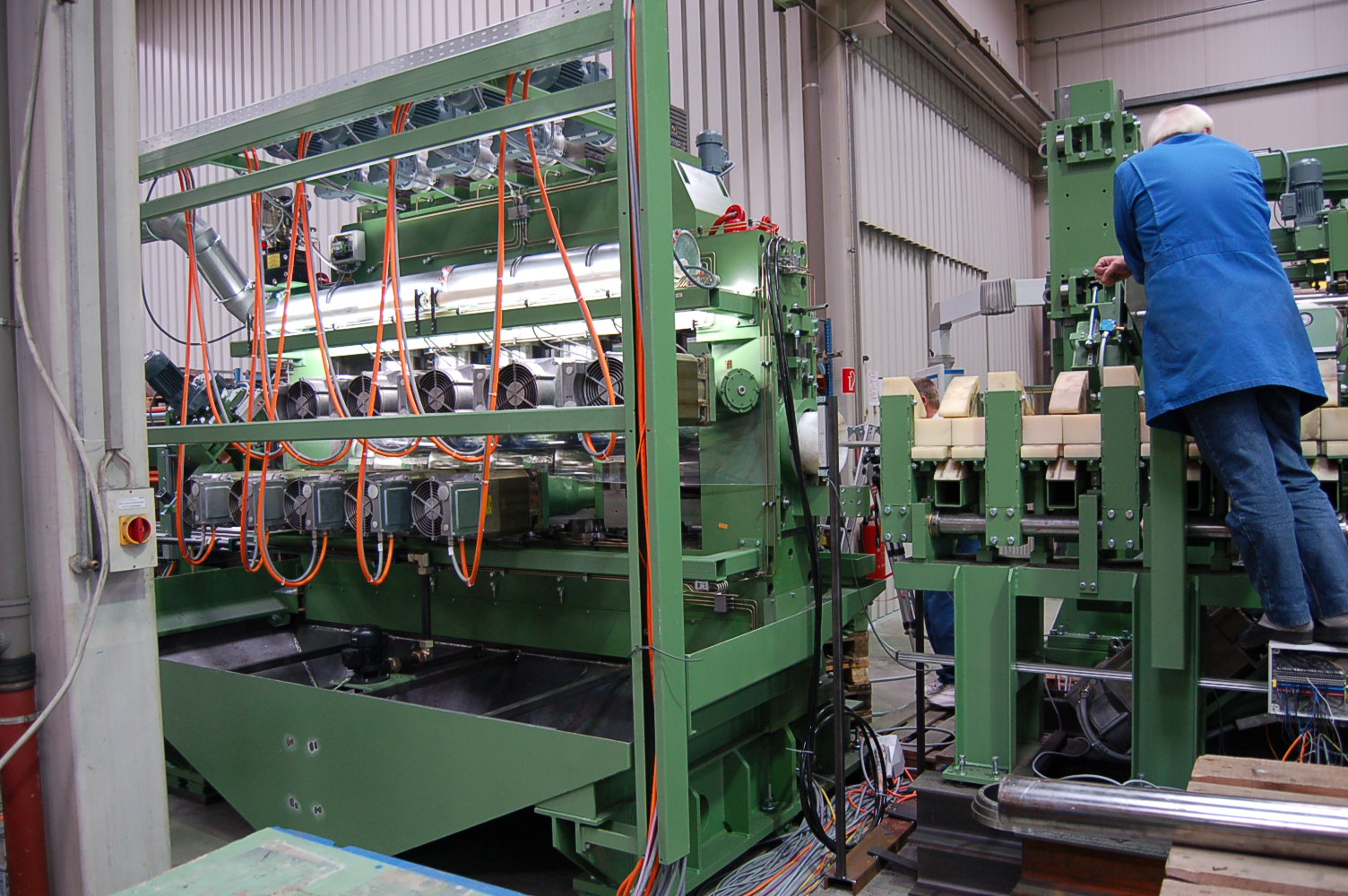

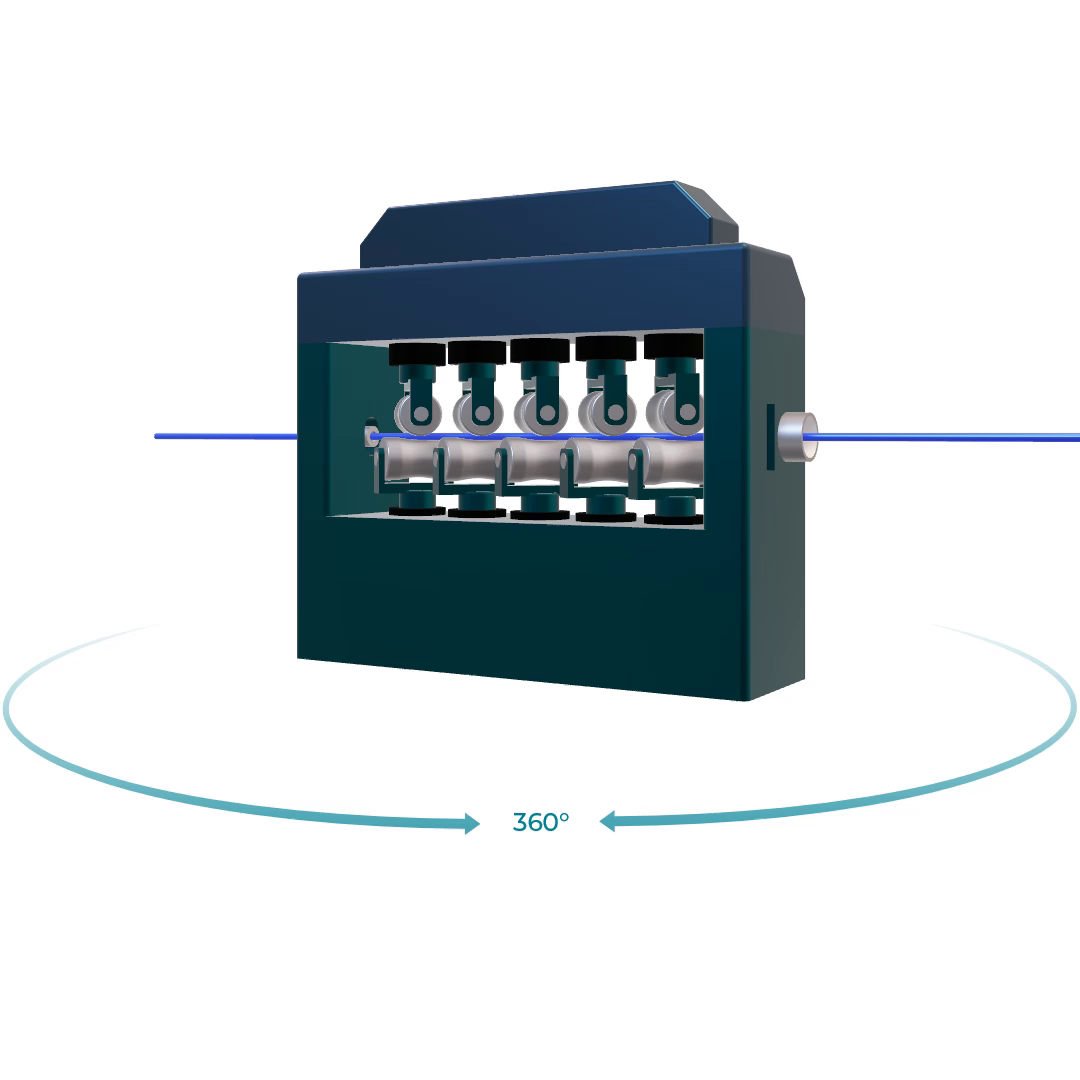

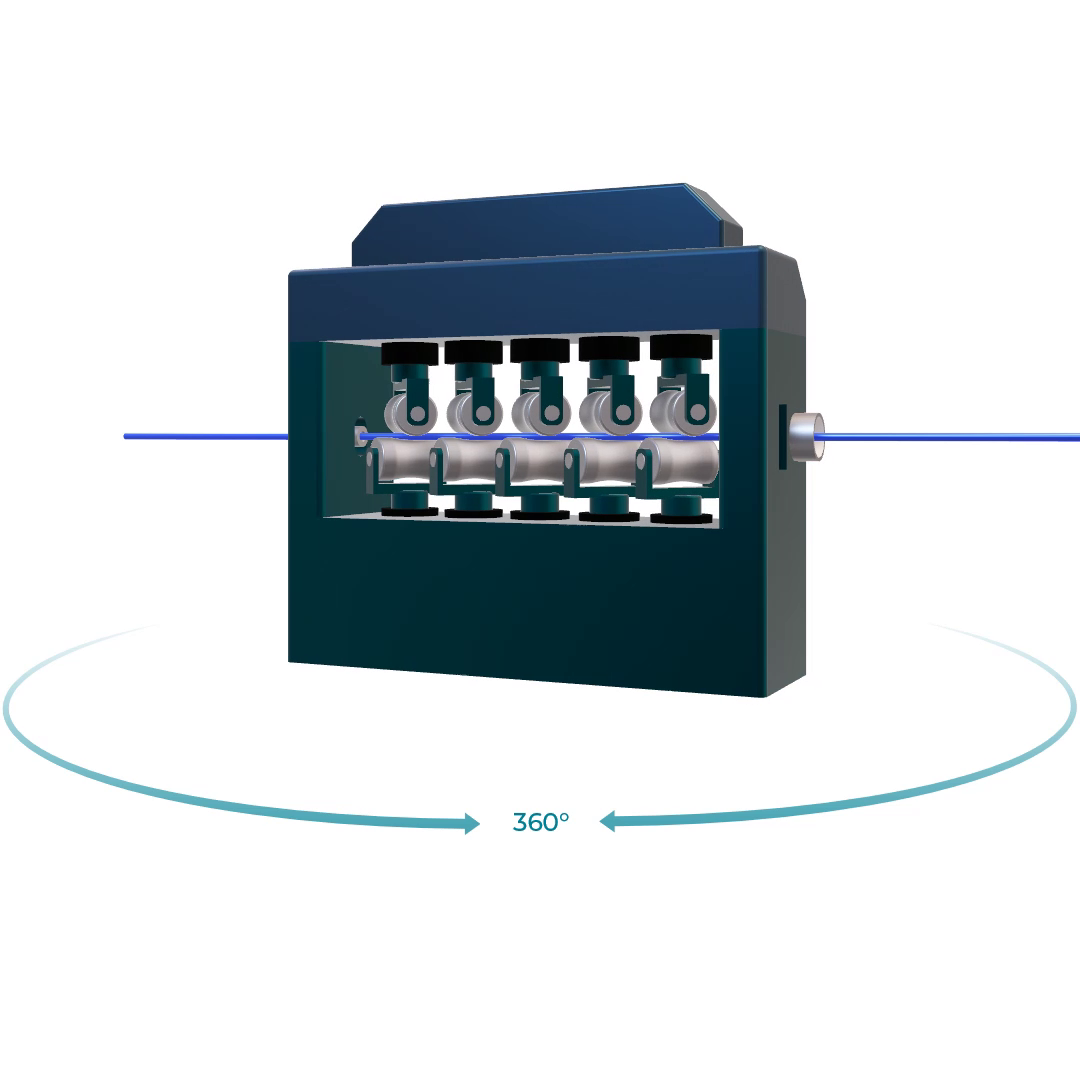

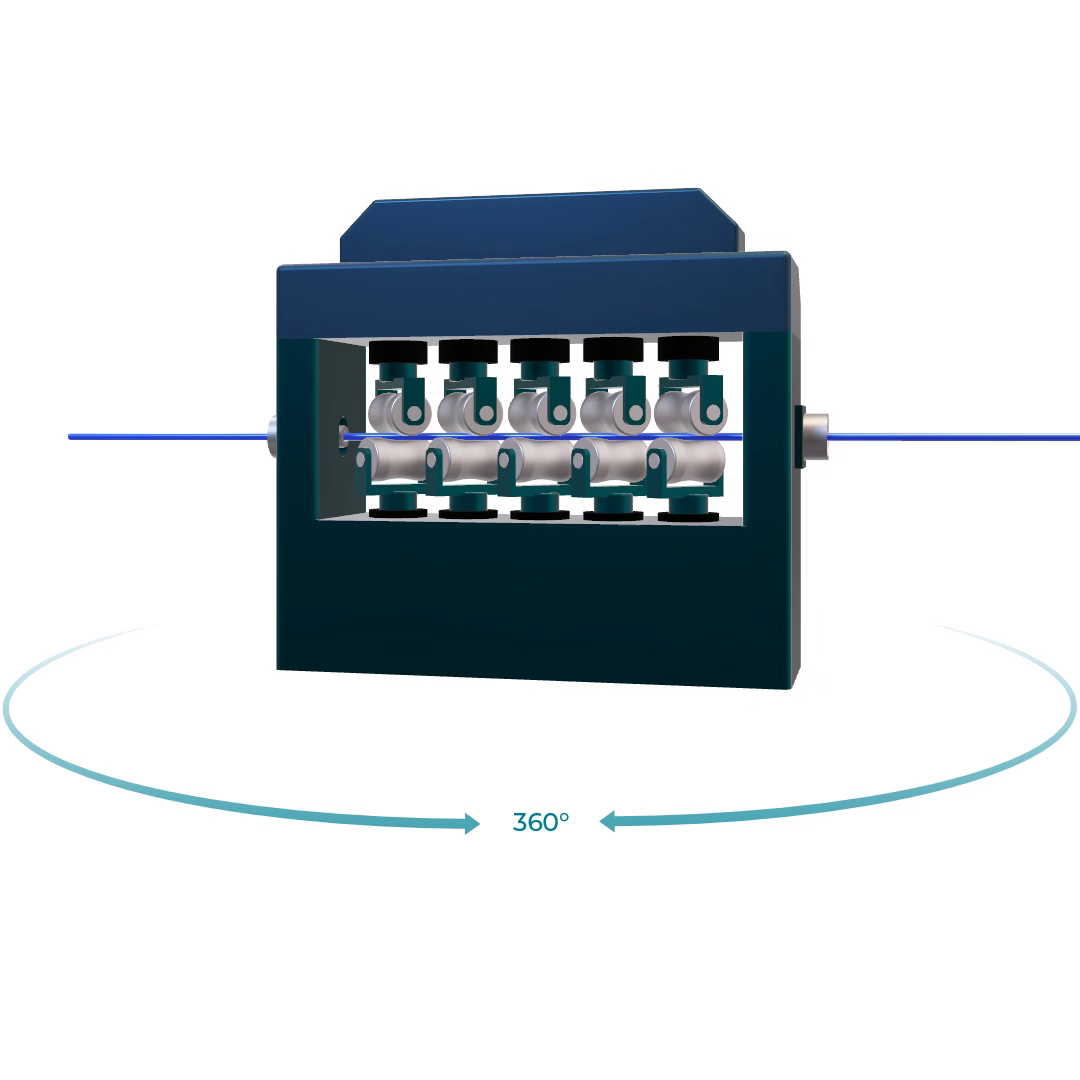

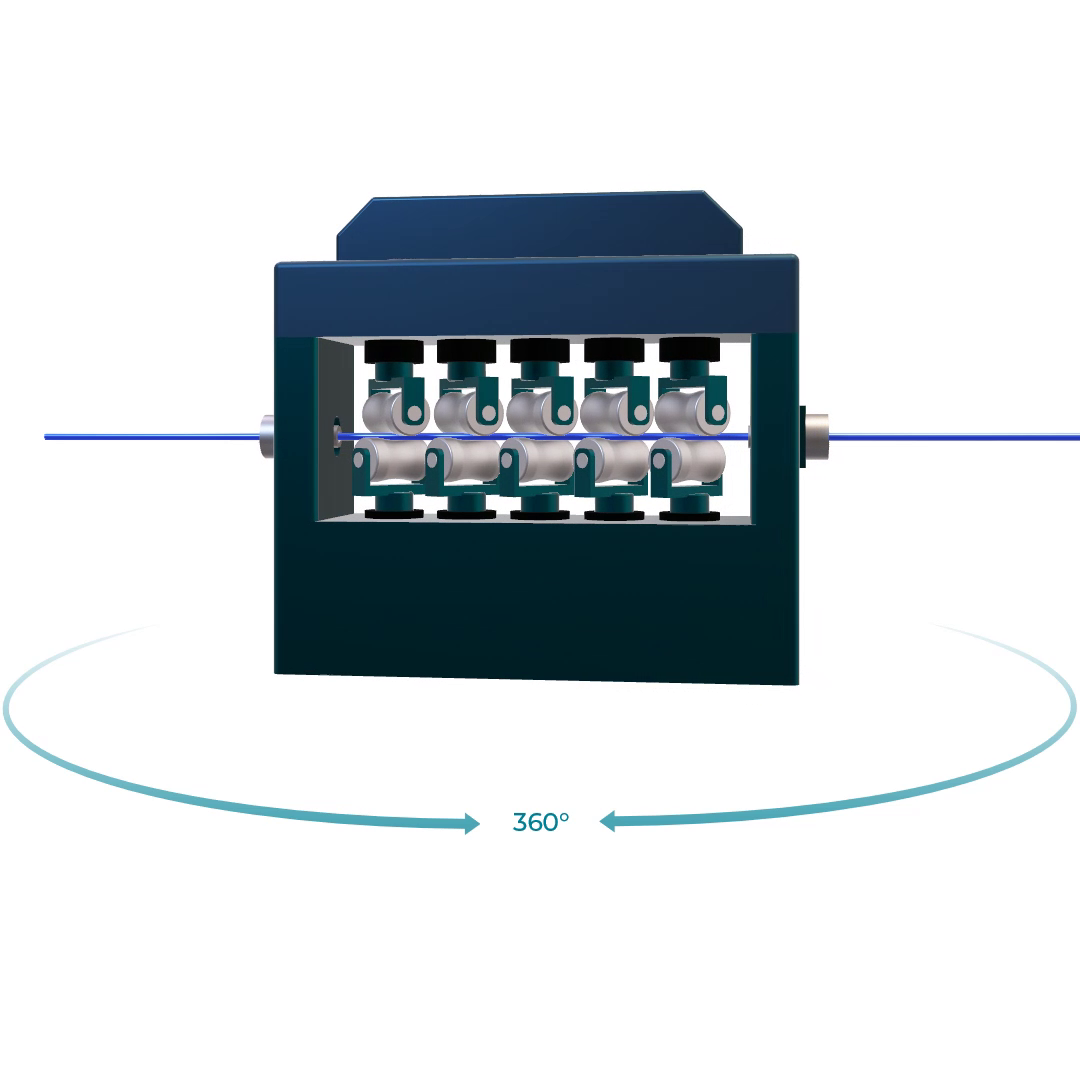

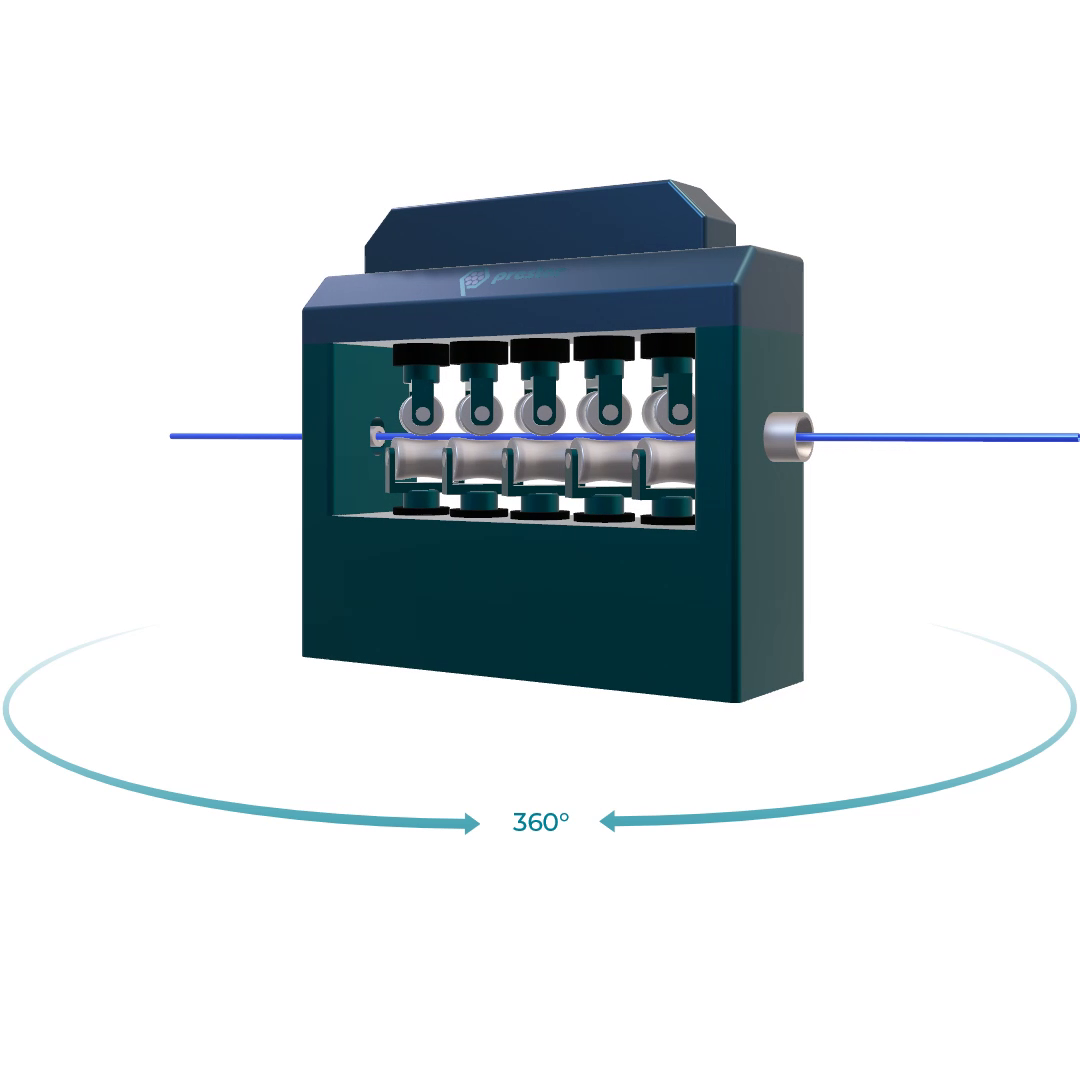

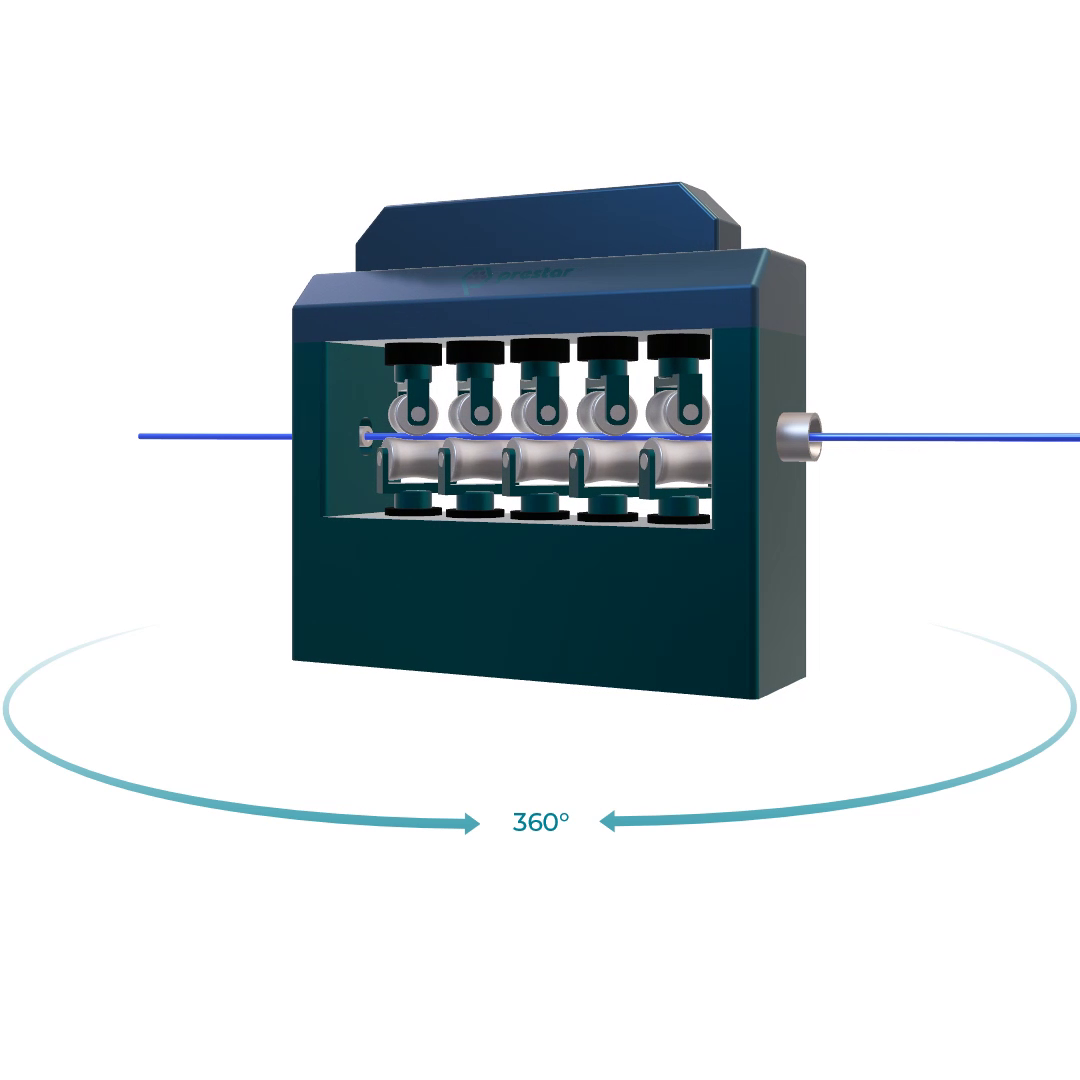

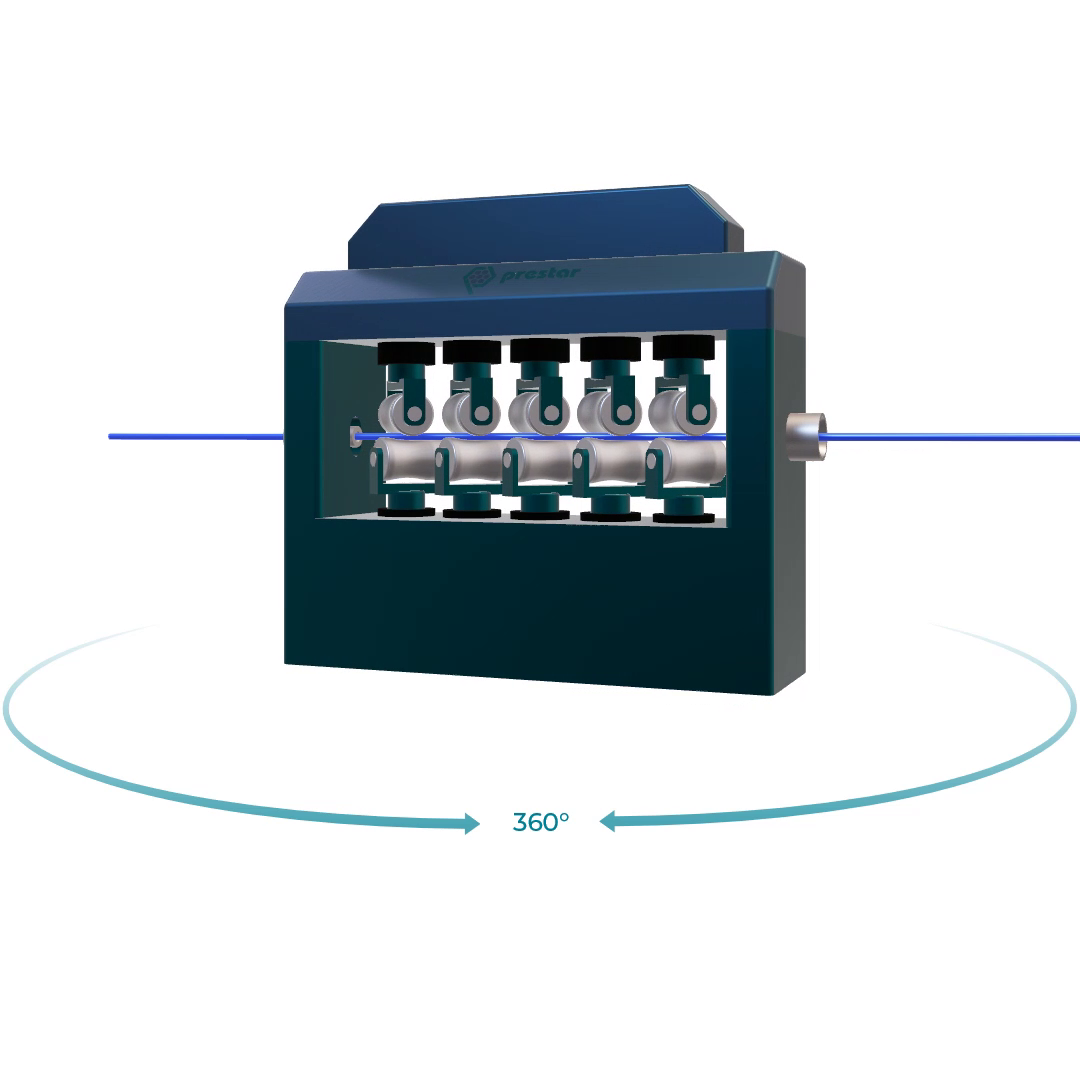

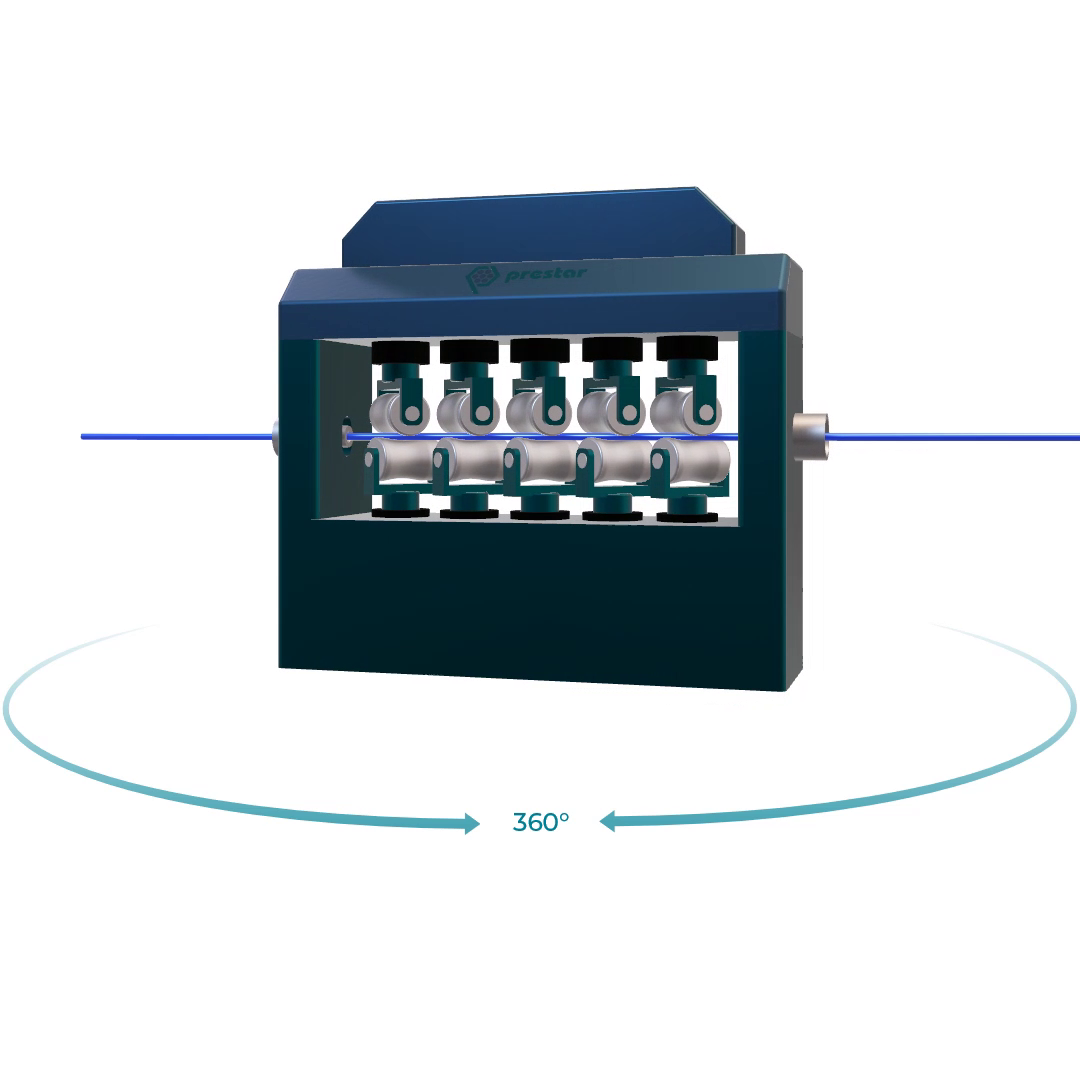

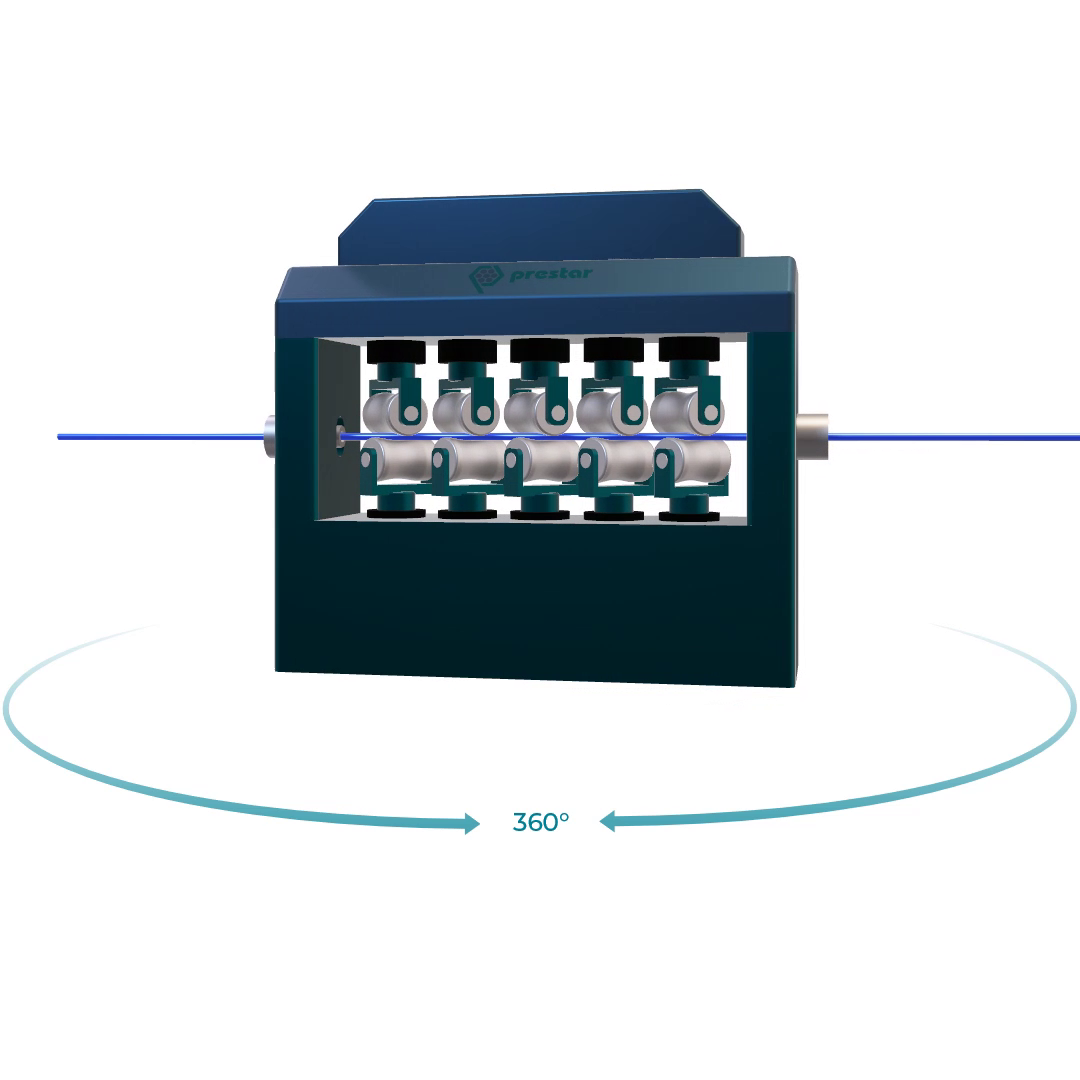

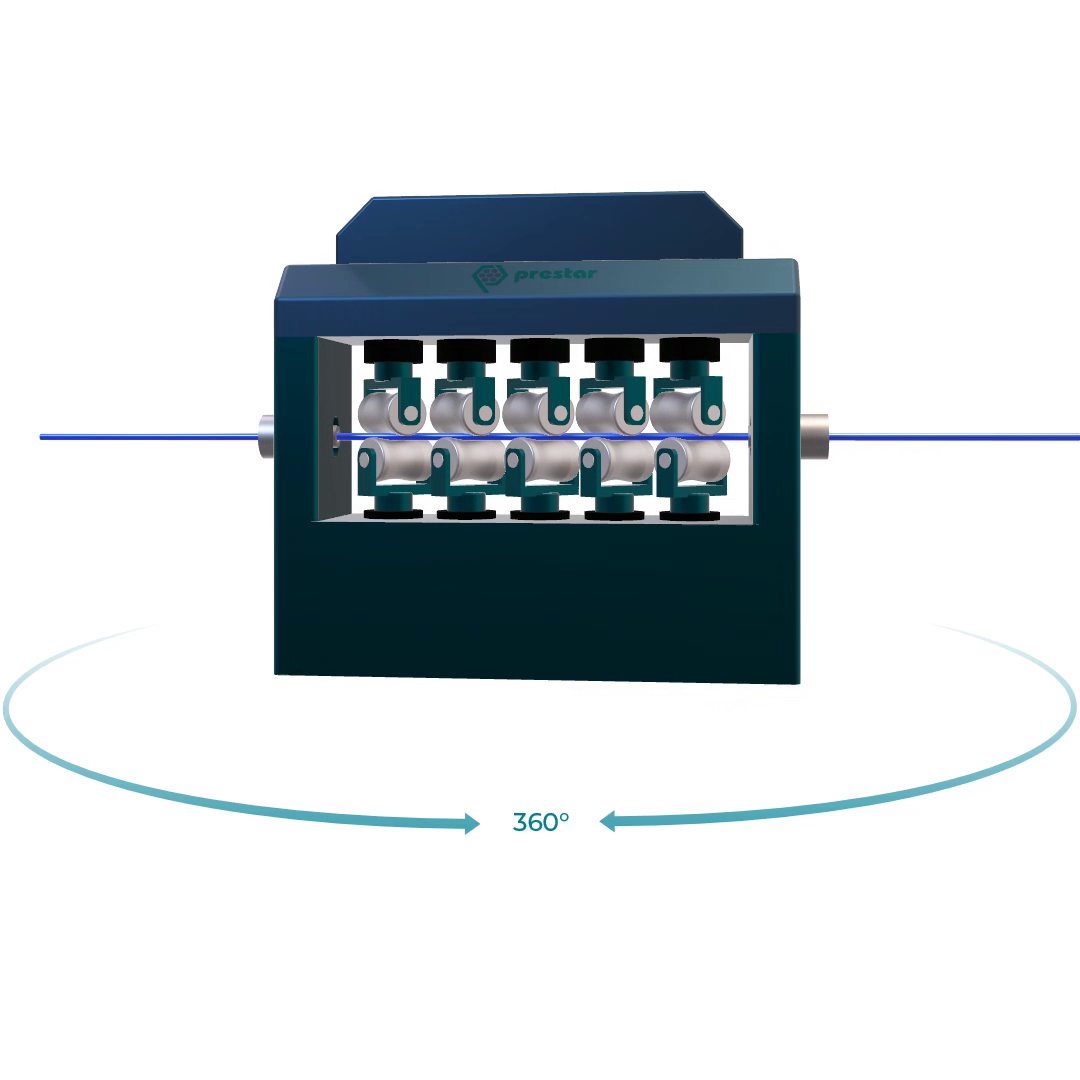

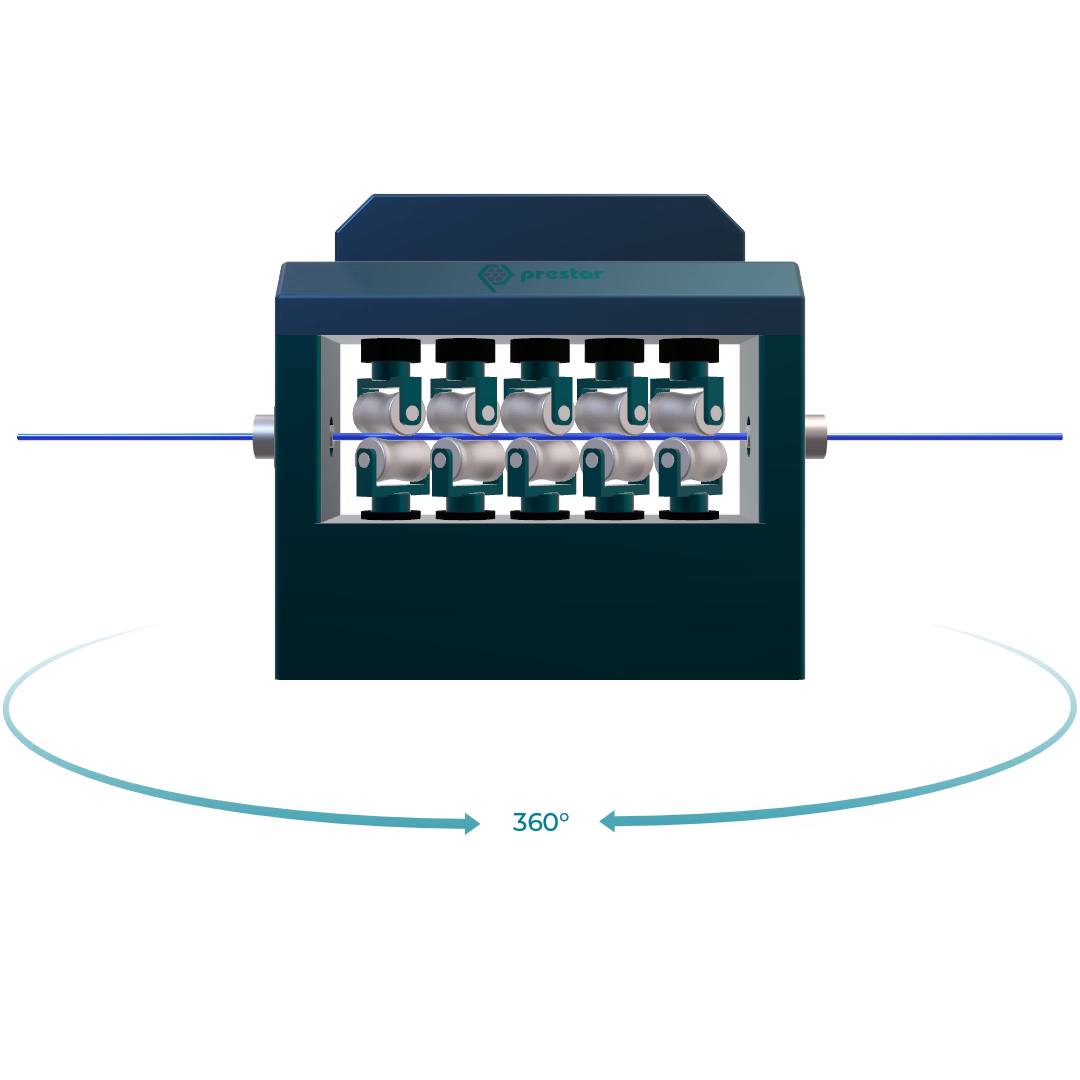

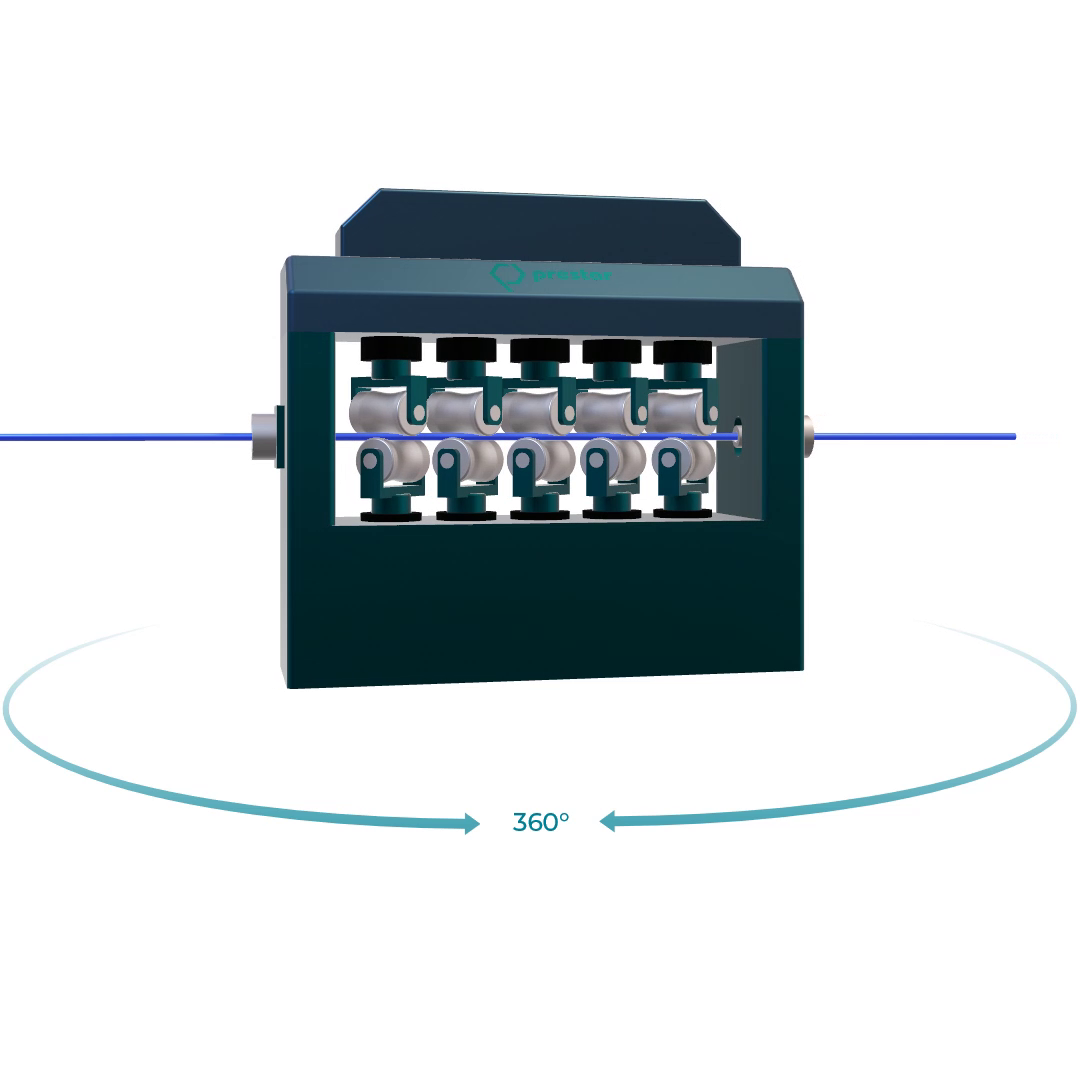

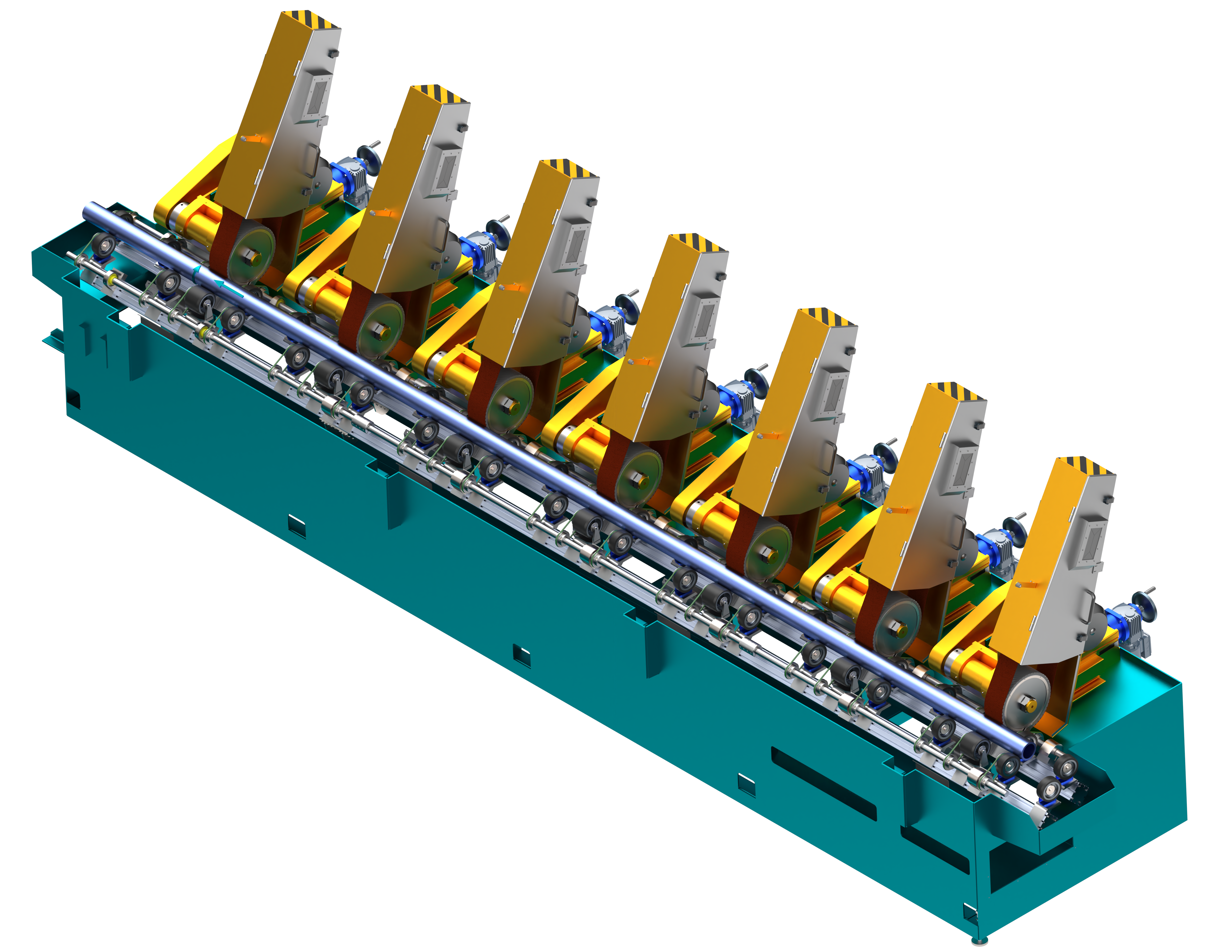

Straightening machines

For quick comparison of tubes and rods

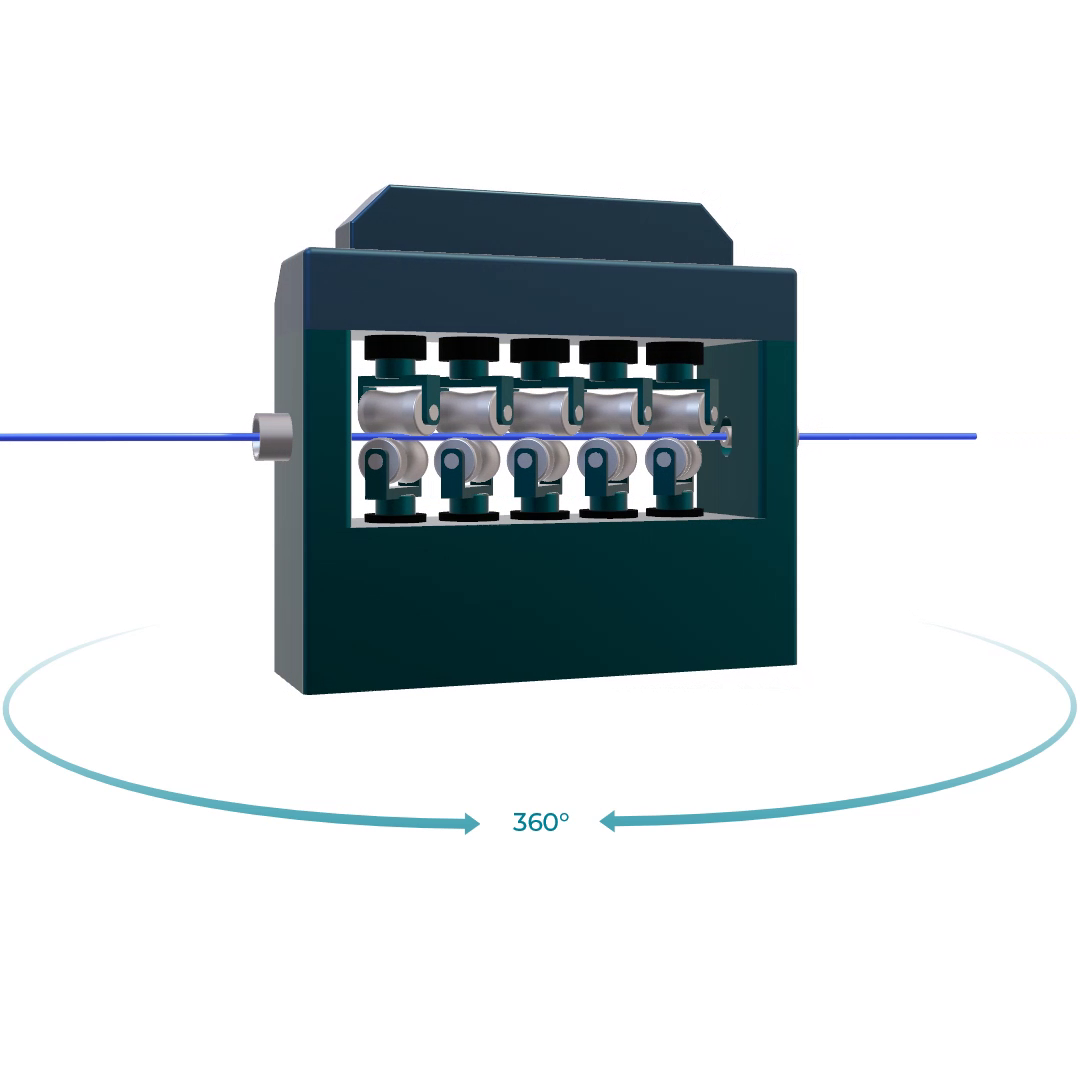

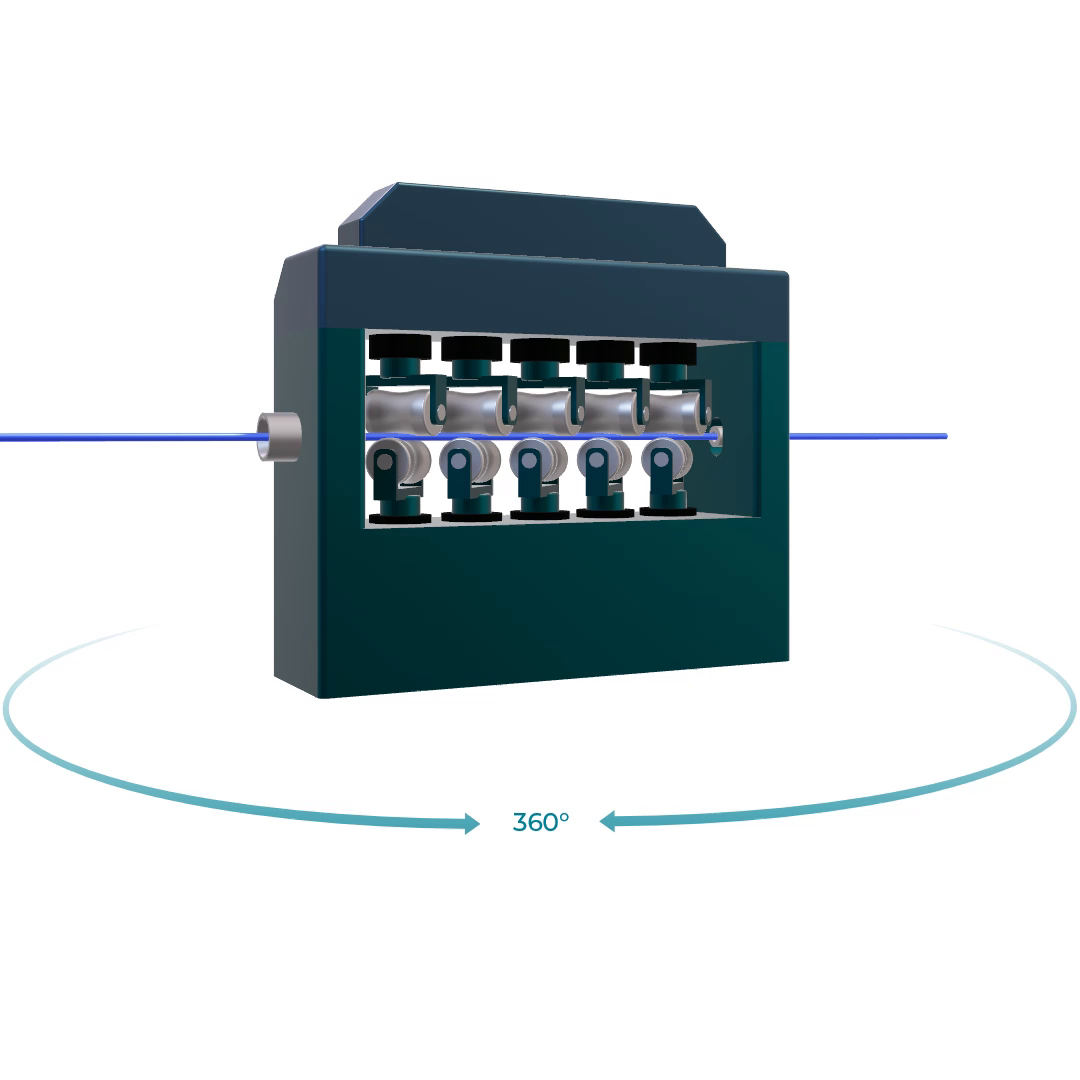

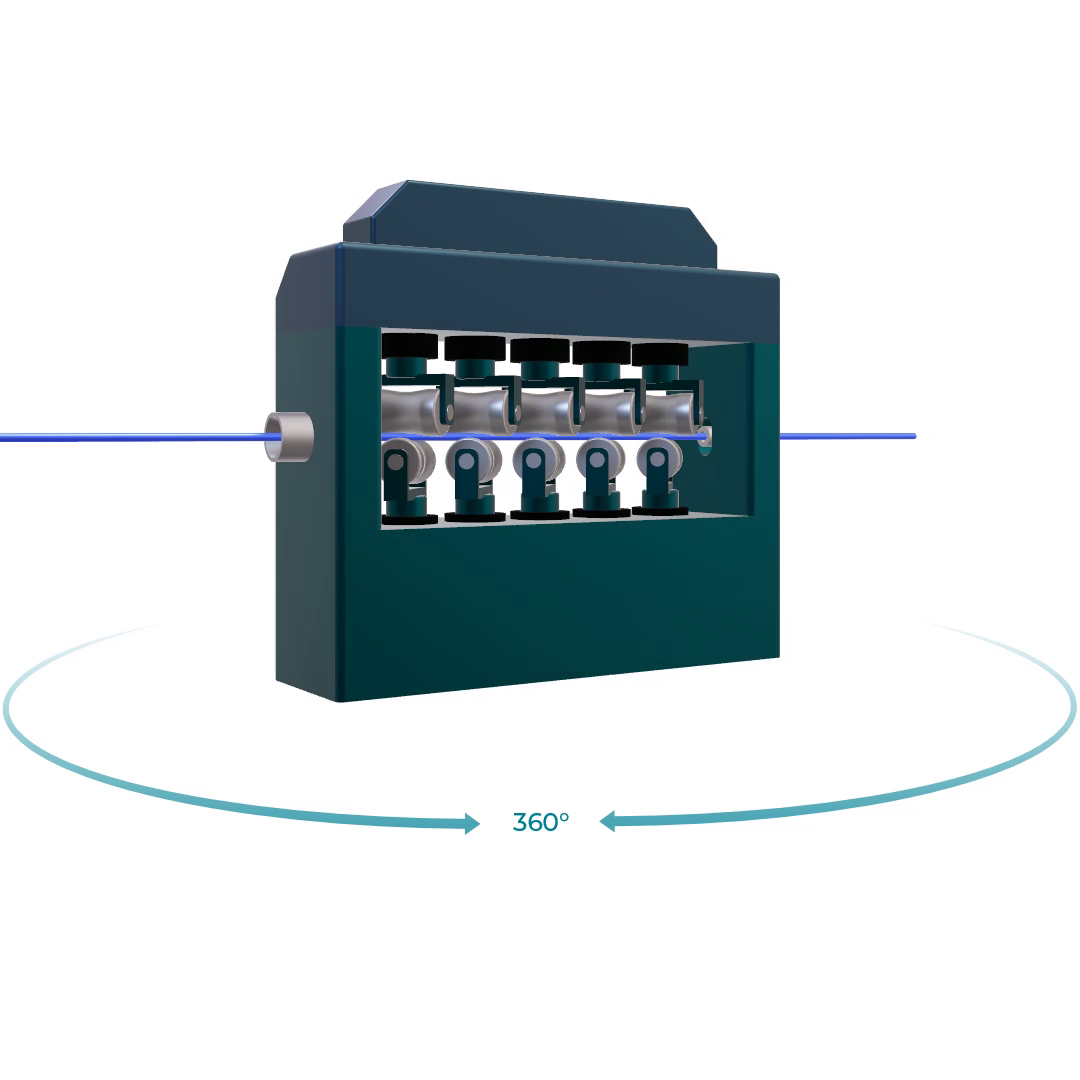

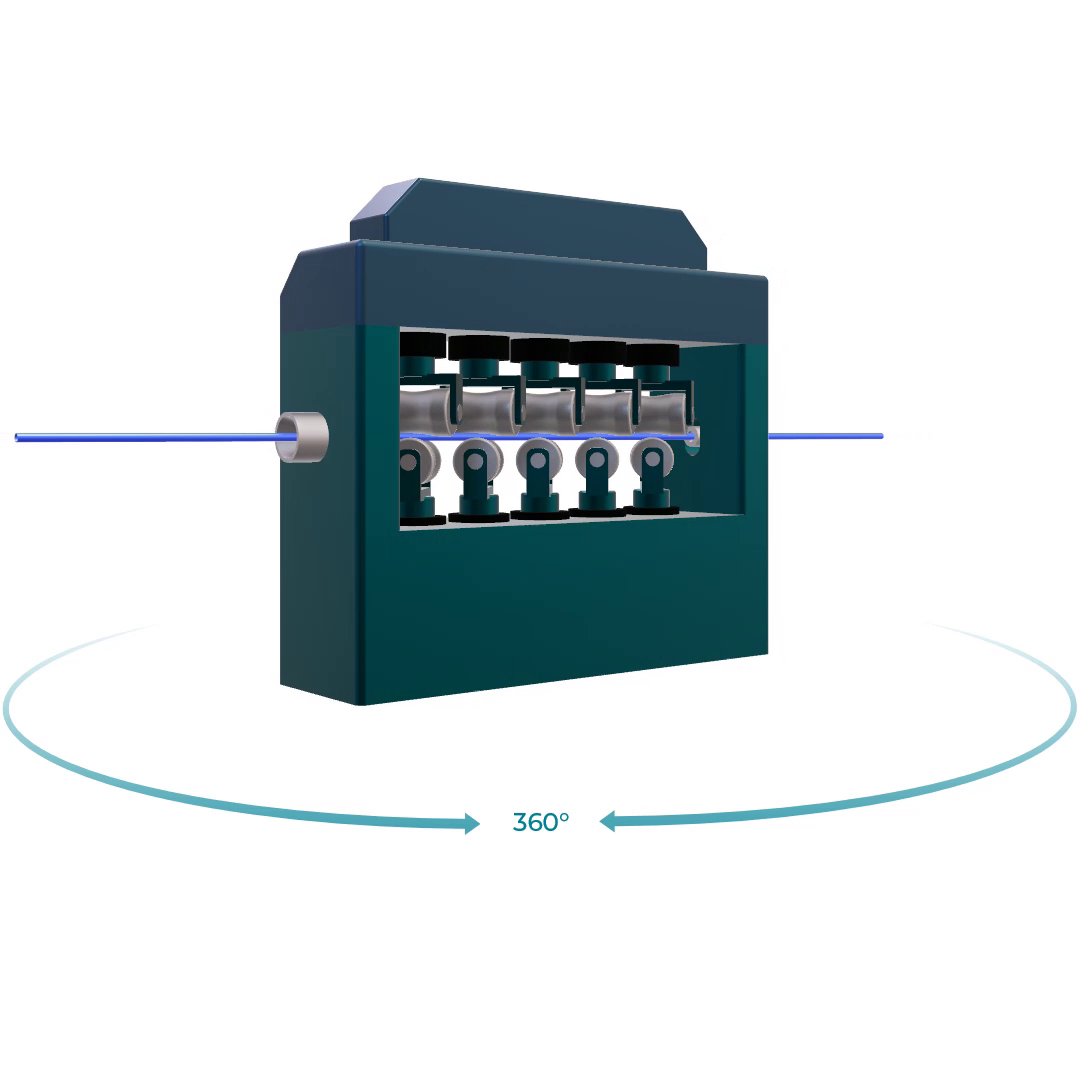

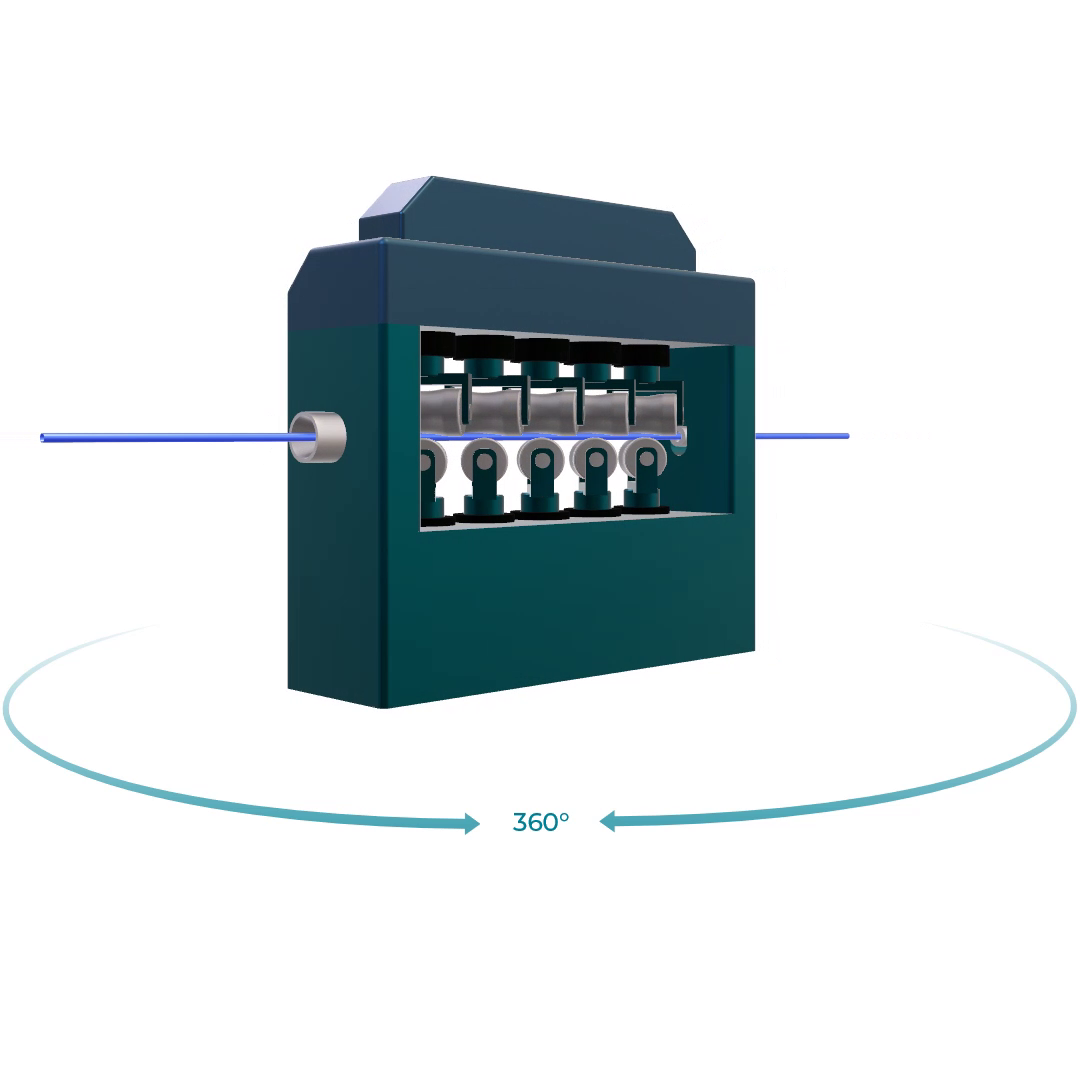

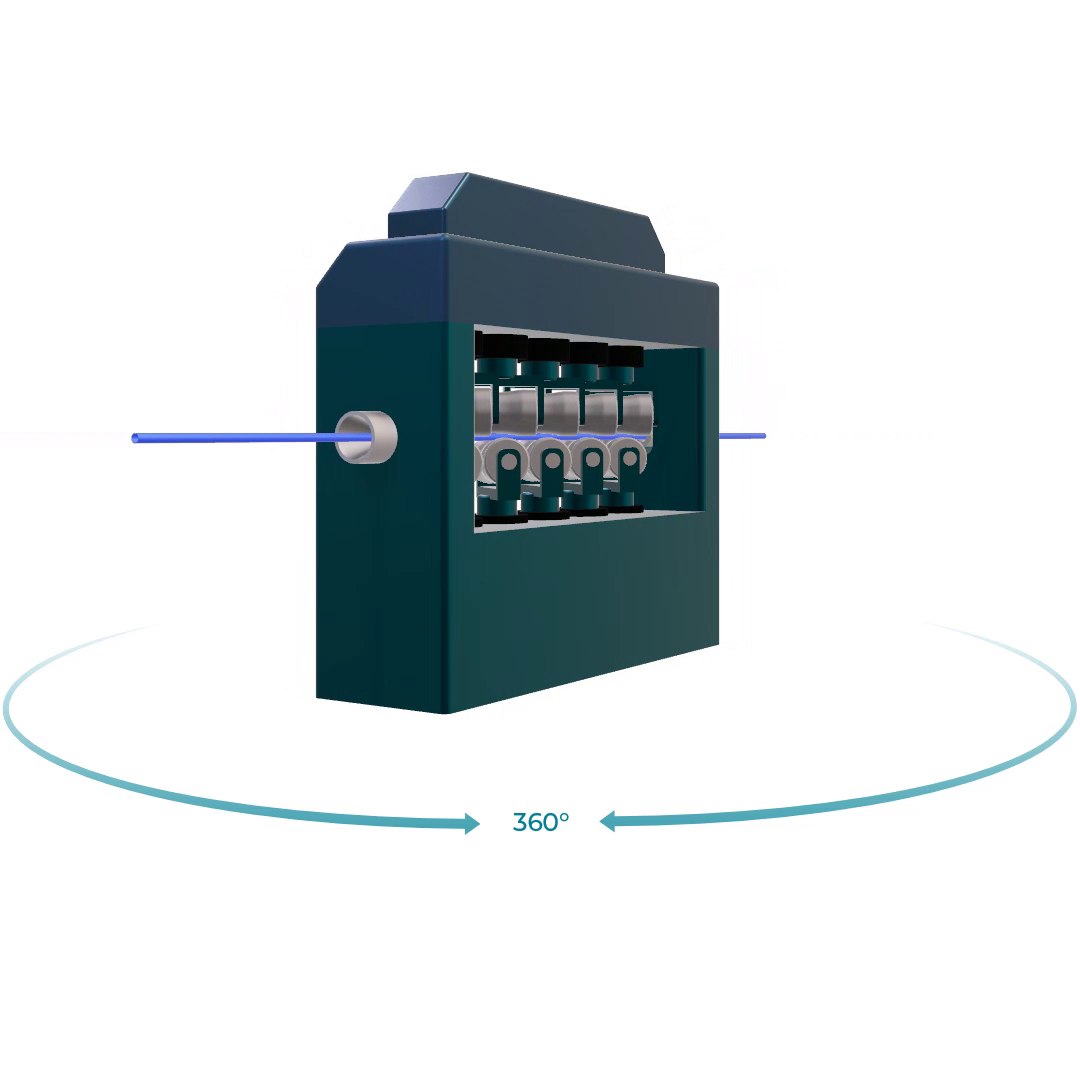

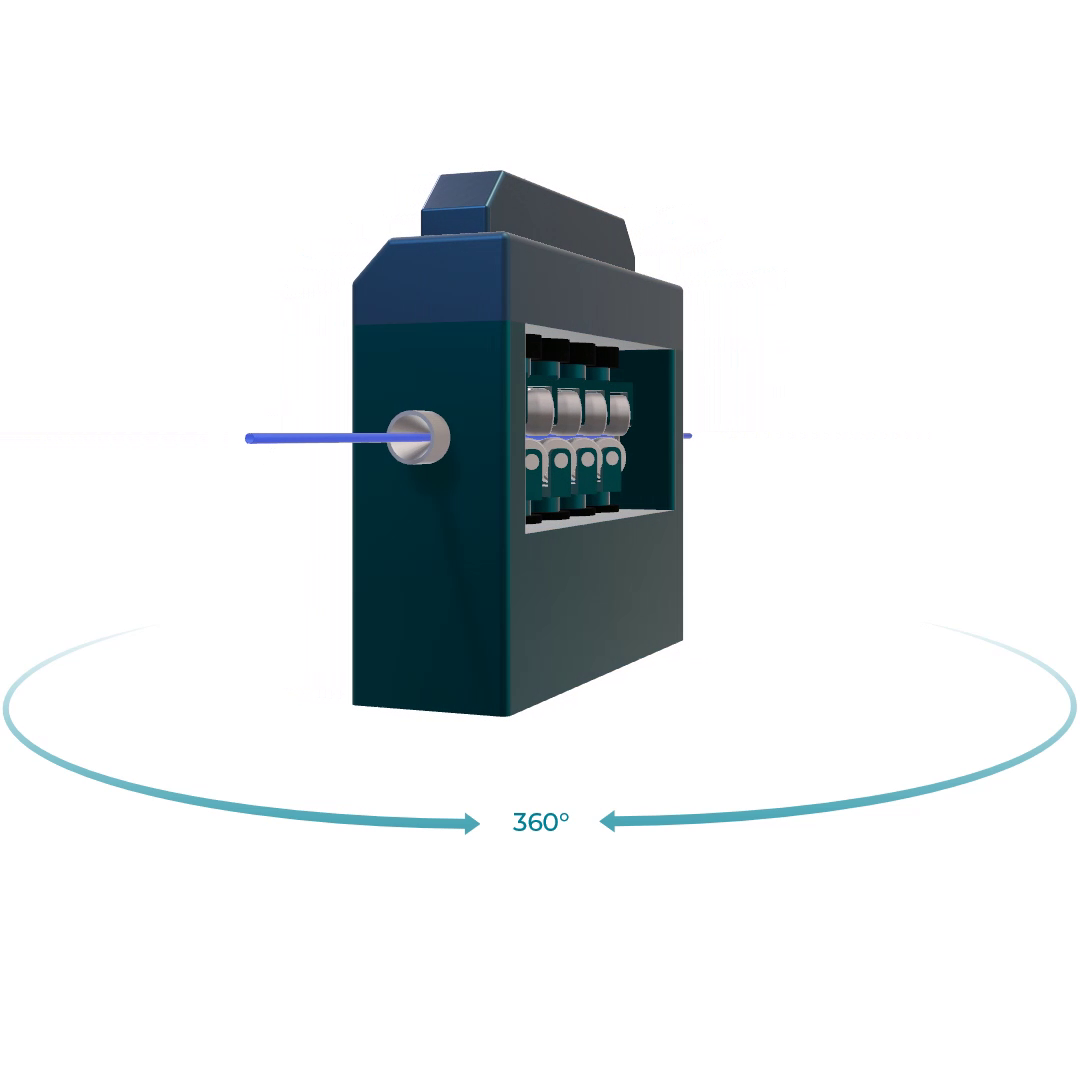

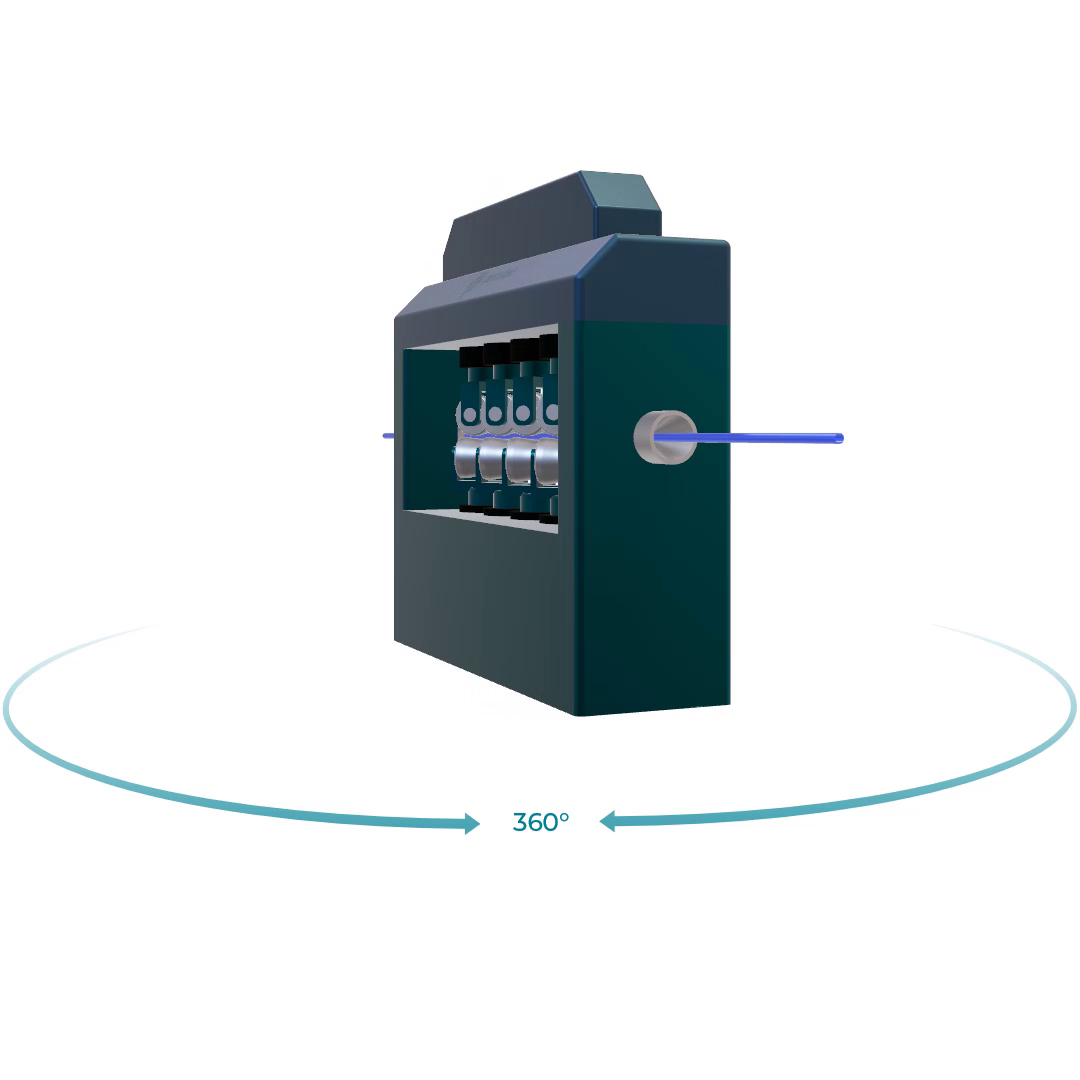

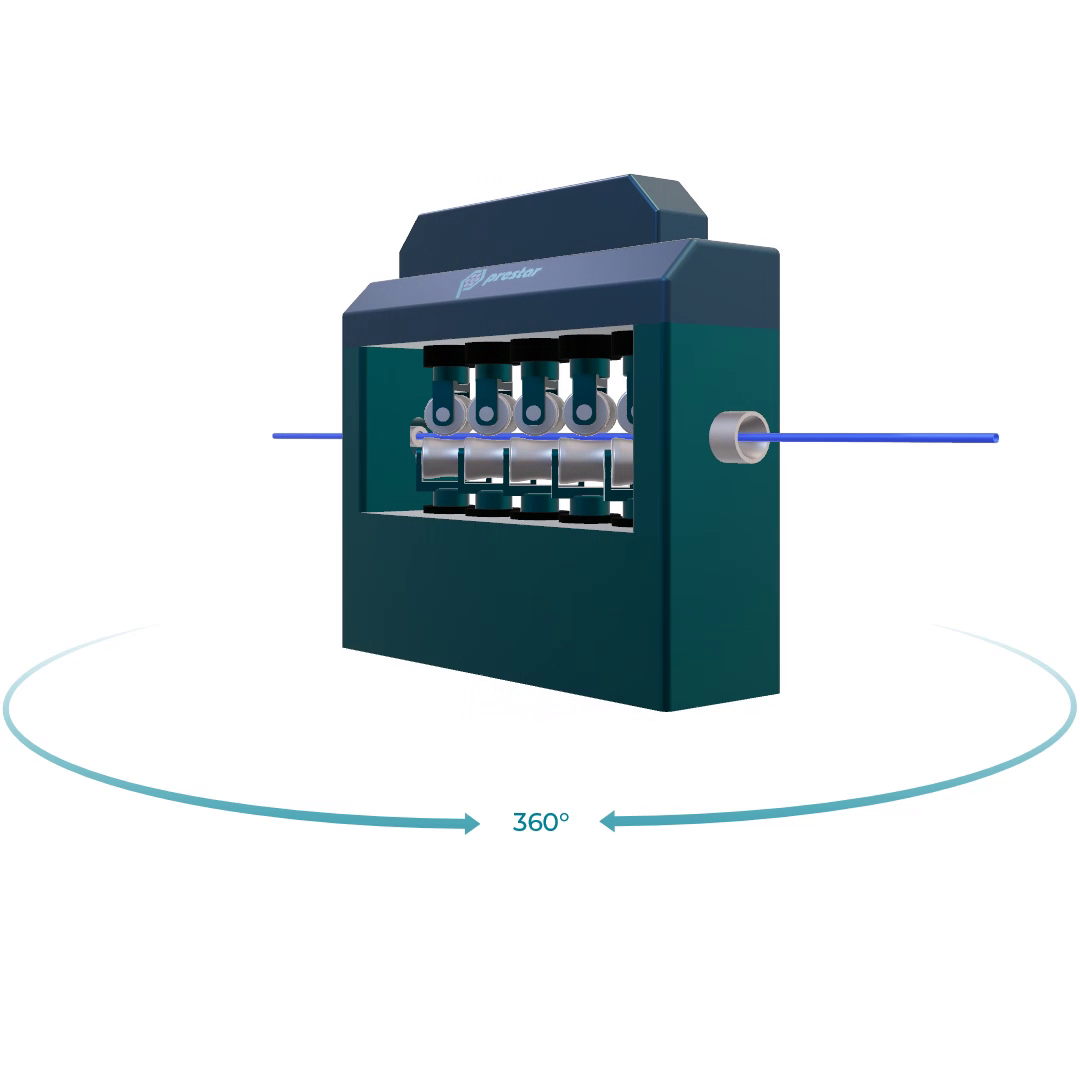

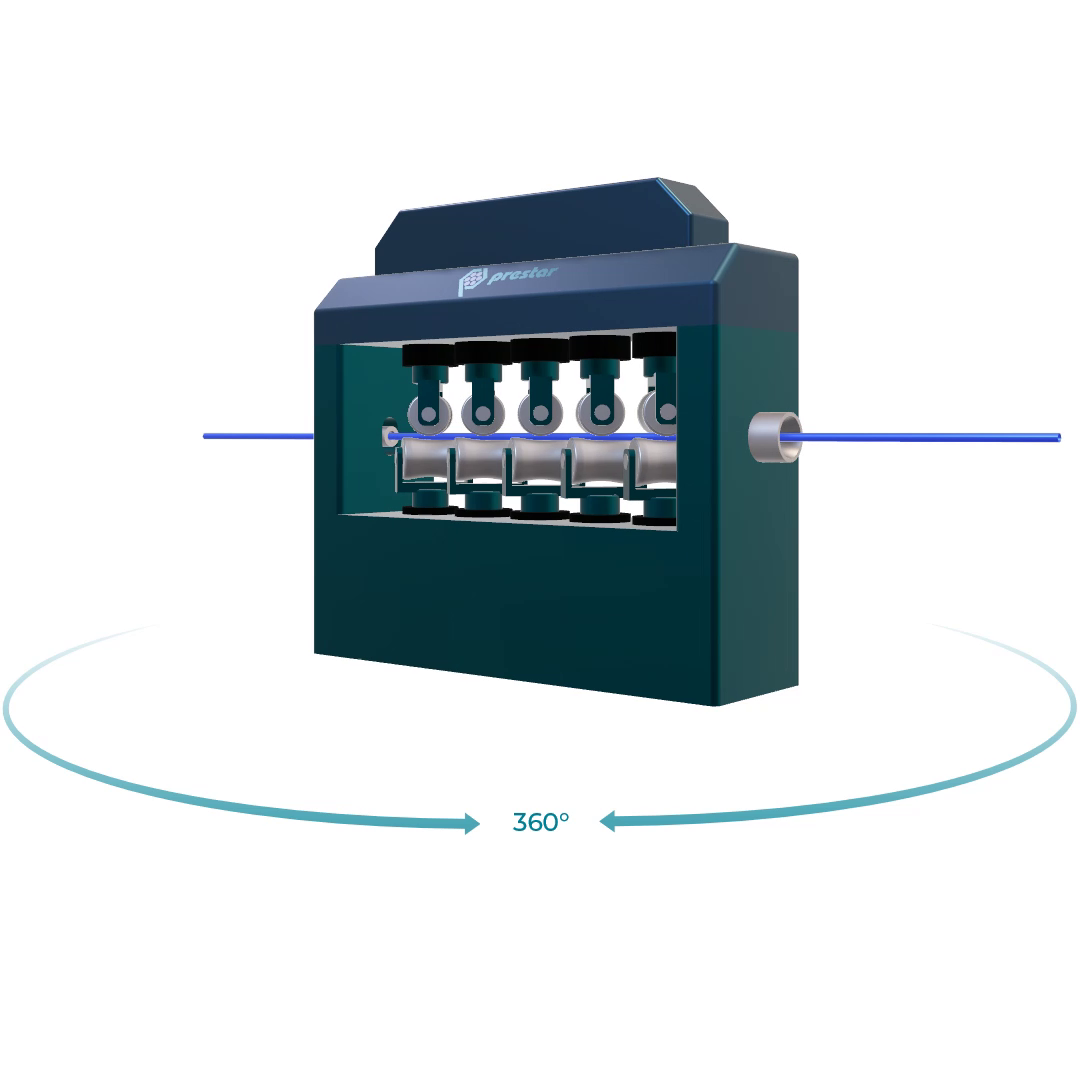

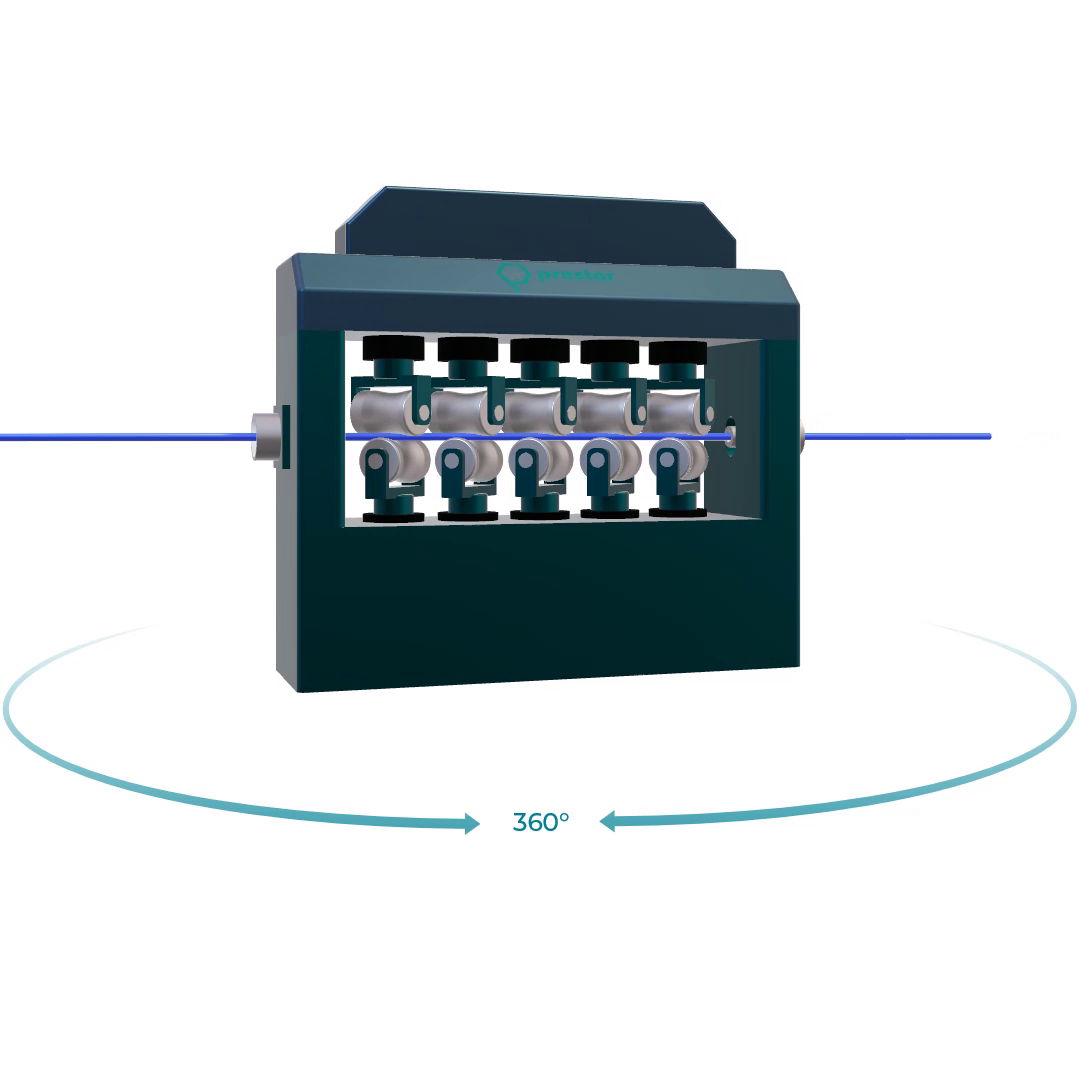

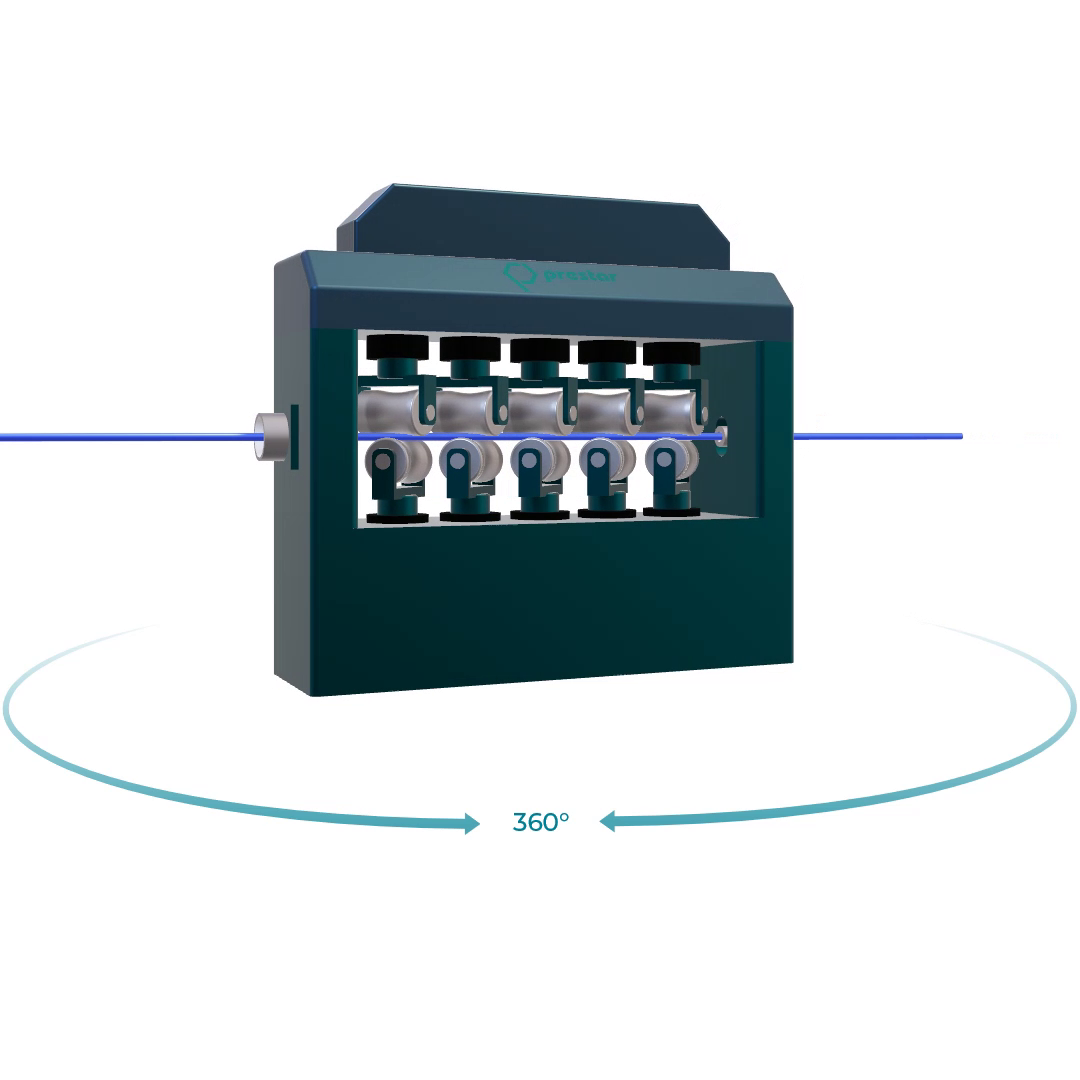

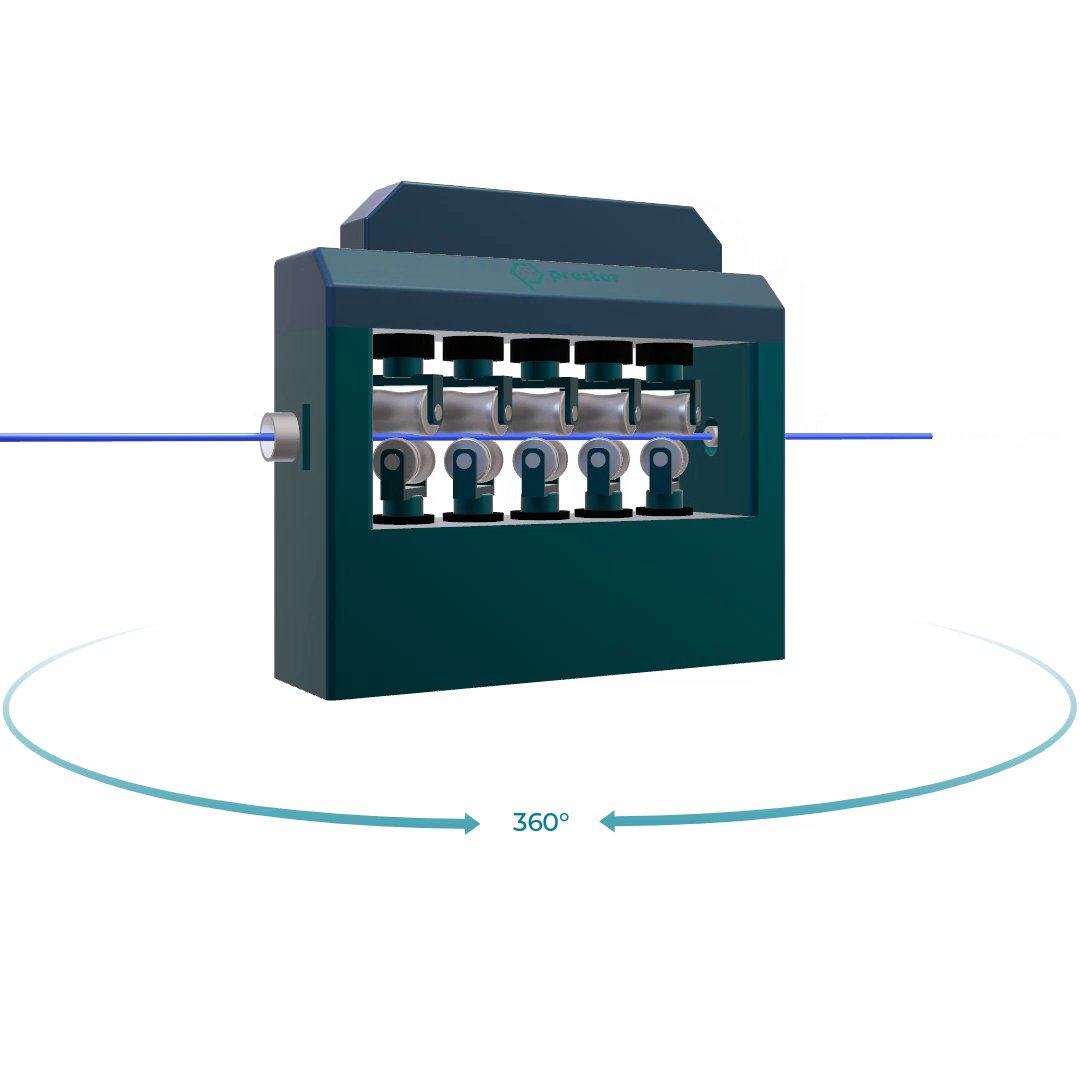

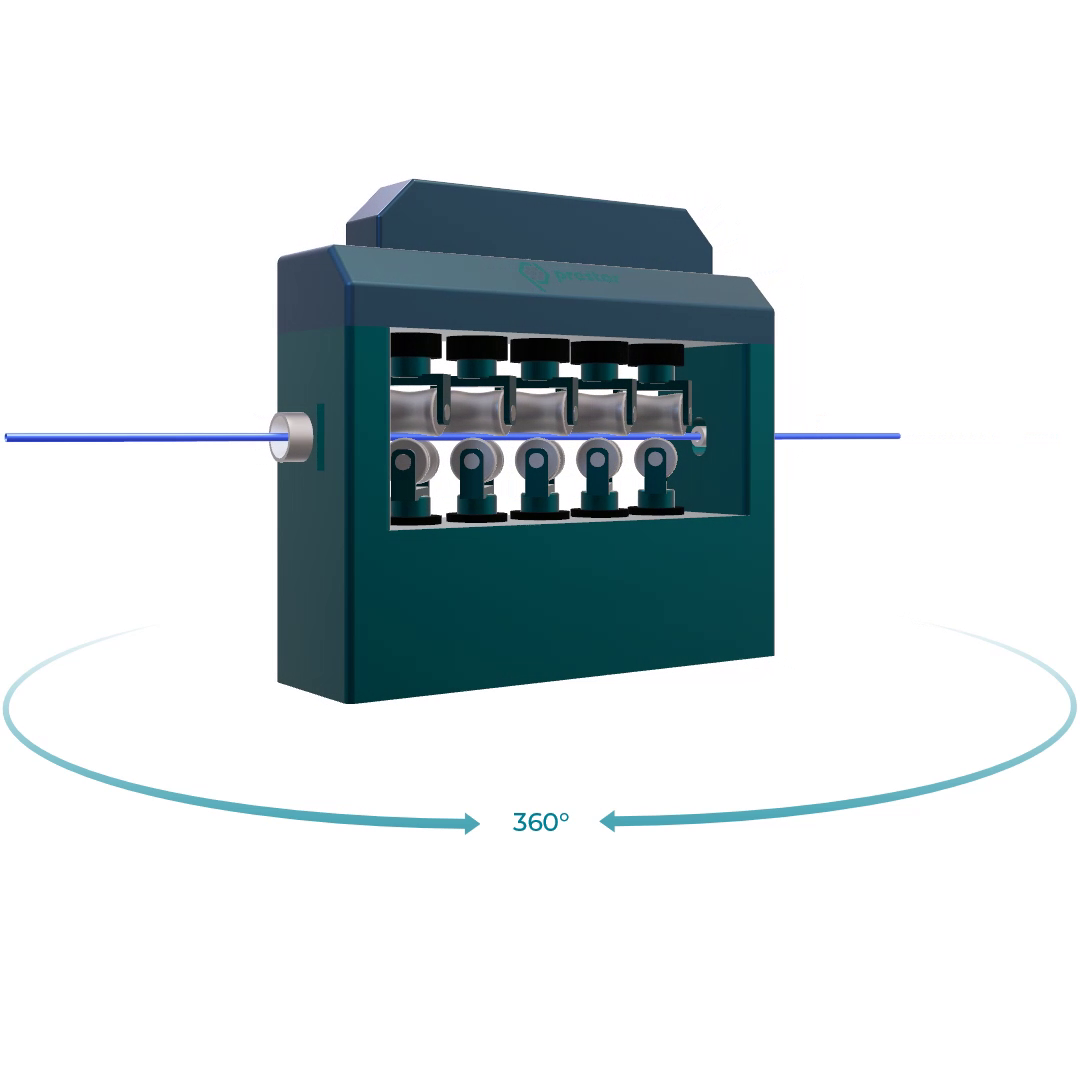

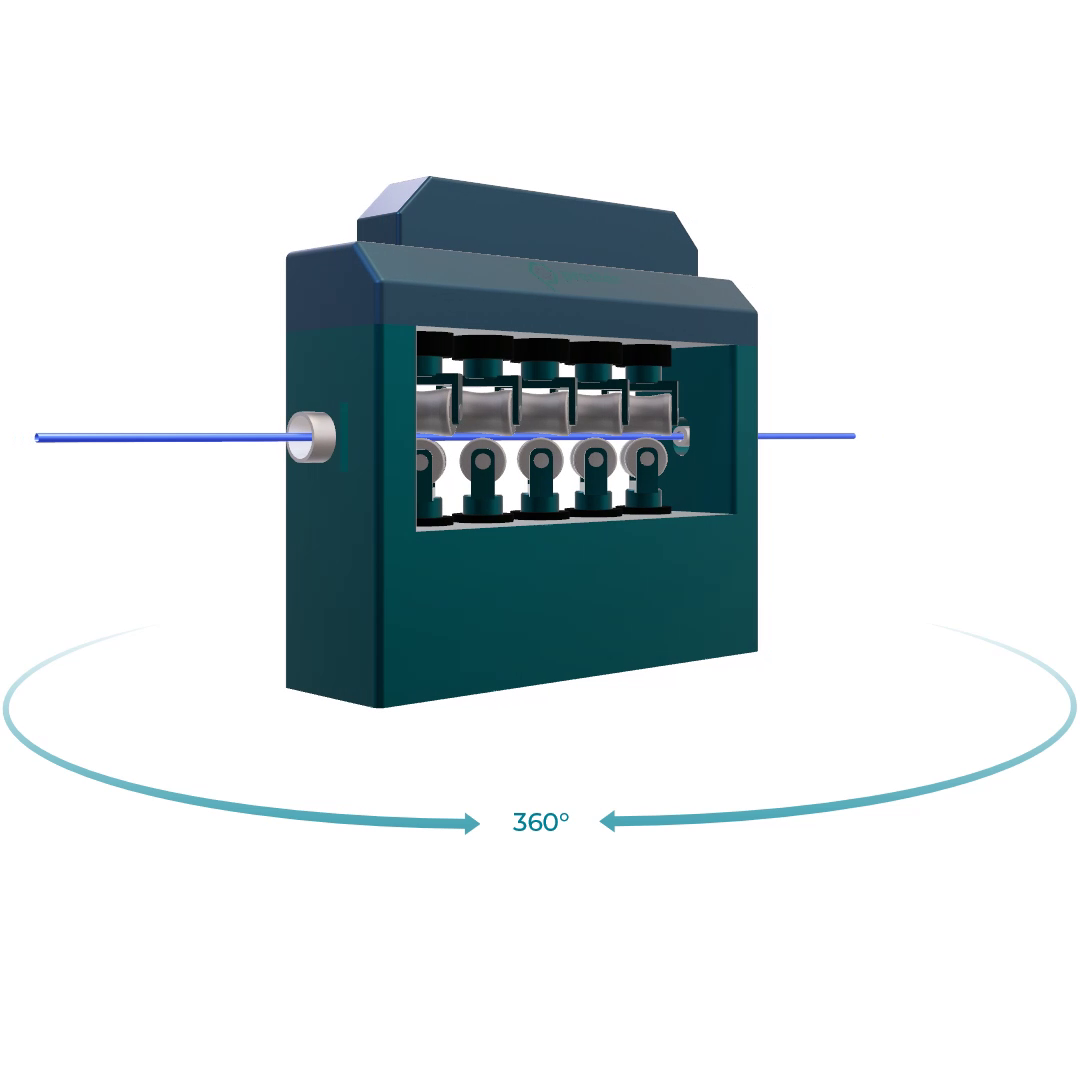

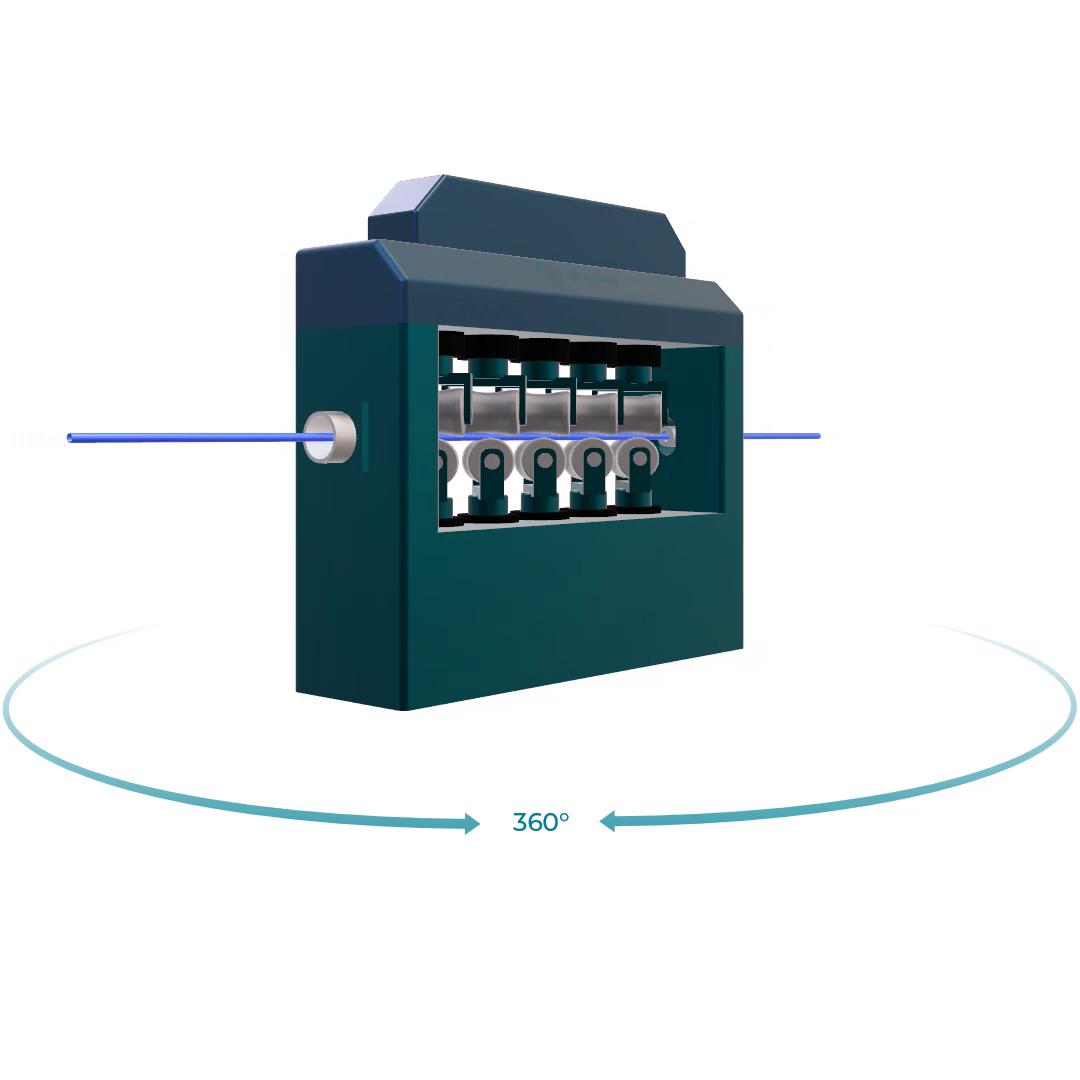

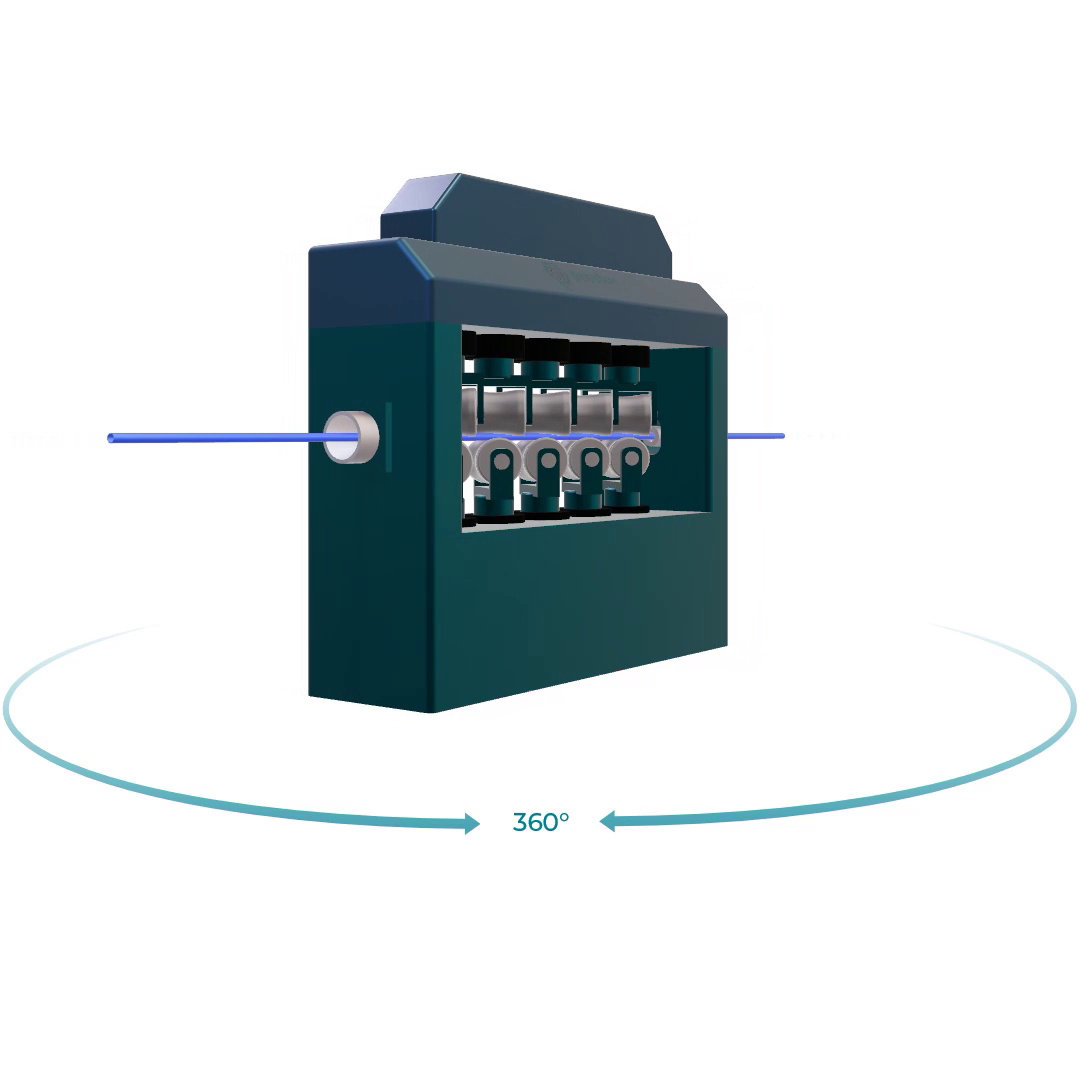

Description of the device

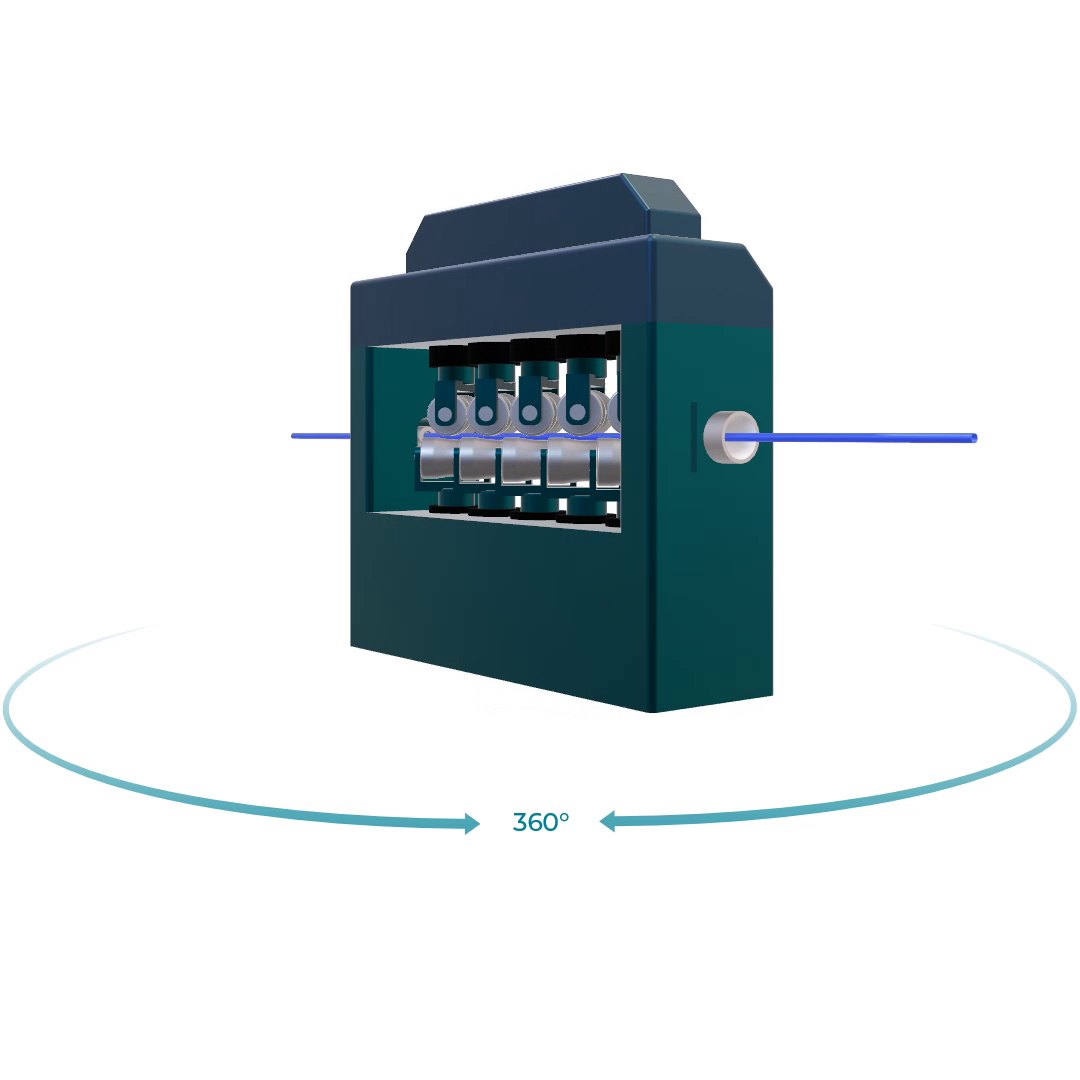

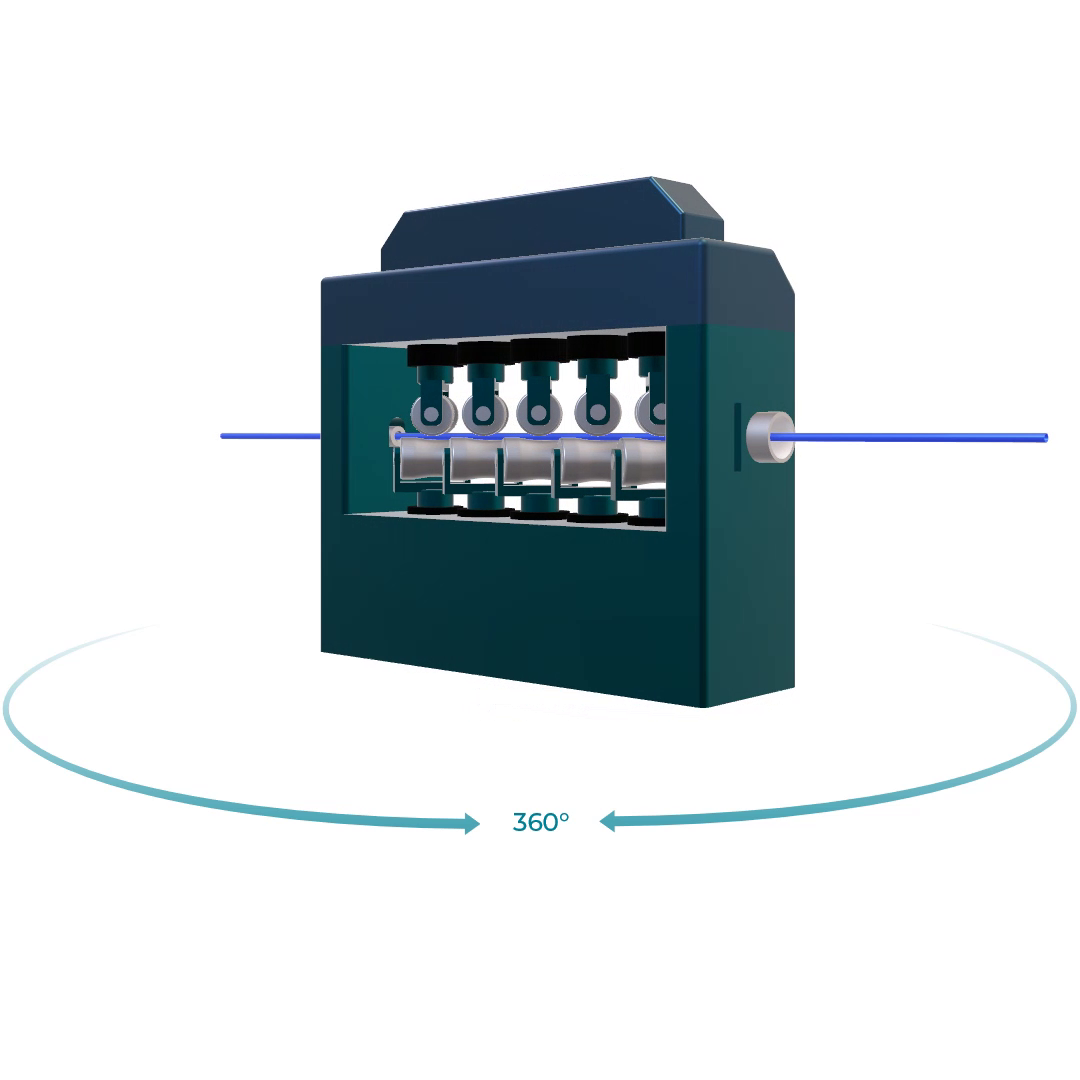

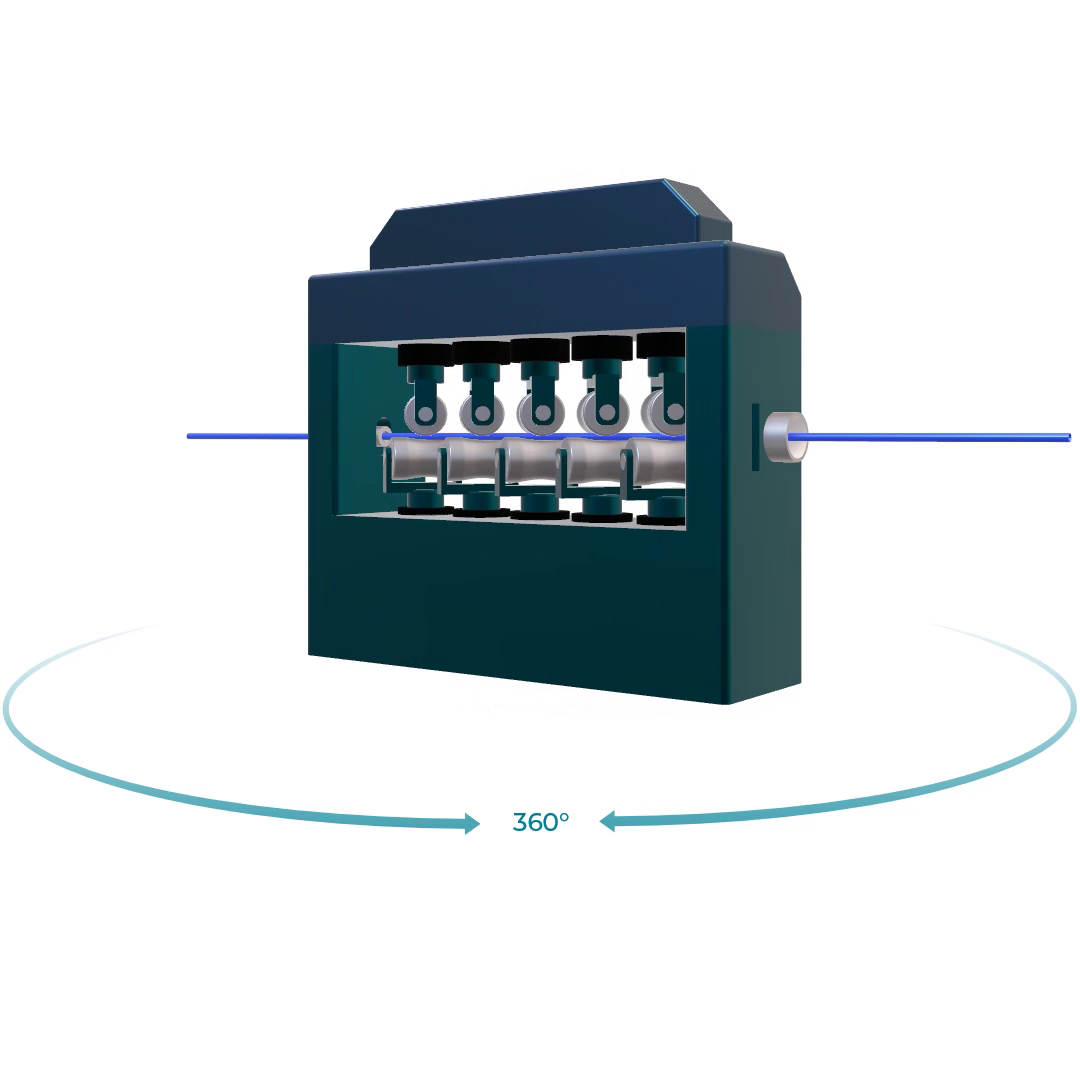

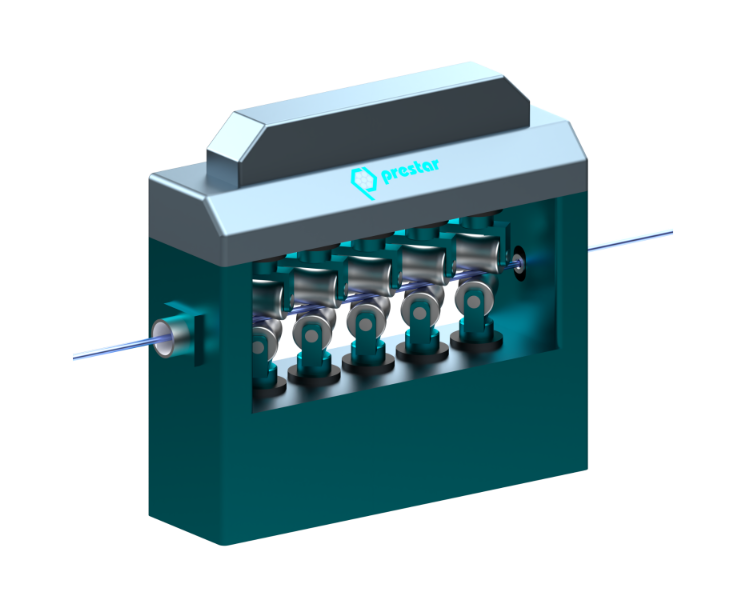

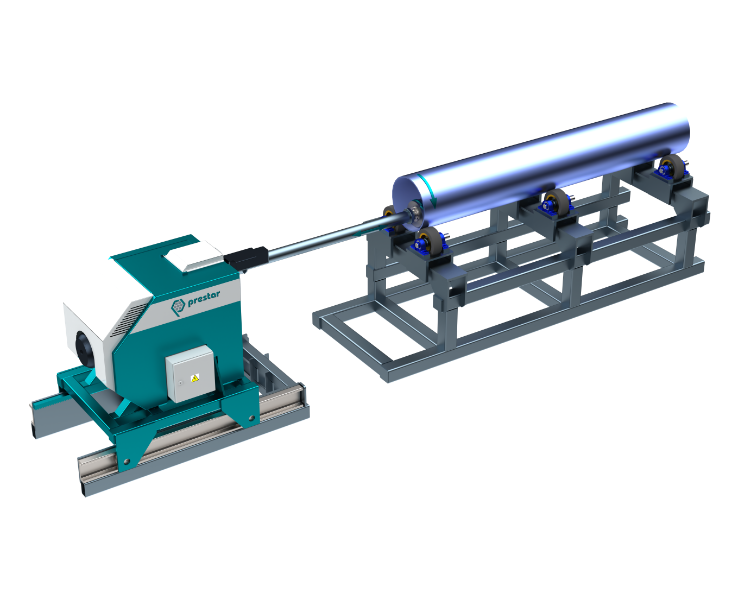

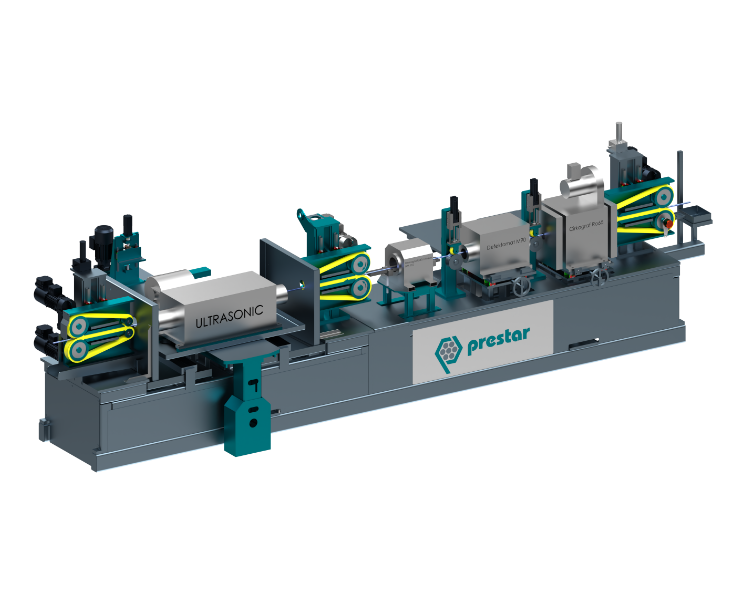

A 6-roll or fully automatic 10-roll straightening machine is used to straighten the tubes.

Technical parameters of the machine

- The use of a 10-roll straightening machine enables high-quality straightening results

- quick adjustment to a new tube size

- manual settings correction, saving settings in recipes and an overview for manual control via the control panel

Other equipment of the machine

- Guide inlet channel

- Input driver to the straightening machine

- Output channel

- Protective cover of the straightening machine

- Cleaning of the straightening rolls

Straightening machines

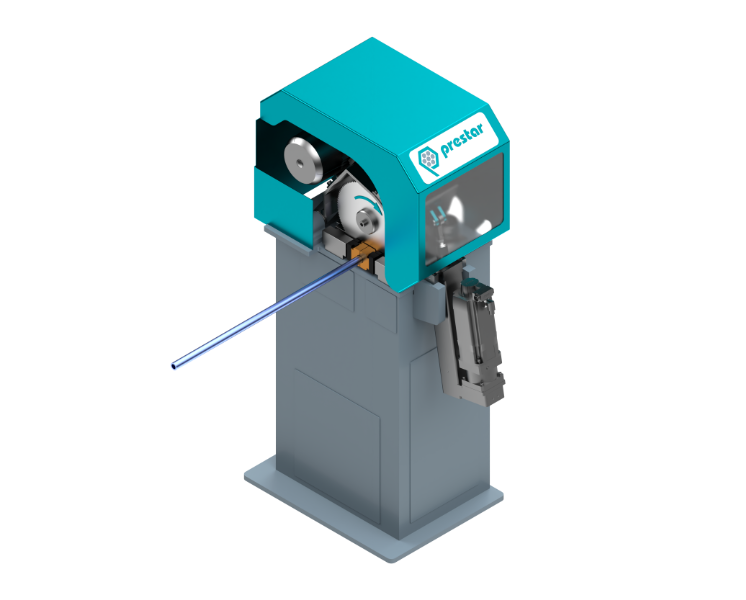

Internal pipe grinder

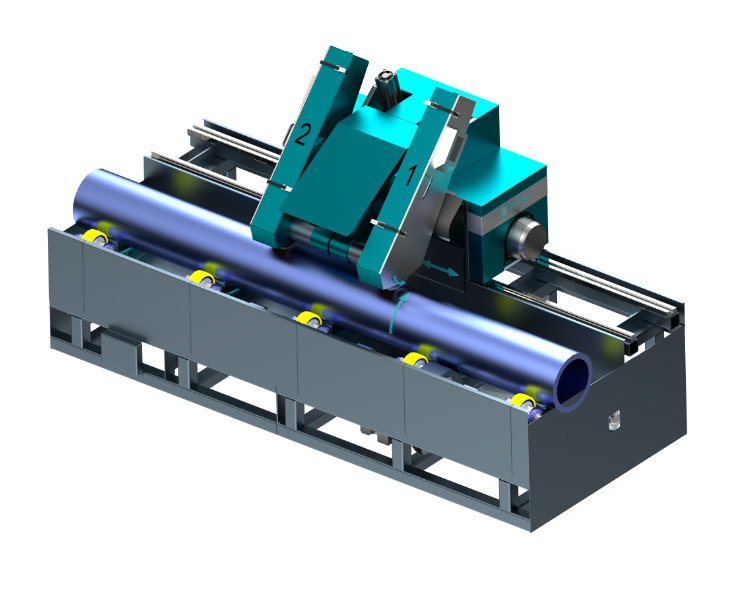

Centerless pipe grinder

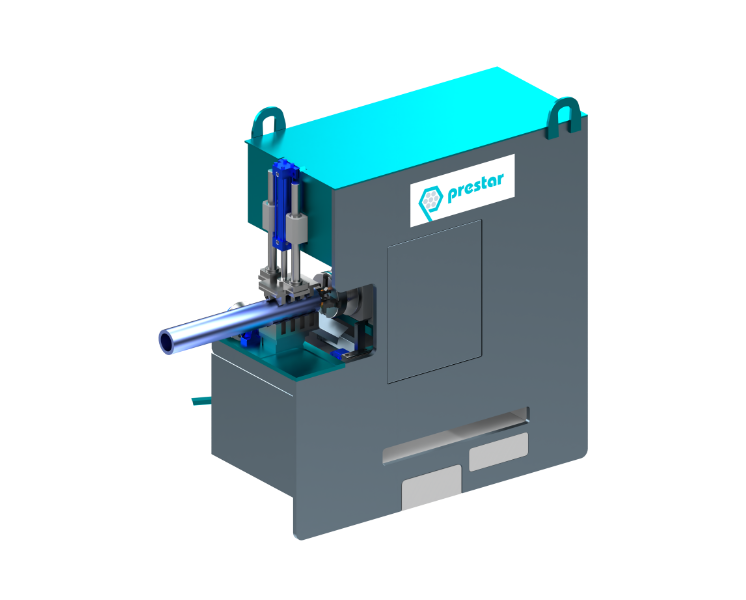

External stationary pipe grinder

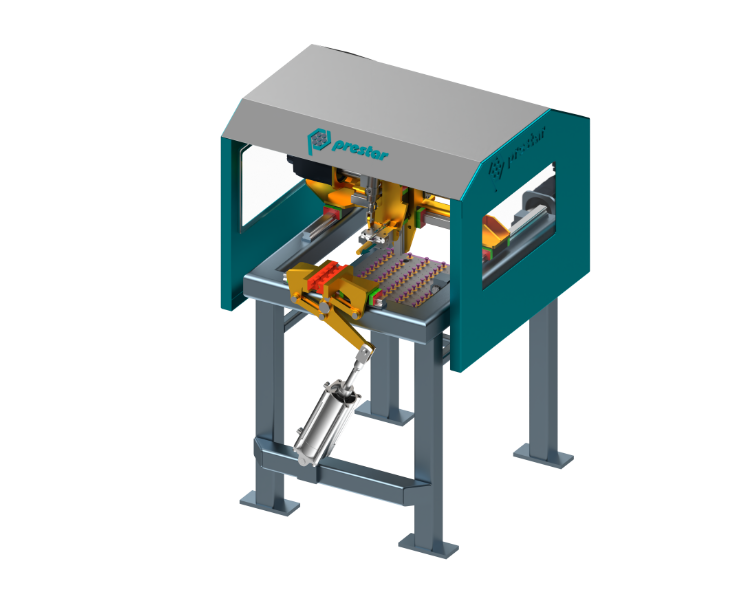

Flying saw

Circular saw

Chamfering of pipes

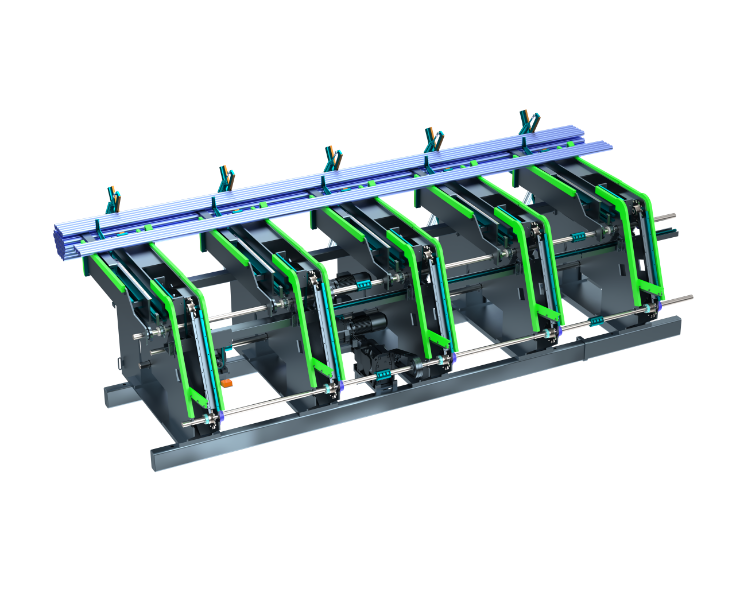

Sorting and plugging

Control tables

Packaging machines

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT