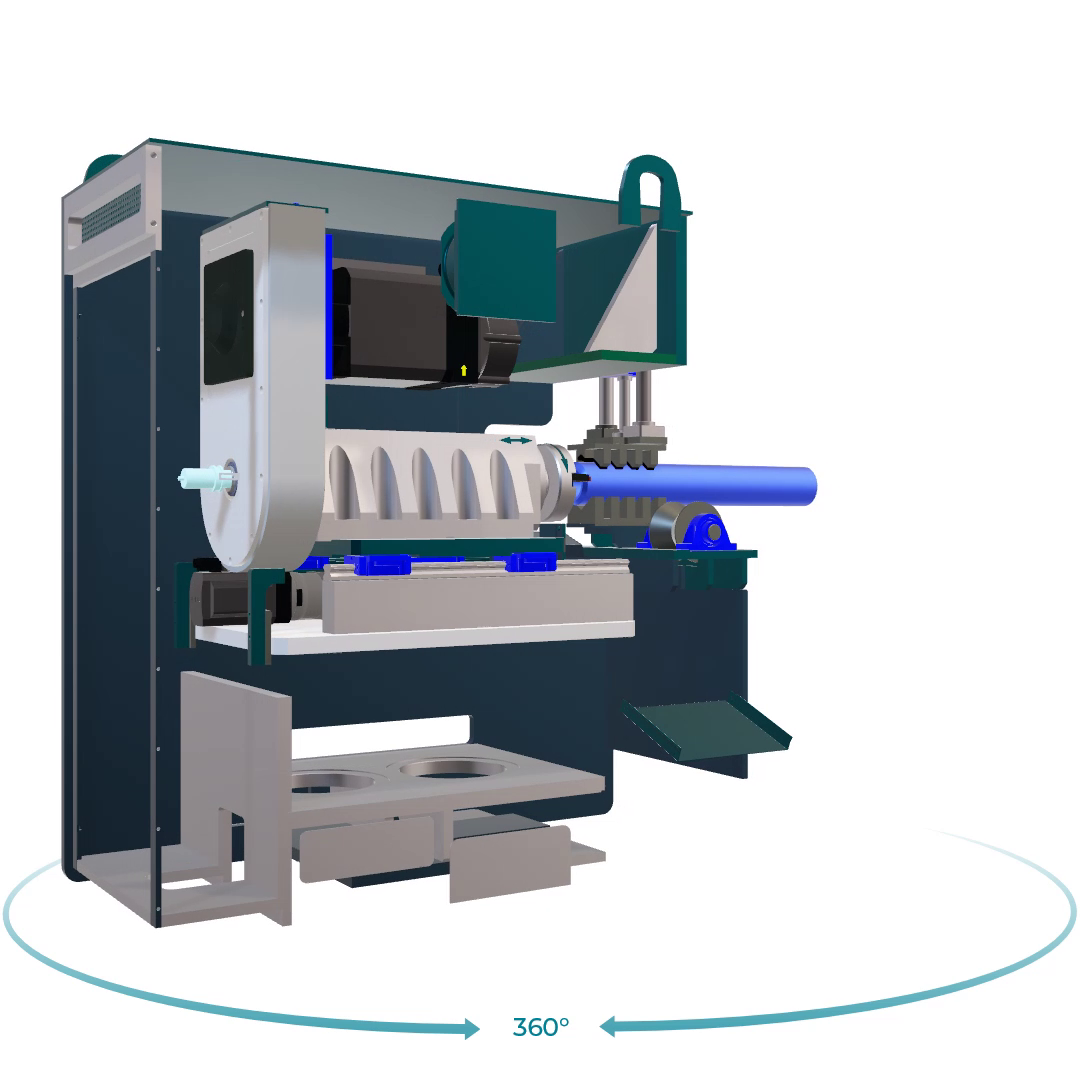

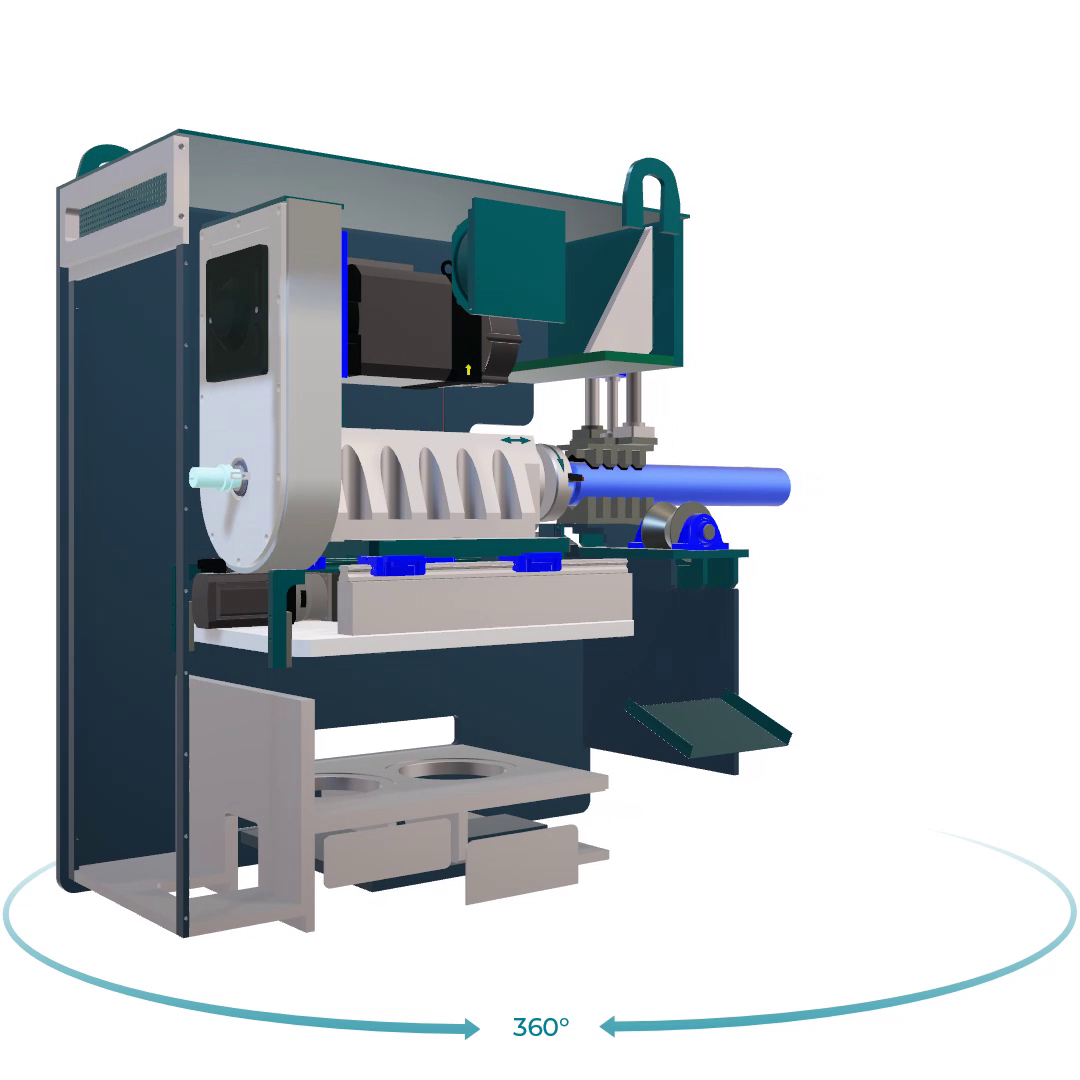

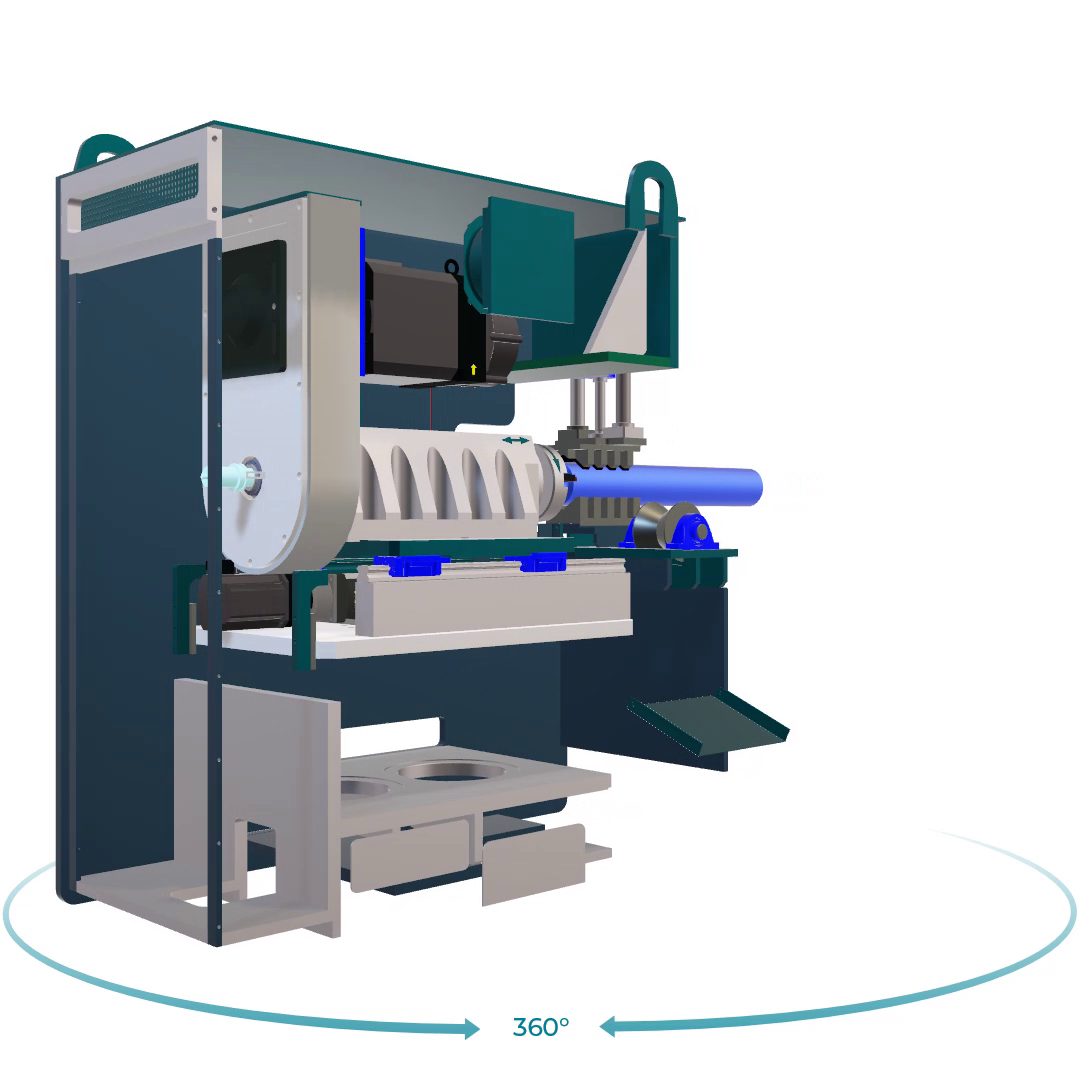

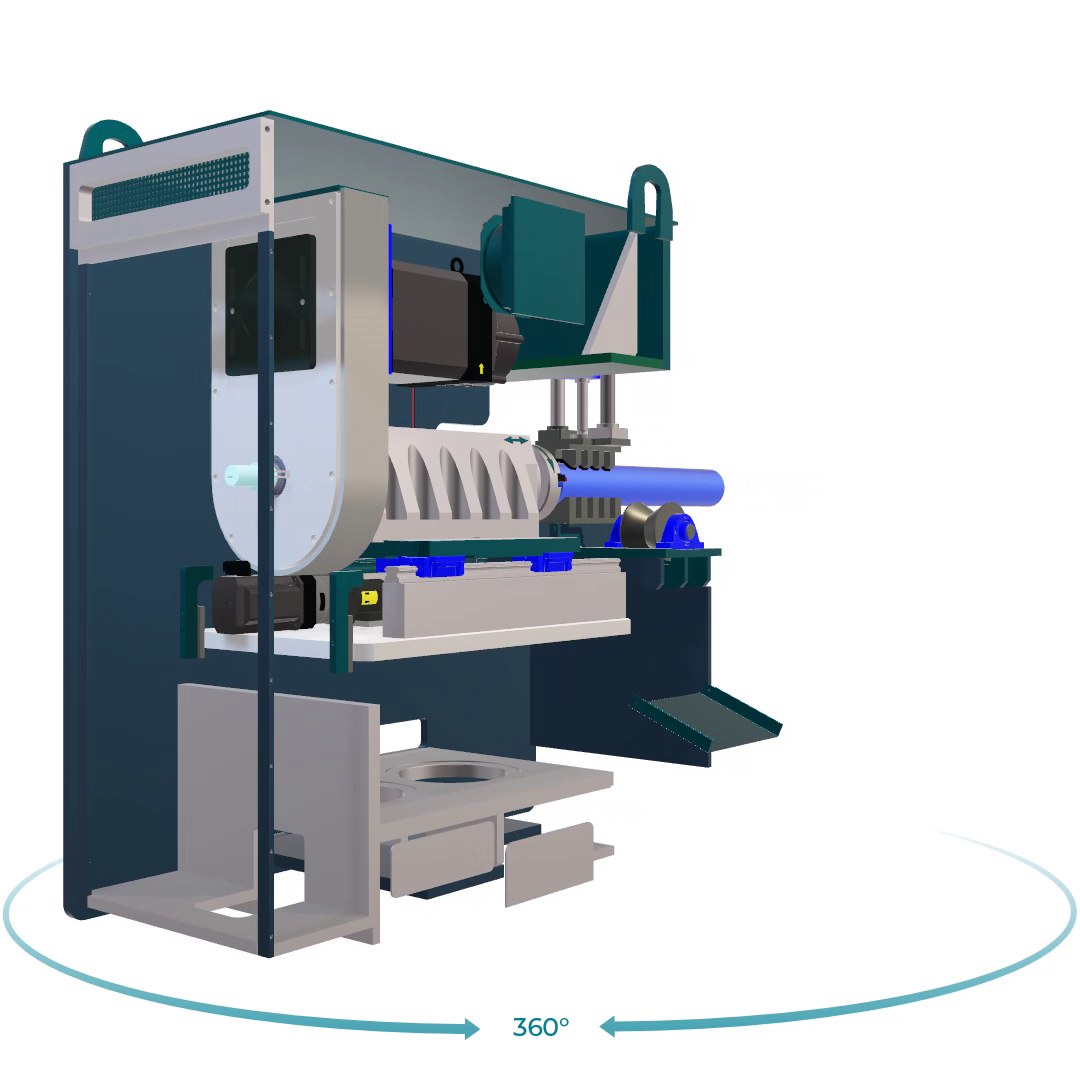

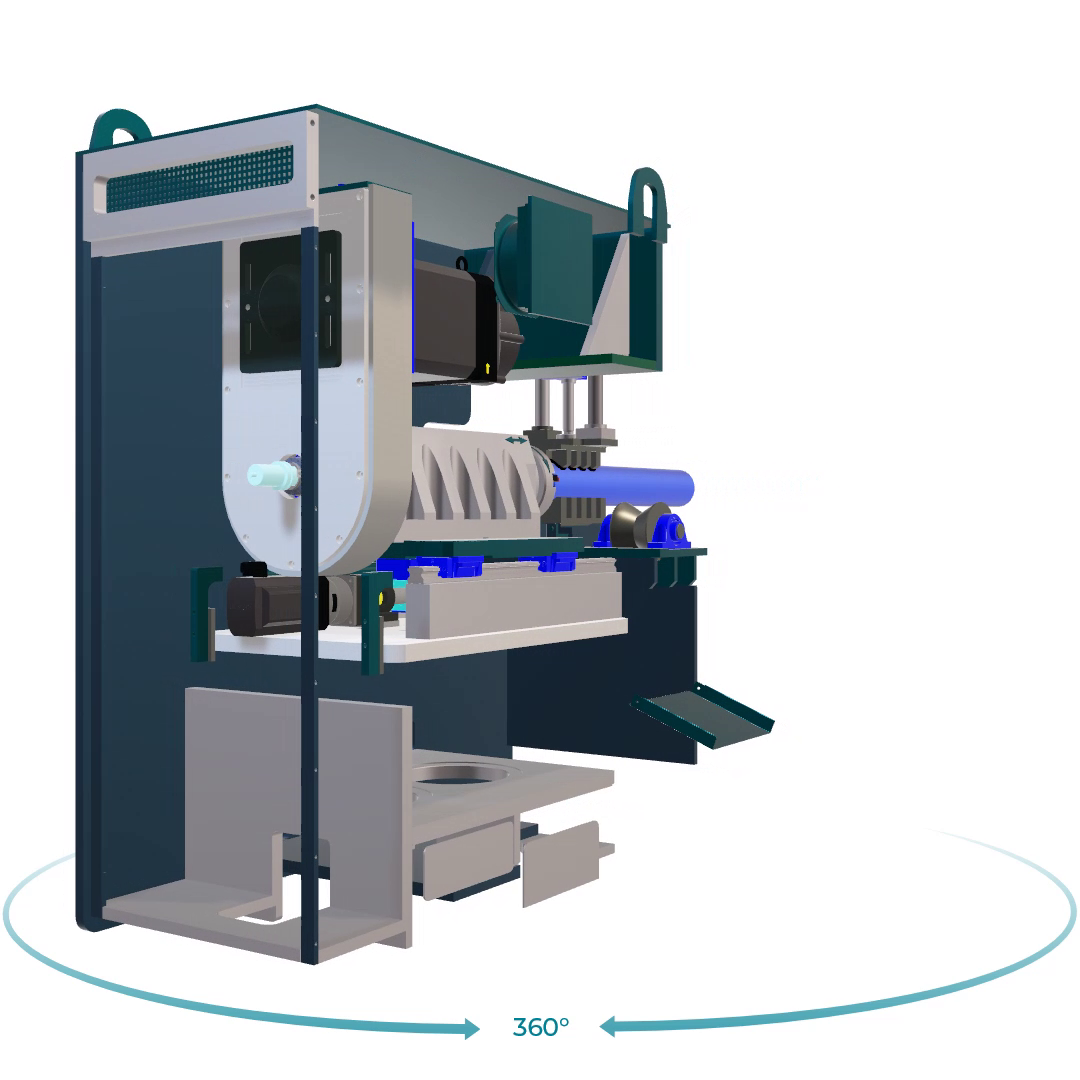

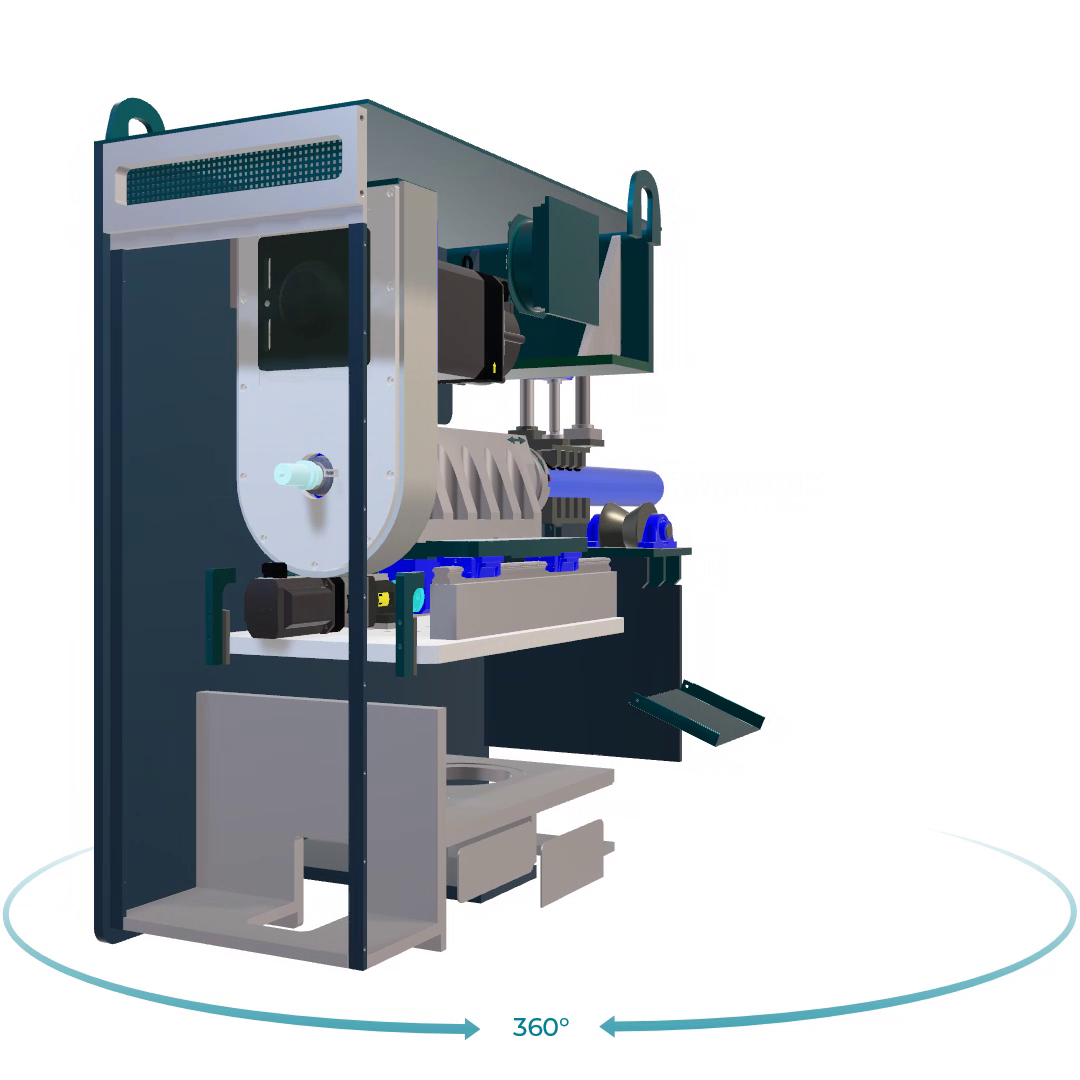

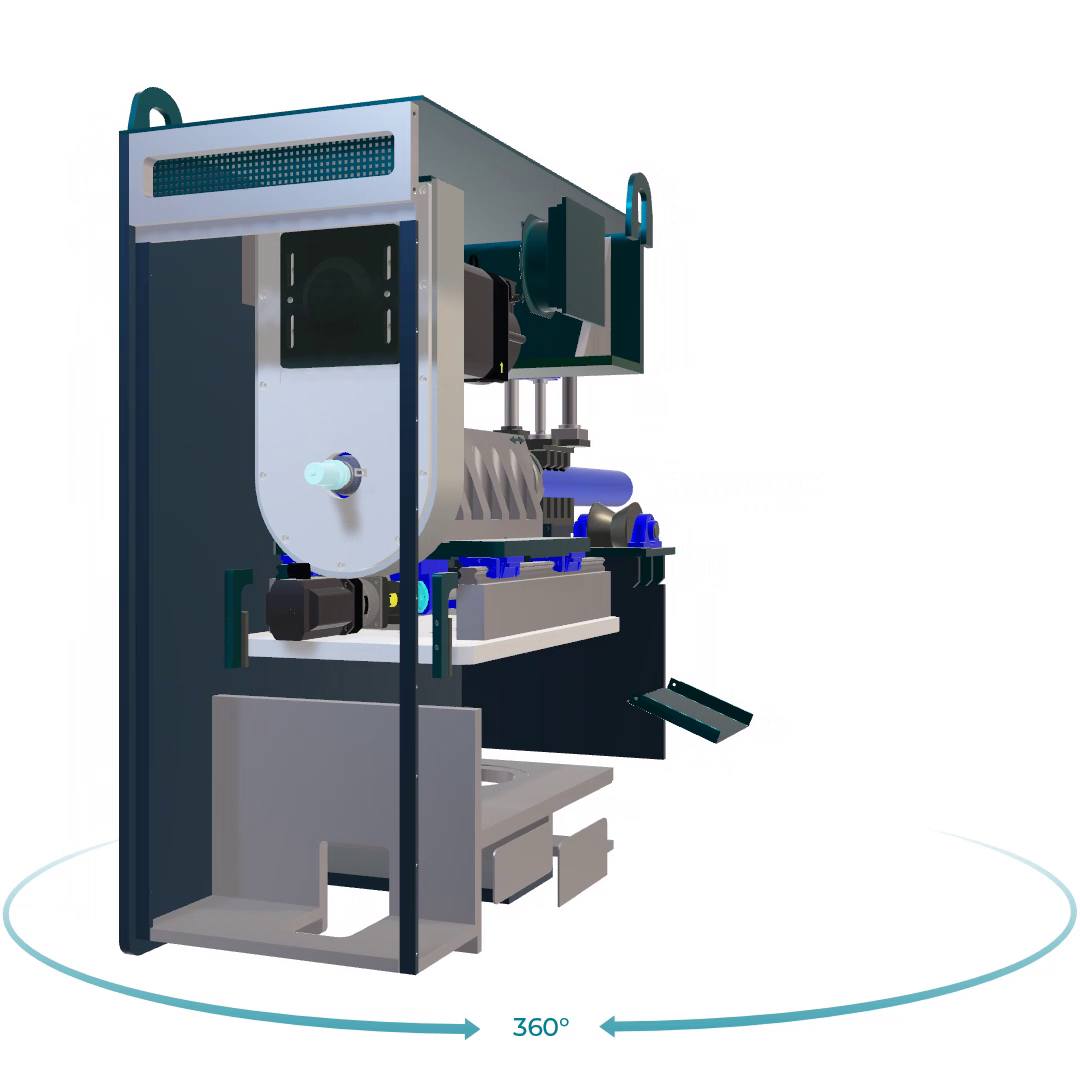

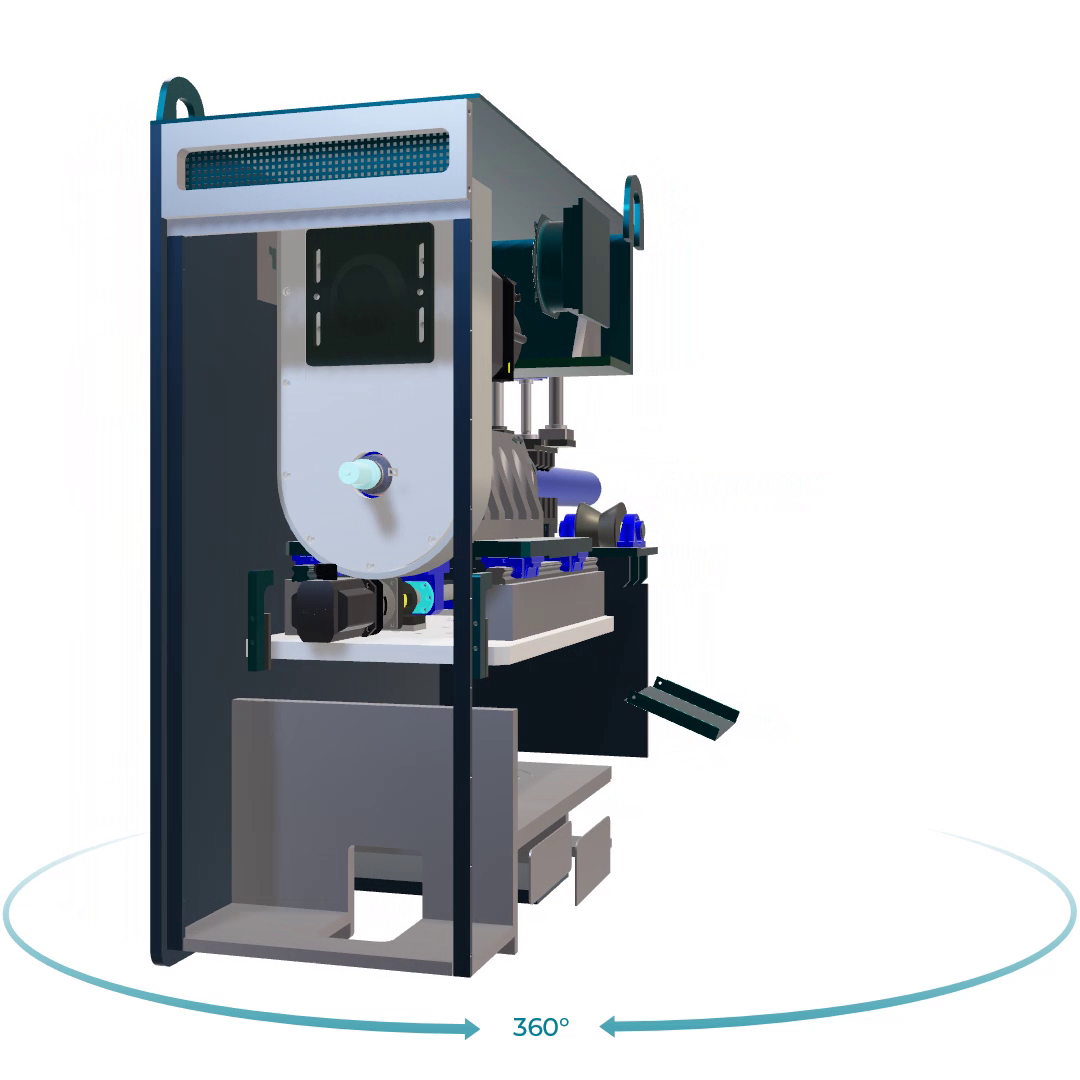

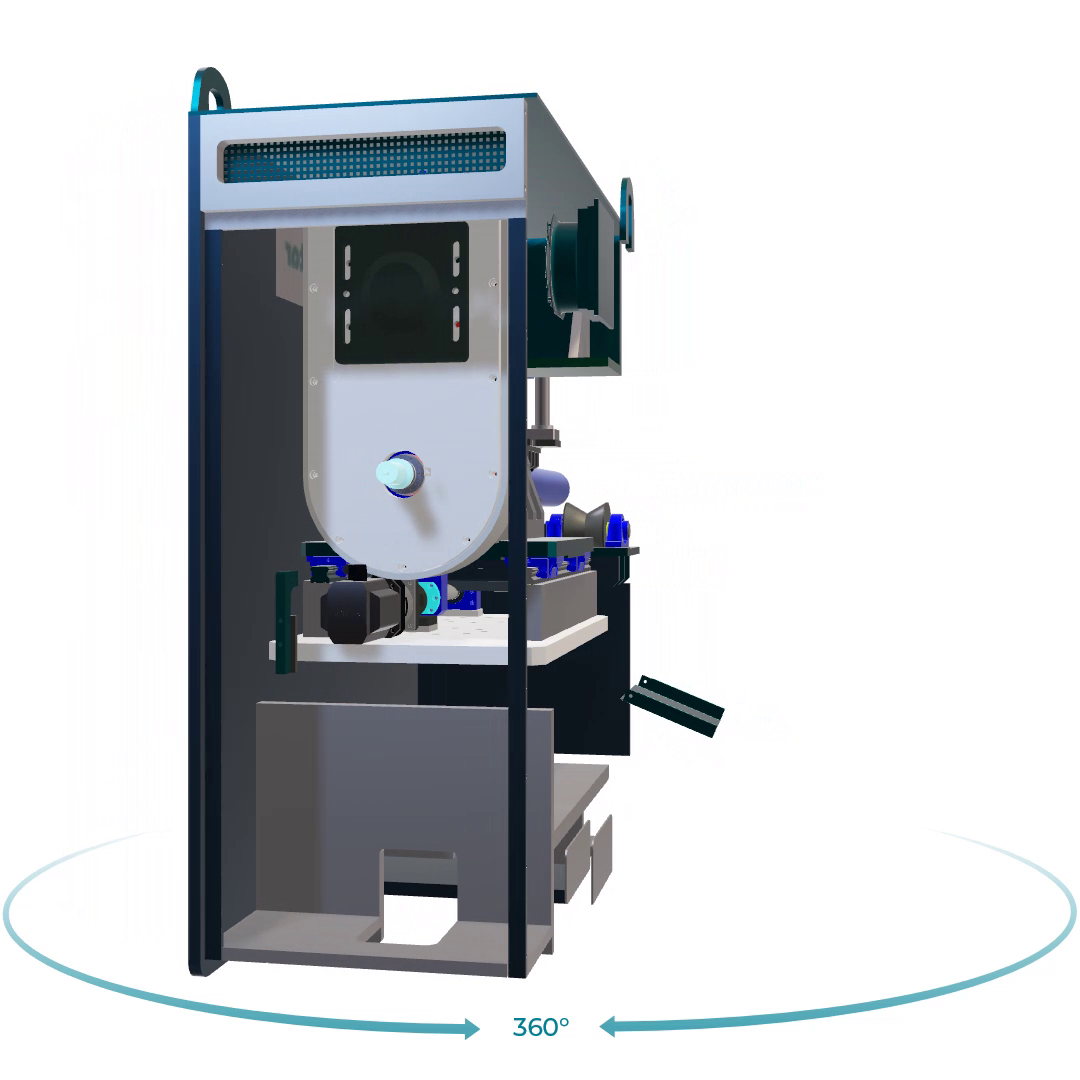

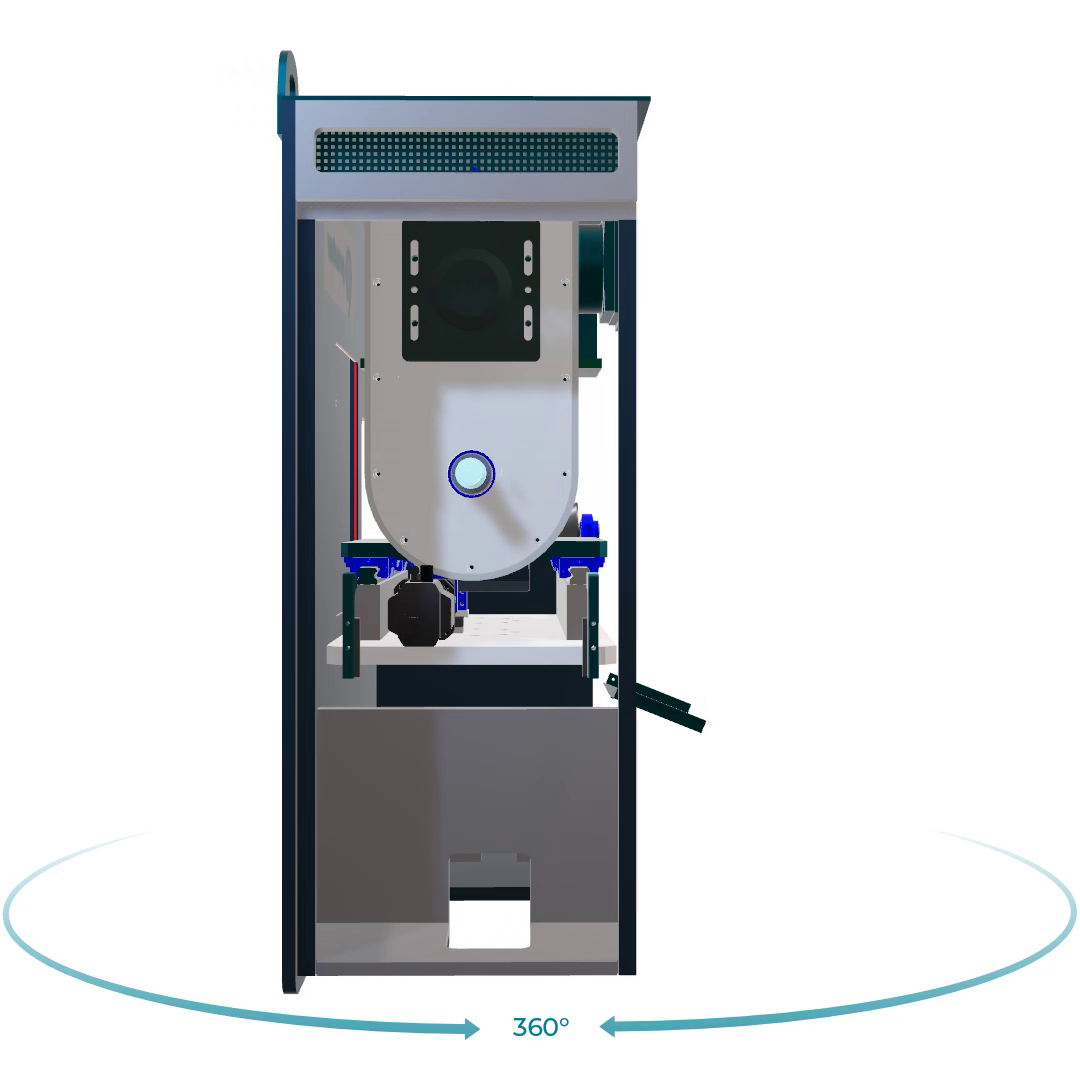

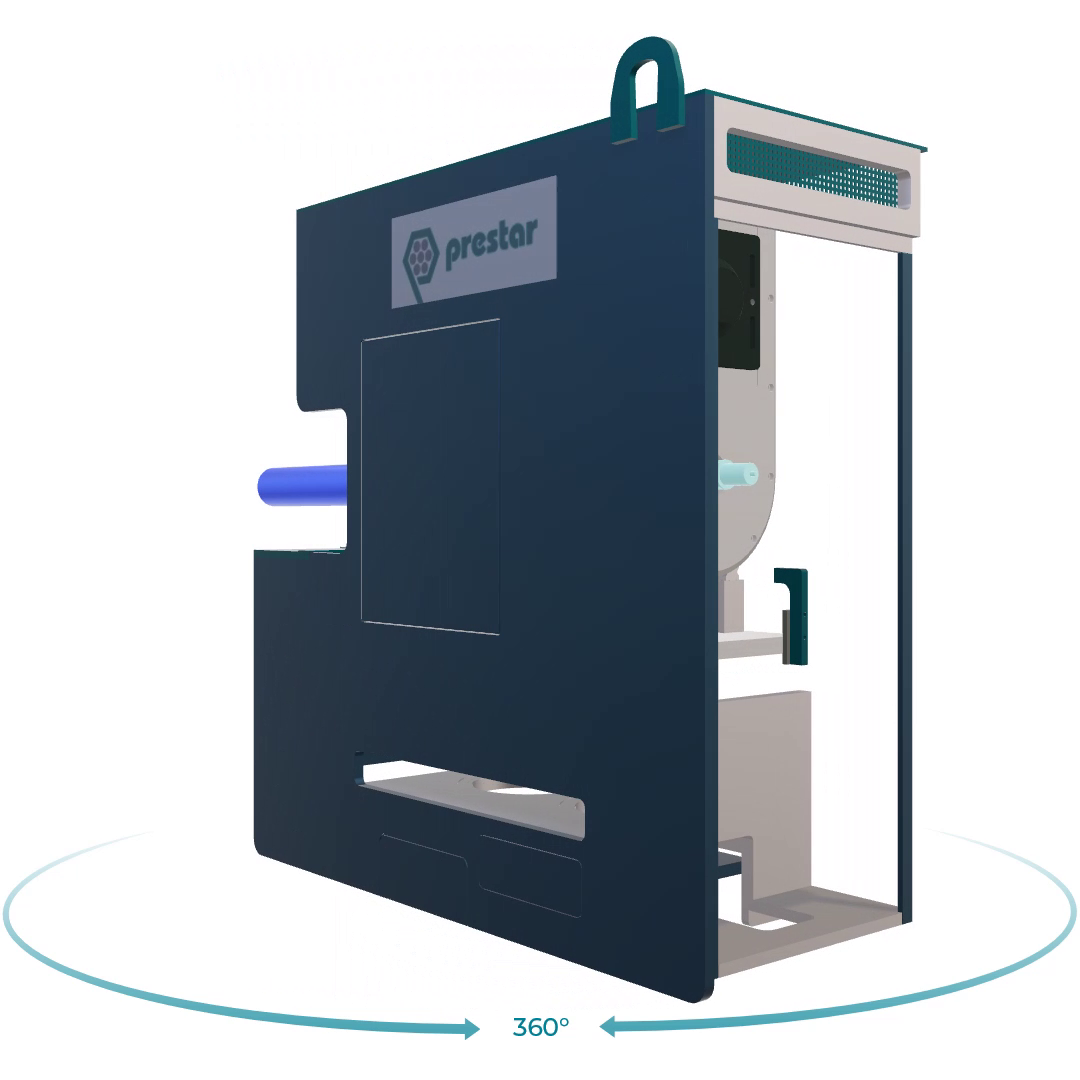

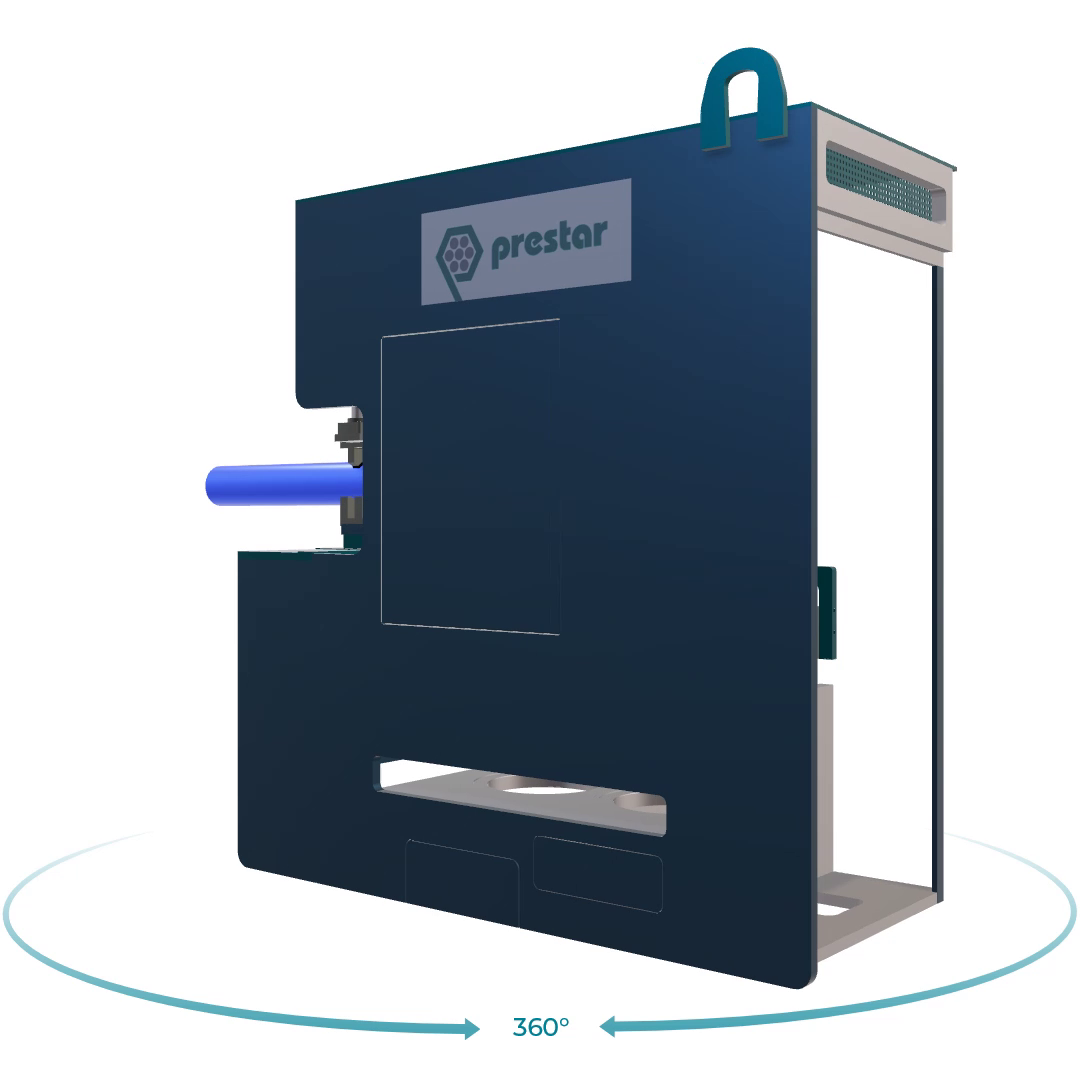

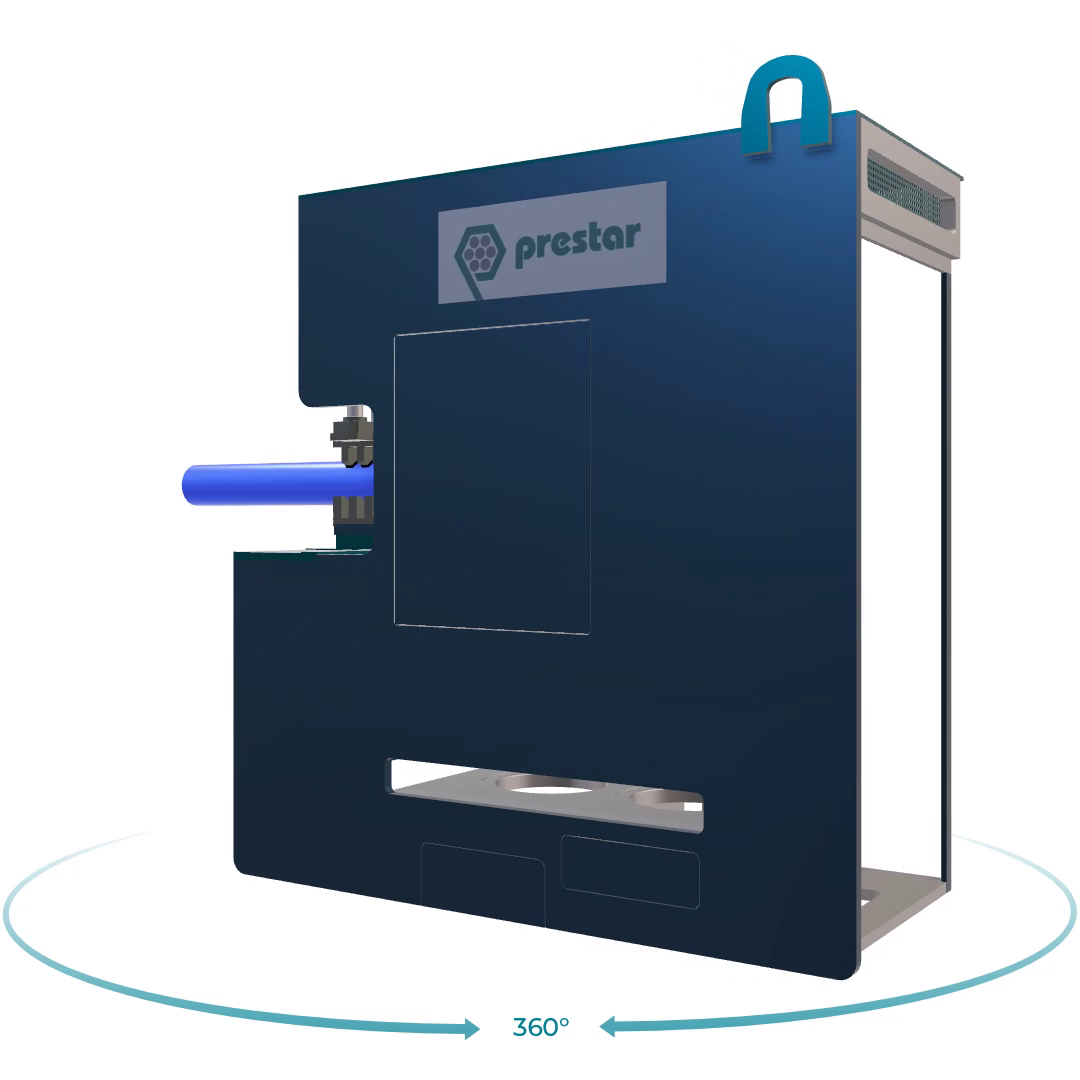

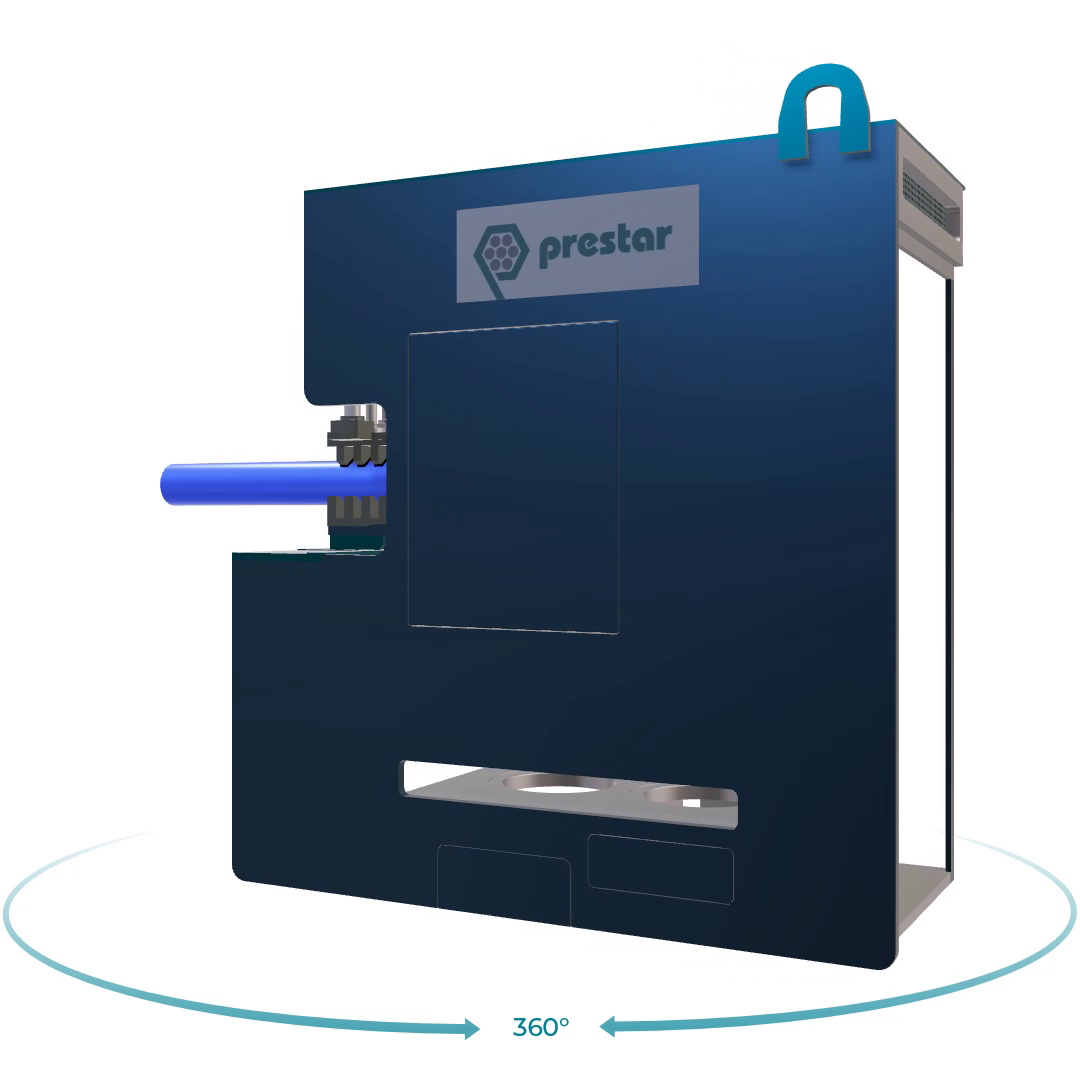

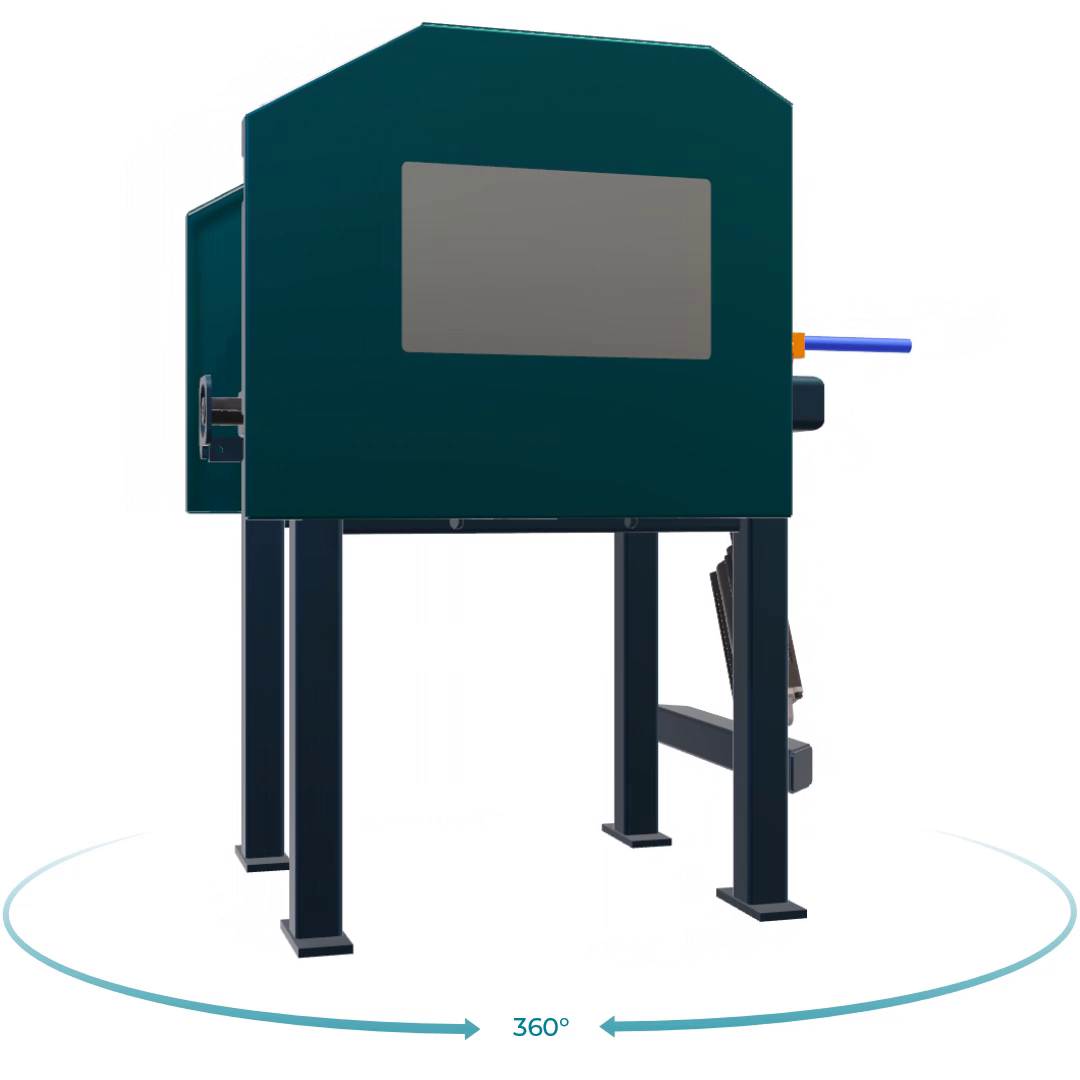

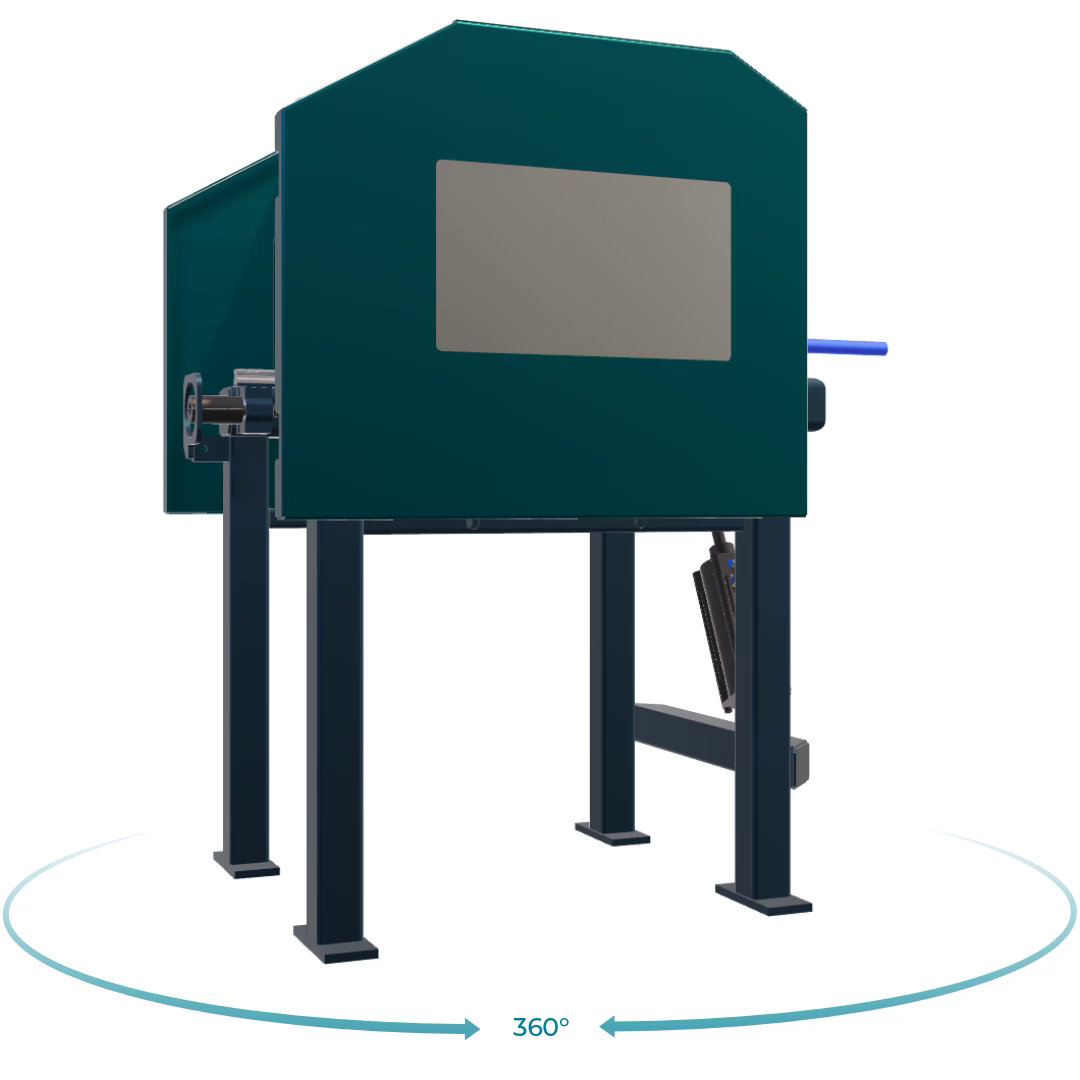

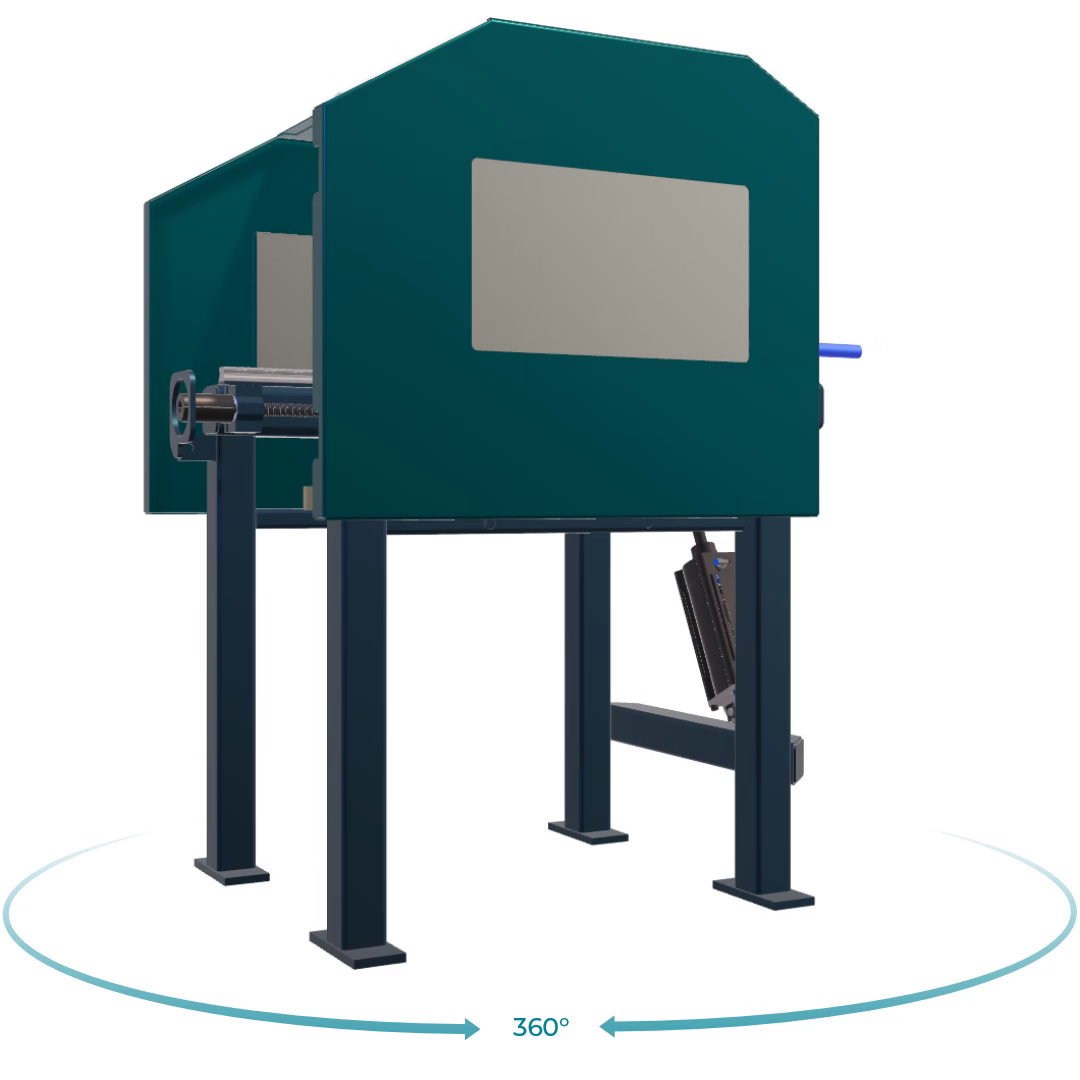

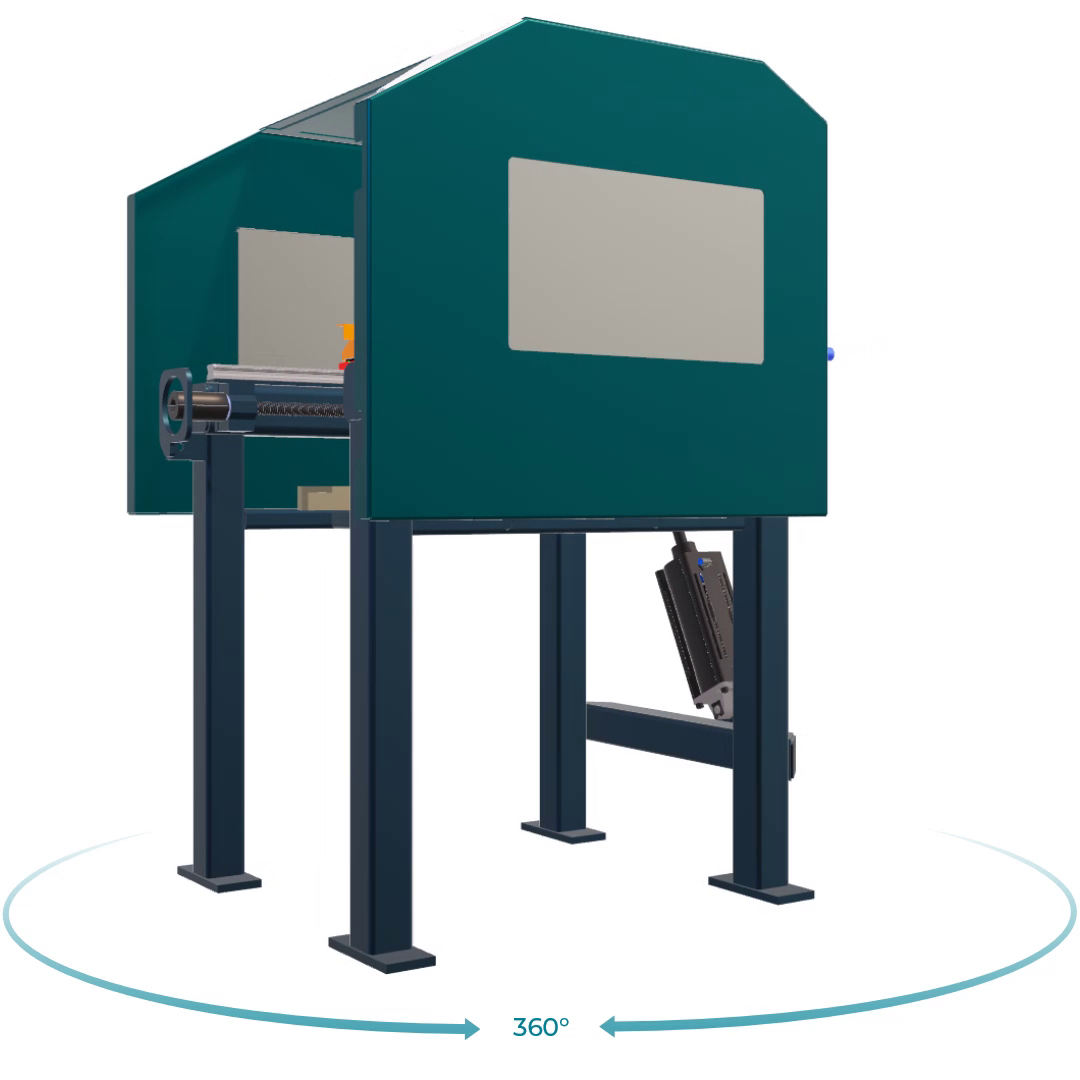

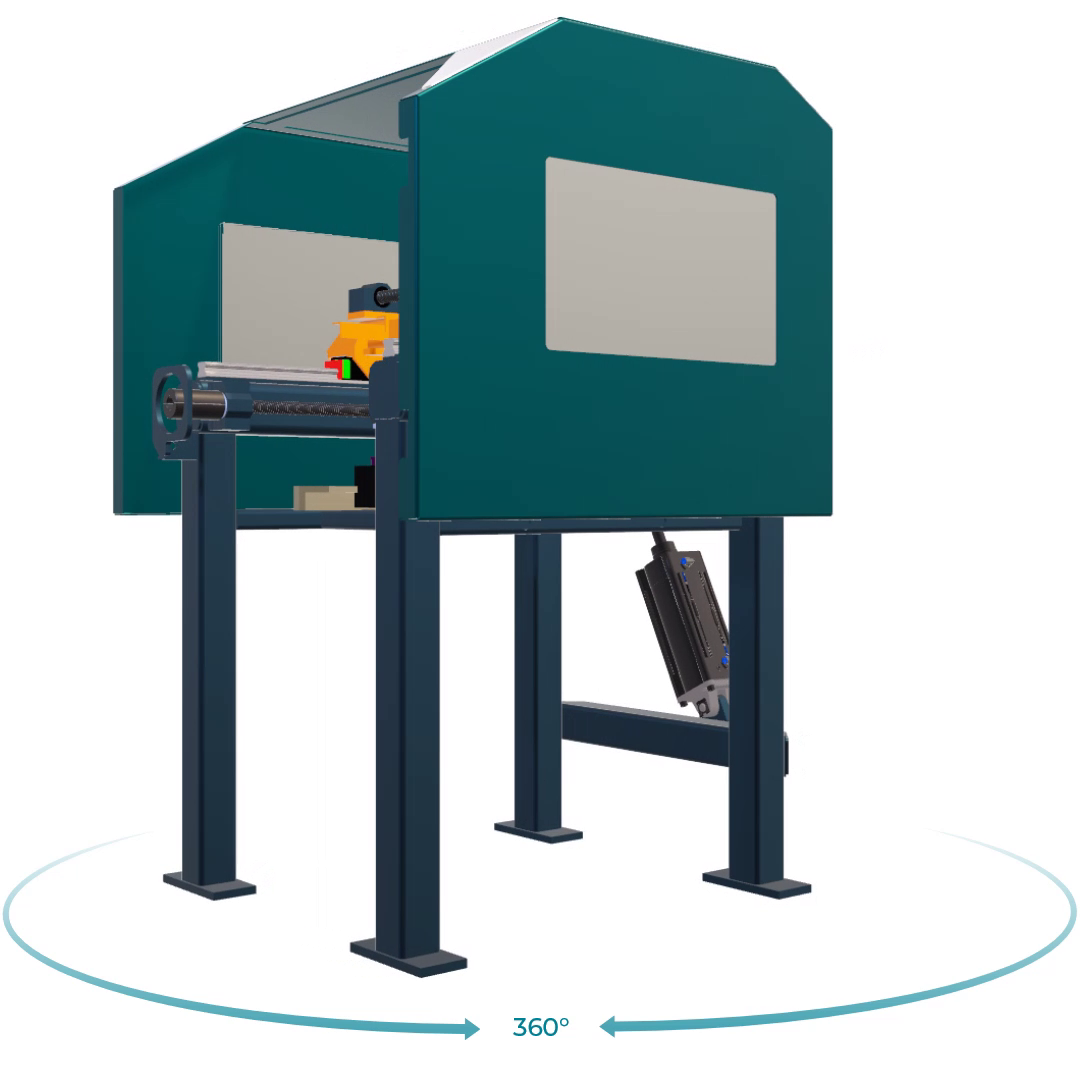

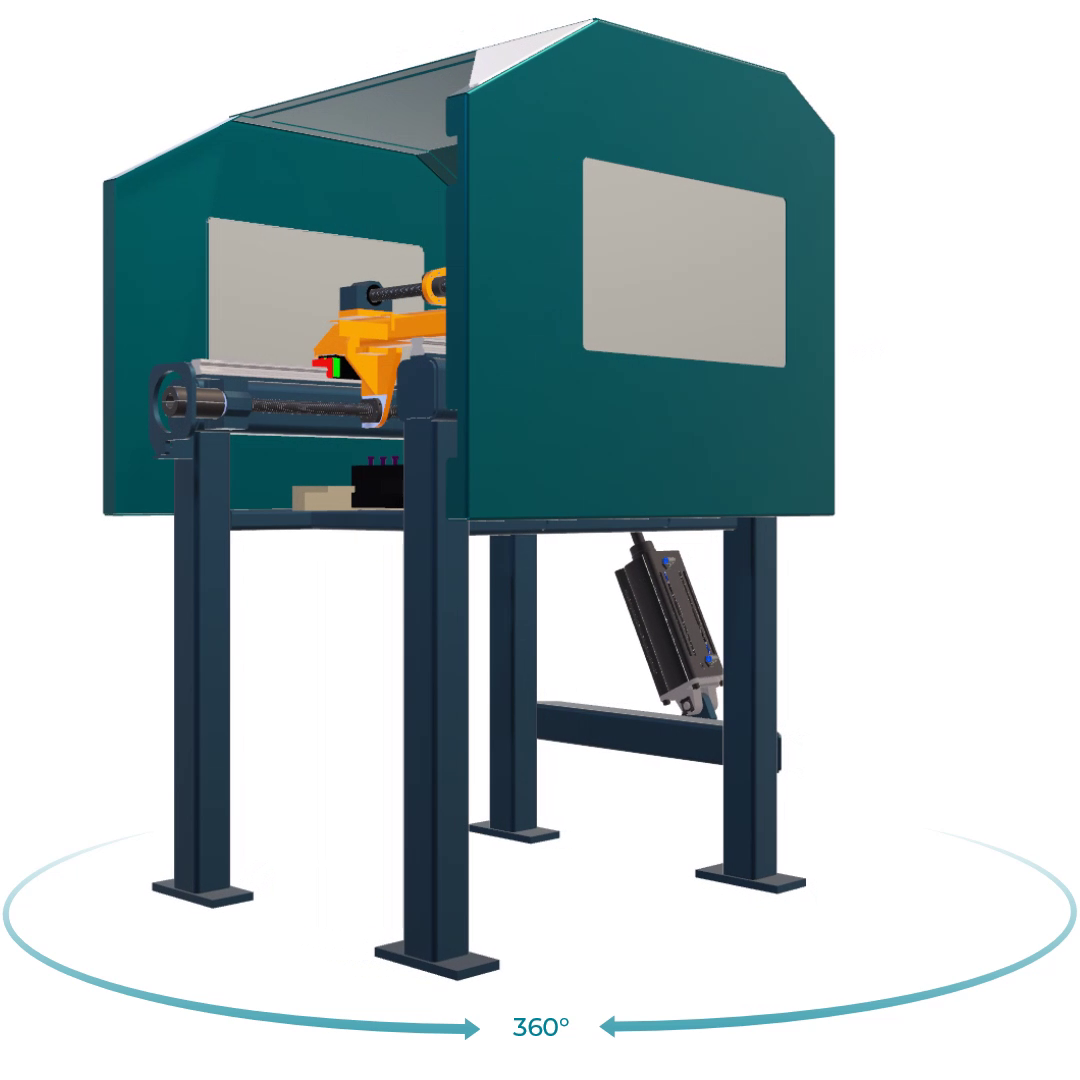

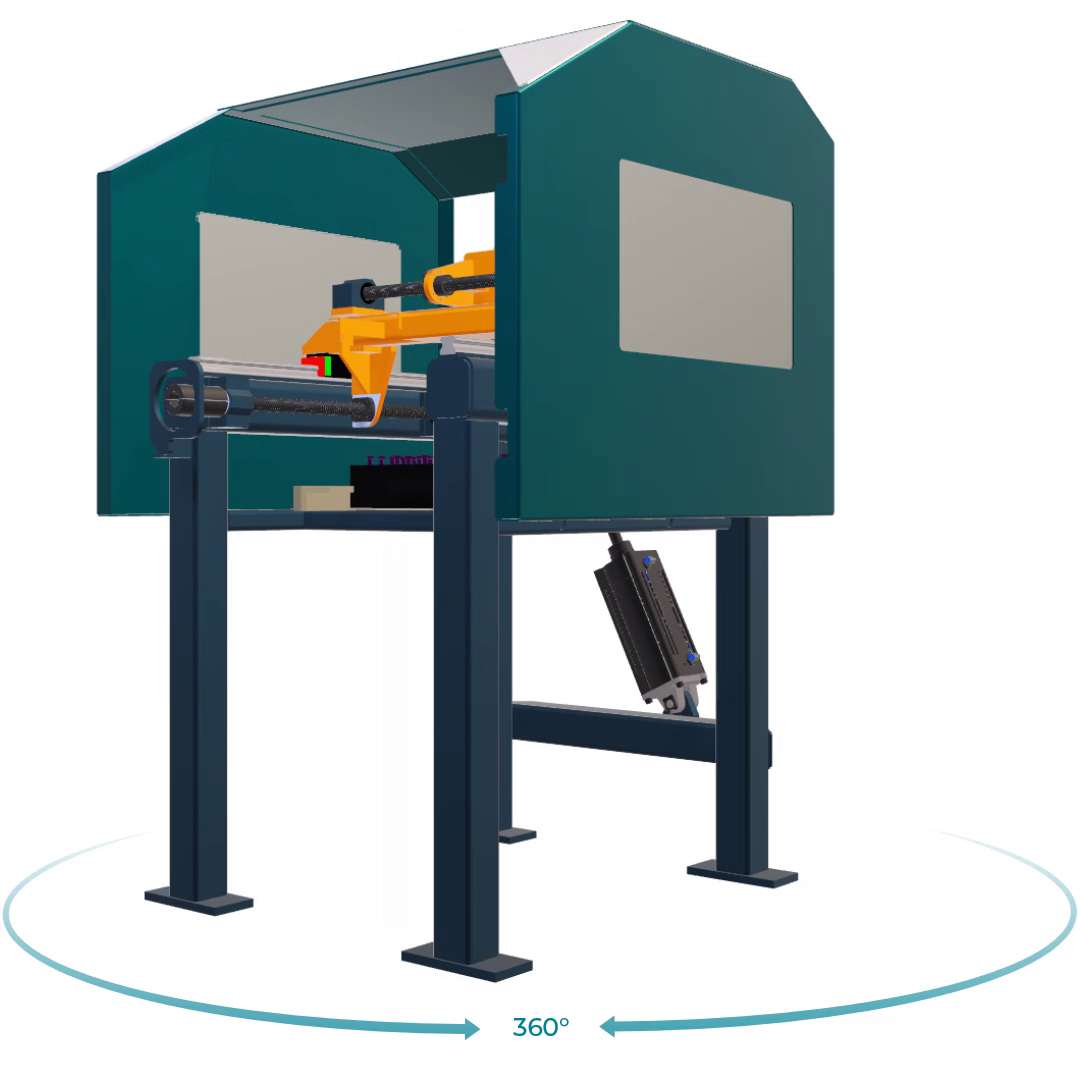

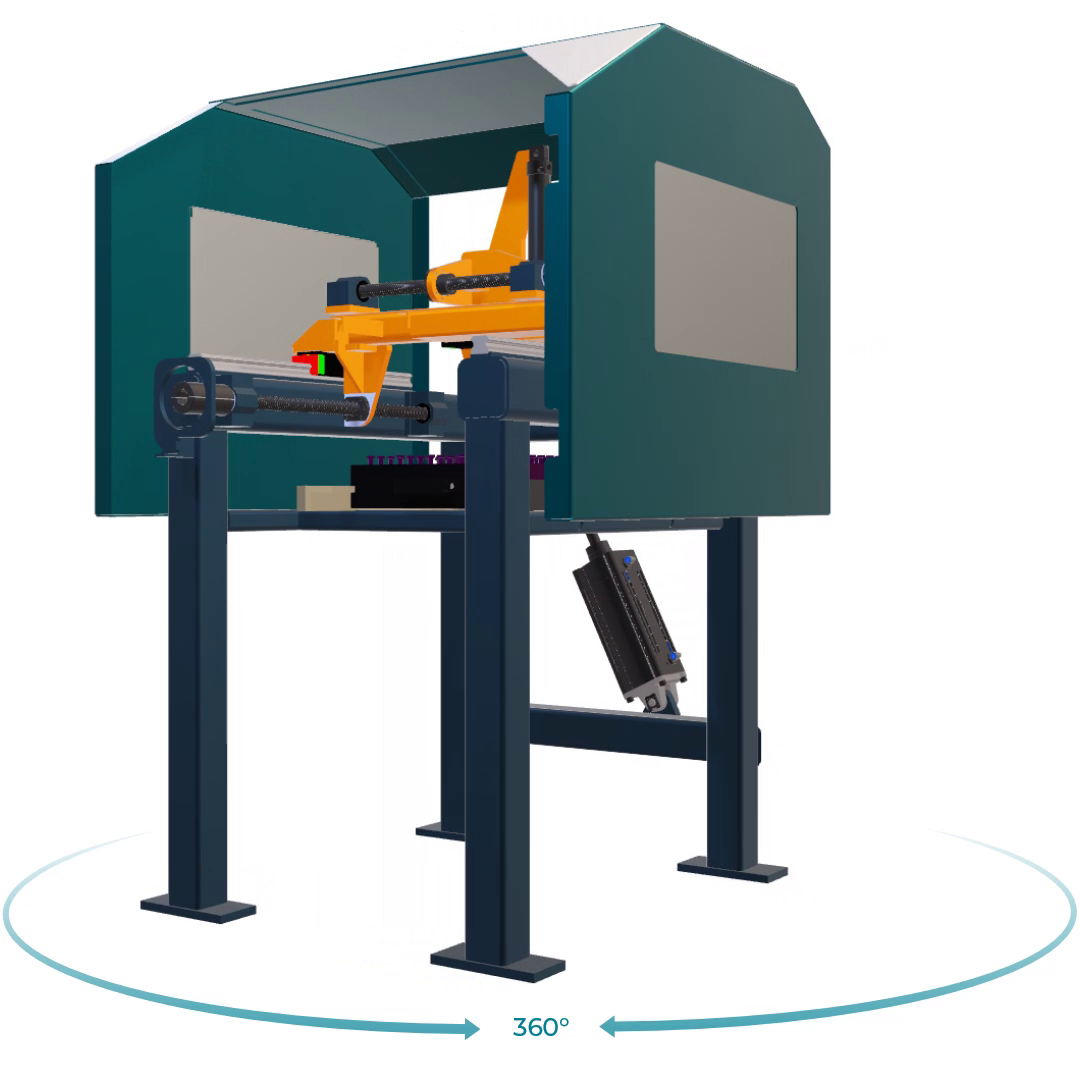

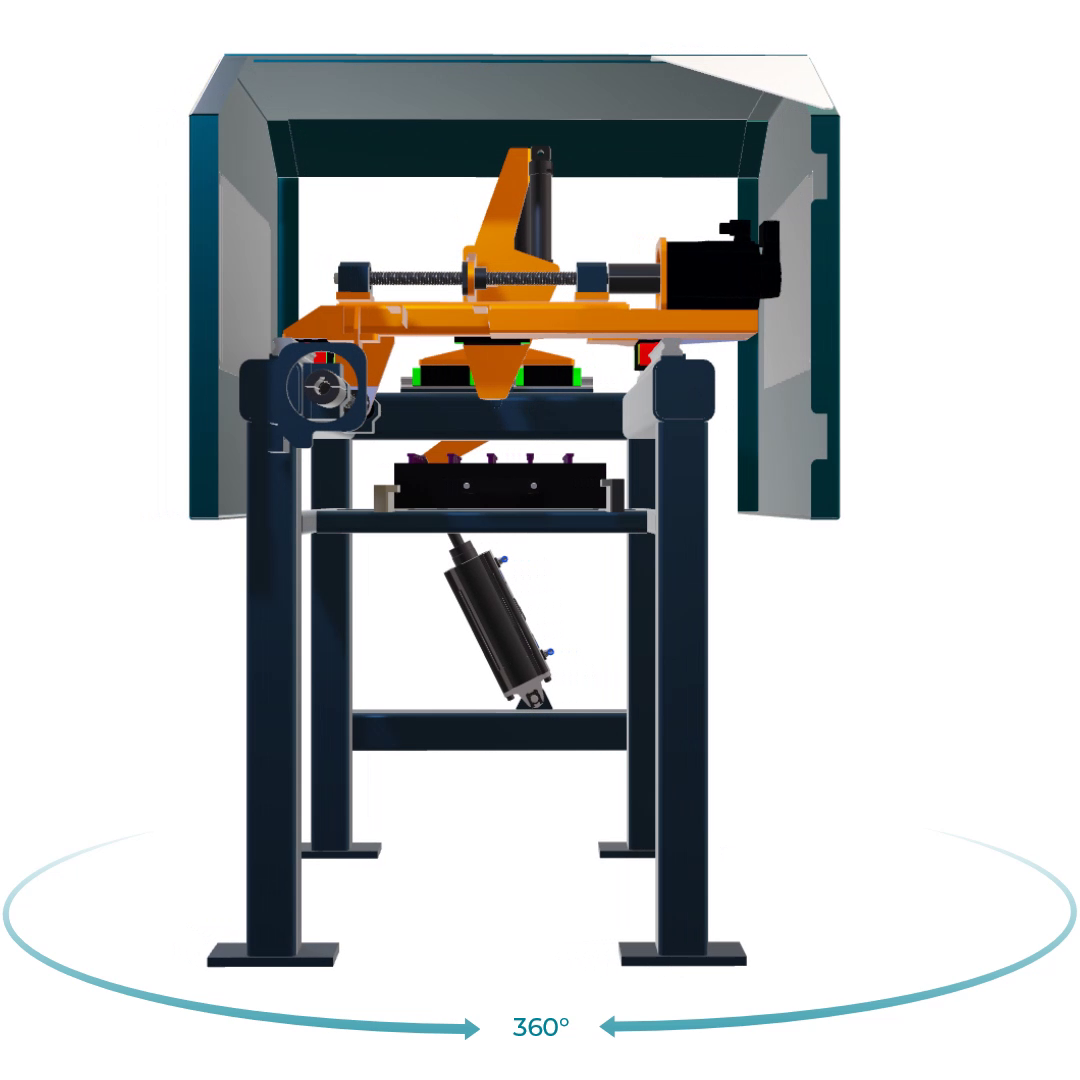

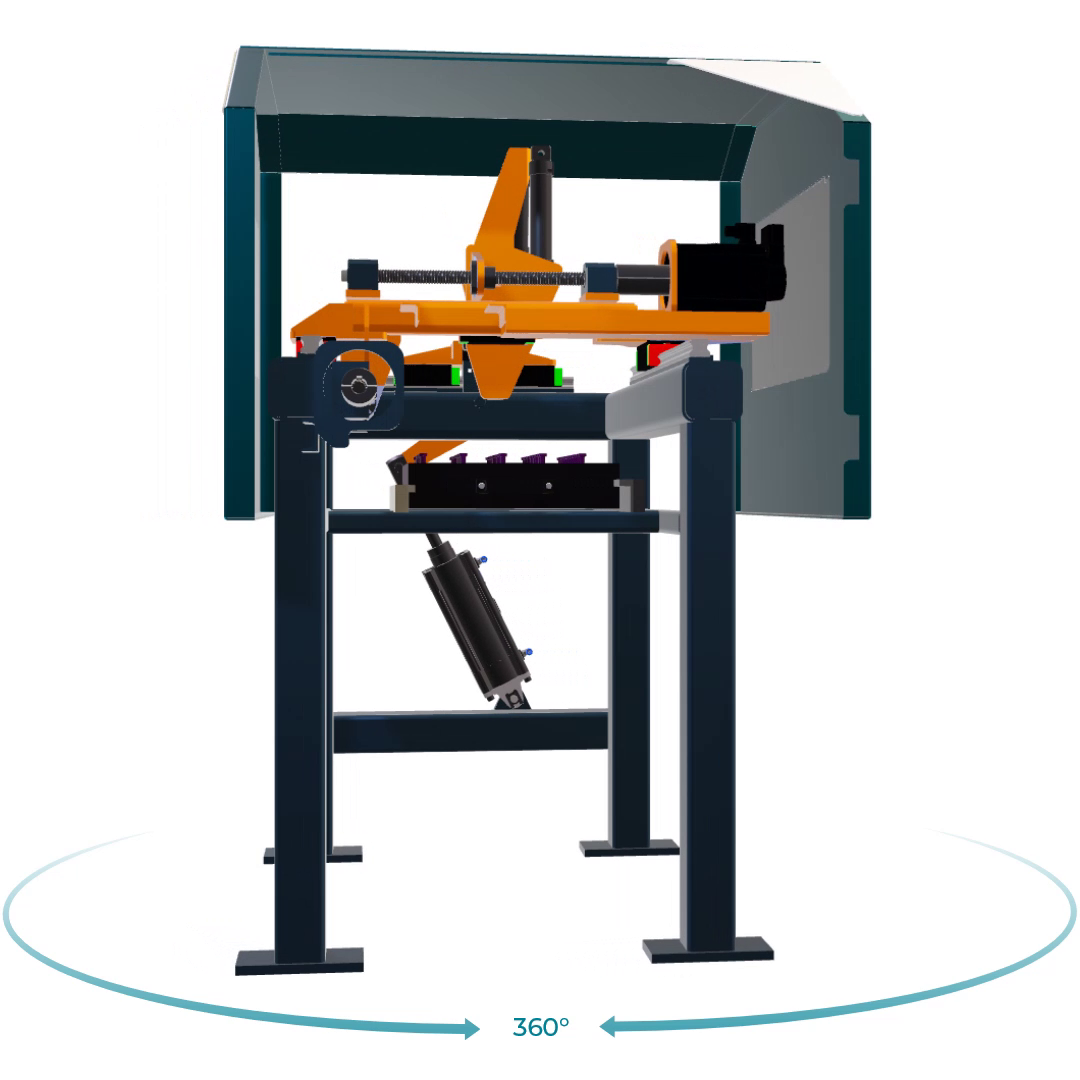

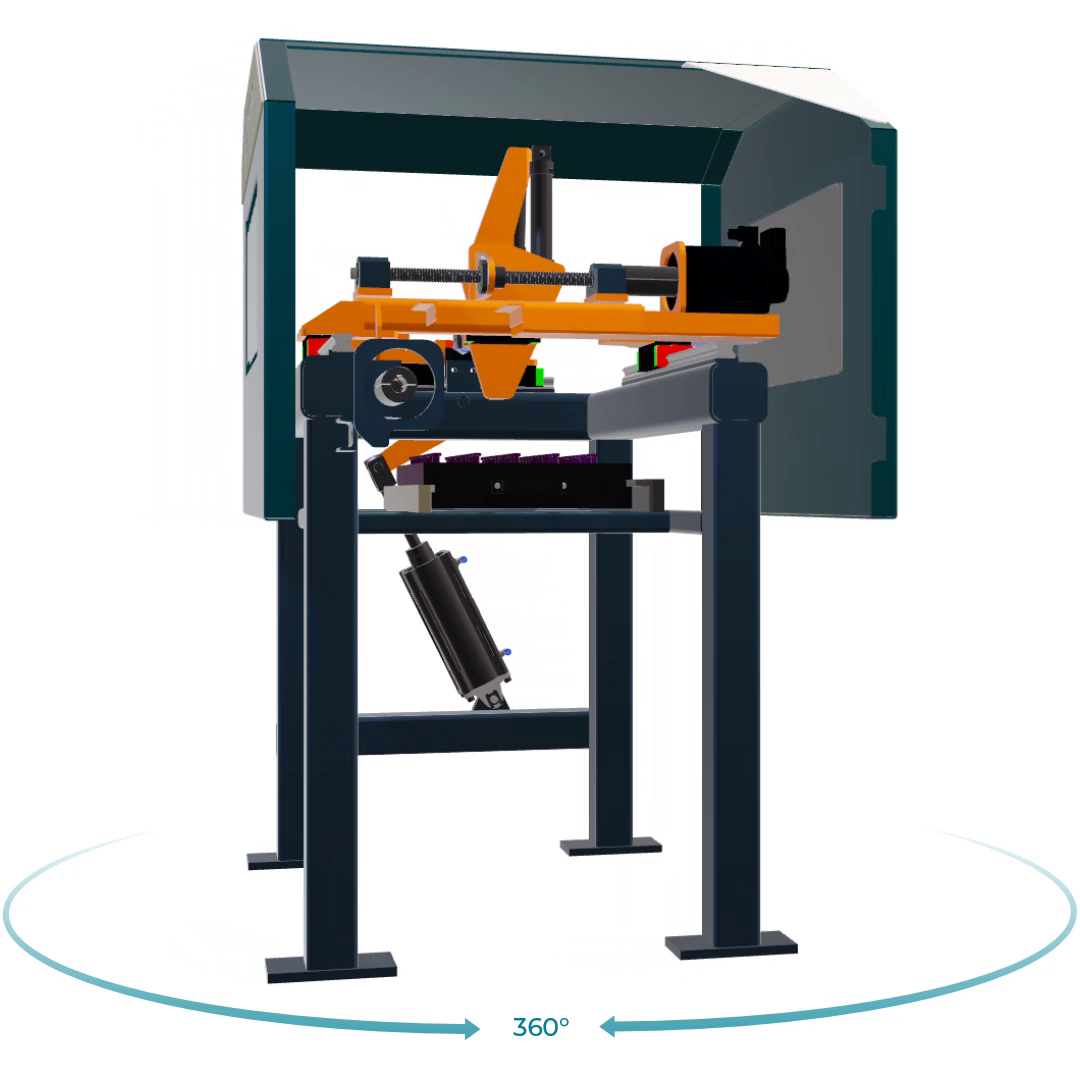

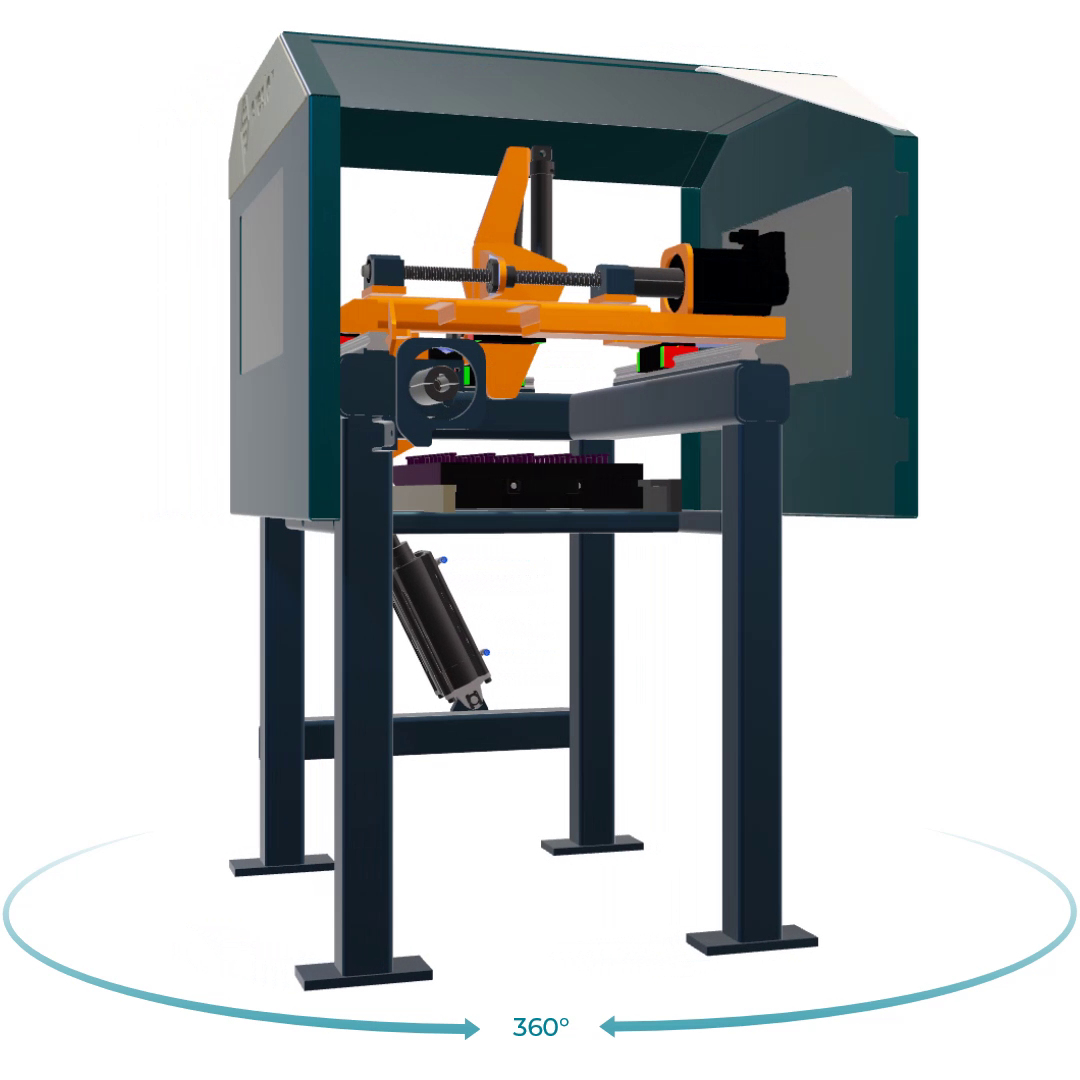

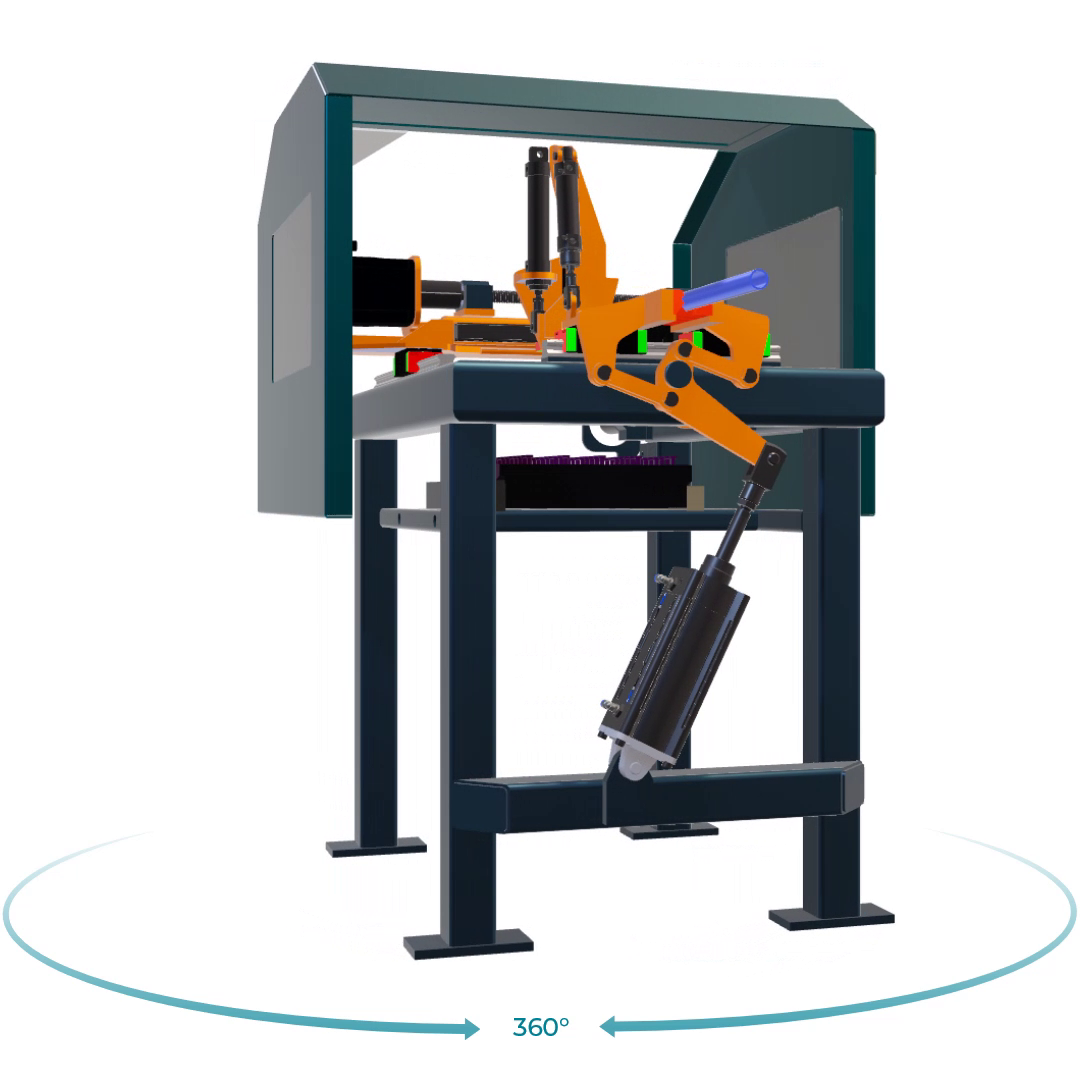

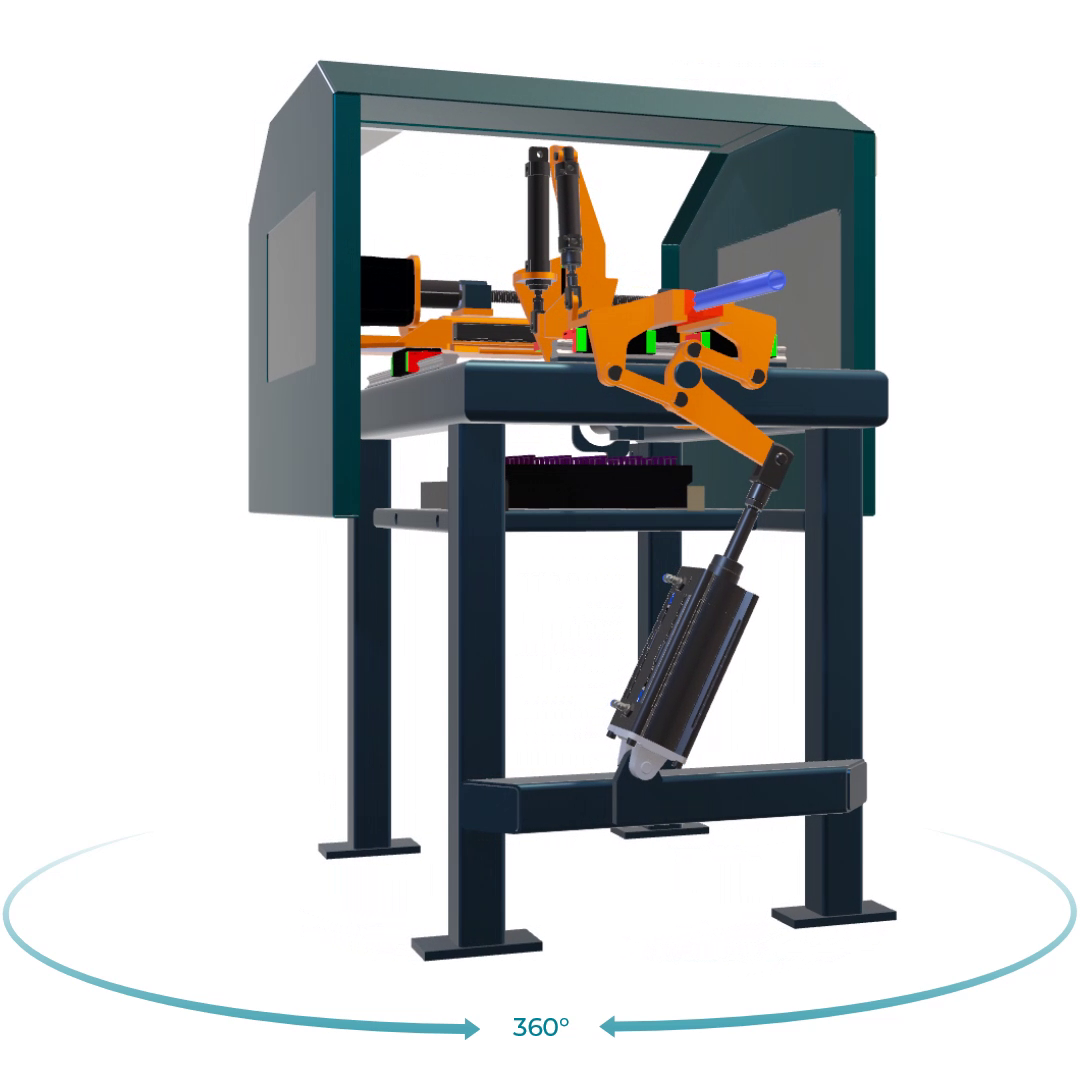

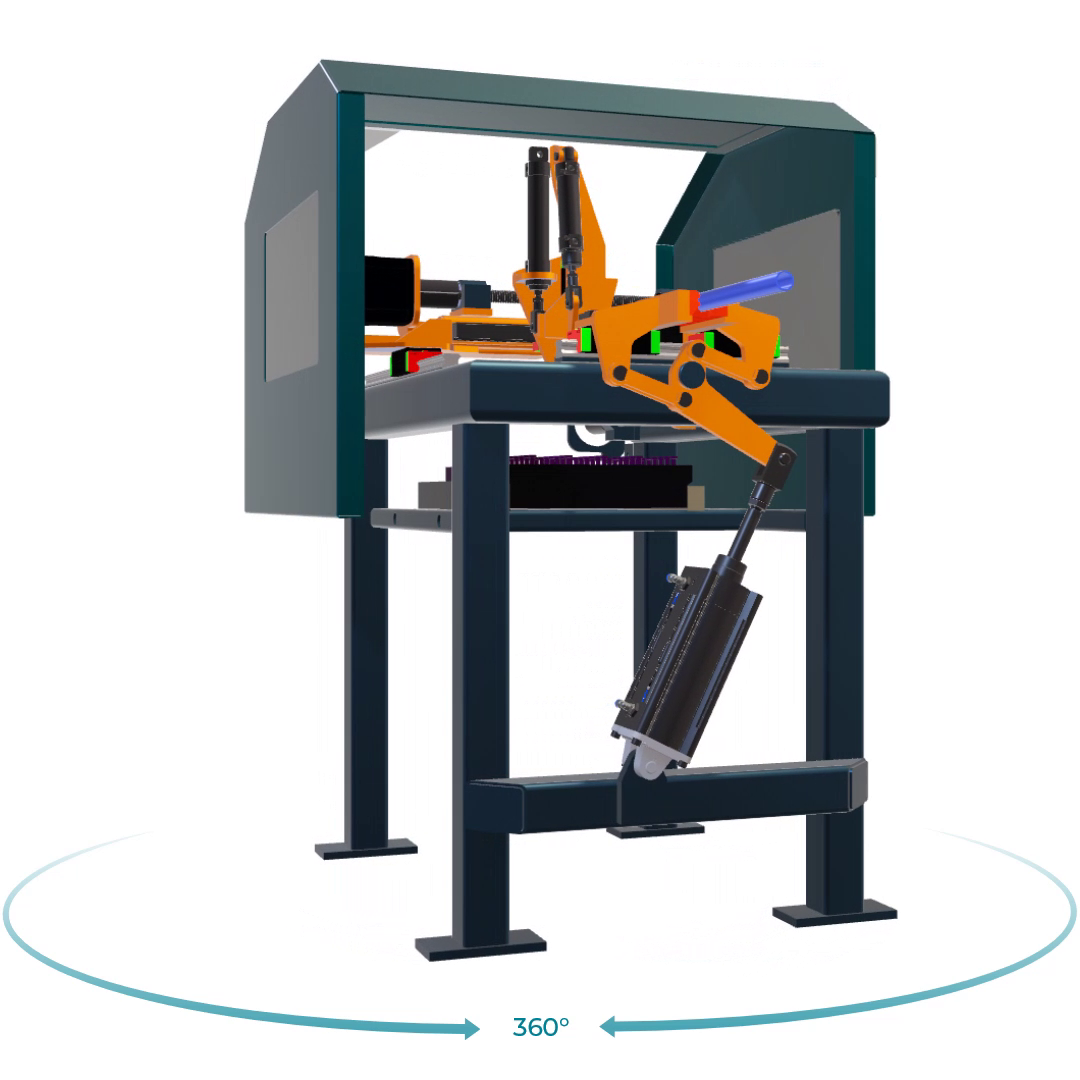

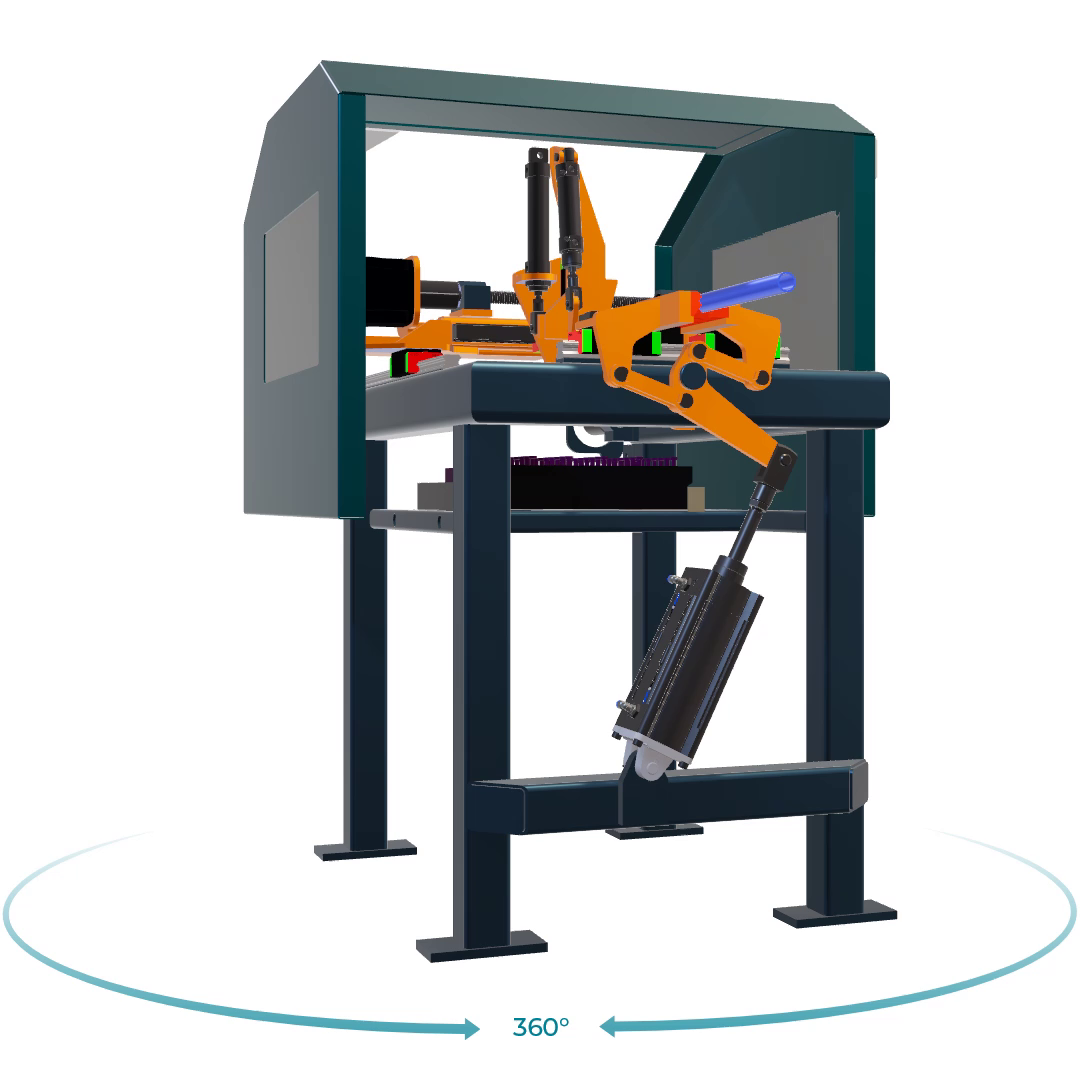

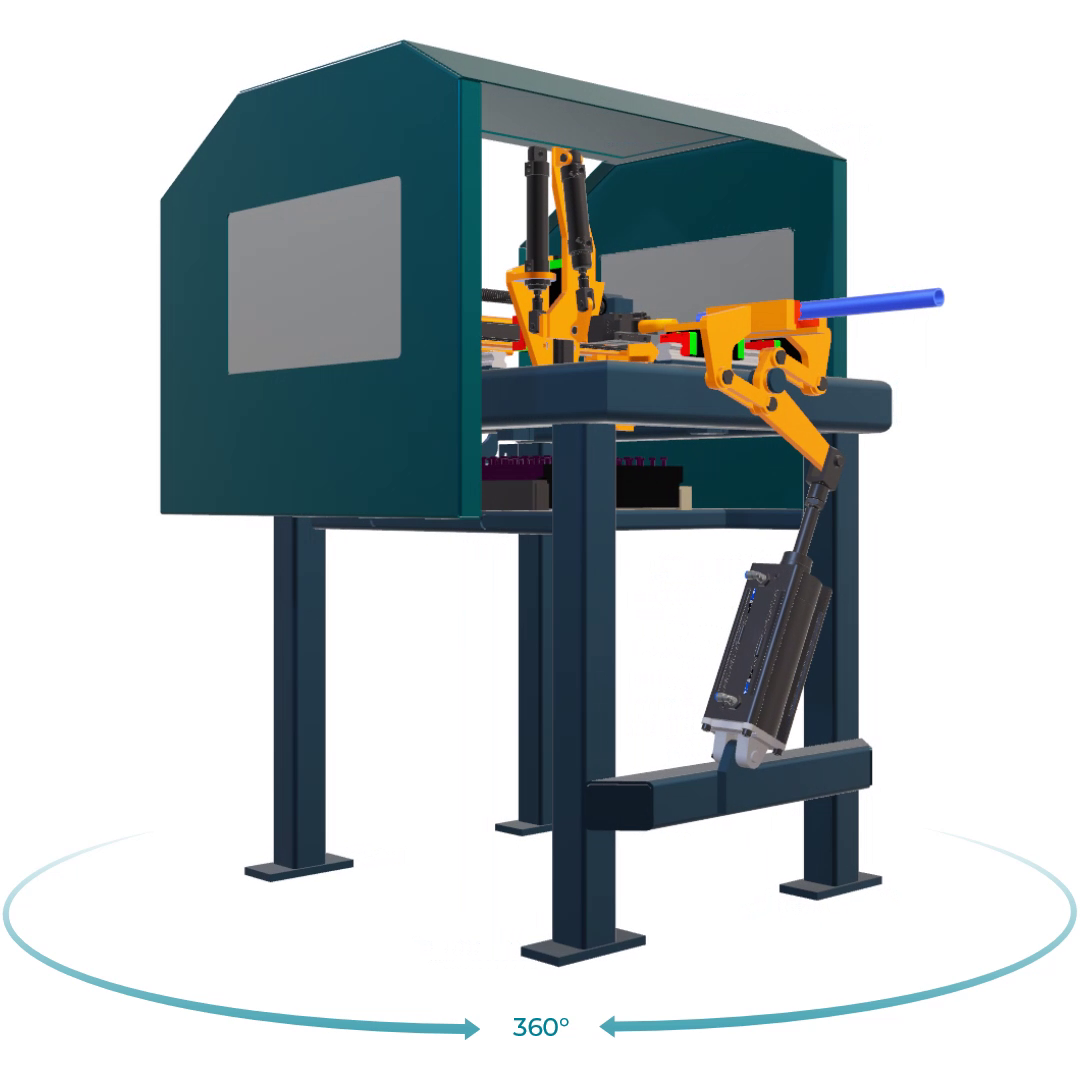

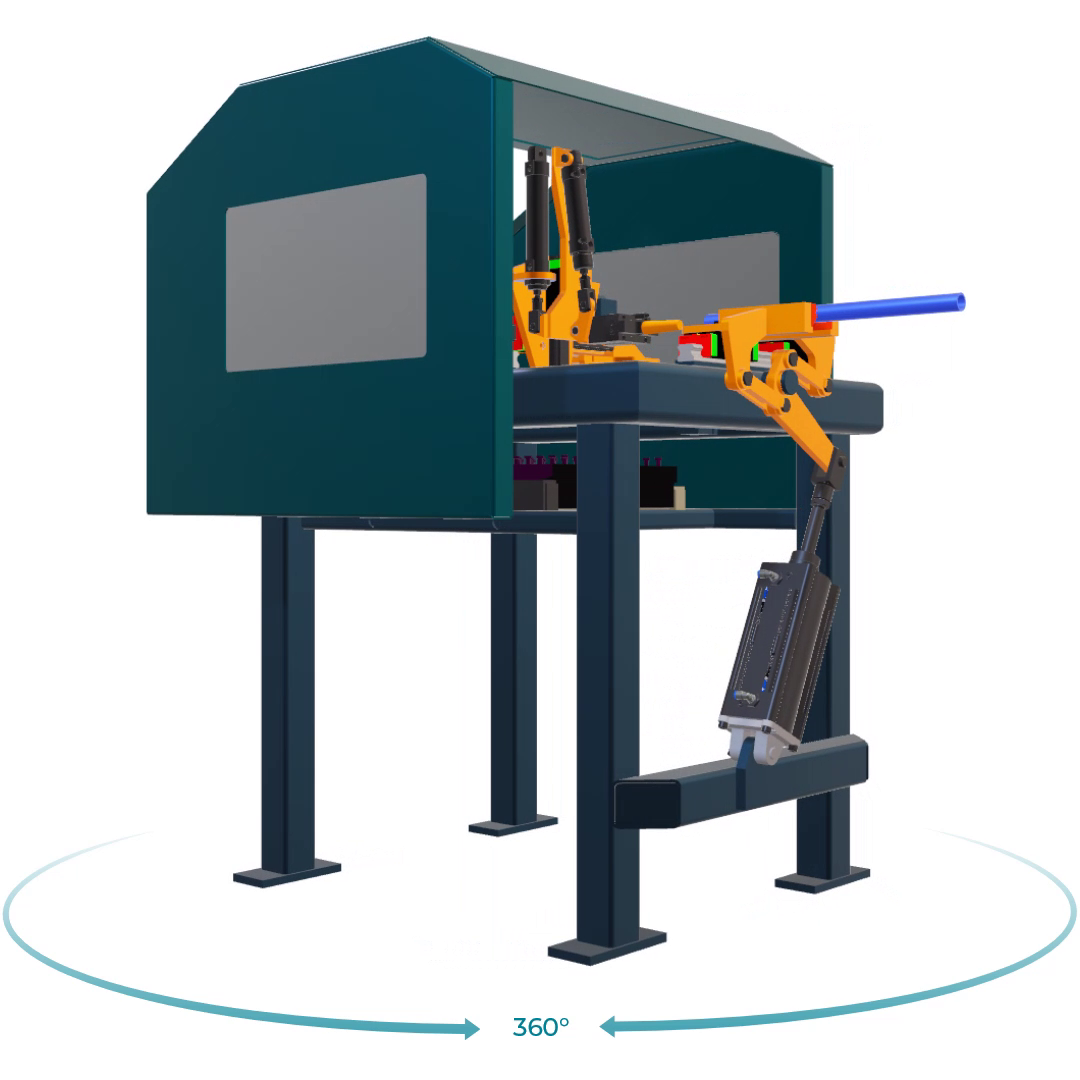

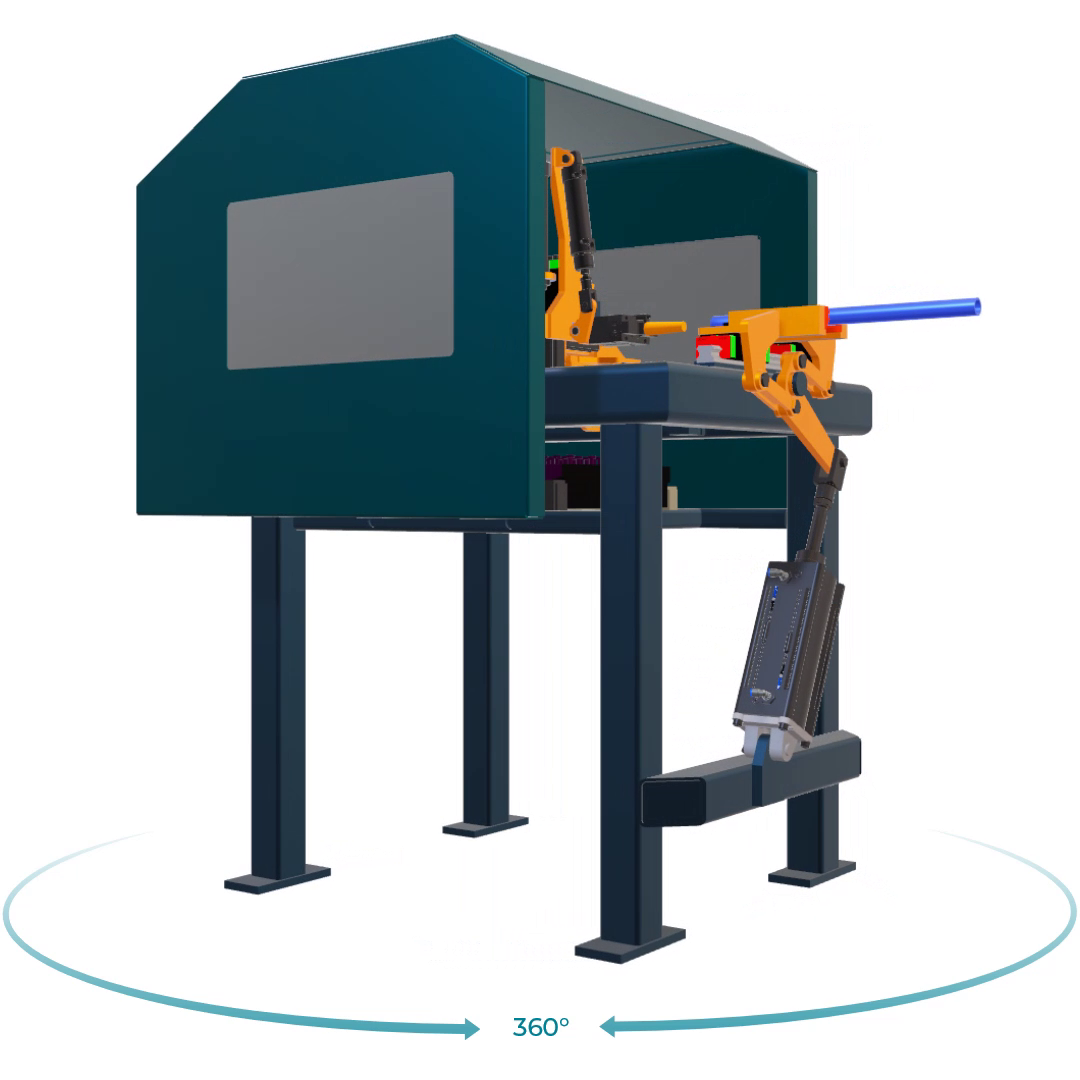

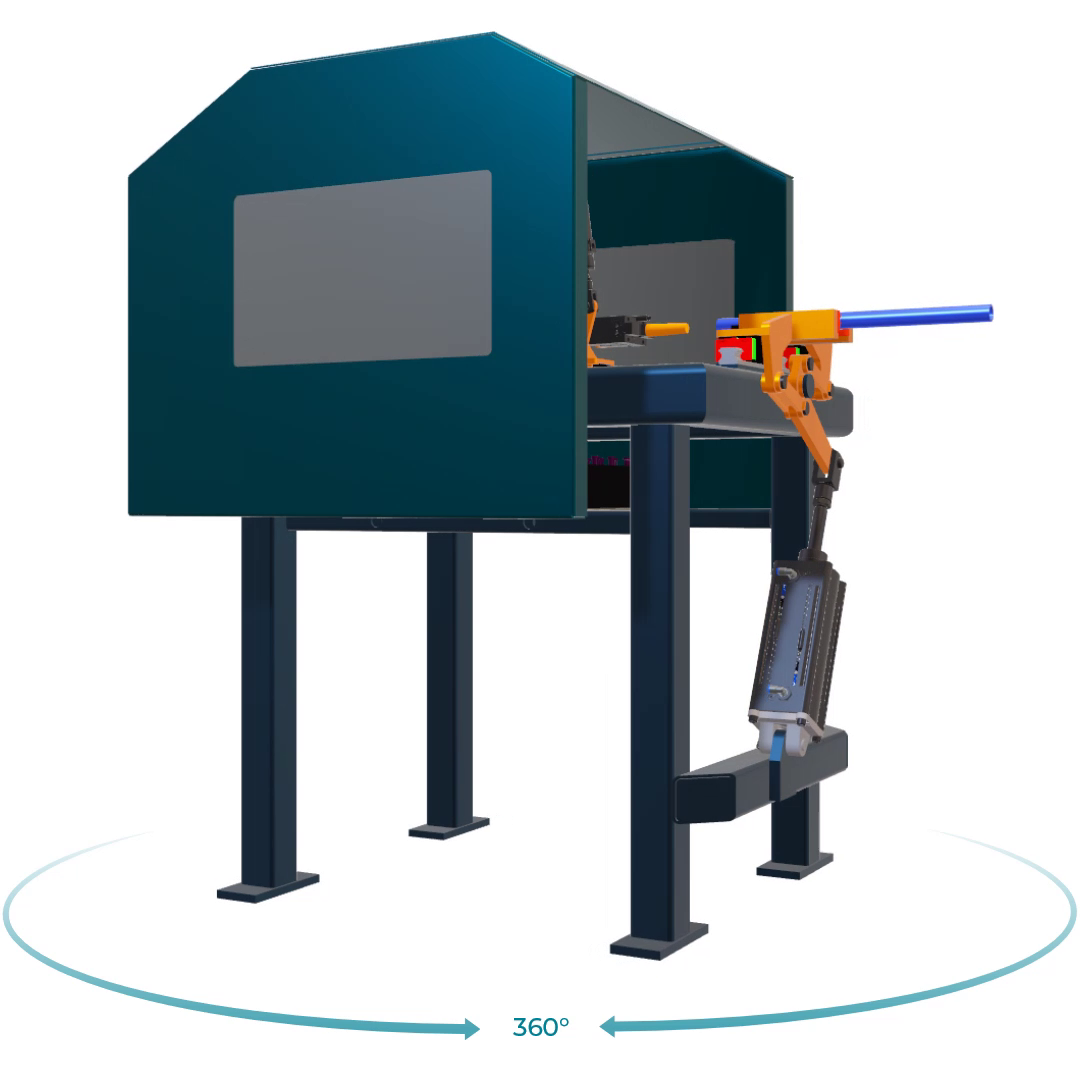

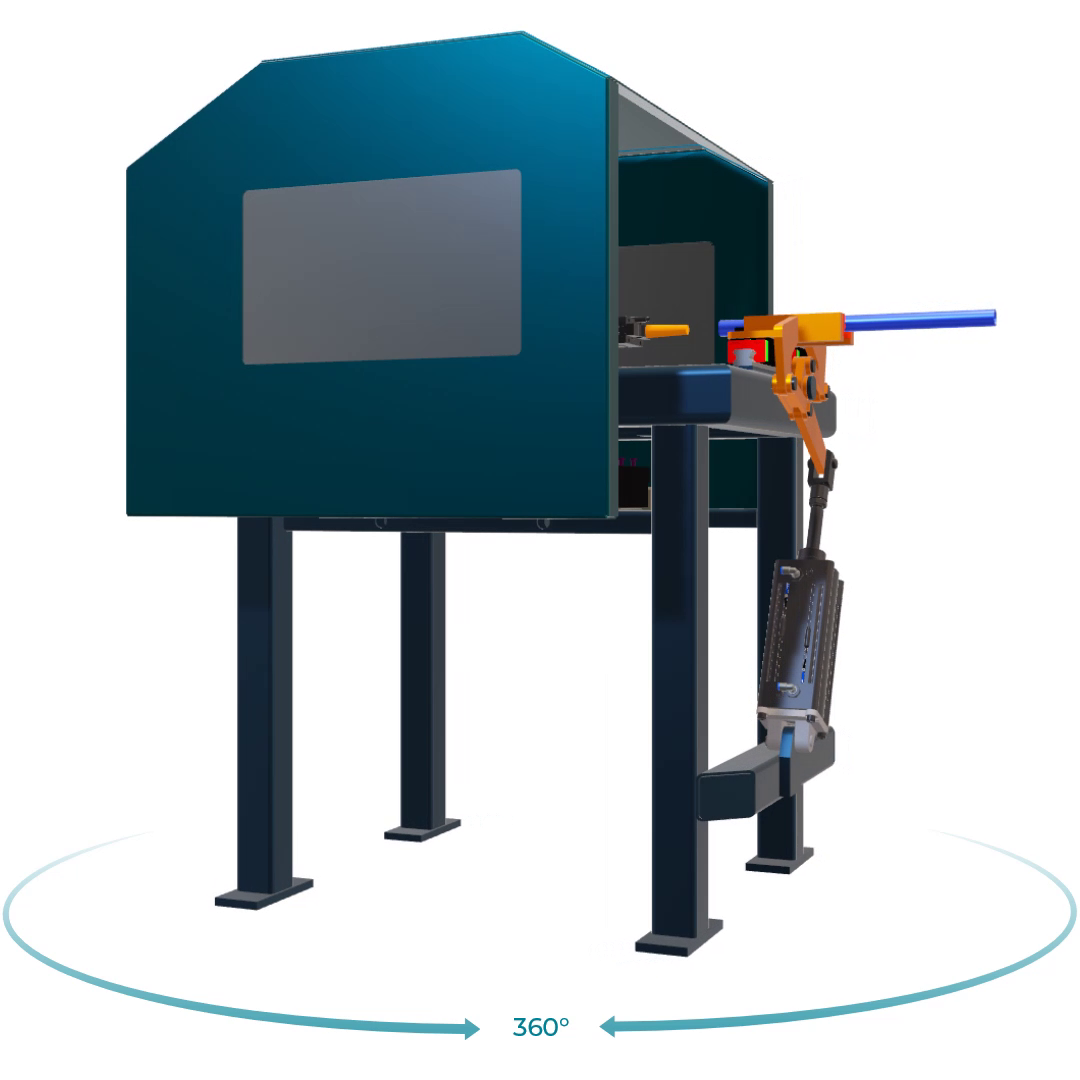

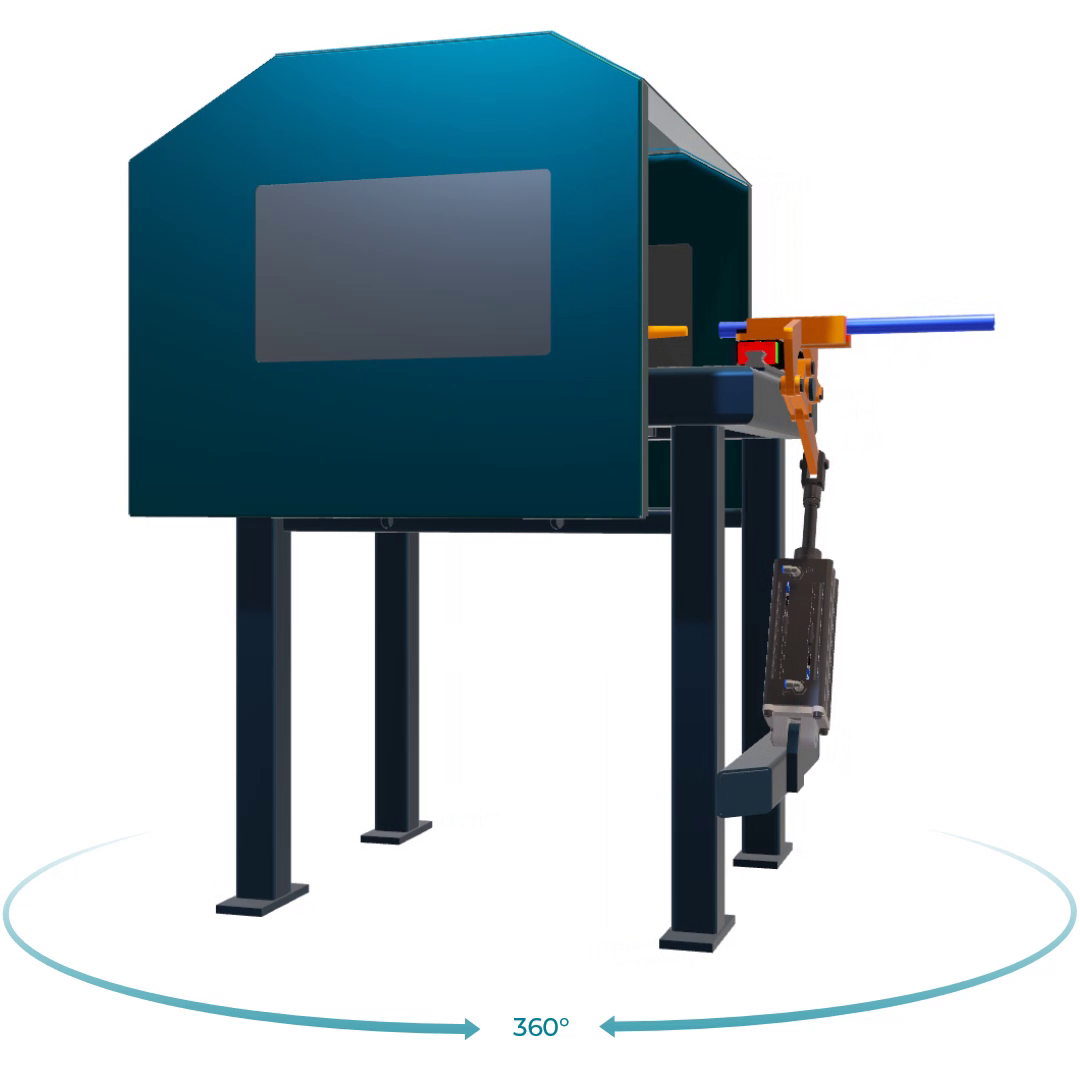

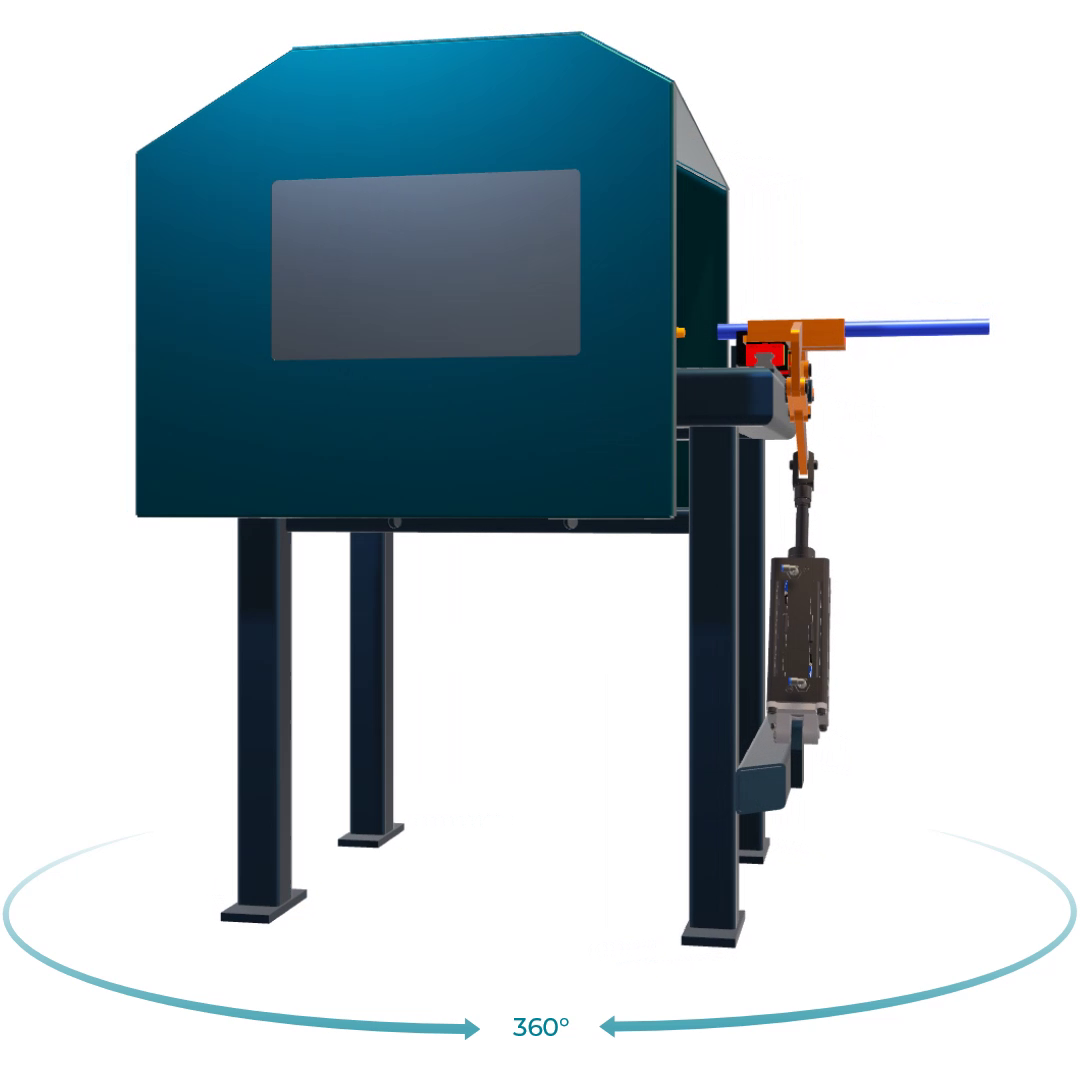

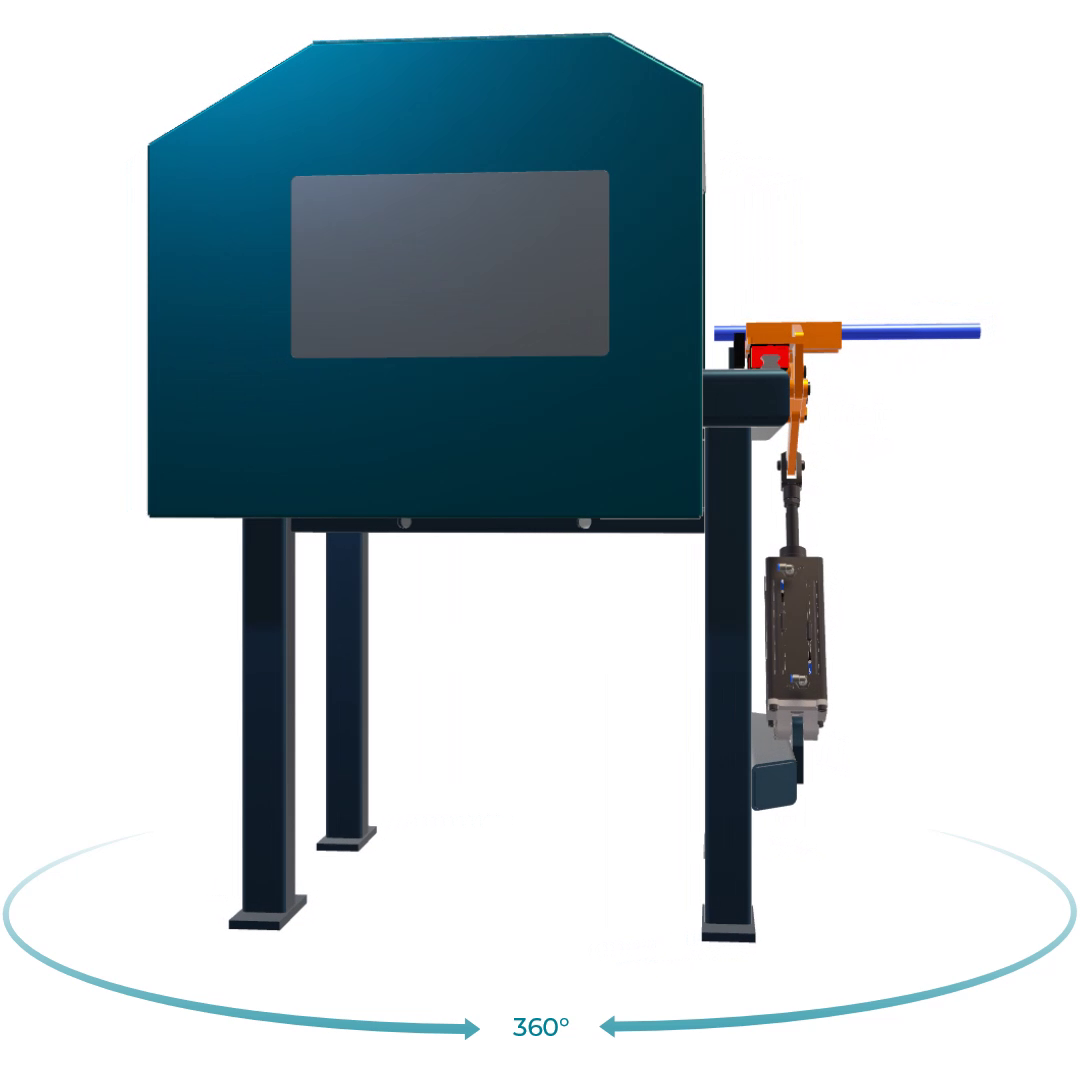

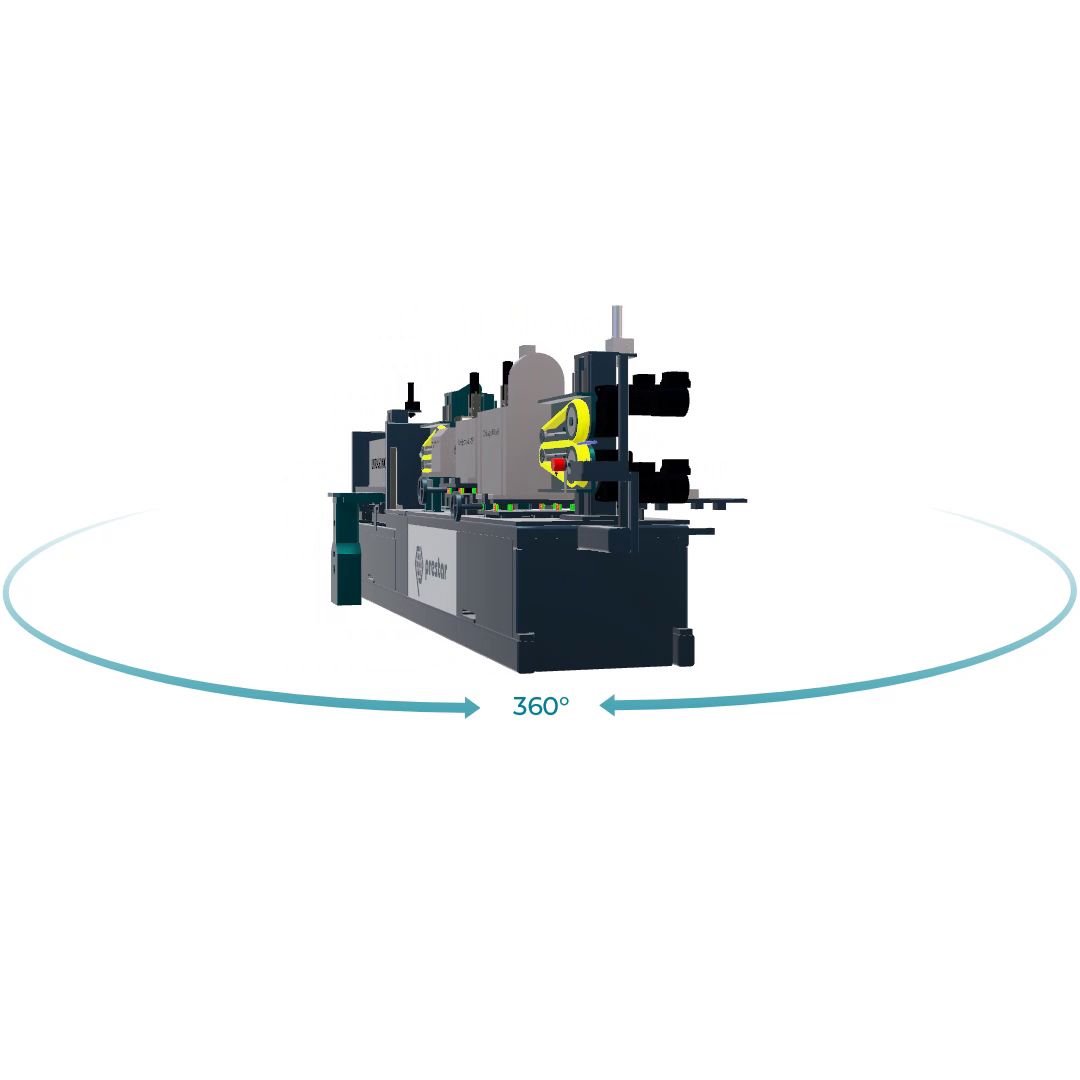

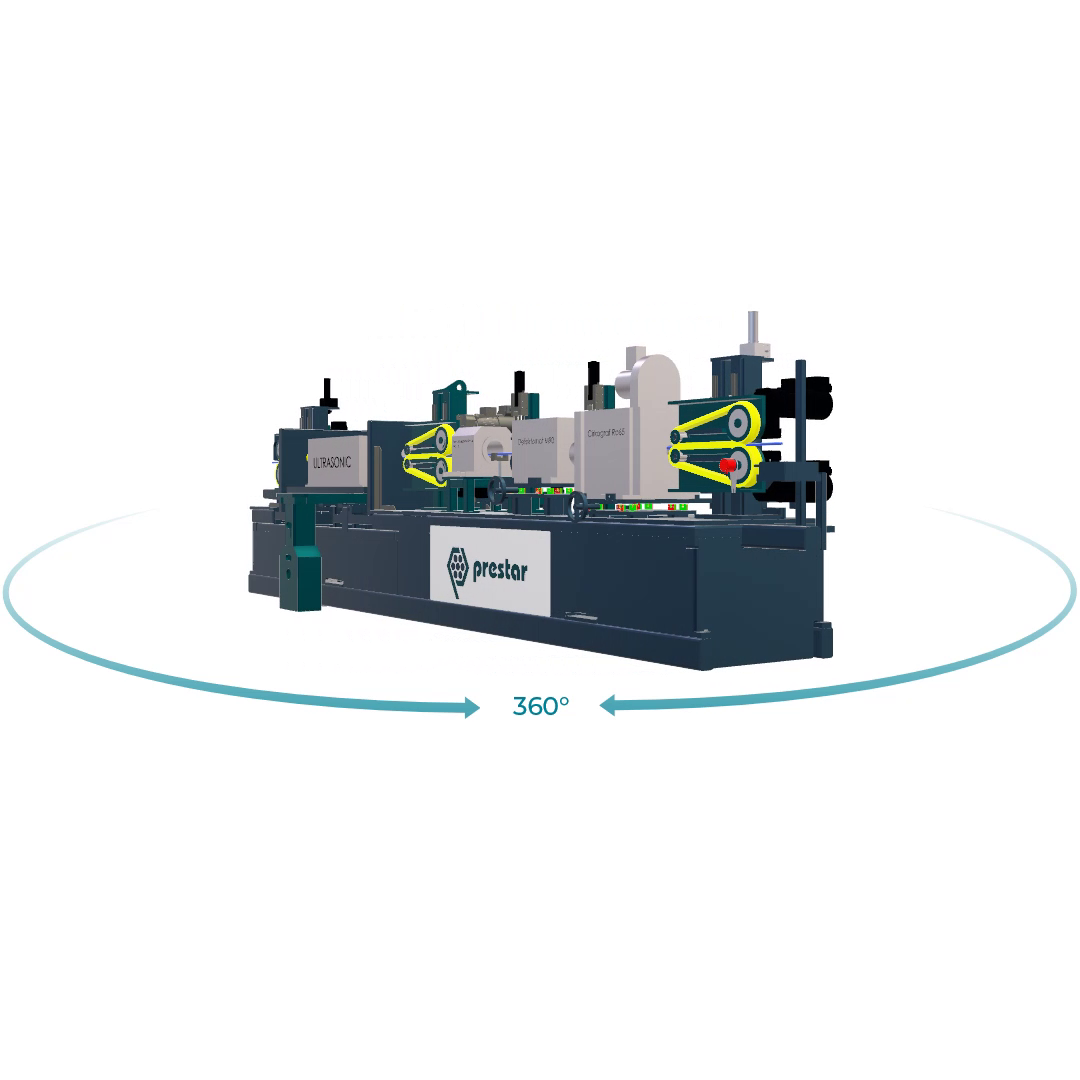

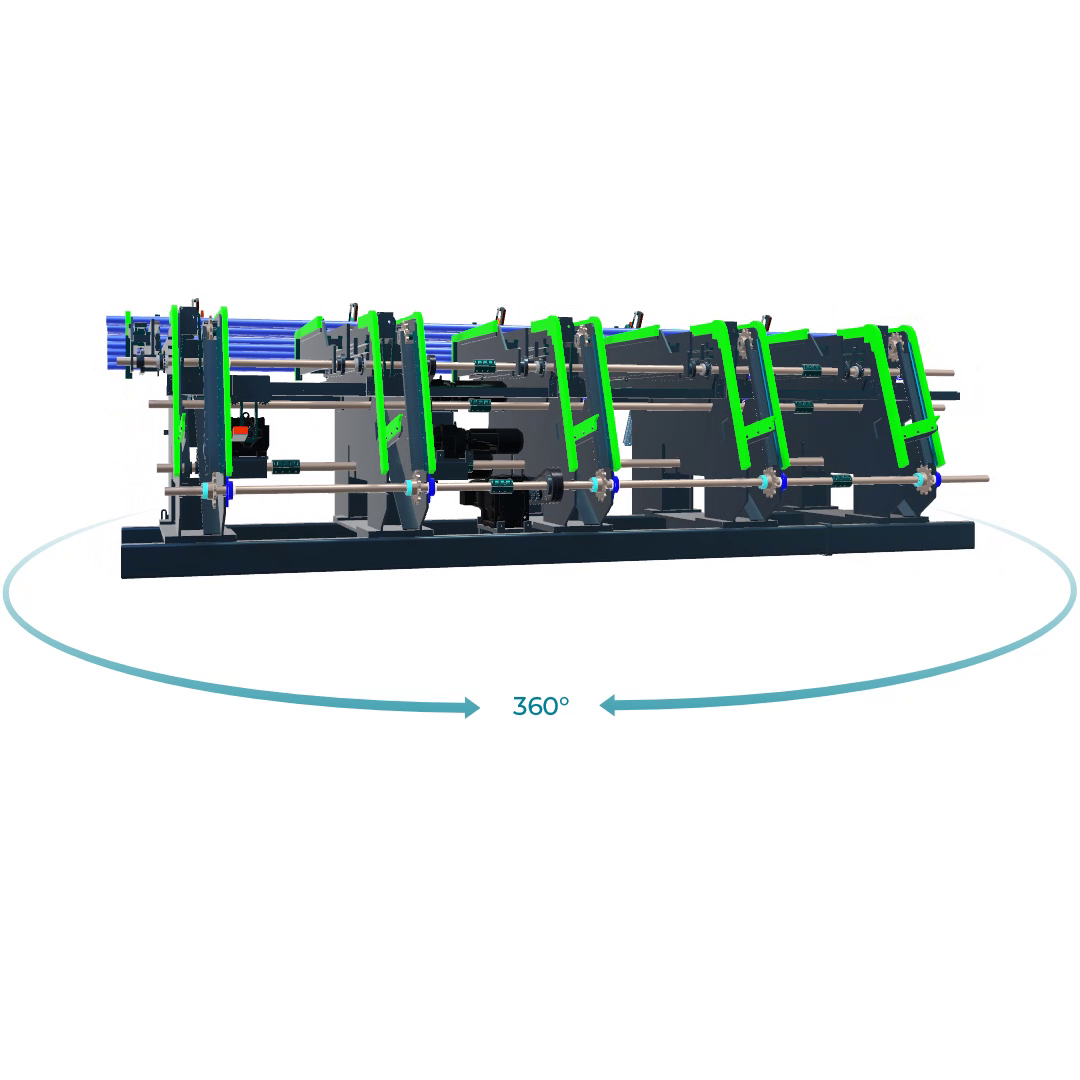

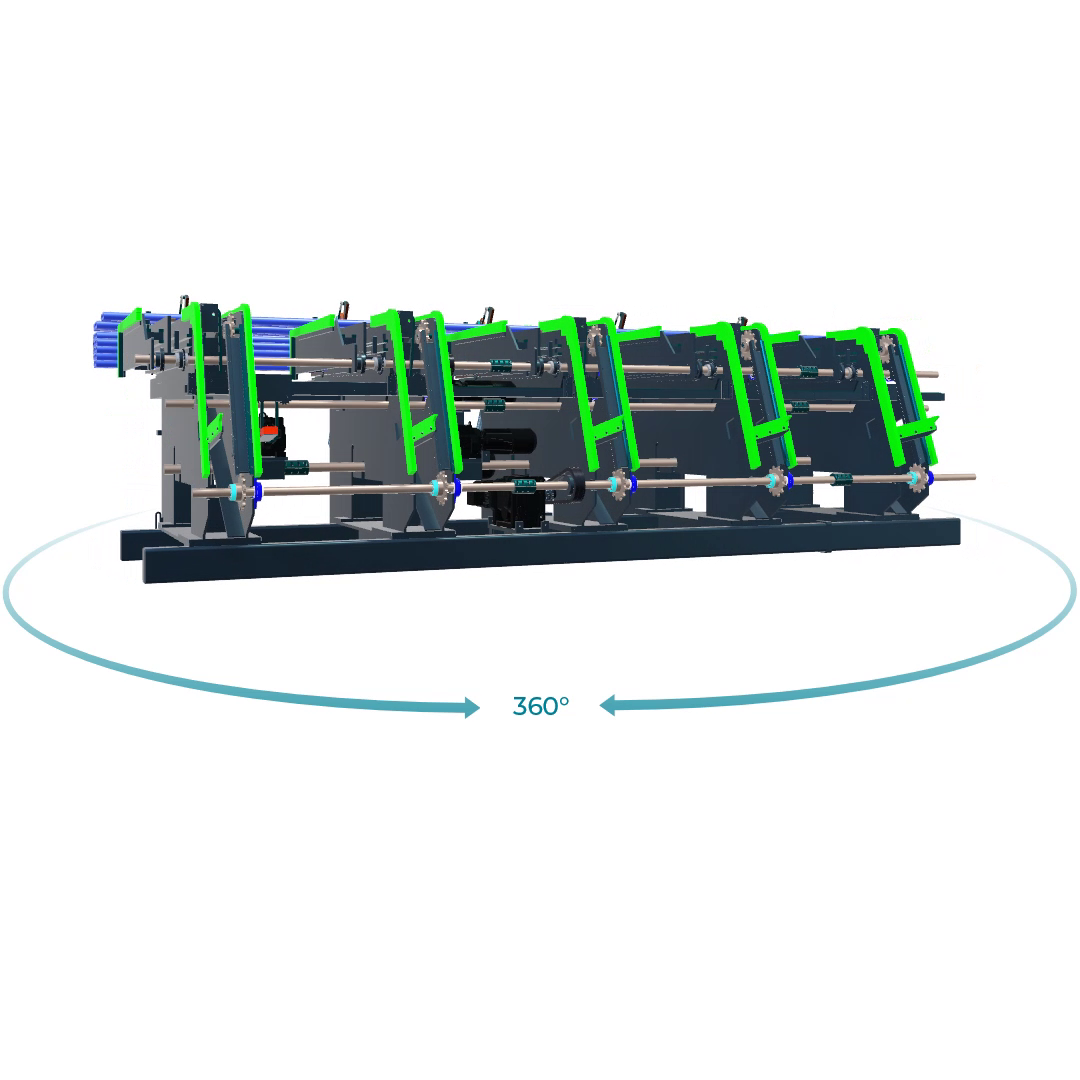

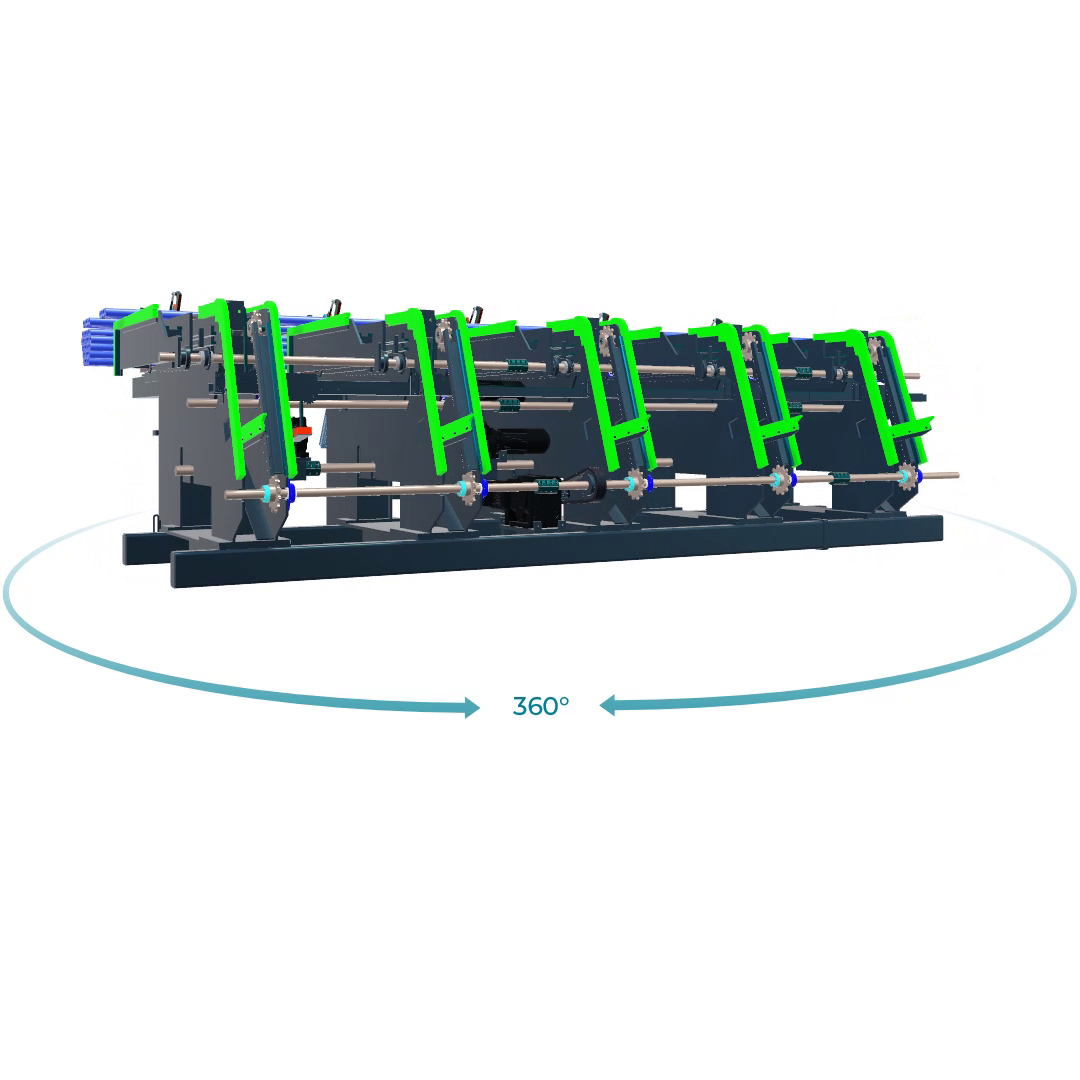

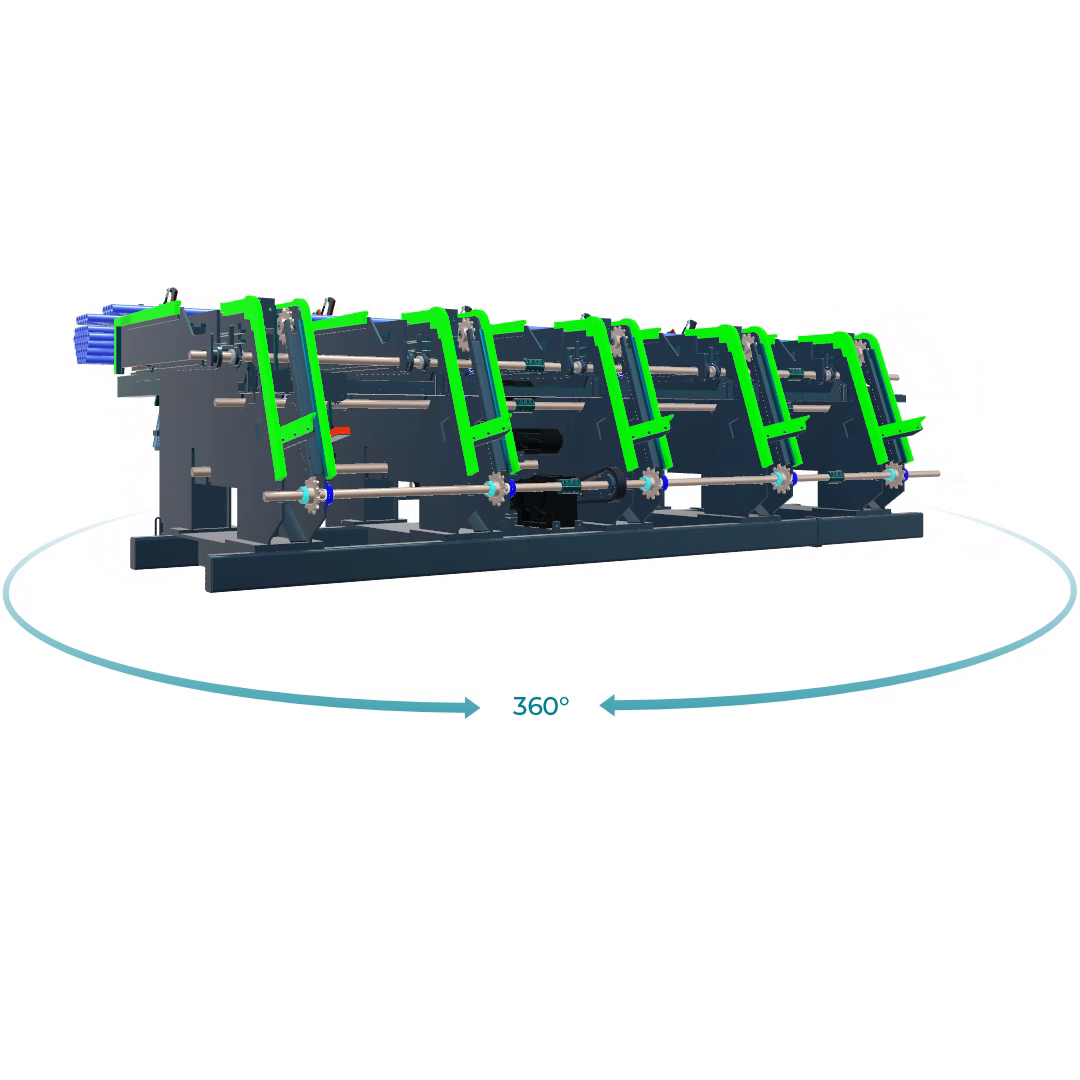

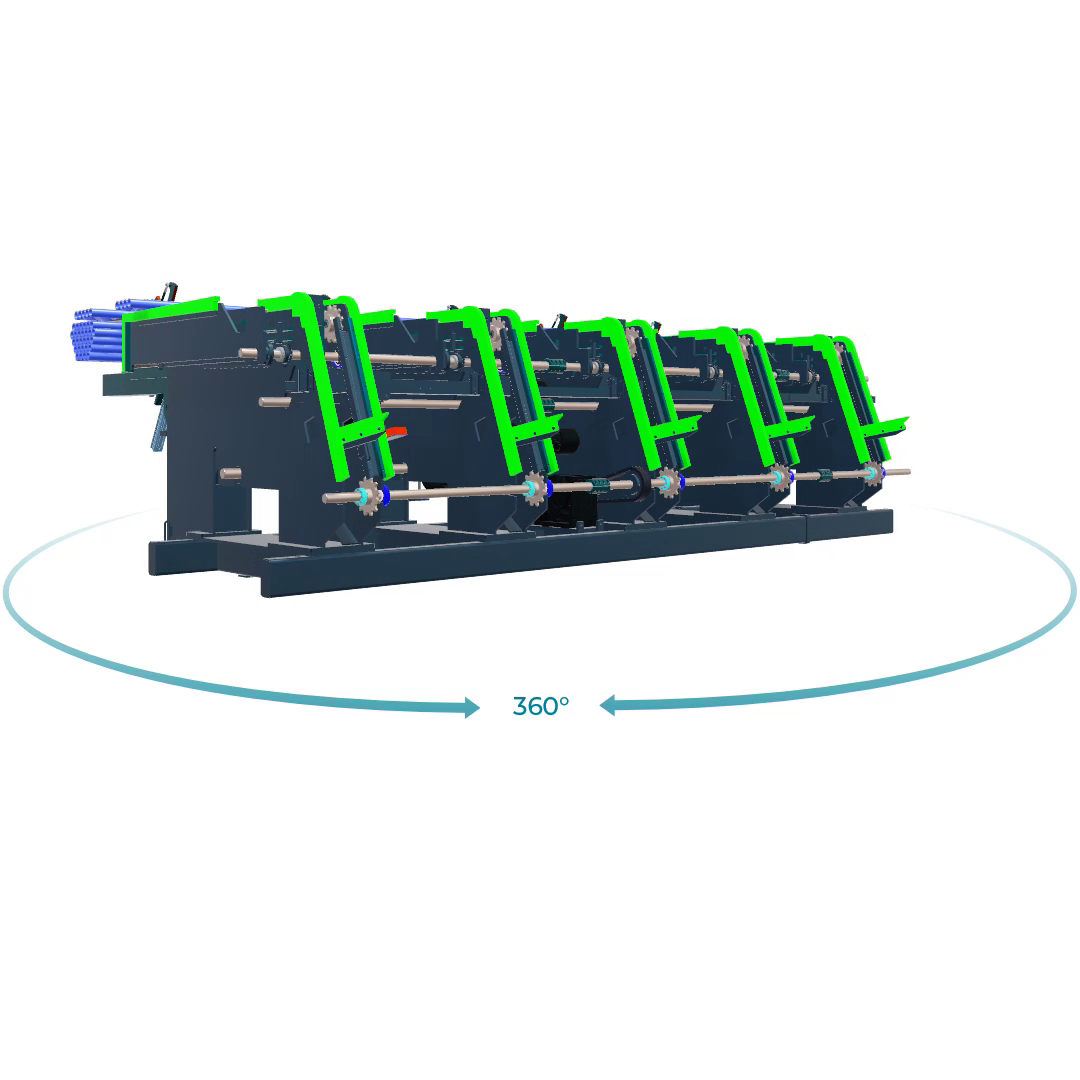

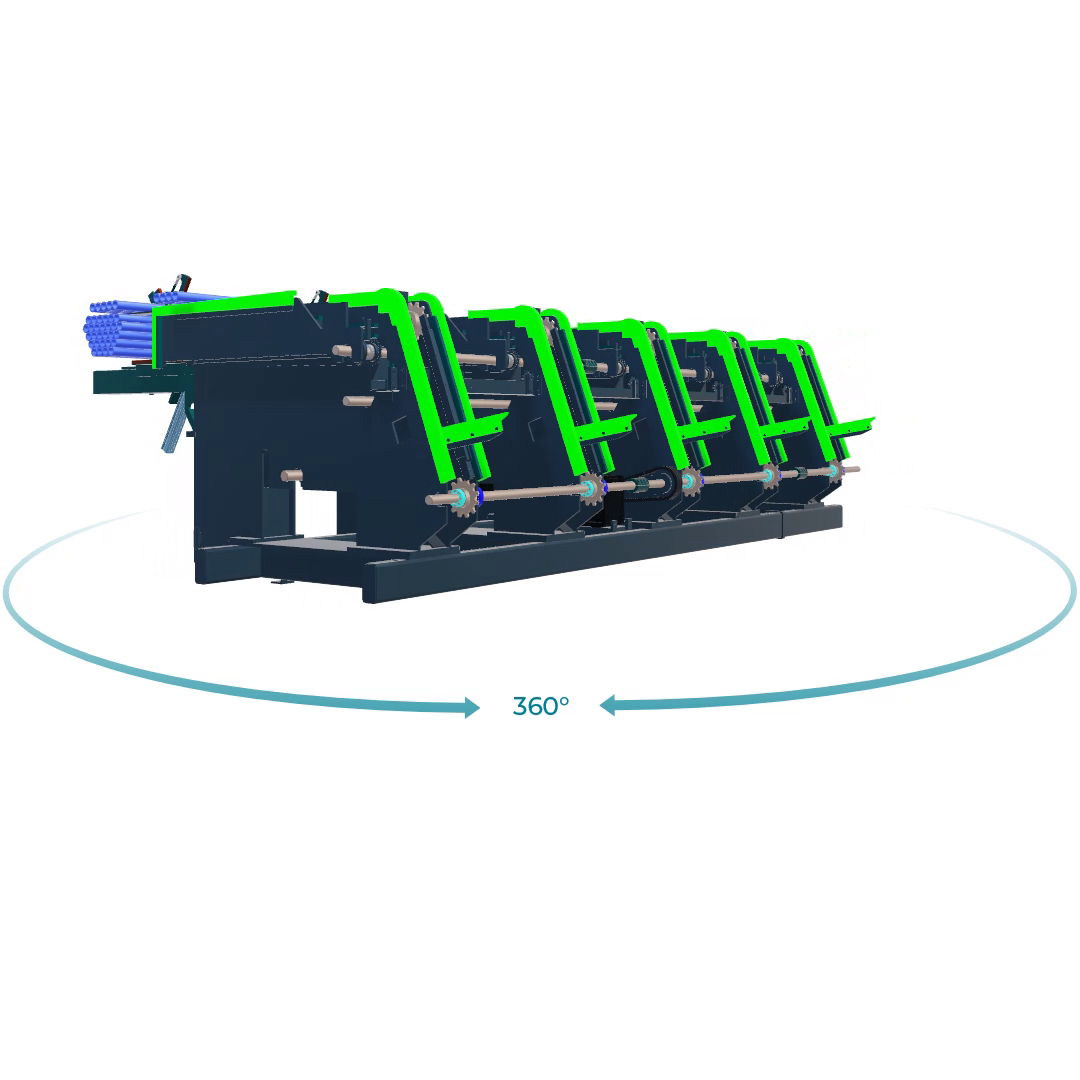

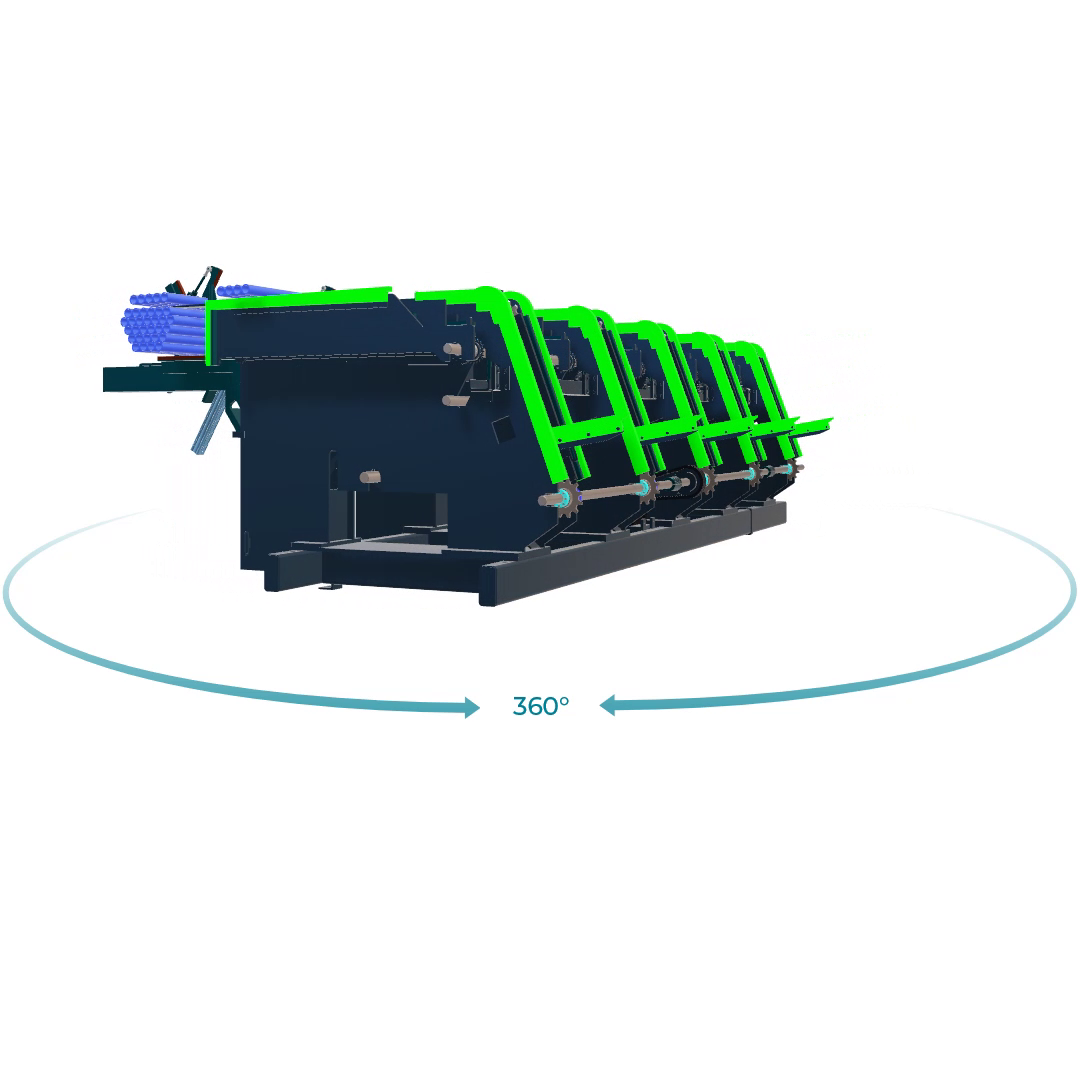

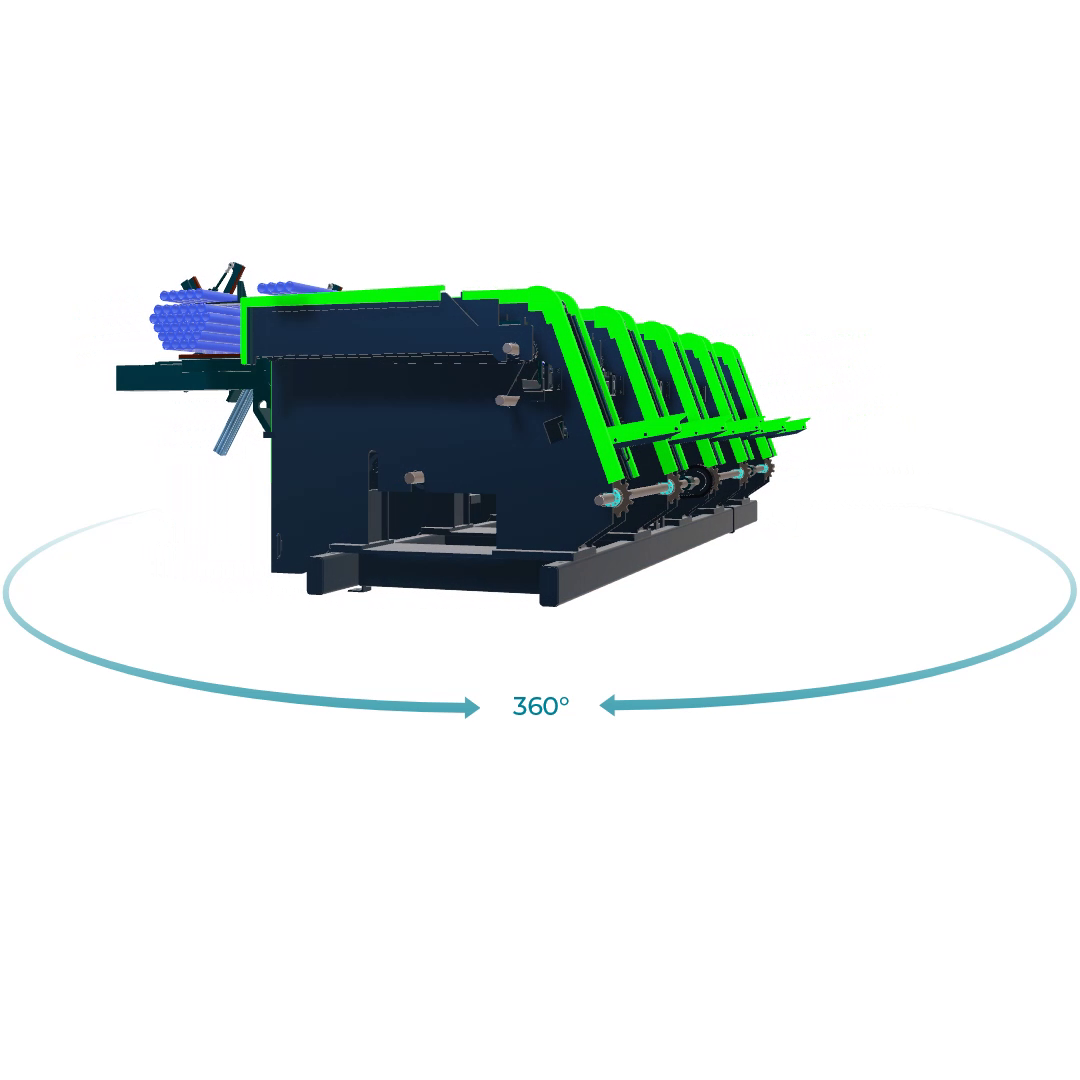

Centerless pipe grinder

Description of the device

Grinding of pipes in the range 9 - 140 mm.

It is used to achieve a high quality ground surface of pipes and to remove surface defects and scales after rolling pipes.

Technical parameters of the machine

- The tube is driven by guide rollers and passes along a series of grinding belts

- The tube is guided along a series of grinding belts by guide rollers at speeds of up to 30 m/min.

- At low removal rates, surface quality up to Ra 0.4 can be achieved.

- Grinding is carried out under water emulsion or dry.