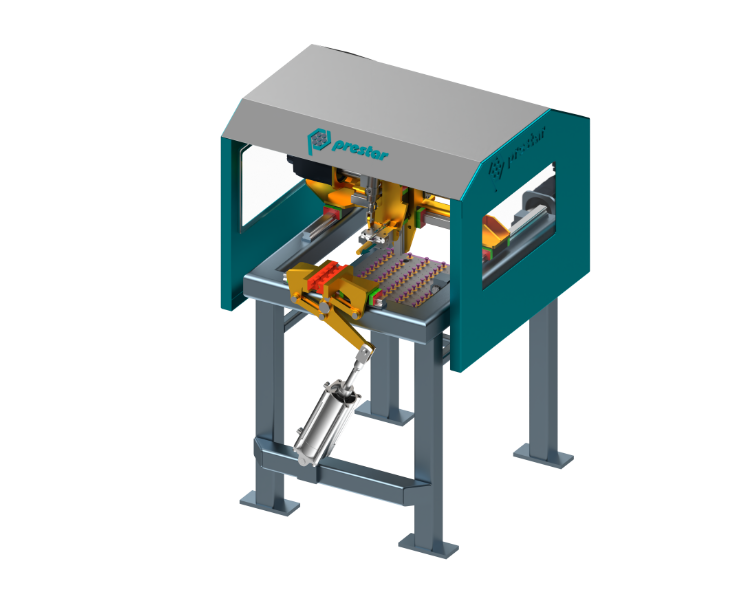

Flying saw

Description of the device

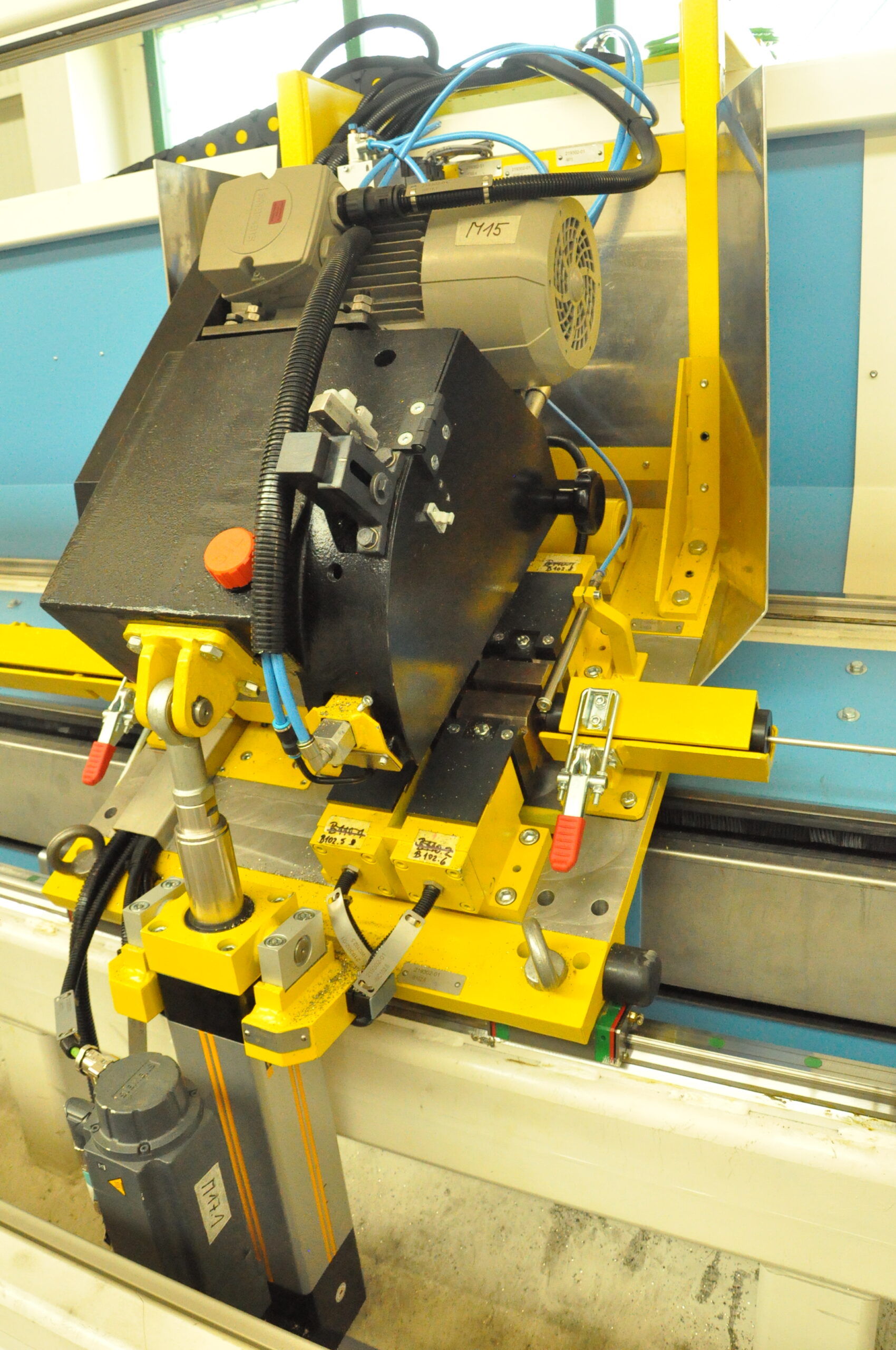

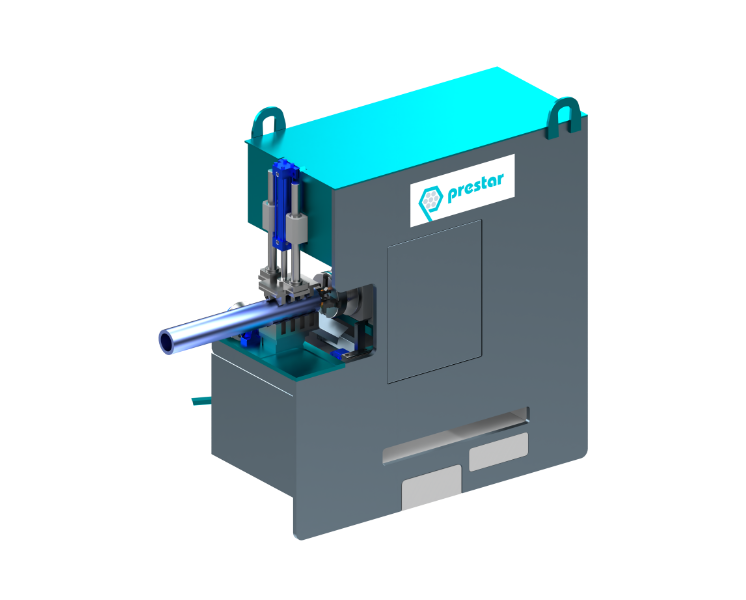

Flying saw is designed to cut pipes into precise lengths in a continuous motion called. endless pipes in a line. In the inlet, these are continuously welded pipes or pipes unwound from coils.

The flying saw is designed for tubes with a diameter of 6 – 90 mm of infinite length. The saw unit with the saw blade clamps the pipe at the saw inlet and drives the pipe at the same feed speed as the pipe feed. After a period of clamping, it cuts the pipe, releases the jaws and returns at high speed to the saw inlet.

They are always designed for a specific range of pipes according to customer requirements.

Technical parameters of the machine

|

Split diameters, profiles: |

6 – 90 mm |

|

Length after division: |

3 –21 m |

|

Feed speed of pipe, rod: |

up to 2,0 m/sec |

|

Cutting accuracy: |

+- 1,5 mm |

|

Control system: |

Simatic S7 1500T |

|

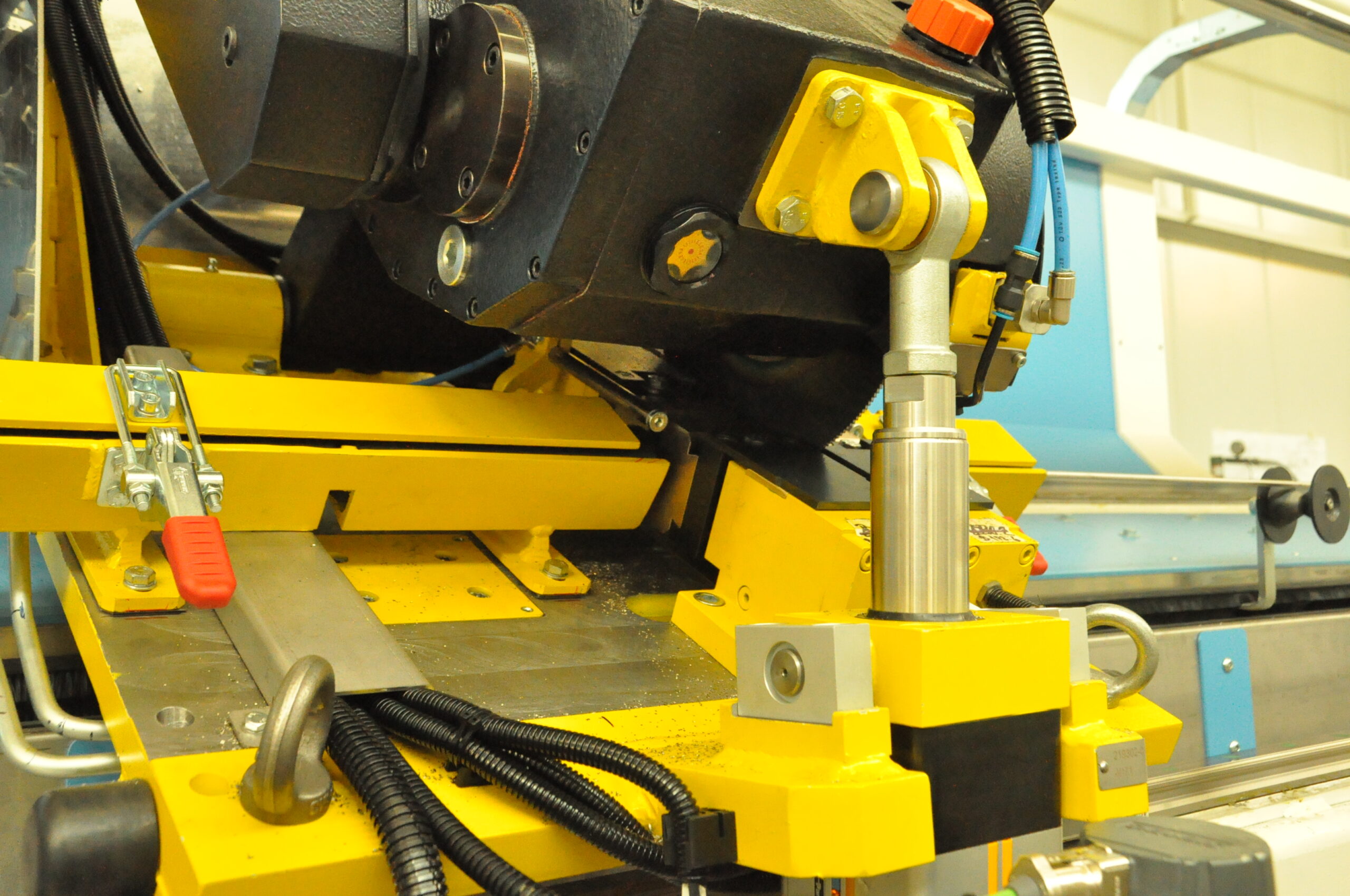

Hydraulic jaw clamping |

|

|

Feed into the section by hydraulic cylinder or servo drive |

|

|

Variable feed of the blade into the cut when cutting pipes |

|

|

Automatic lubrication system |

|

|

Safety covering with transparent glass |

|

Other equipment of the machine

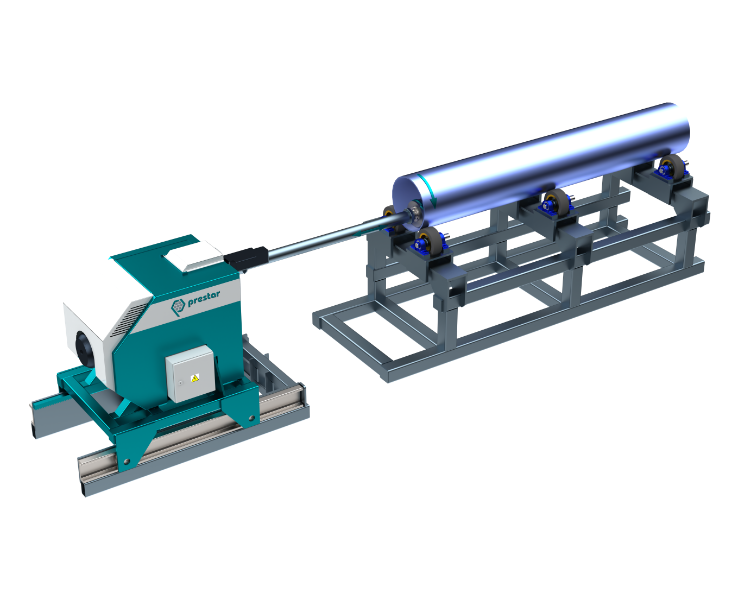

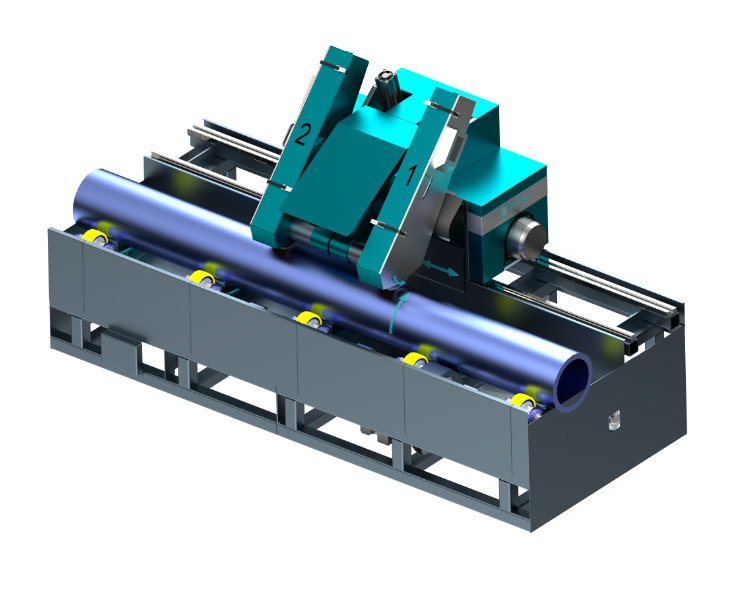

- Unwinding device before entering the flying saw with speed control.

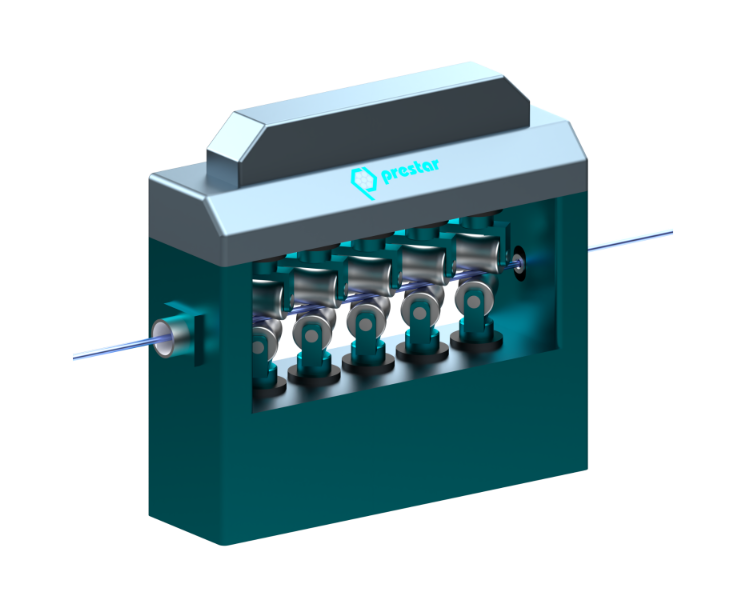

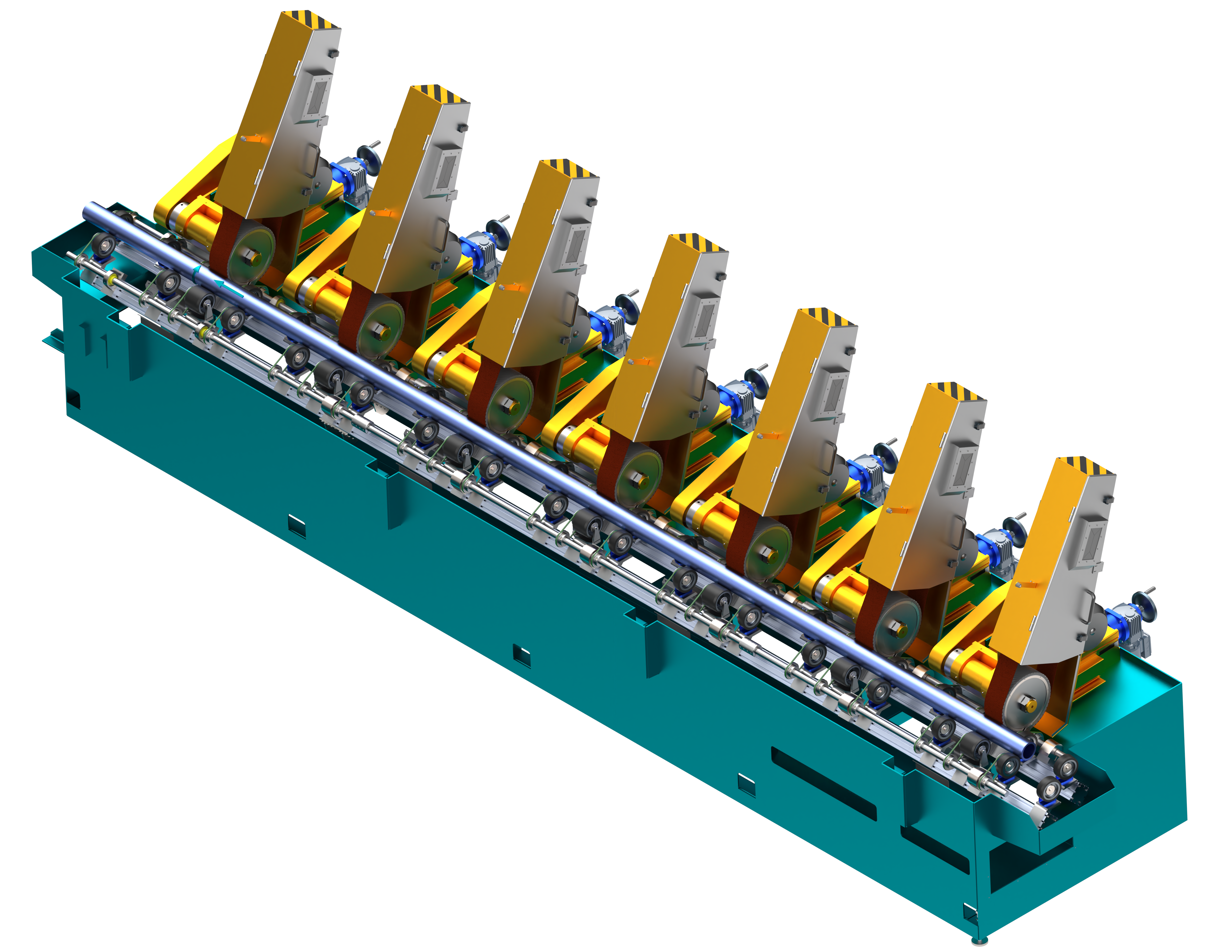

- Pre levelling of pipes and rods after unwinding before cutting on a flying saw.

- Continuous monitoring of defects and automatic carving of identified defects.

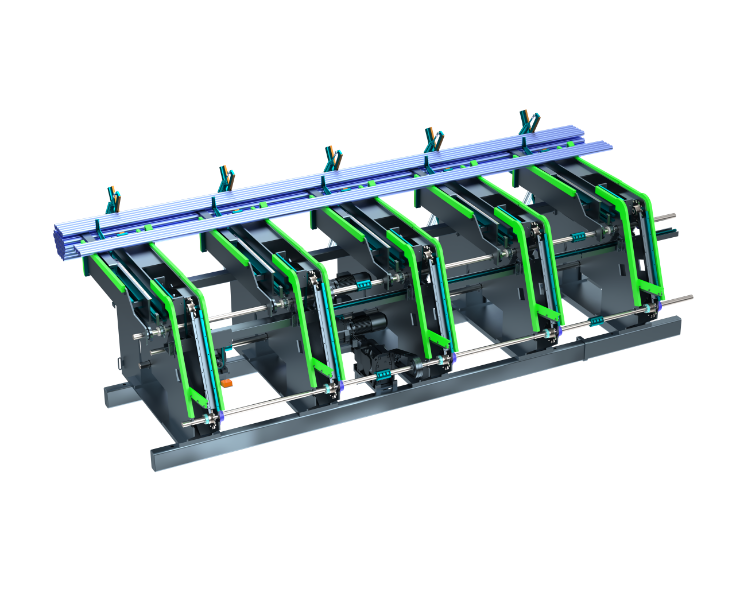

- Storage of gifted tubes and bars in pockets according to different lengths.

- Storing carved defects in a separate pocket.

- Description and marking profile

Straightening machines

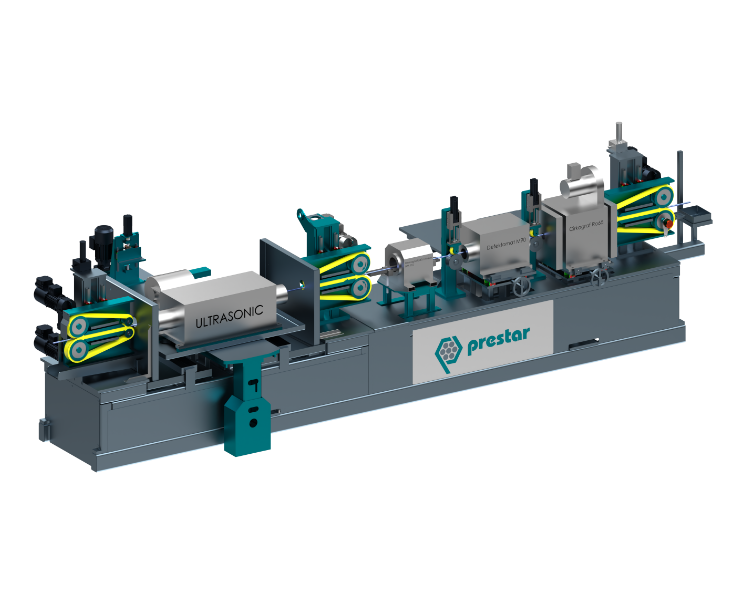

Internal pipe grinder

Centerless pipe grinder

External stationary pipe grinder

Flying saw

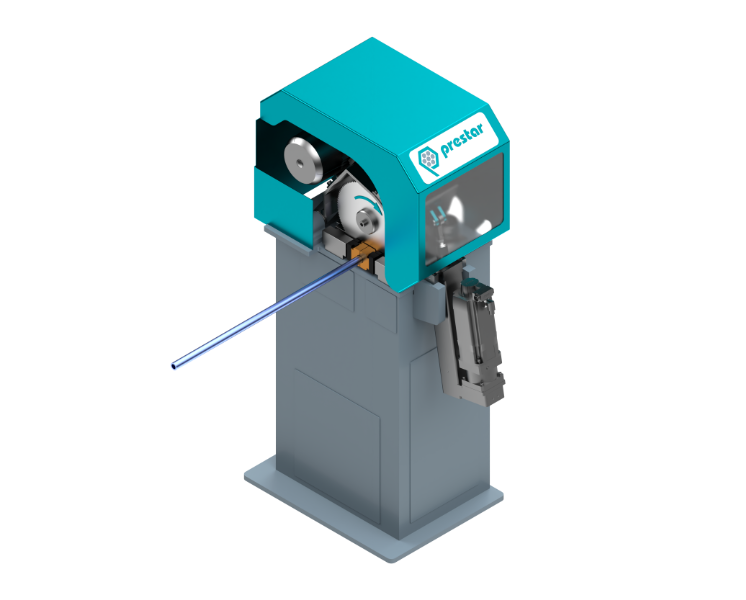

Circular saw

Chamfering of pipes

Sorting and plugging

Control tables

Packaging machines

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT

90% of customers perceive Prestar's technology as highly advanced

Our solutions in industry:

Tube end deburring – the safe and precise by Prestar s.r.o.

Sharp edges, burrs and small needles often occur when cutting or machining pipes. These irregularities can compromise safety, complicate assembly and adversely affect joint quality....

Equipment for sealing pipe ends before ultrasonic testing

Automatic plugging/uncorking stations - safe and precise sealing of pipes To ensure accuracy and reliability in non-destructive testing (NDT) of pipes, especially ultrasonic testing, the...

External pipe grinding machine – precision surface finishing for steel tubes

Why use an external pipe grinding machine? Grinding the outer surface of large-diameter steel pipes is essential for quality, safety, and finishing. Our external pipe grinding machine is specifically engineered for...