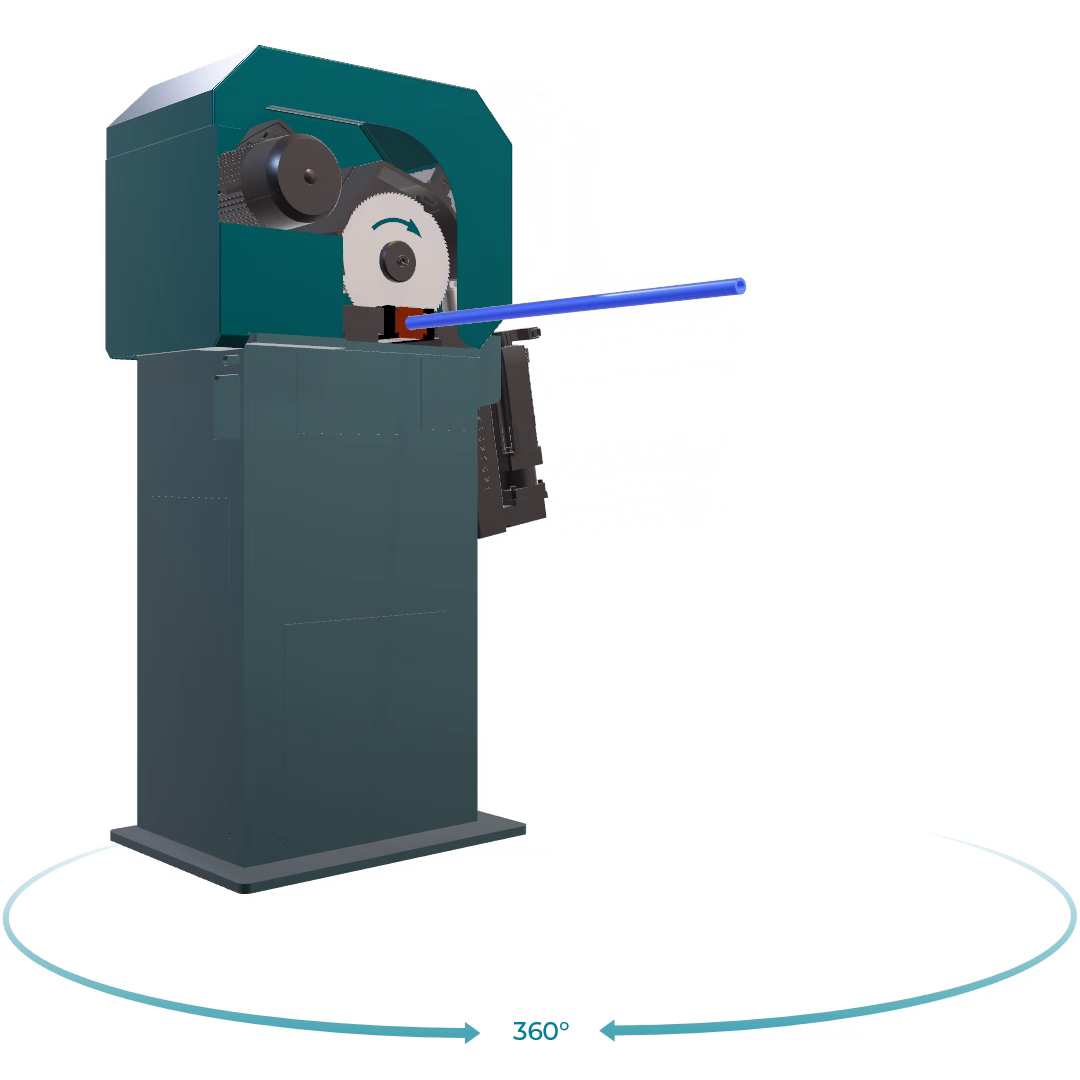

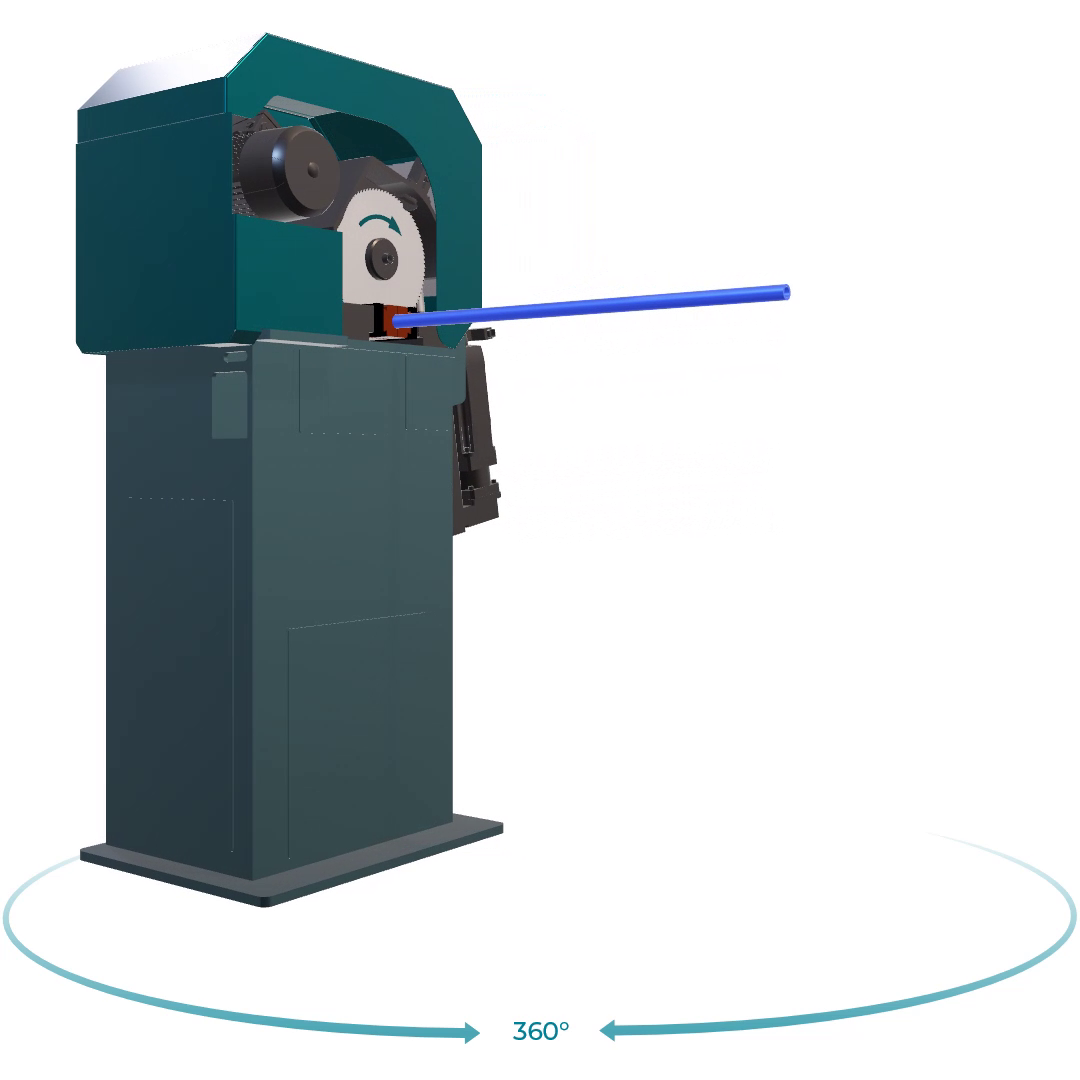

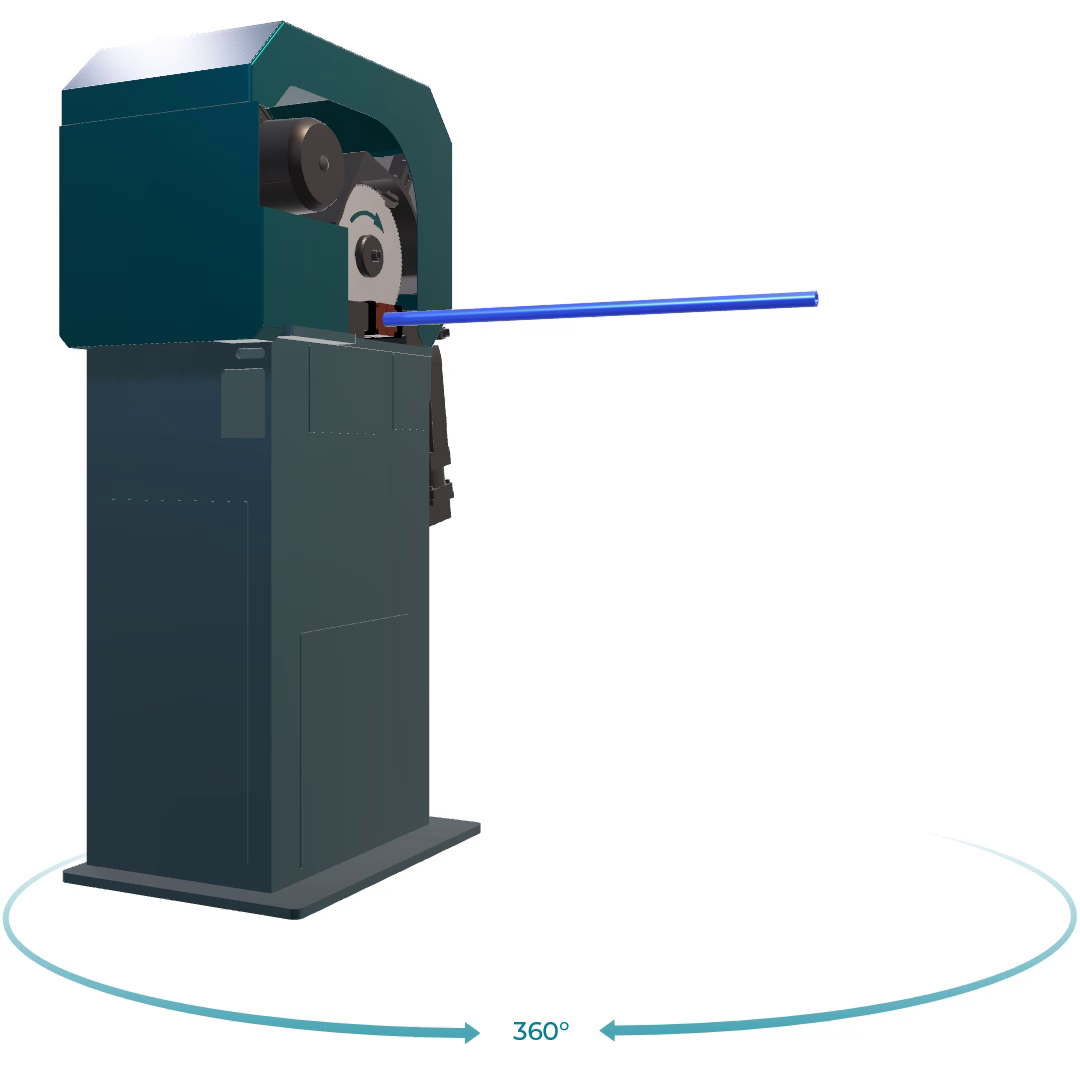

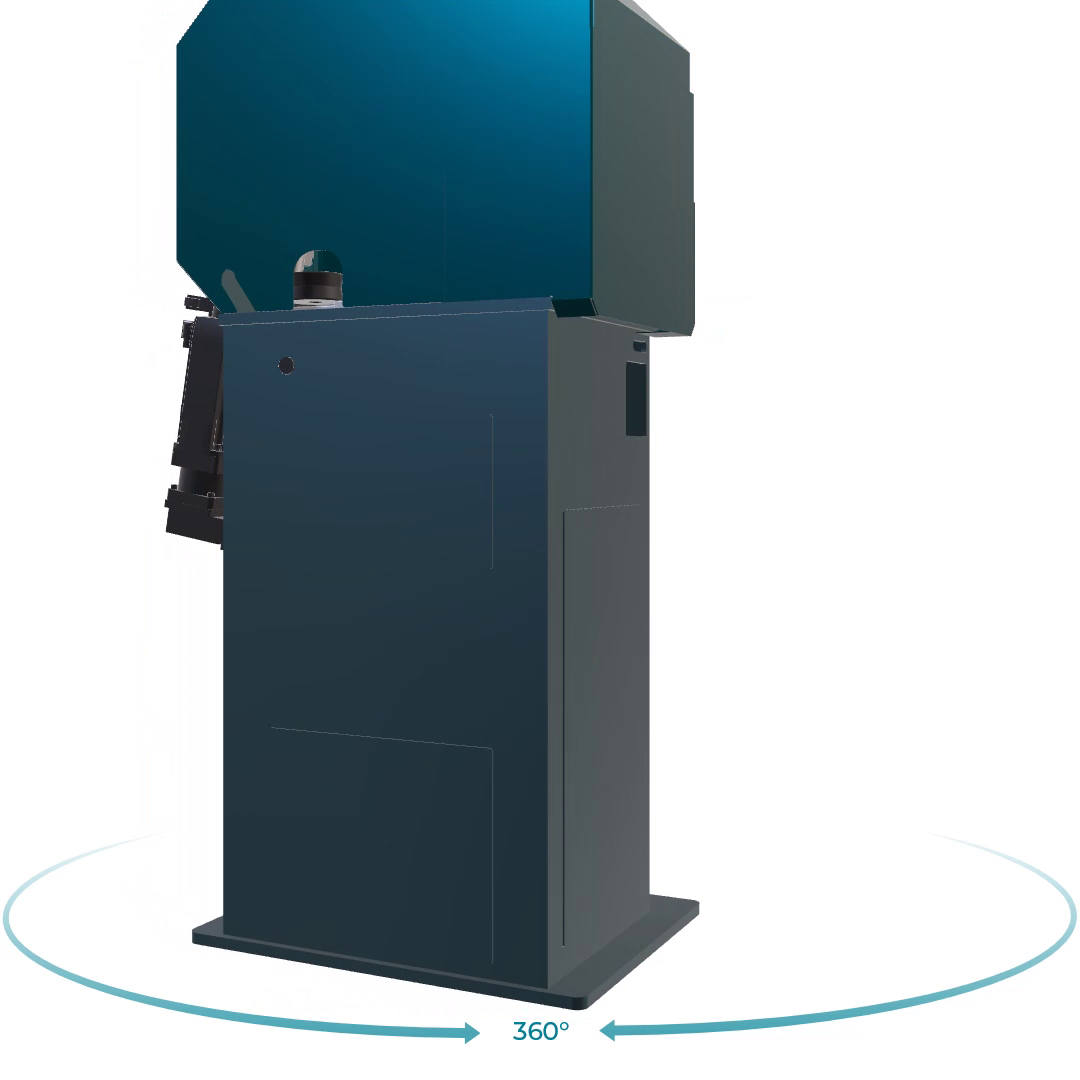

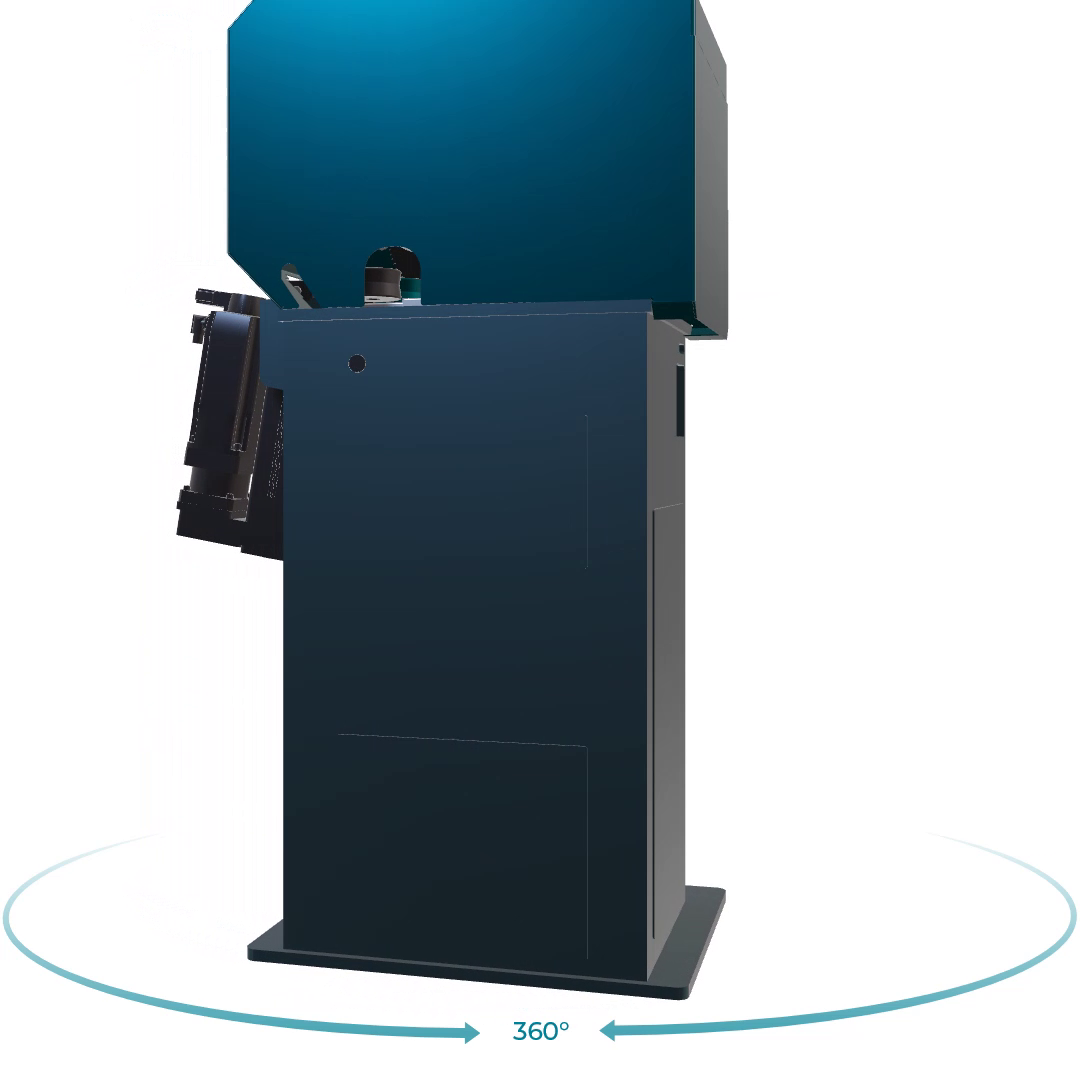

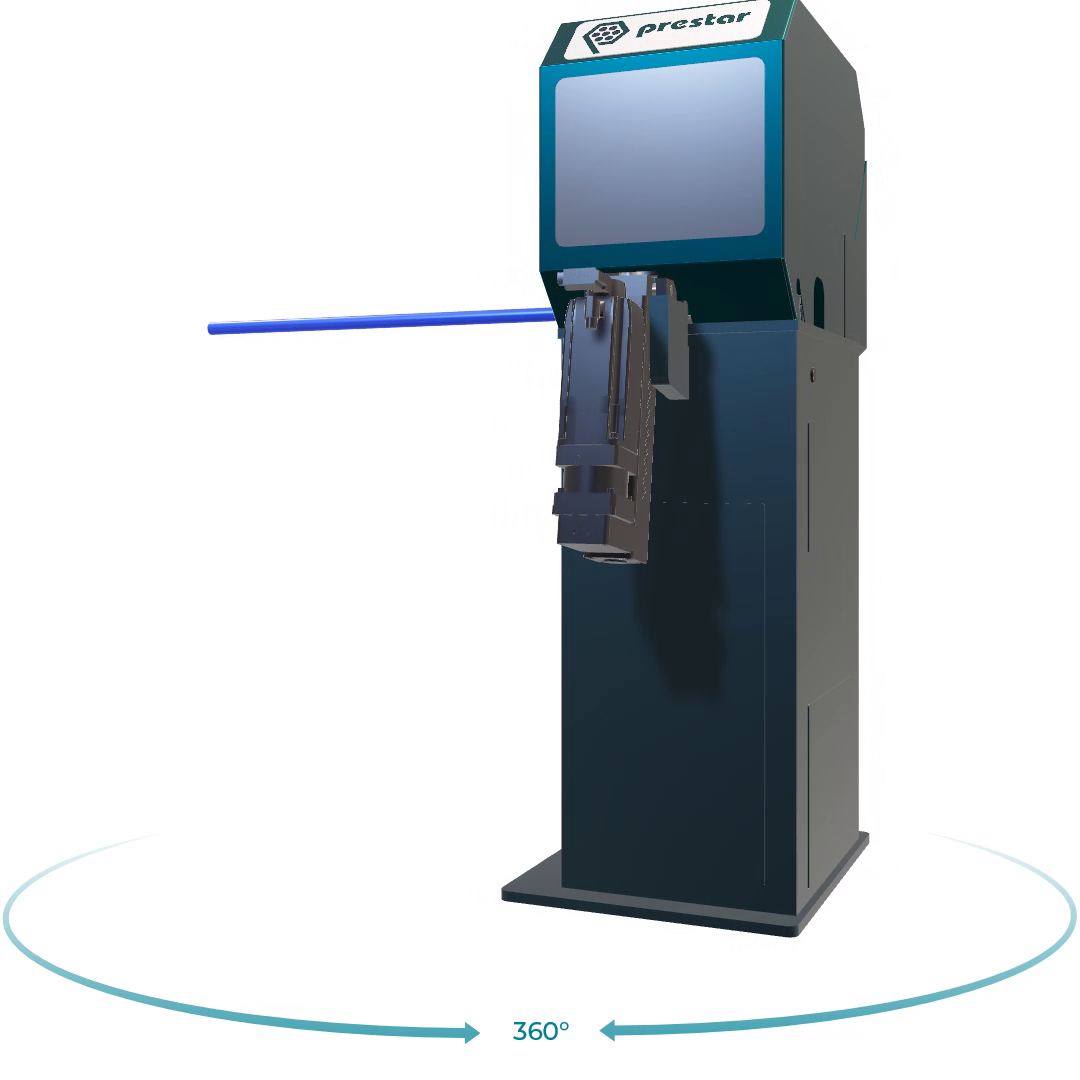

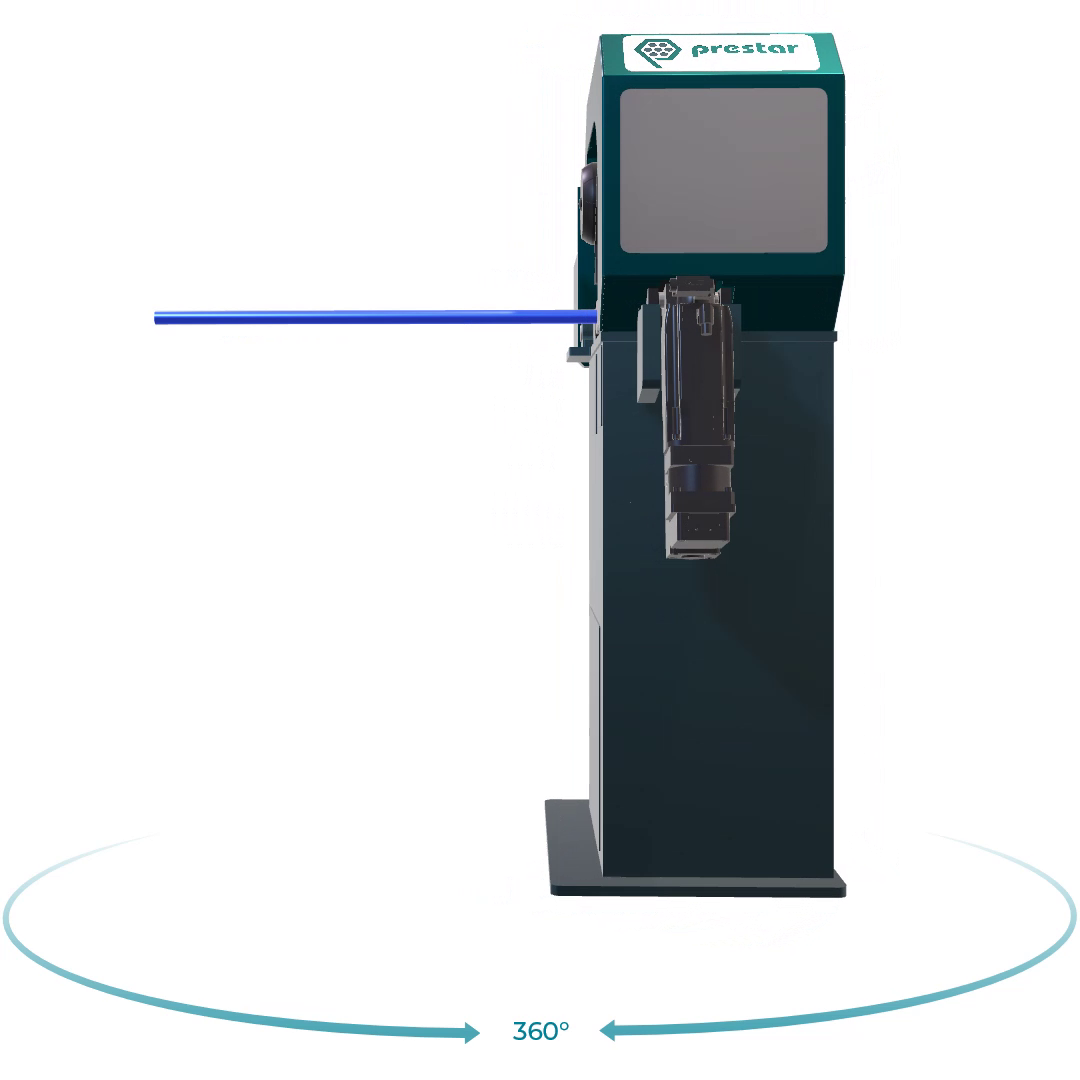

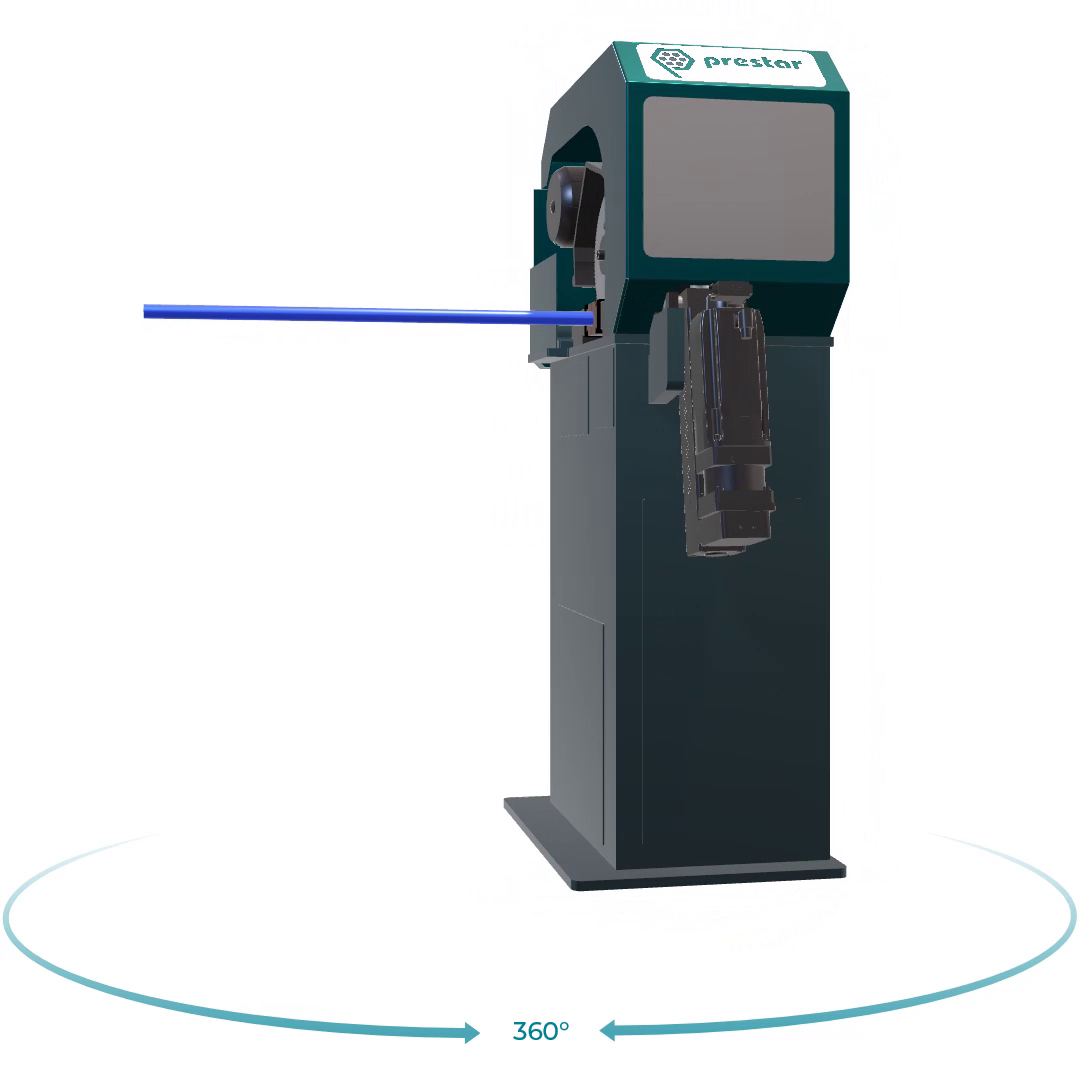

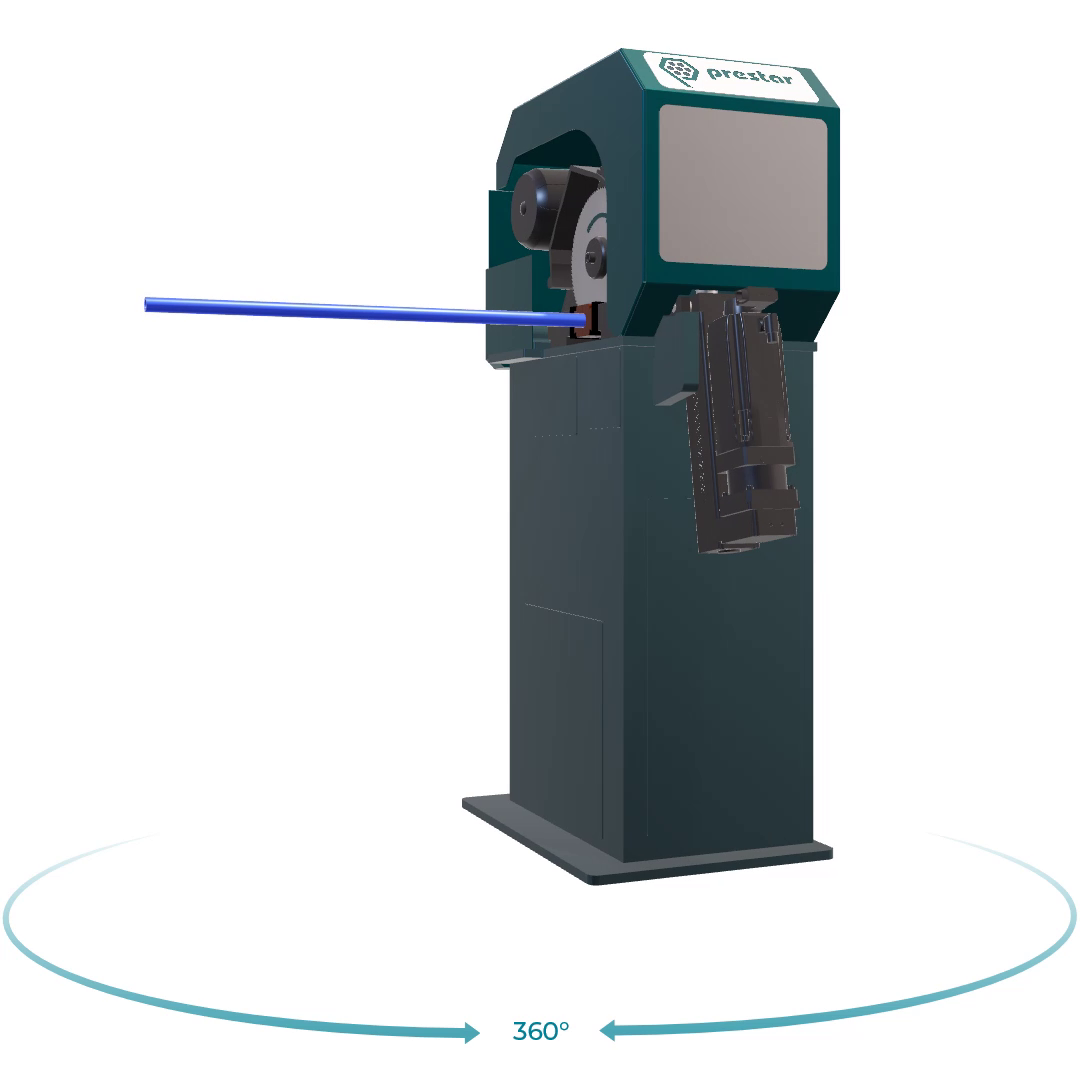

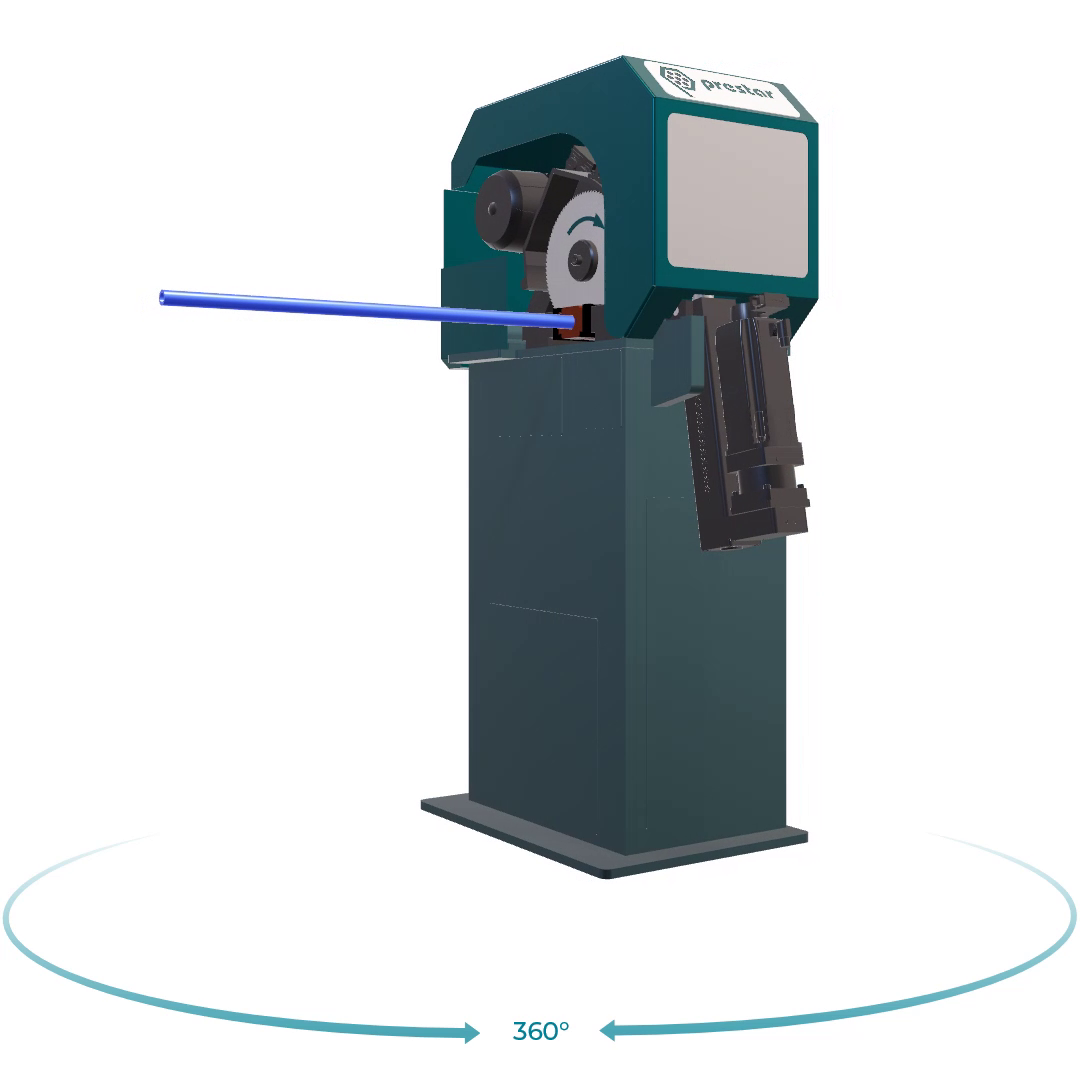

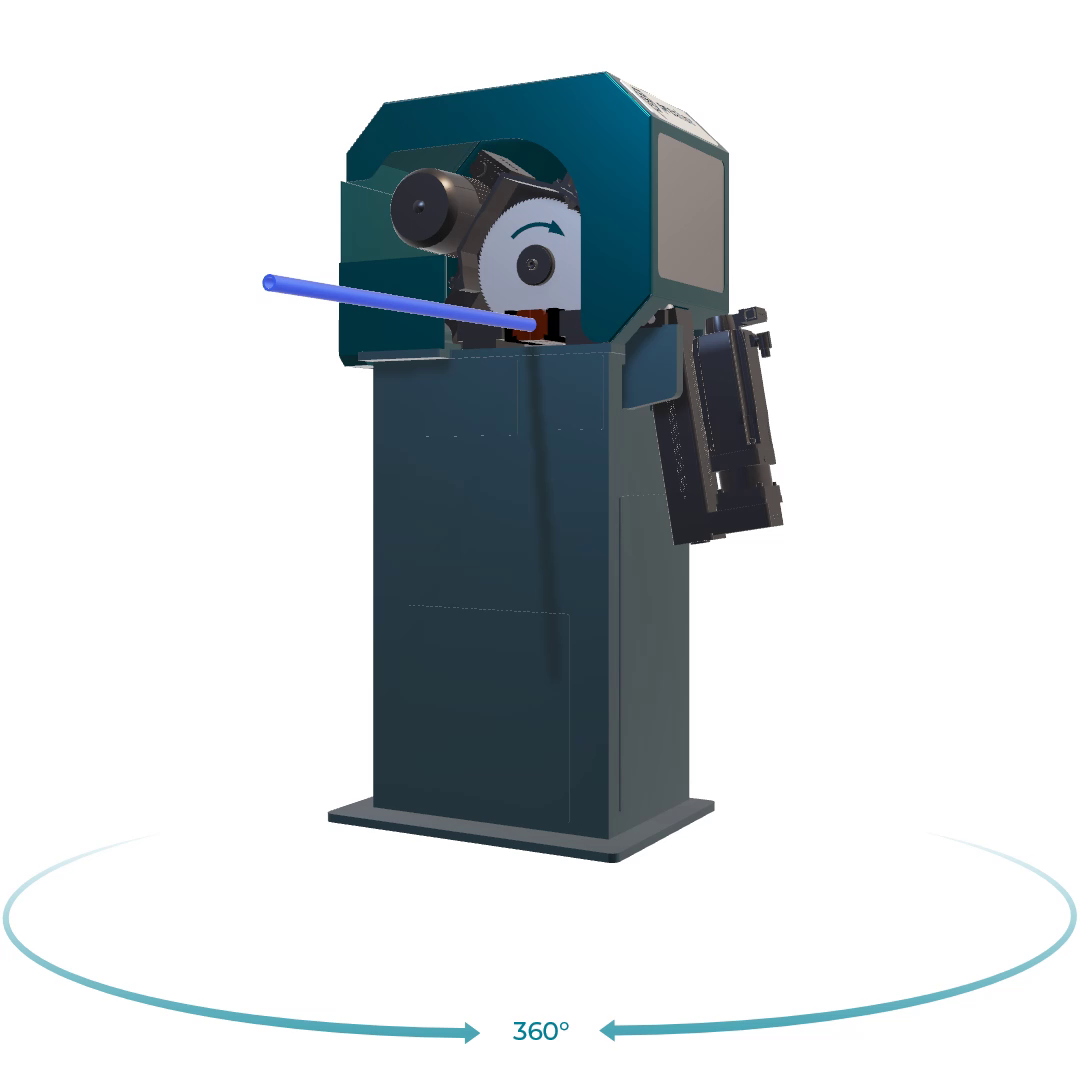

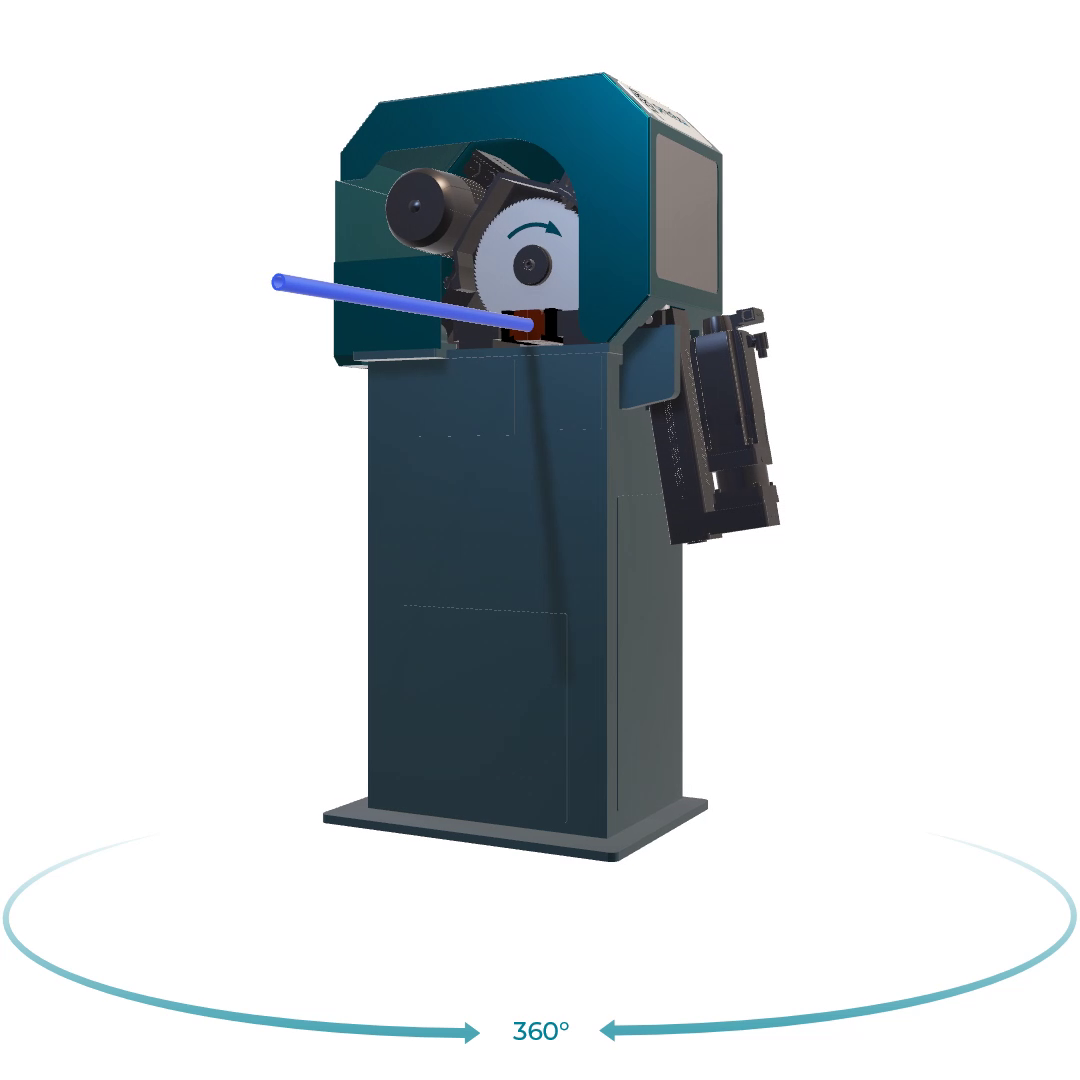

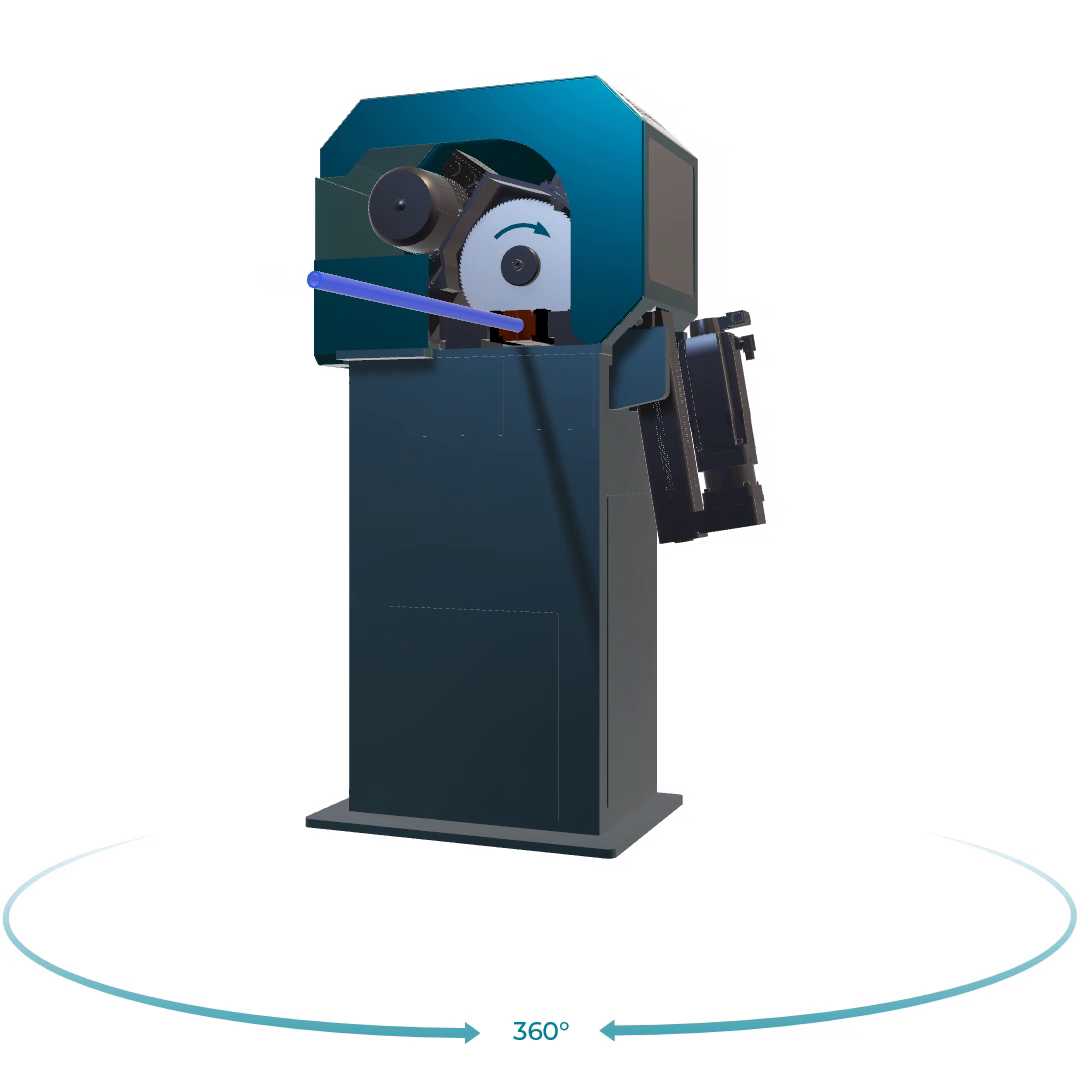

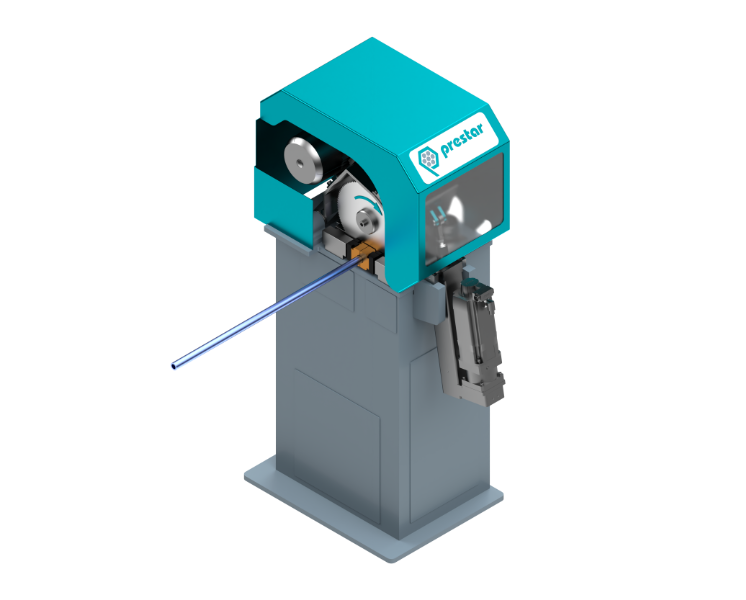

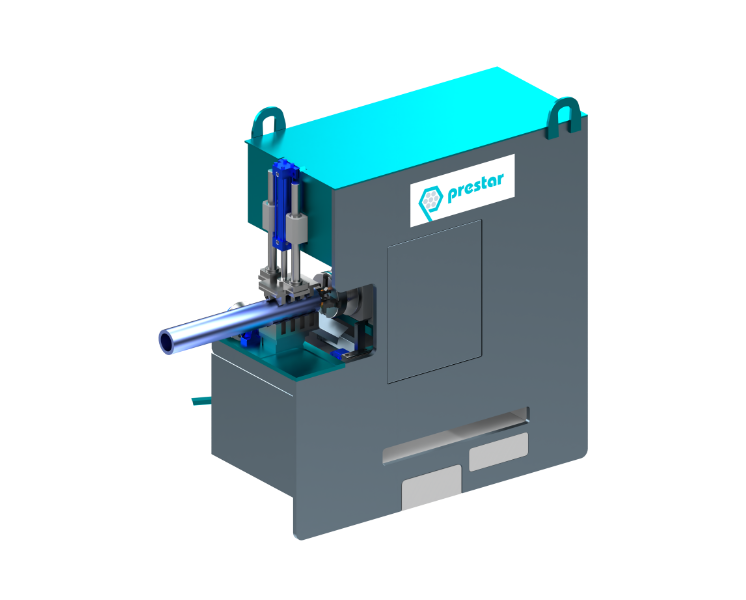

Circular saw

Description of the device

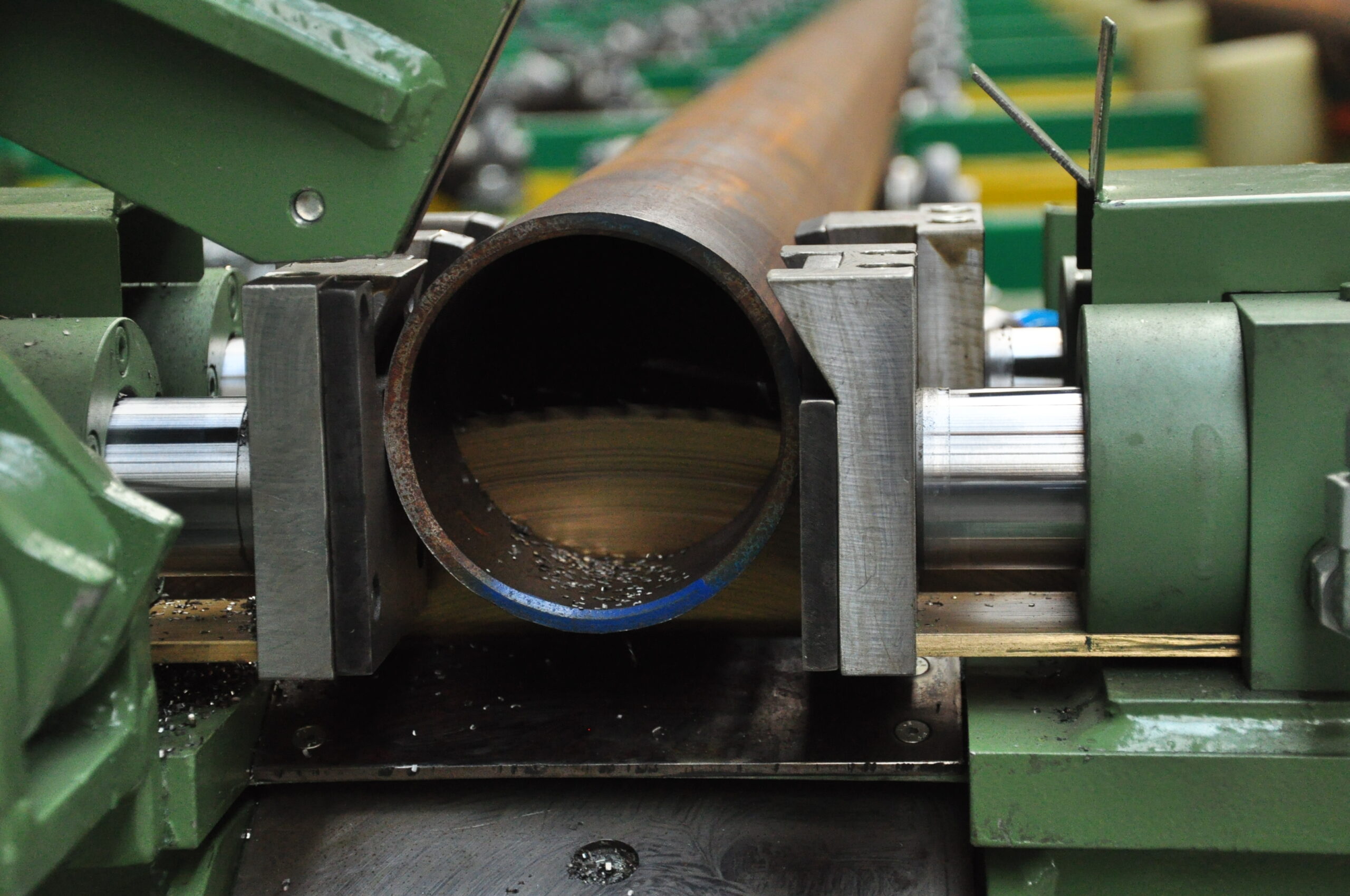

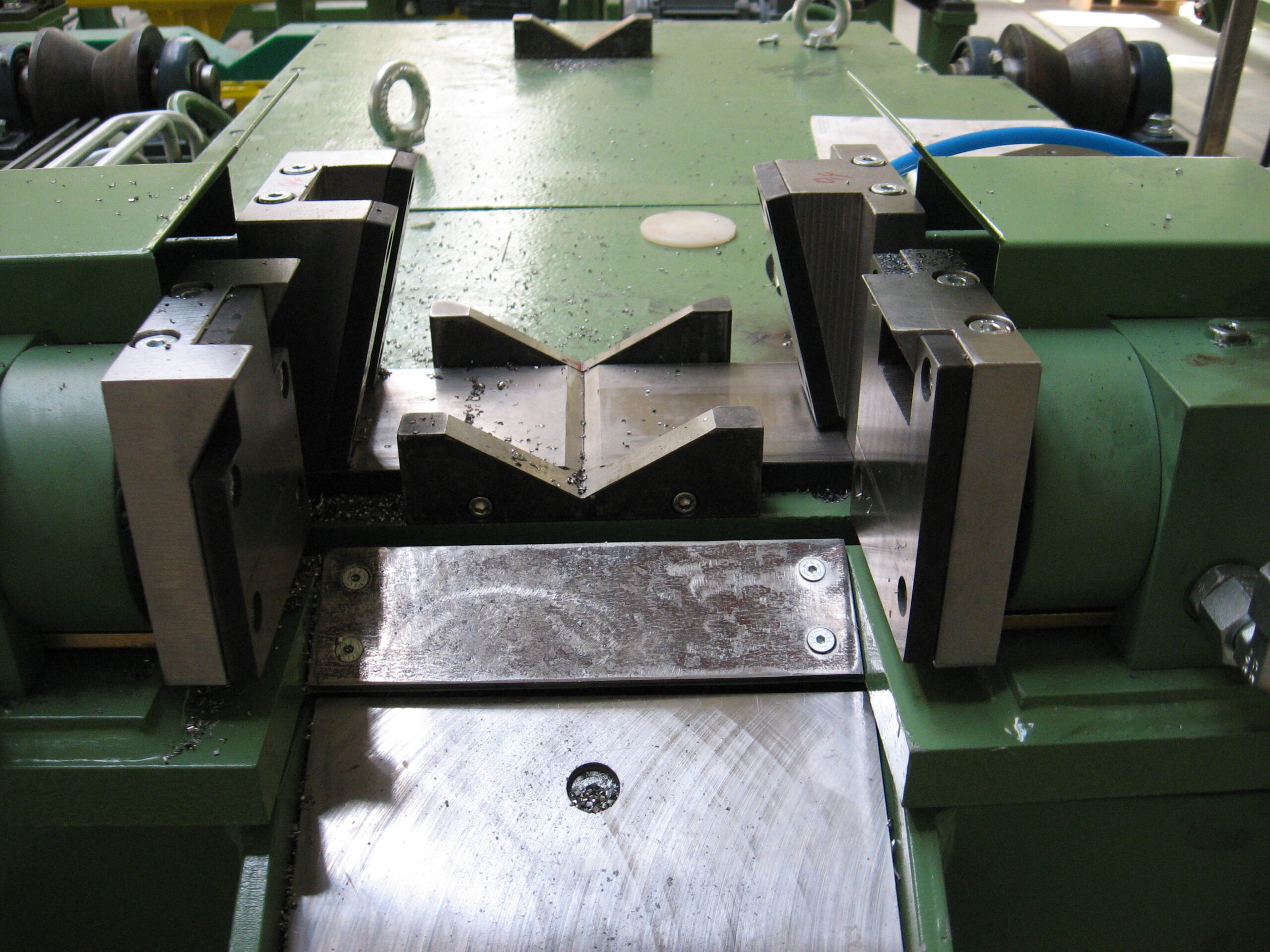

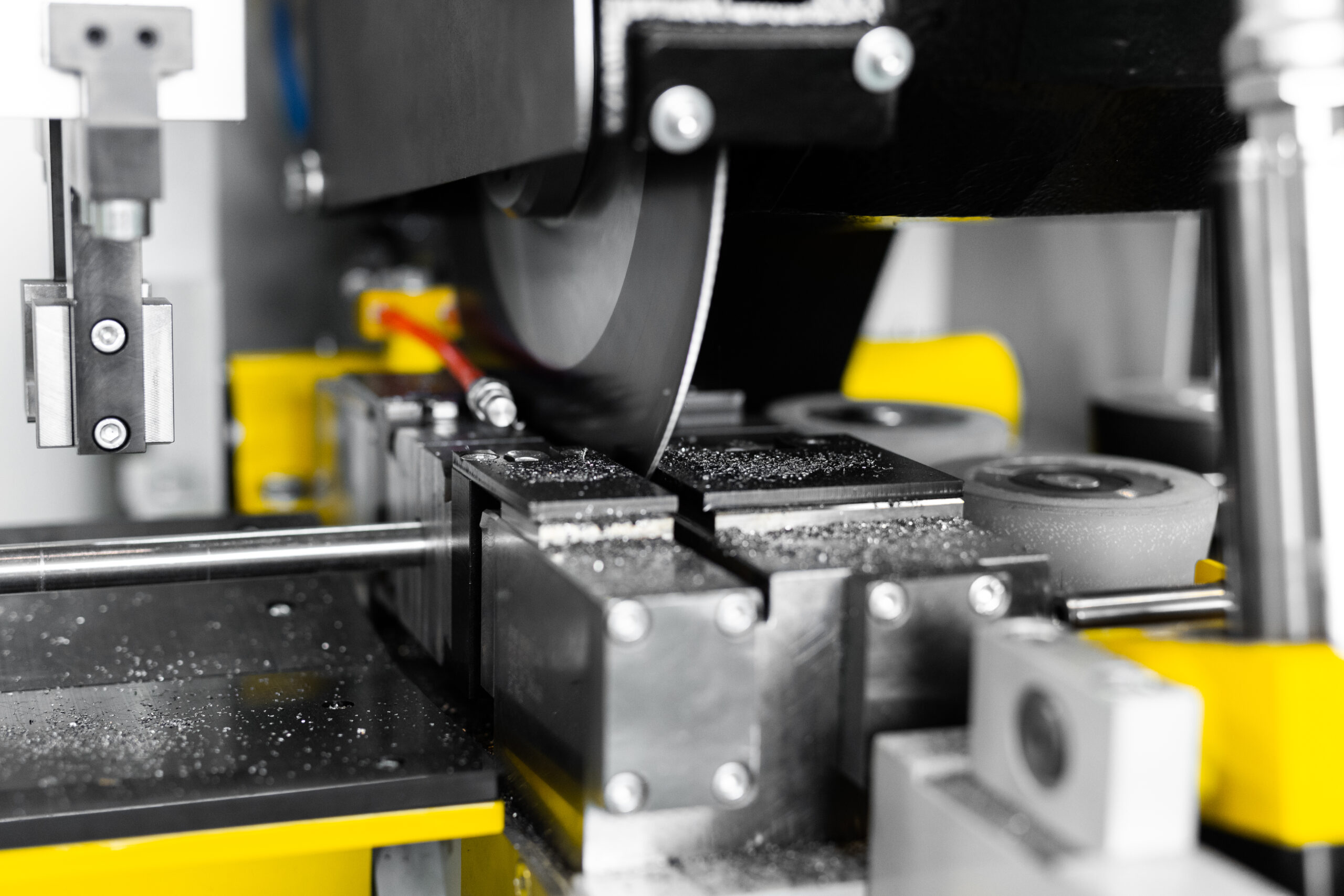

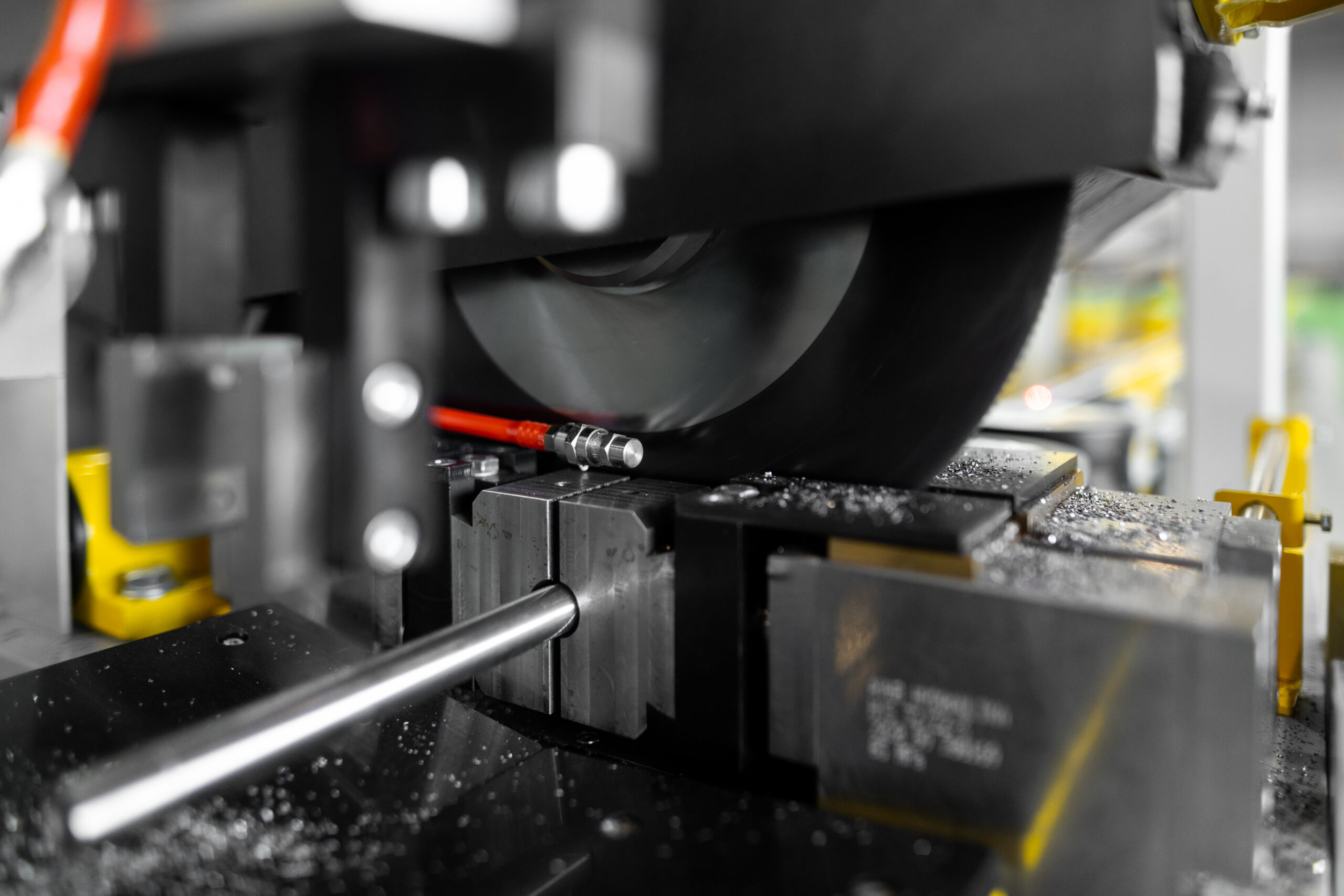

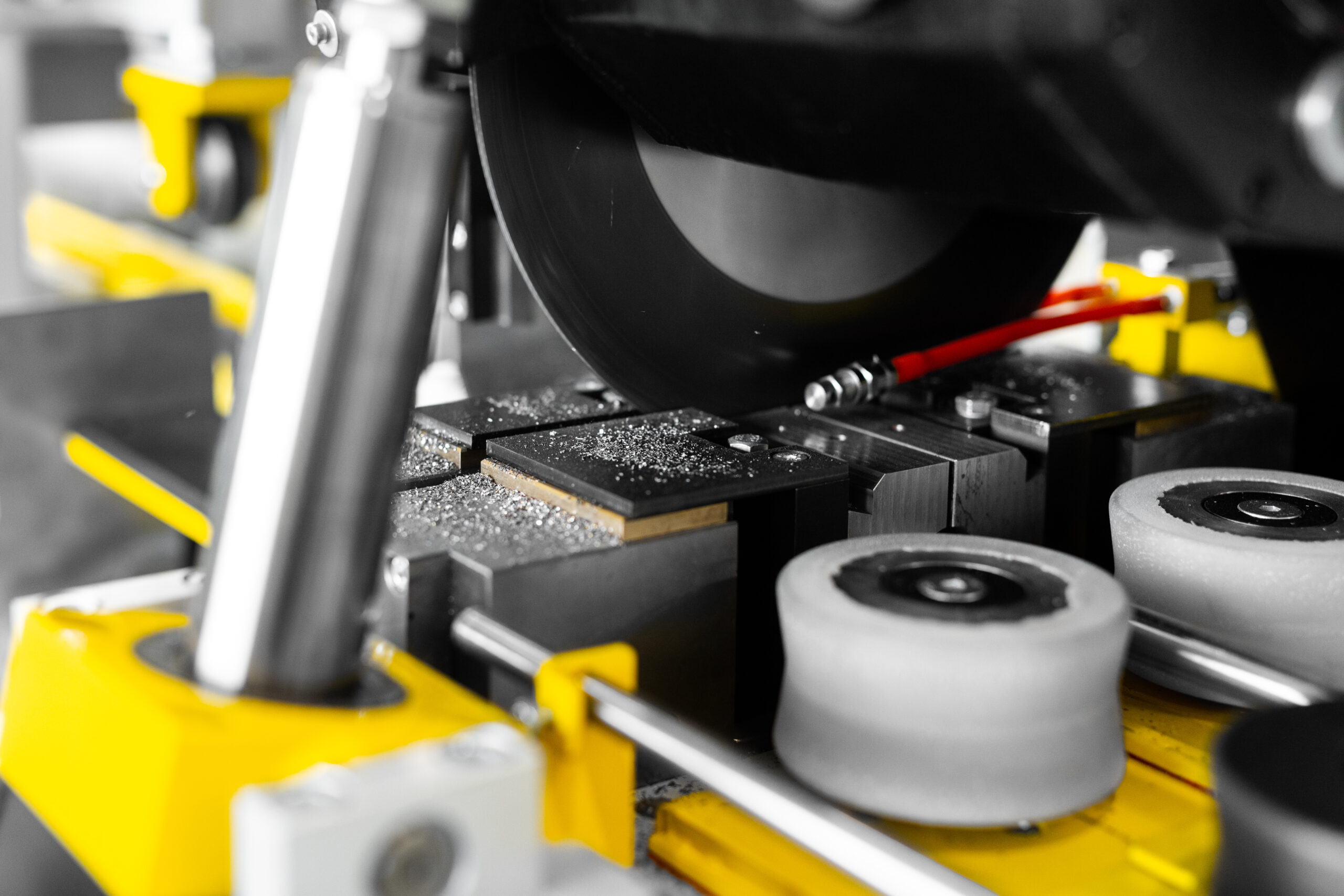

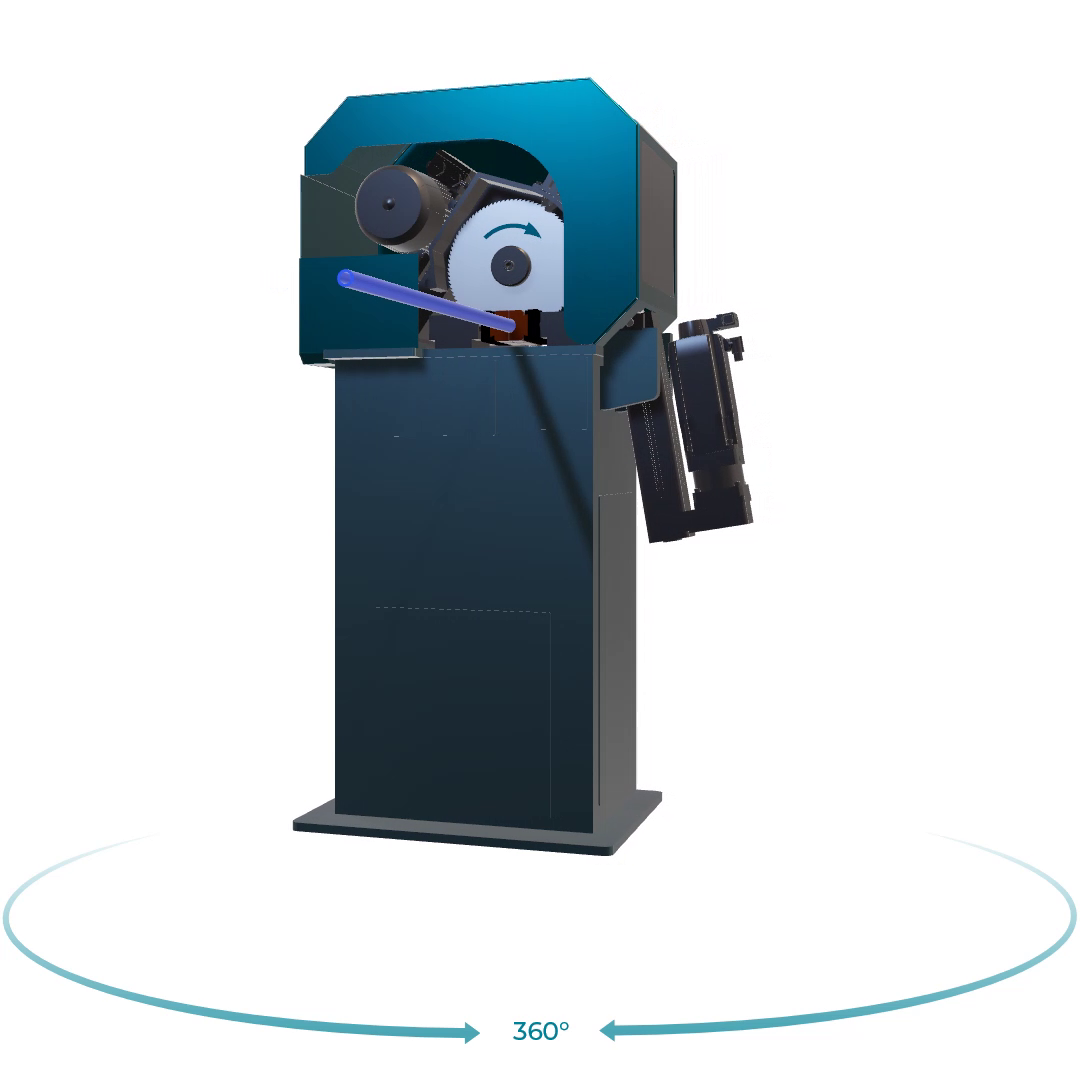

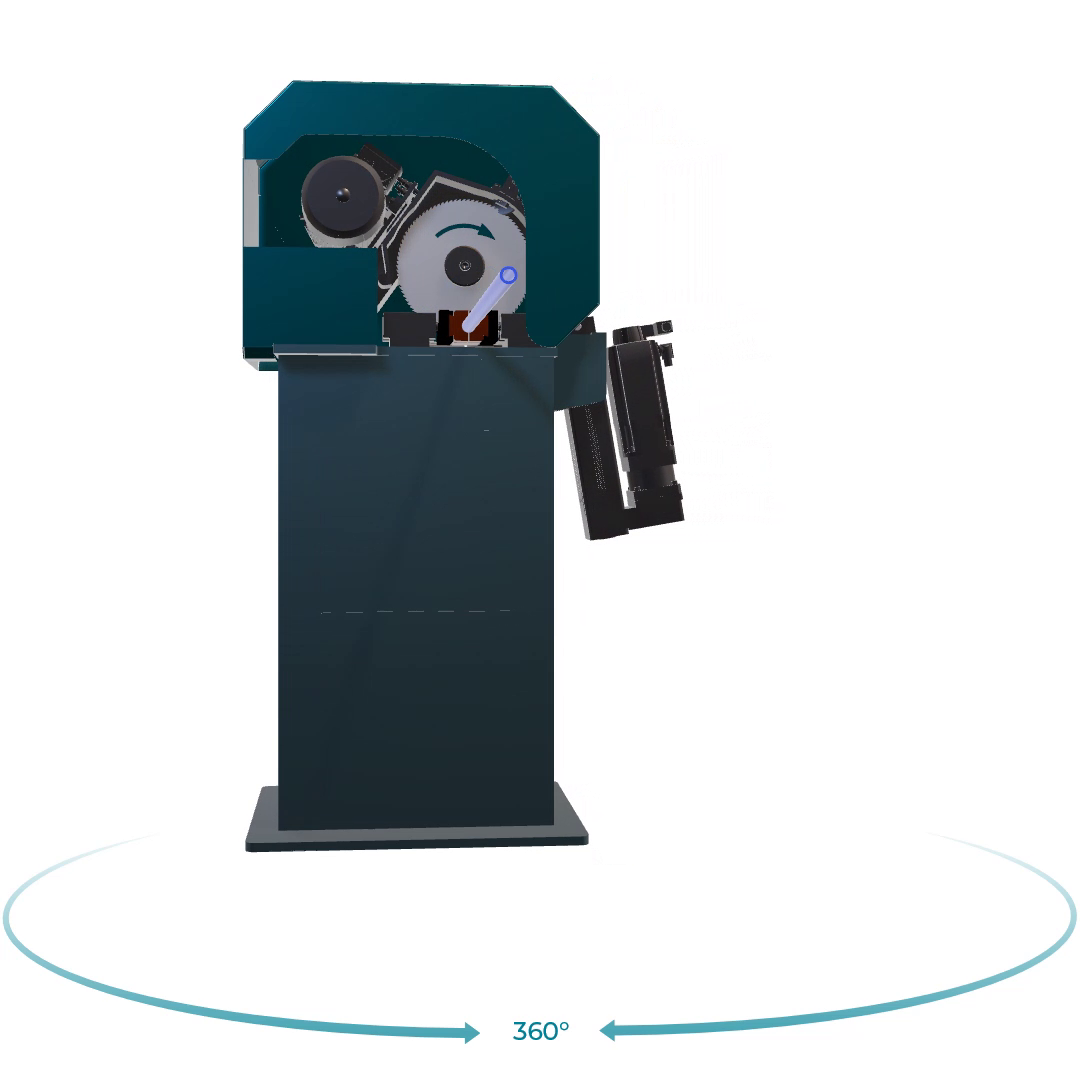

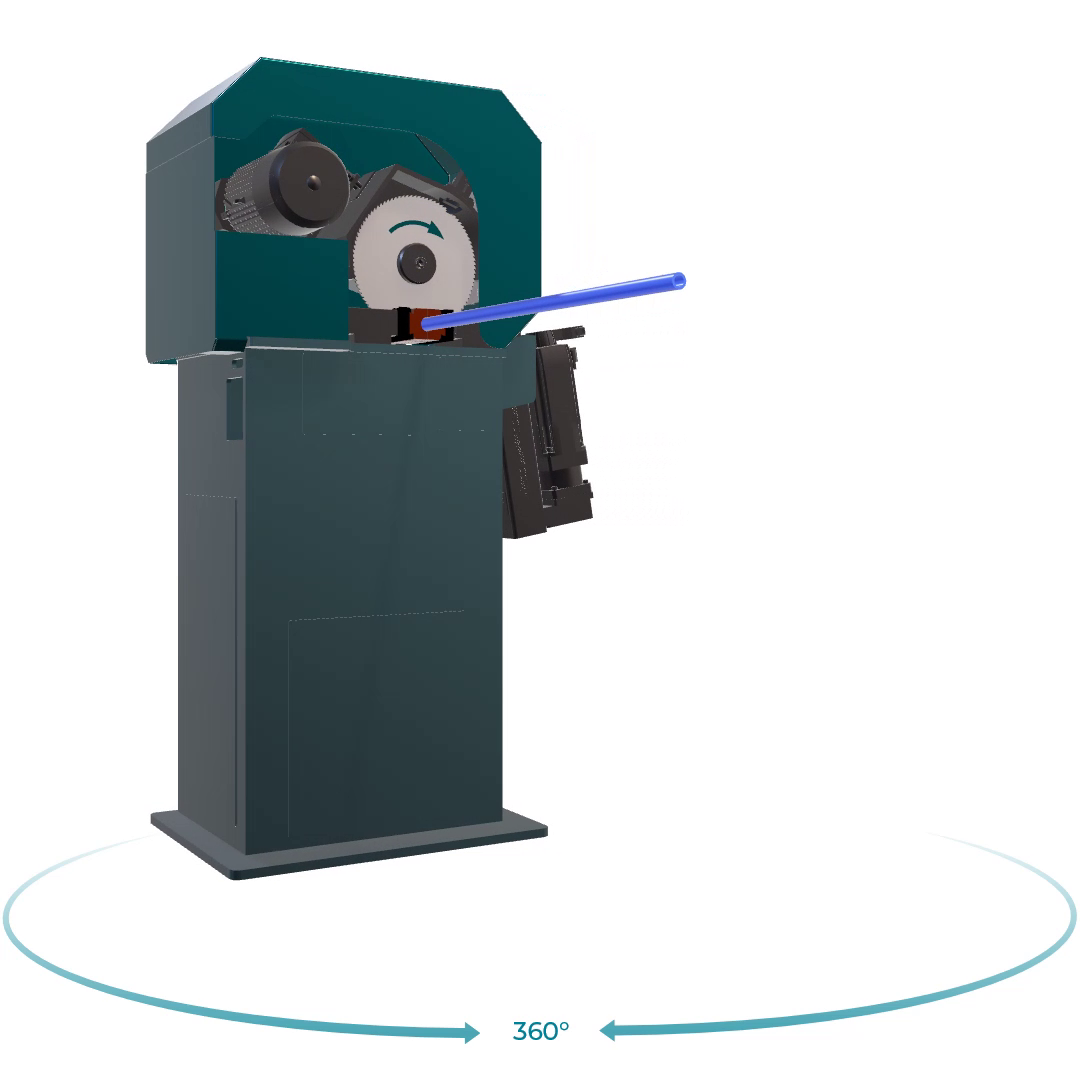

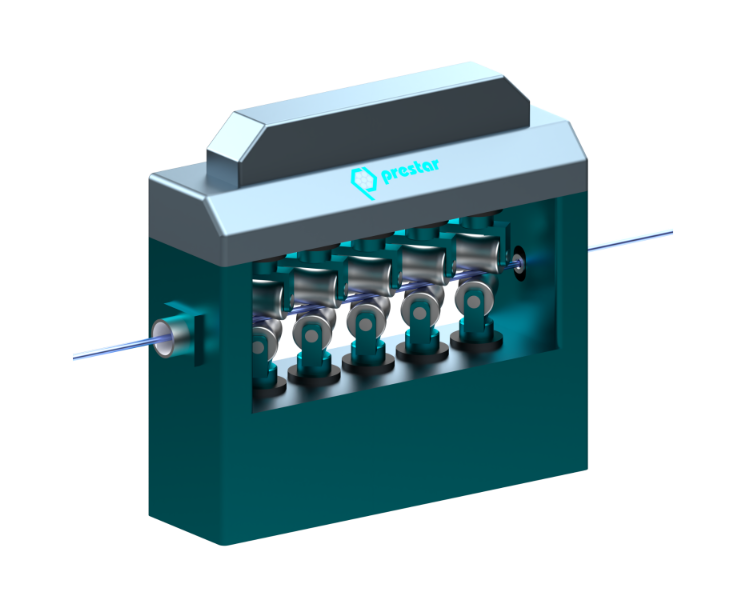

Circular saws are designed to cut tubes and bars to precise lengths. The range of tubes is from 6 to 140 mm. Cutting with HSS discs or discs with HM inserts.

A feed of the dividing disc according to the requirement of the production technology. The force of the clamping jaws is by hydraulics and is infinitely adjustable according to the wall thickness of the tubes. The feed into the cut is provided by a hydraulic cylinder or servo drive with variable tube cutting speed. The saw always operates in automatic or manual mode and is controlled by the control panel.

Optimization of the blade feed with respect to the diameter and wall thickness of the tube.

Technical parameters of the machine

| Diameter of split tubes or rods | 6 – 140 mm |

| Cutting lengths: | 10 -21 000 mm |

| Cutting accuracy: | + – 0,5 mm/ 6 m lengh |

| Cutting cycle: | from 5 sec/piece |

|

|

Other equipment of the machine

- To clean up the ends after cutting, the circular saw can be supplemented by brushing or beveling the ends of the pipes

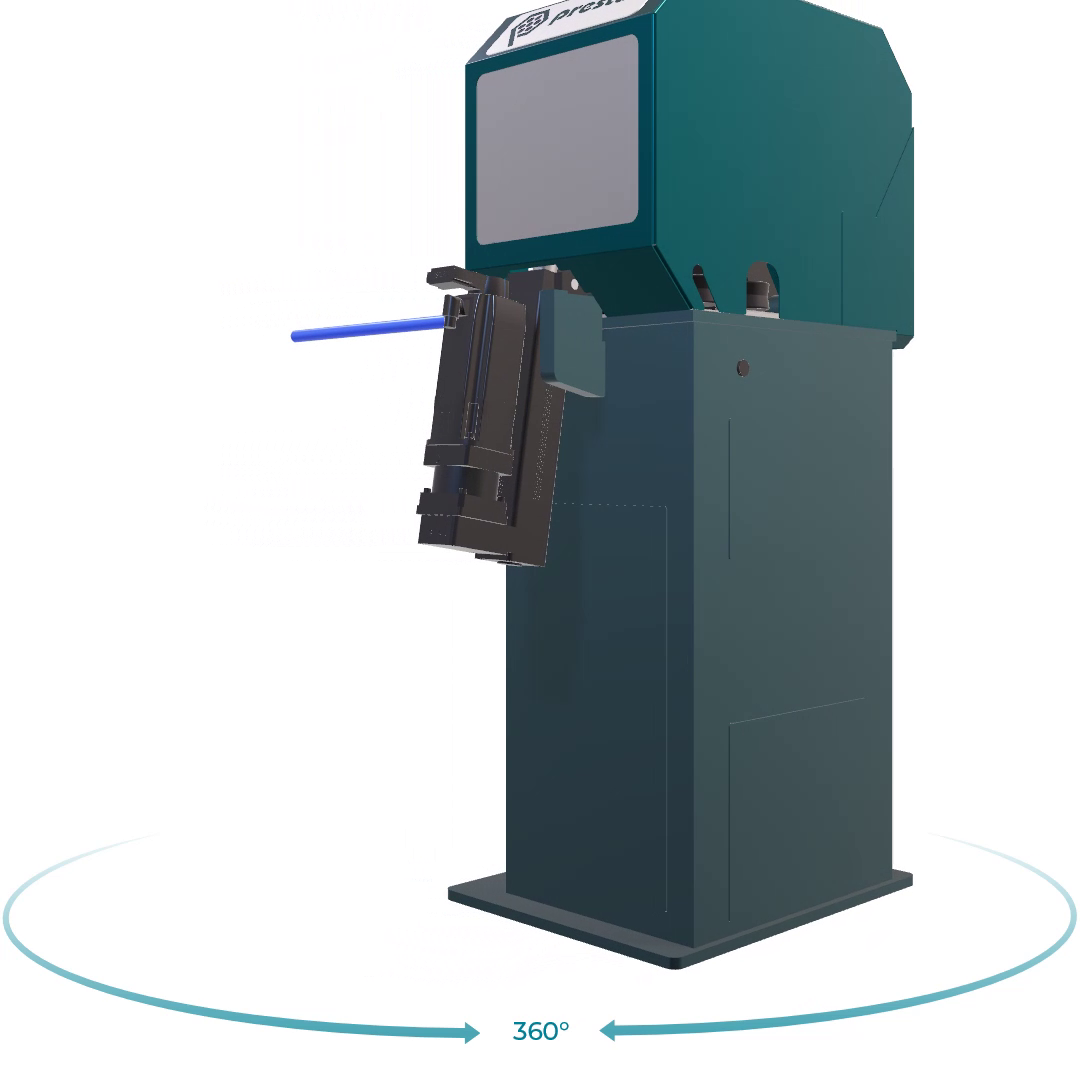

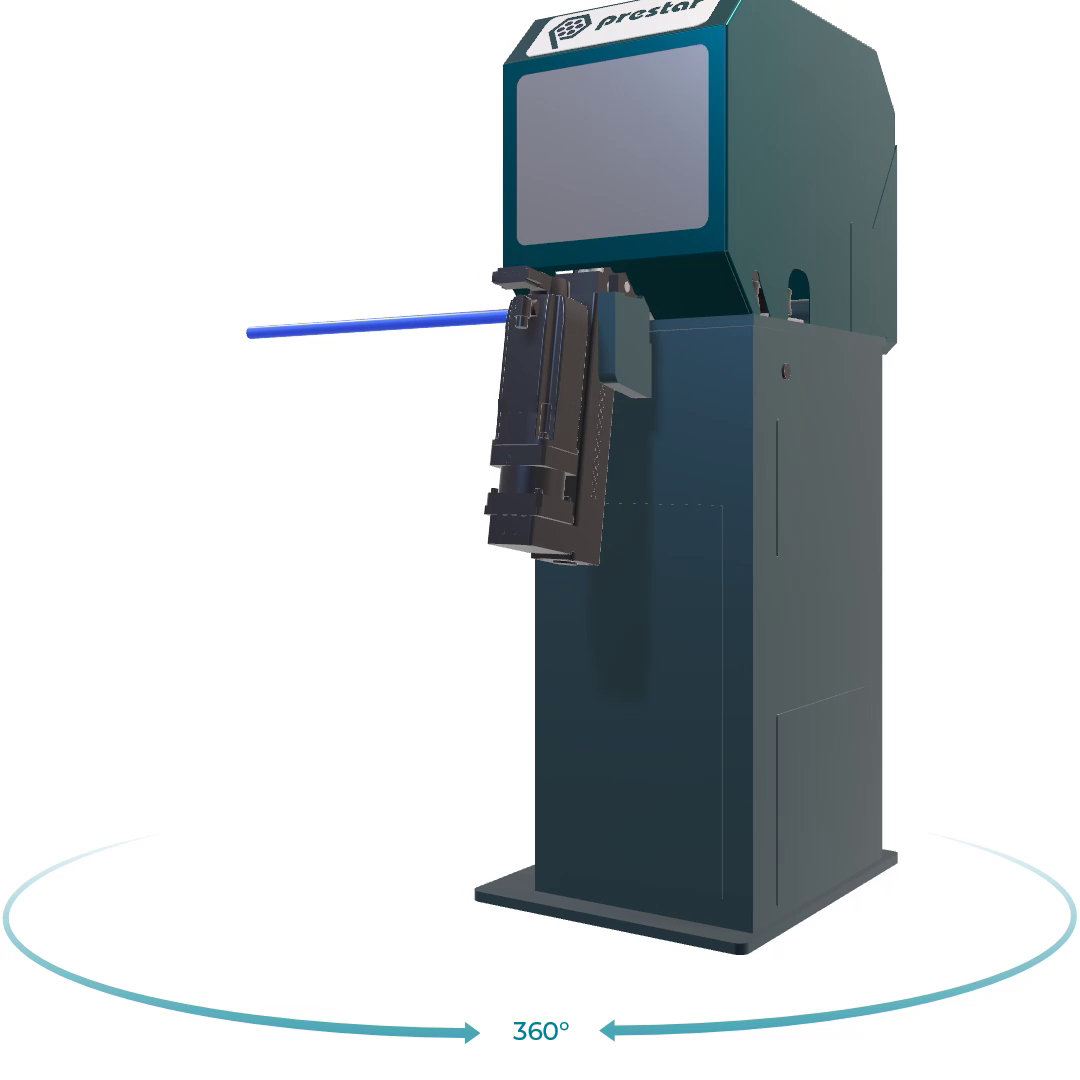

- Saw travel for setting the cut length or laser length measurement

- Collection conveyor under the saw for scraps and chips

- Waste collection containers suspended from the saw

- Collection of agreed production parameters with automatic saving, display and data export.

- Enhanced service with the ability to display manuals, service guides and other necessary documentation on the machine HMI to minimize service times

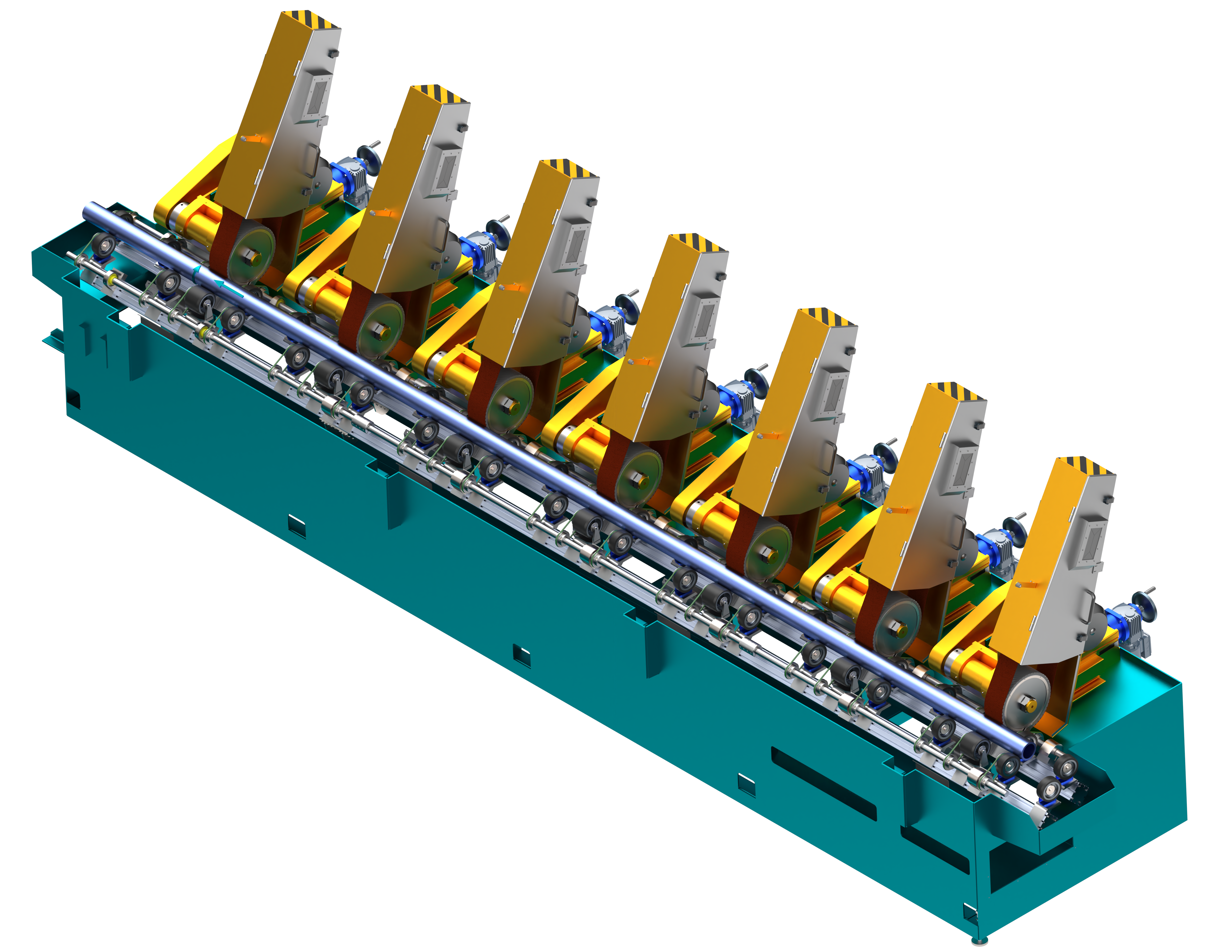

Straightening machines

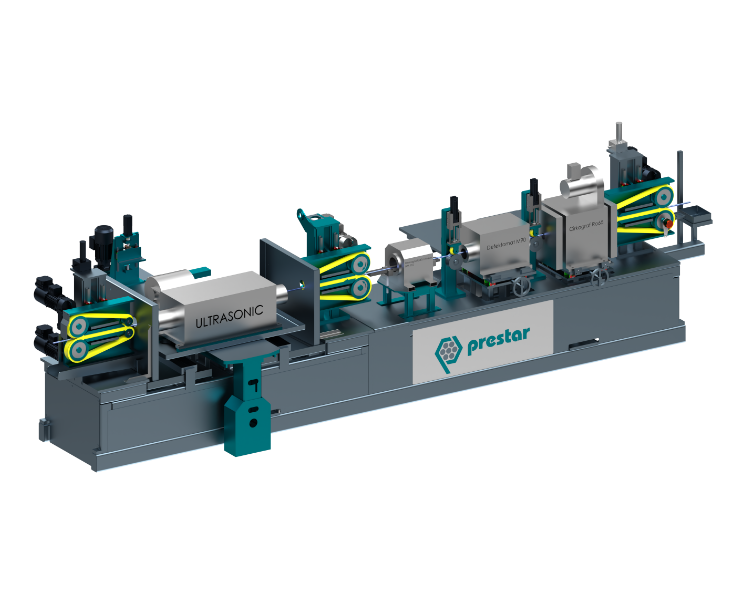

Internal pipe grinder

Centerless pipe grinder

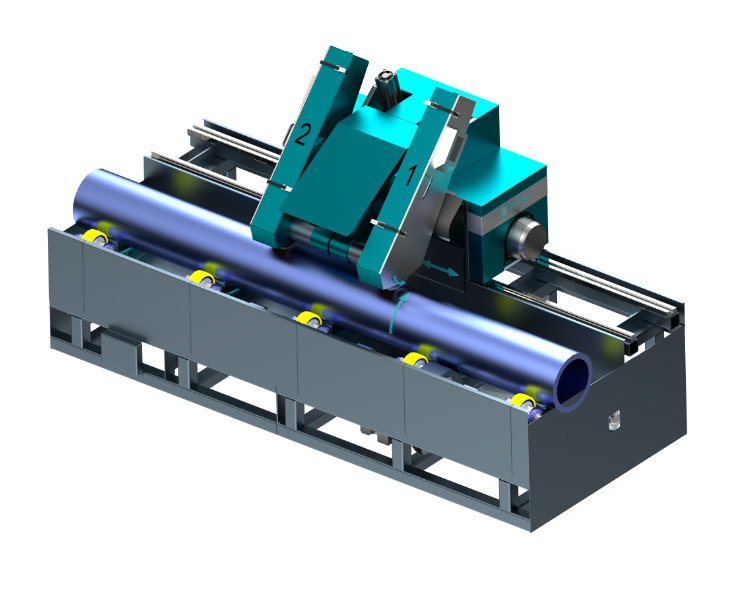

External stationary pipe grinder

Flying saw

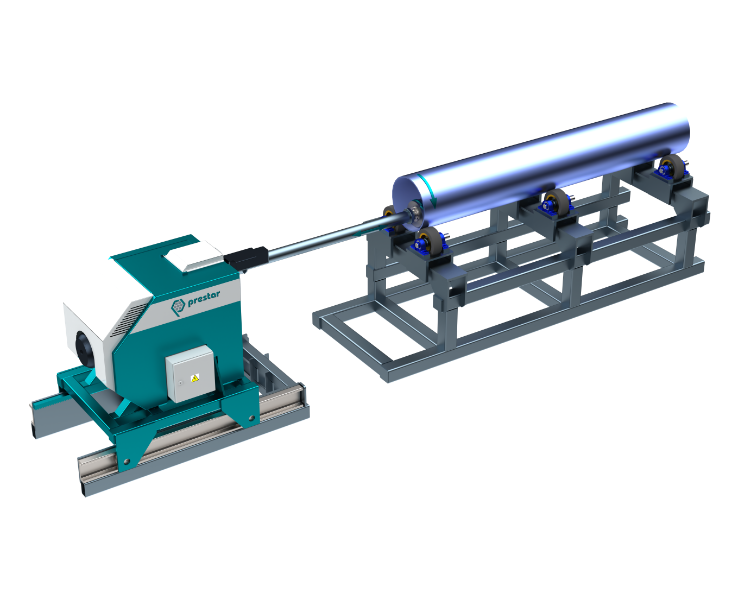

Circular saw

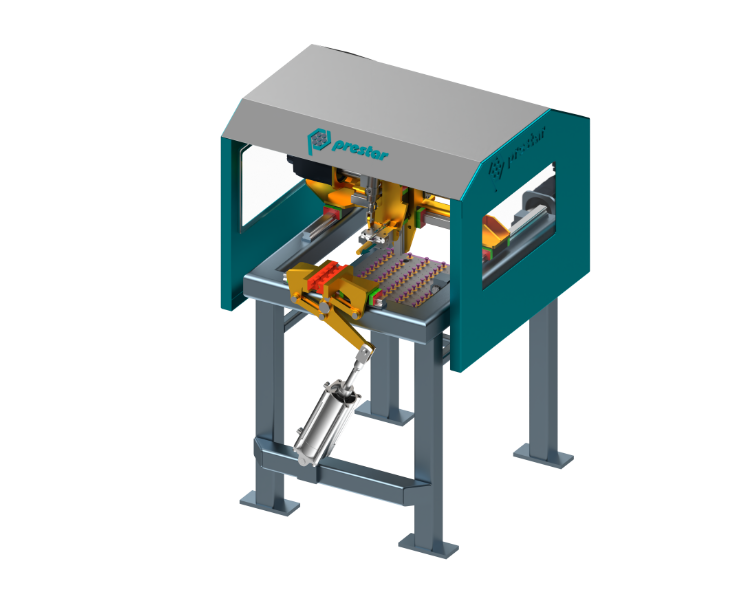

Chamfering of pipes

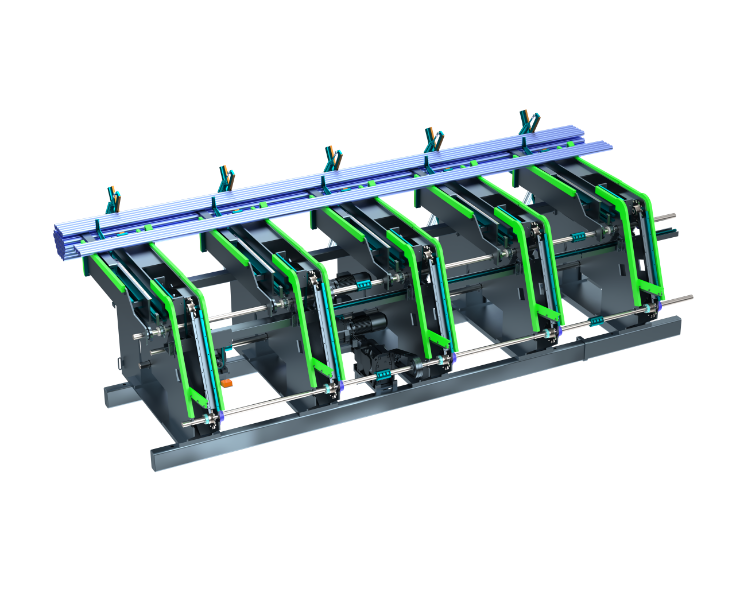

Sorting and plugging

Control tables

Packaging machines

A NEW LINE FOR PIPES OR RODS WILL DEMONSTRABLY MAKE PRODUCTION MORE EFFICIENT